Fan cover and air conditioner

A technology of fan cover and air inlet end, which is applied in the field of air conditioning, which can solve the problems that the airflow cannot be smoothly discharged from the installation cavity and the heat exchange capacity of the air conditioner is reduced, so as to achieve the effect of reducing the contact area and improving the heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

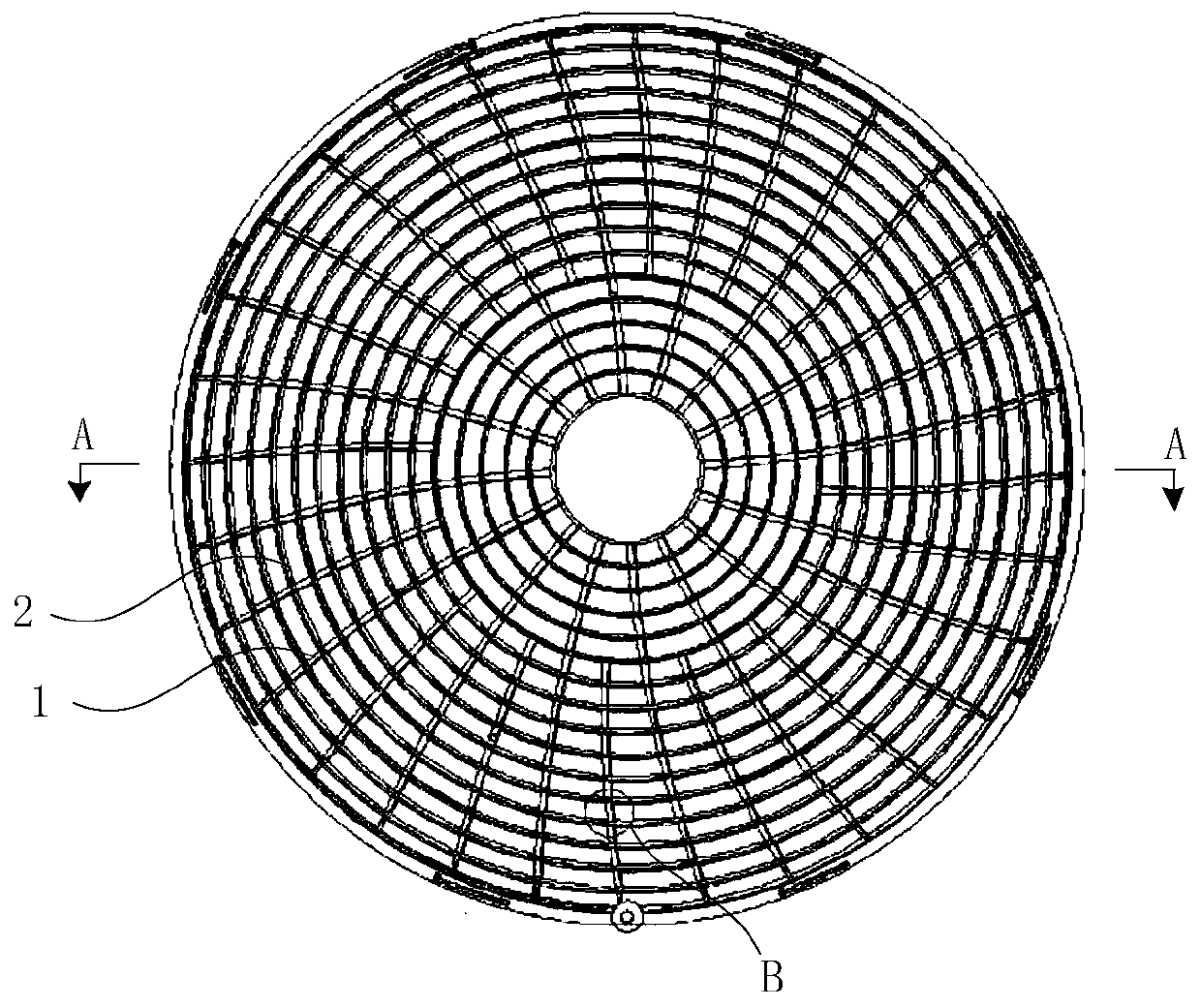

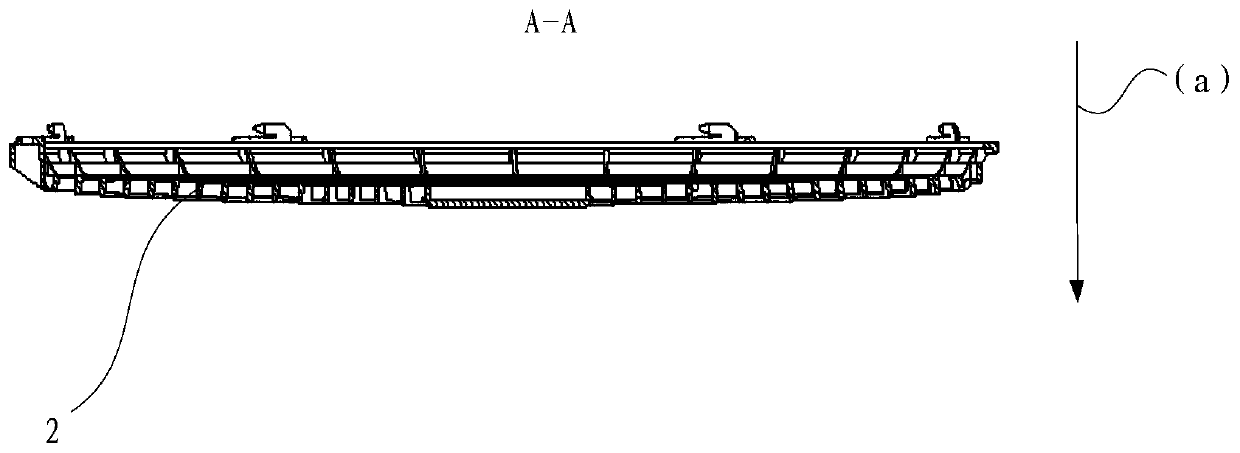

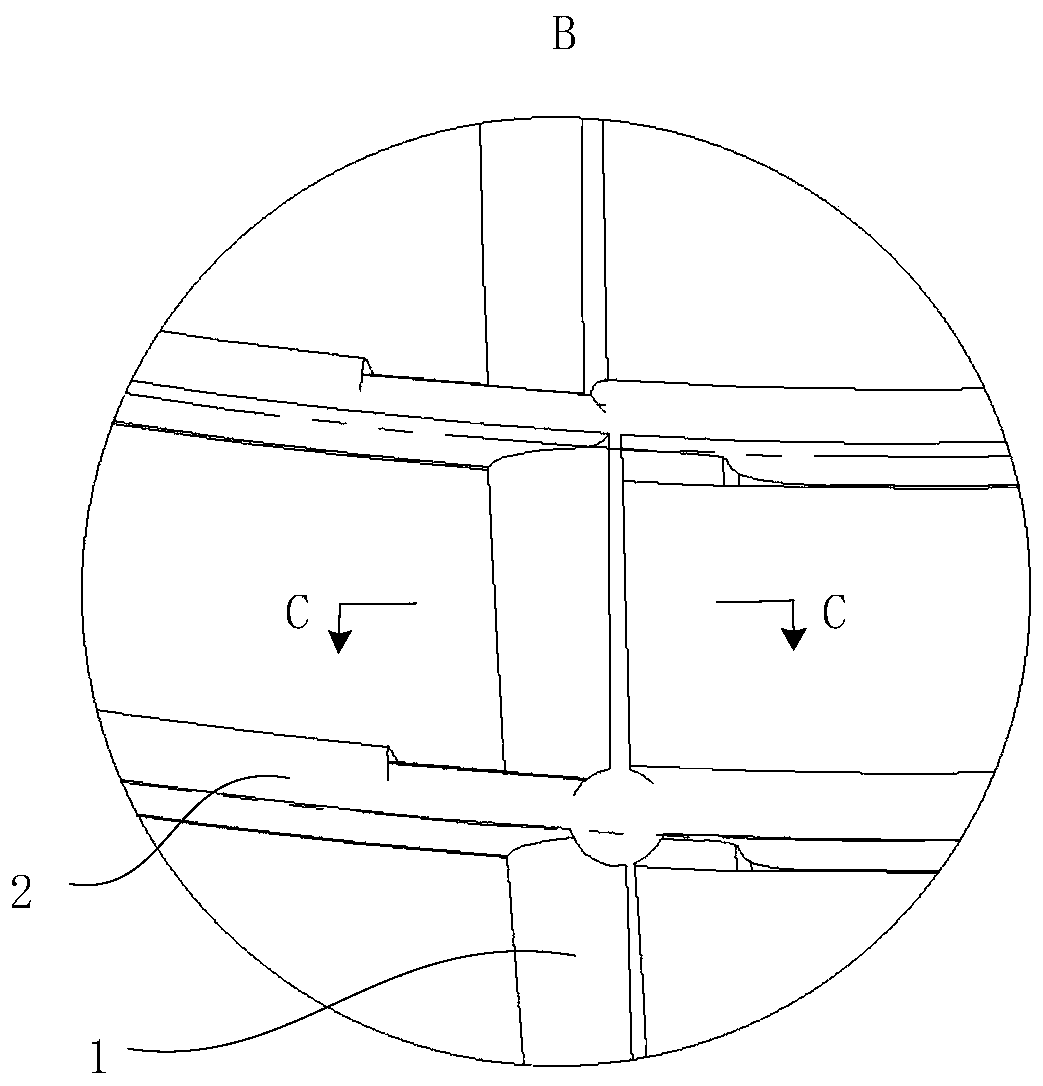

[0030] The fan cover of the embodiment of the present invention, such as Figure 4 As shown, the windward side of the radial rib 1 along the circumferential component of the airflow is the second side 14, and the second side 14 is concave along the axial middle of the fan case to form a curved surface away from the center of the fan case. Similar to the first side 12, the tangential direction of the air inlet end 11 of the second side 14 ( Figure 4 , dotted line c 3 The direction shown) and the tangential direction of the air outlet 13 ( Figure 4 , dotted line c 4 The direction shown) forms a certain included angle, and along the axial direction of the fan case, from the air inlet end 11 to the air outlet end 13 of the radial rib 1, the included angle between the tangent direction of the second side surface 14 and the fan case axial direction gradually get smaller. When the airflow flows through the second side 14 of the radial rib 1, the second side 14 can guide the air...

Embodiment 2

[0034] The fan cover of the embodiment of the present invention, such as Figure 5 As shown, the windward side of the radial rib 1 along the circumferential component of the airflow is the second side 14 , and the second side 14 is a plane along the axial direction of the fan case. It should be understood that "the second side 14 is a plane along the axial direction of the fan case" specifically refers to, for example, Figure 5 As shown, the second side 14 extends in a straight line in the axial direction of the fan case; the second side 14 itself has an extension along the radial direction of the fan case and an extension along the axial direction of the fan case. Viewed along the axial direction of the fan case, the first The two sides 14 are planes. Compared with Embodiment 1, the second side 14 is concave along the axial middle of the fan case to the leeward side of the radial rib 1 along the circumferential component of the airflow to form a curved surface, and its seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com