Fabricated bentonite interior partition wall board and combination wall

An internal partition wall, prefabricated technology, applied in the direction of walls, building components, buildings, etc., to ensure overall safety, good mechanical performance, and good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

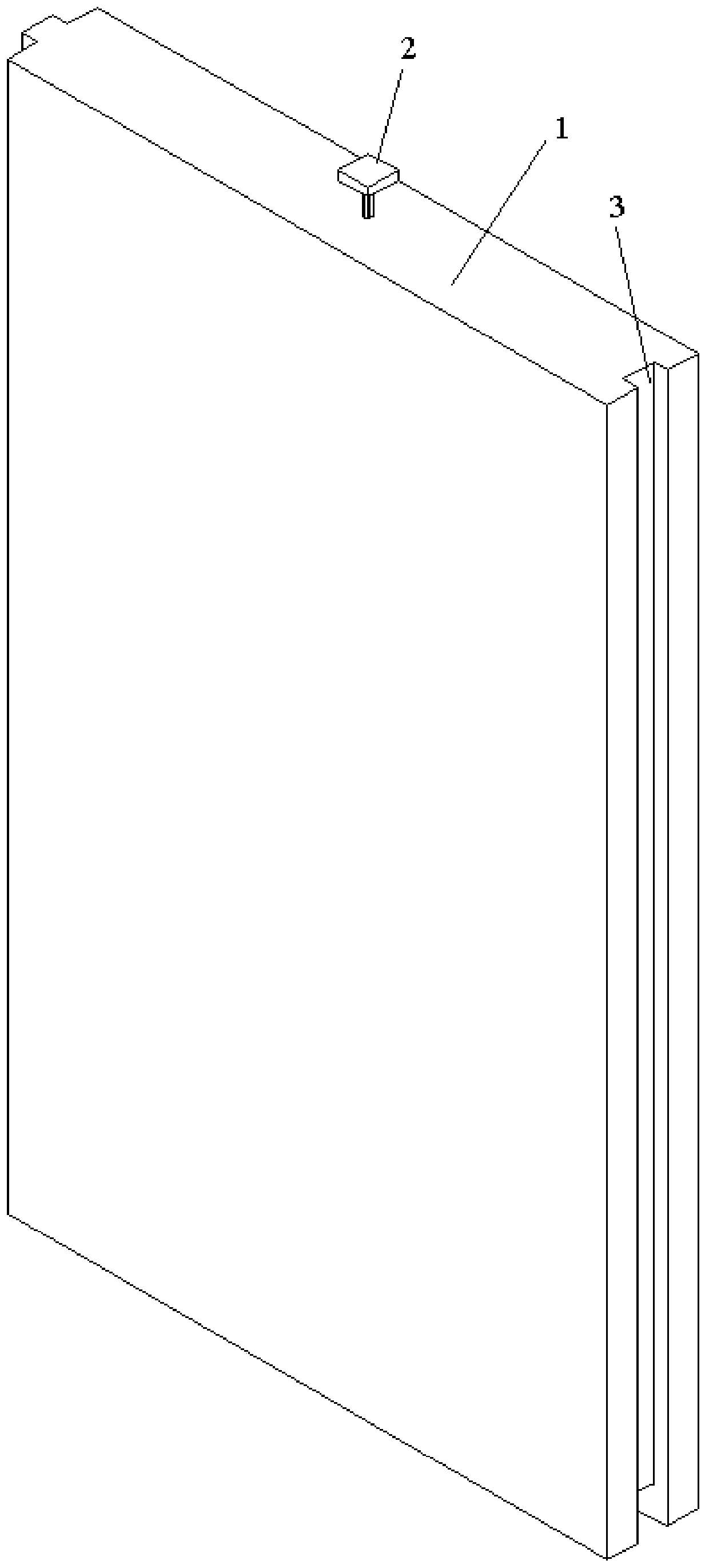

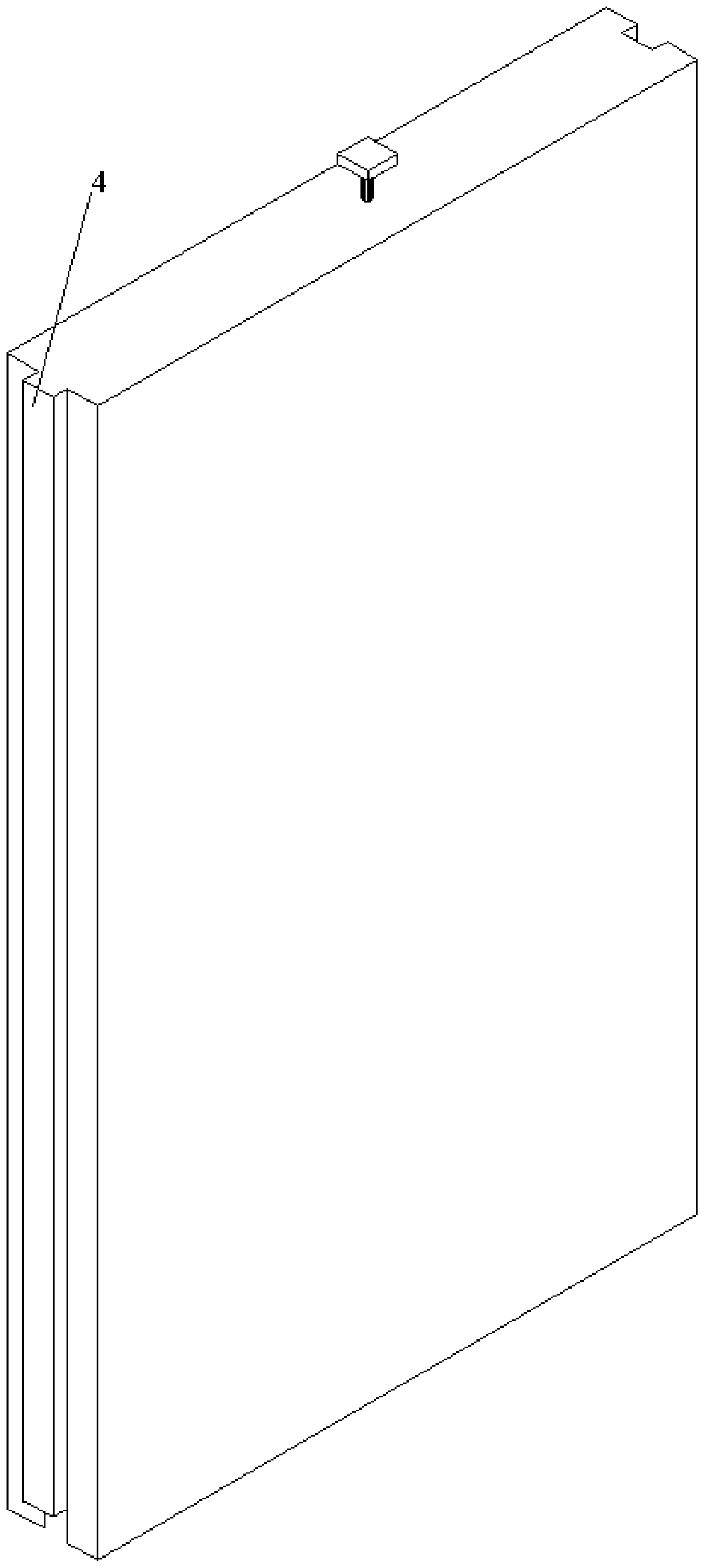

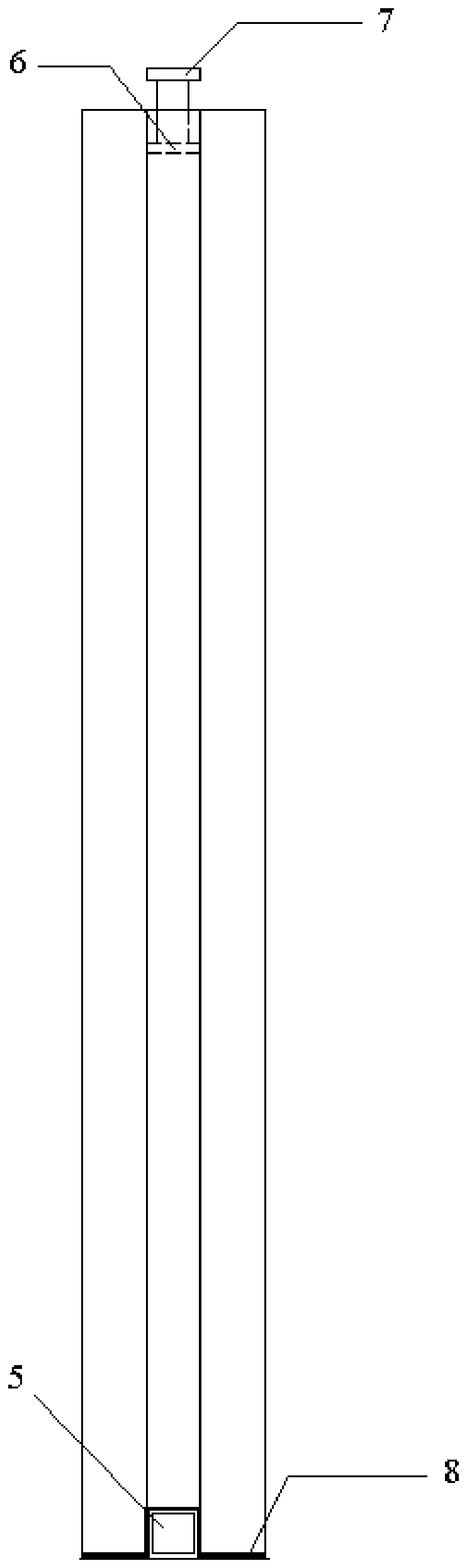

[0040] This embodiment provides a prefabricated puffed stone inner partition wall board, such as figure 1 As shown, the assembled puffed stone inner partition wall board includes a pre-pressure device (2), a chute (5) and a puffed stone inner partition wall block (1), and the pre-pressed device (2) is installed on the expanded stone The upper end of the partition wall block (1) in the stone, and the chute is installed on the lower end of the partition wall block (1) in the puffed stone;

[0041] The shape of the puffed stone inner partition wall block is a narrow strip, and the puffed stone inner partition wall block includes a middle board and a side board; the middle board is arranged in the middle of the side board;

[0042] One side of the middle plate for connection is provided with a tenon (4), and the other side for connection is provided with a mortise (3); the side of the side plate connected to the middle plate is provided with a mortise Groove or tenon, the other s...

Embodiment 2

[0059] This embodiment discloses a prefabricated puffed stone internal partition composite wall, which adopts a plurality of puffed stone internal partition wall blocks arranged in tenon and tenon connection as described in embodiment 1 to form a composite wall. The specific installation method is as follows:

[0060] S1, set the slide rail (15) on the ground at the main structure of the composite wall to be installed:

[0061] According to the design and use requirements, lay out the wires at the position corresponding to the floor surface where the inner partition wall is located, pave and level the floor surface at this place, drill the holes (16) required for installing the sinking expansion bolts, and then place 30× A 30×3 square steel pipe with a 30×30 hole on the top is fixed on the upper surface of the lower floor as a slide rail.

[0062] S2, put the prefabricated puffed stone inner partition wall panels to be installed into the slide rails, and slide them into the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com