Conical dryer for treating waste resins with radioactivity

A waste resin and radioactive technology, applied in the field of radioactive waste treatment equipment, can solve the problems of non-compliance with the principle of minimization of nuclear power waste treatment, waste price increase and large capacity increase, radioactive pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

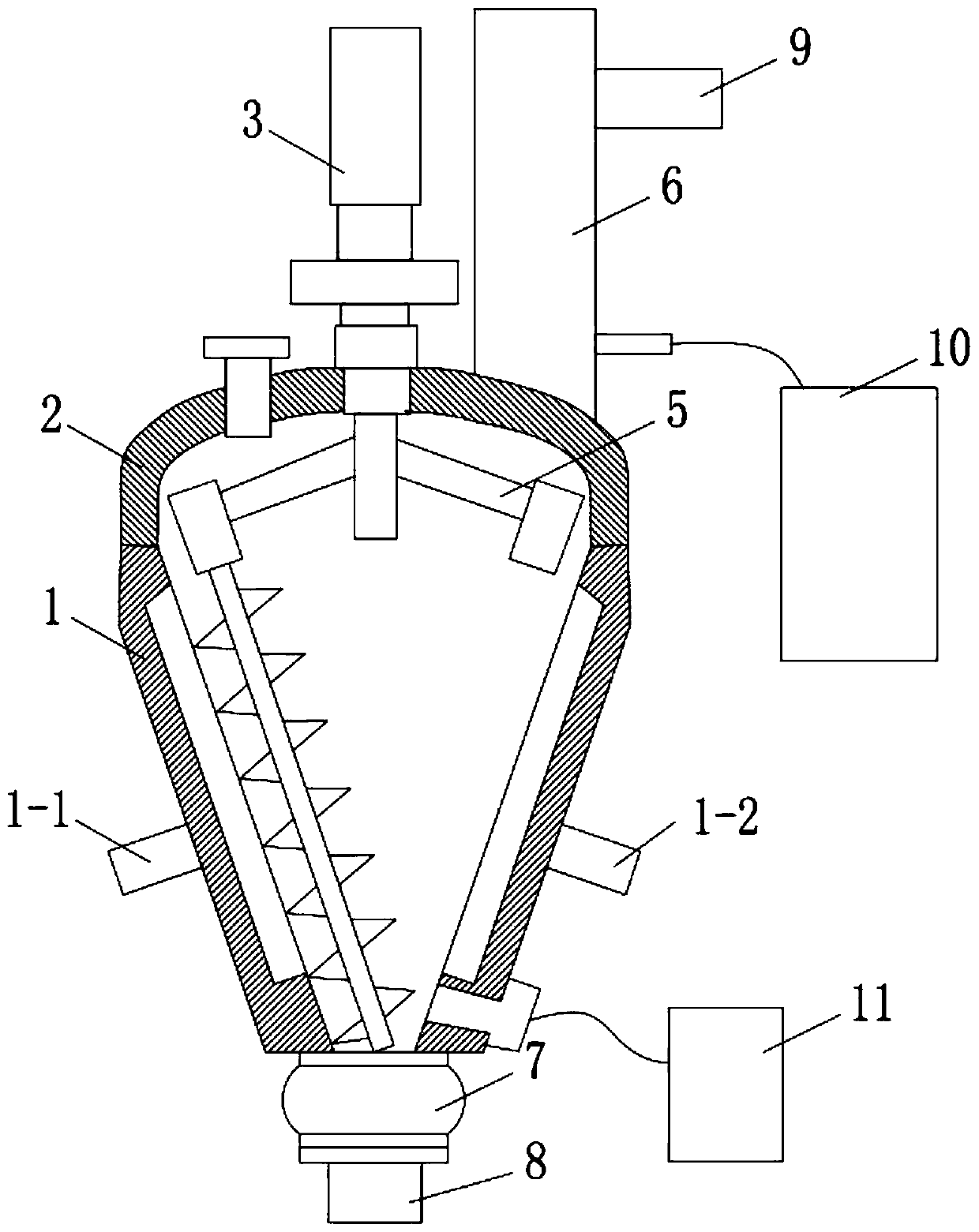

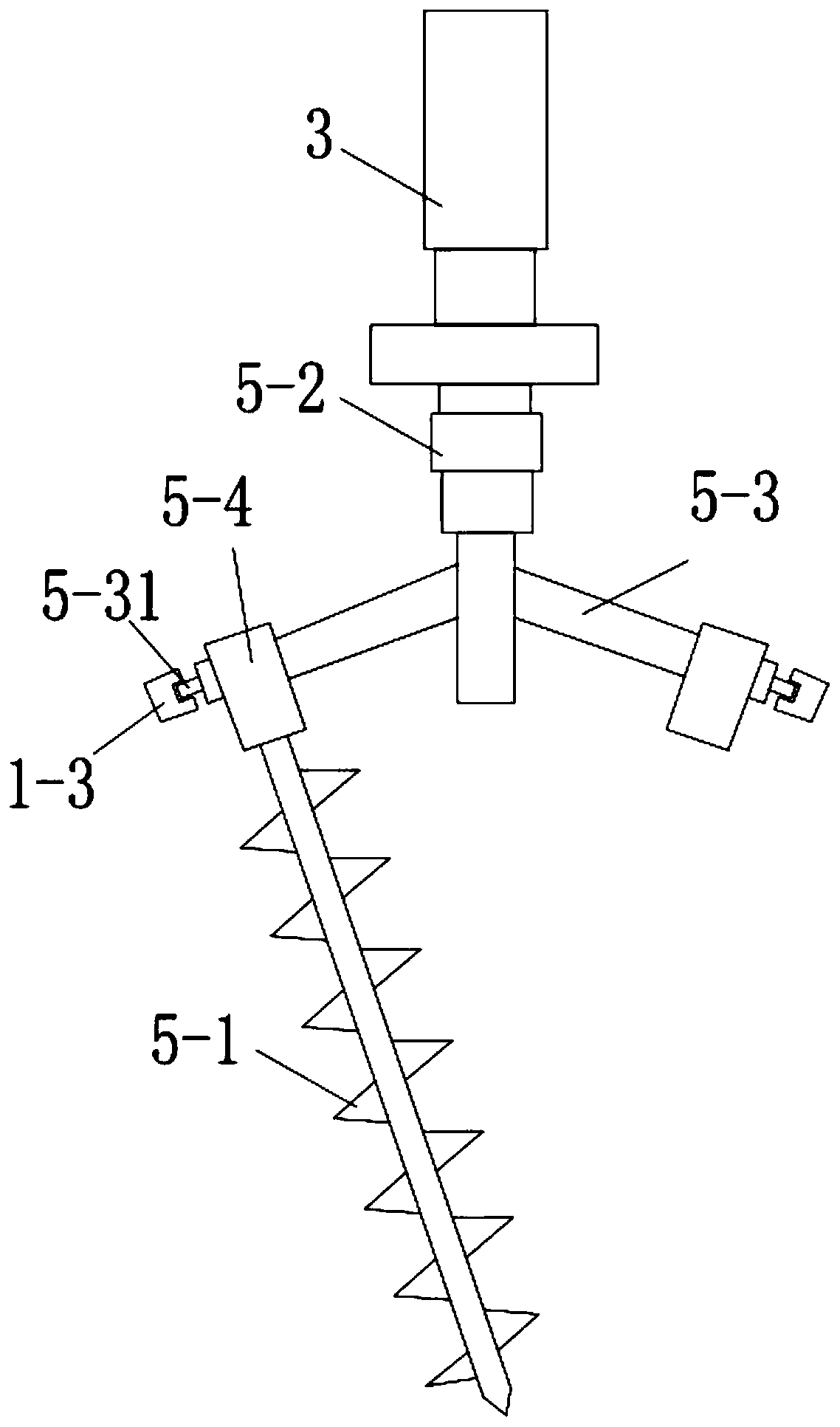

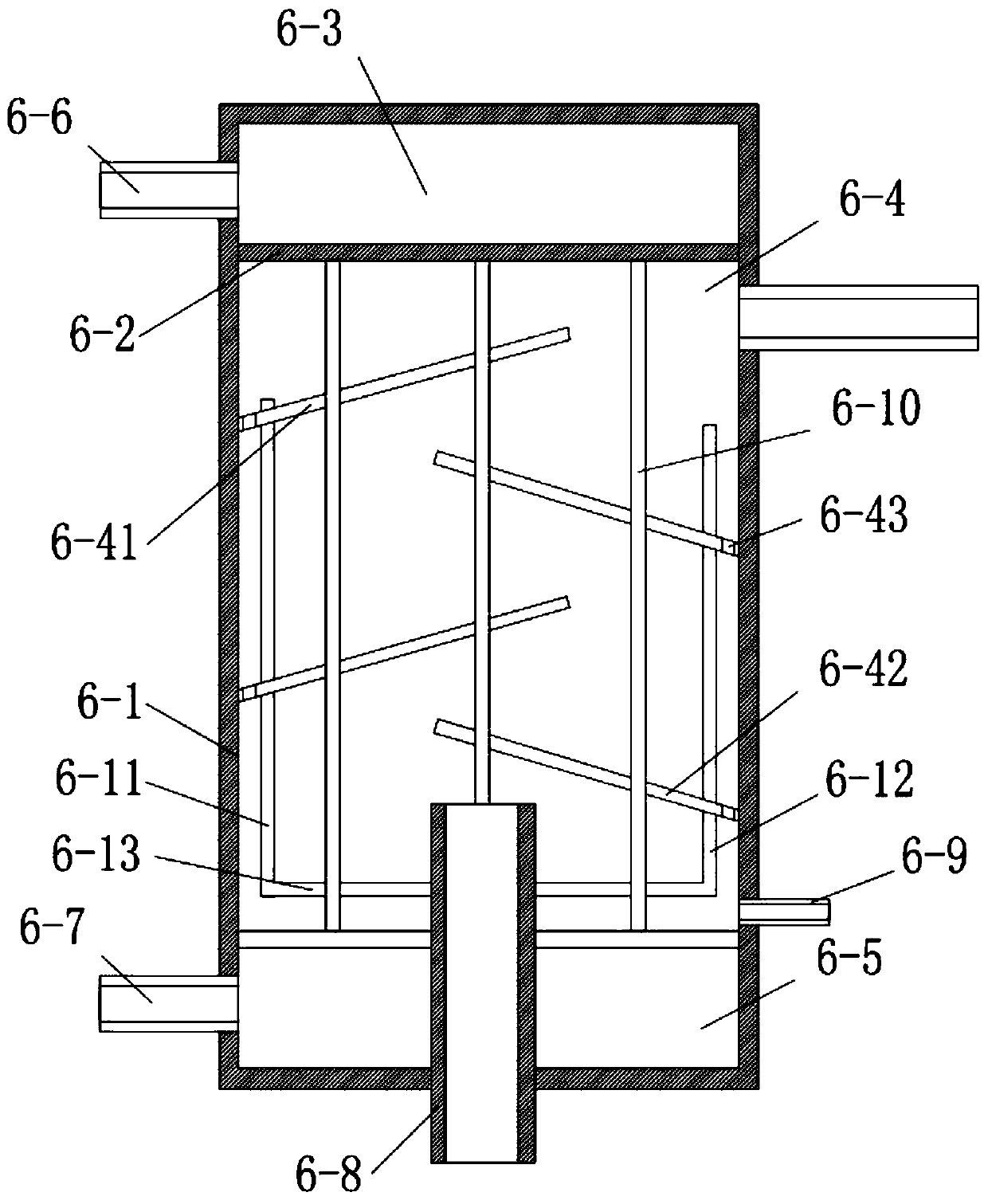

[0032] Such as figure 1 as shown,

[0033] The invention provides a conical drier for processing radioactive waste resin, comprising

[0034] The conical shell 1 is used to hold the waste resin. The conical shell 1 is a double-layer jacket structure with heat transfer oil in the middle. The side of the conical shell 1 is provided with a heat transfer oil inlet 1-1 and a cone Body heat transfer oil outlet 1-2, the heat transfer oil inlet 1-1 and heat transfer oil outlet 1-2 are respectively connected to the thermal oil unit through oil pipes;

[0035] The upper end cap 2 of the conical housing is arranged on the top of the conical housing 1 for sealing the conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com