Ultrasonic probe operating device with pressure sensor

A pressure sensor and operating device technology, used in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Apply pressure and other issues to achieve the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

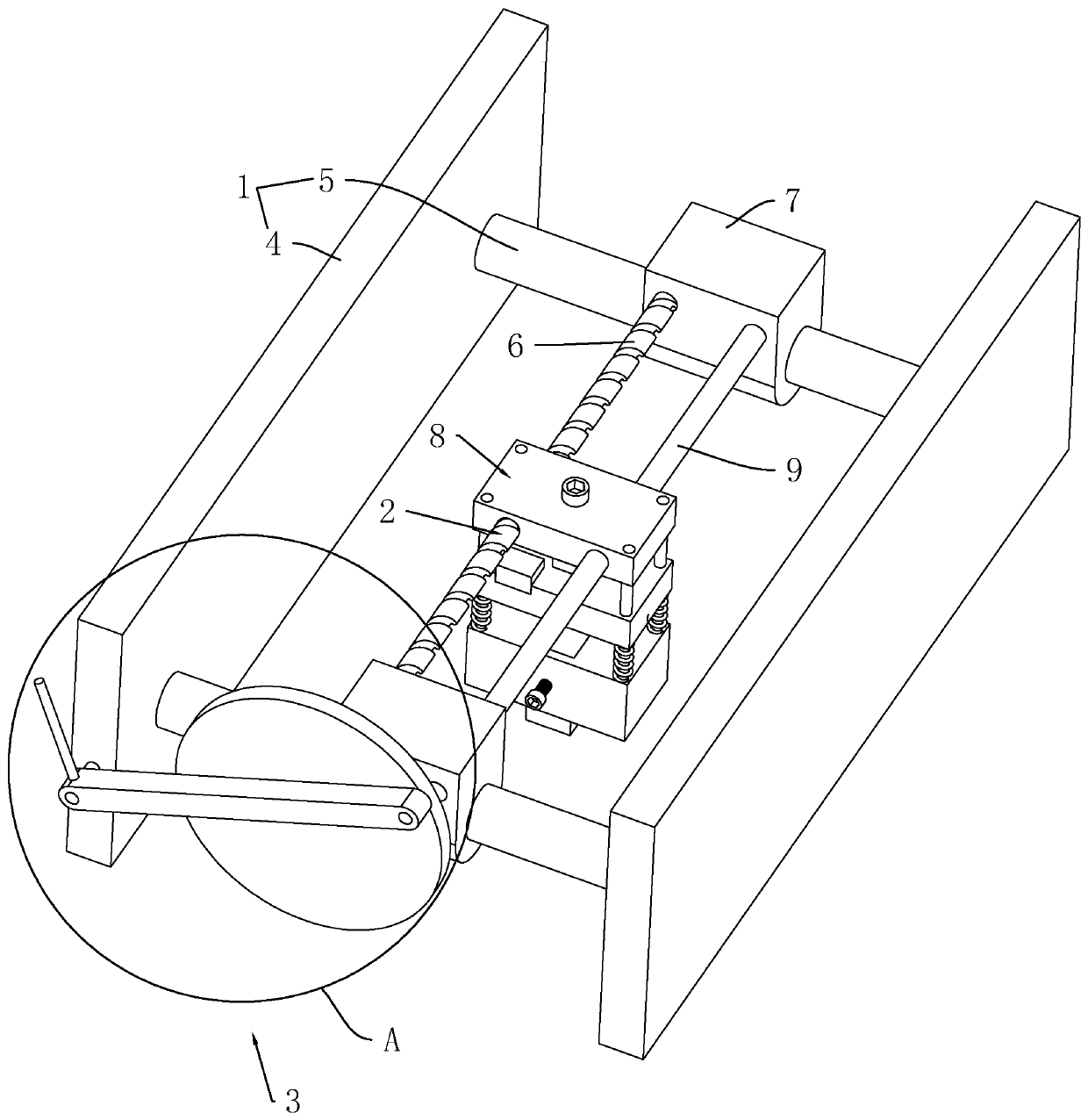

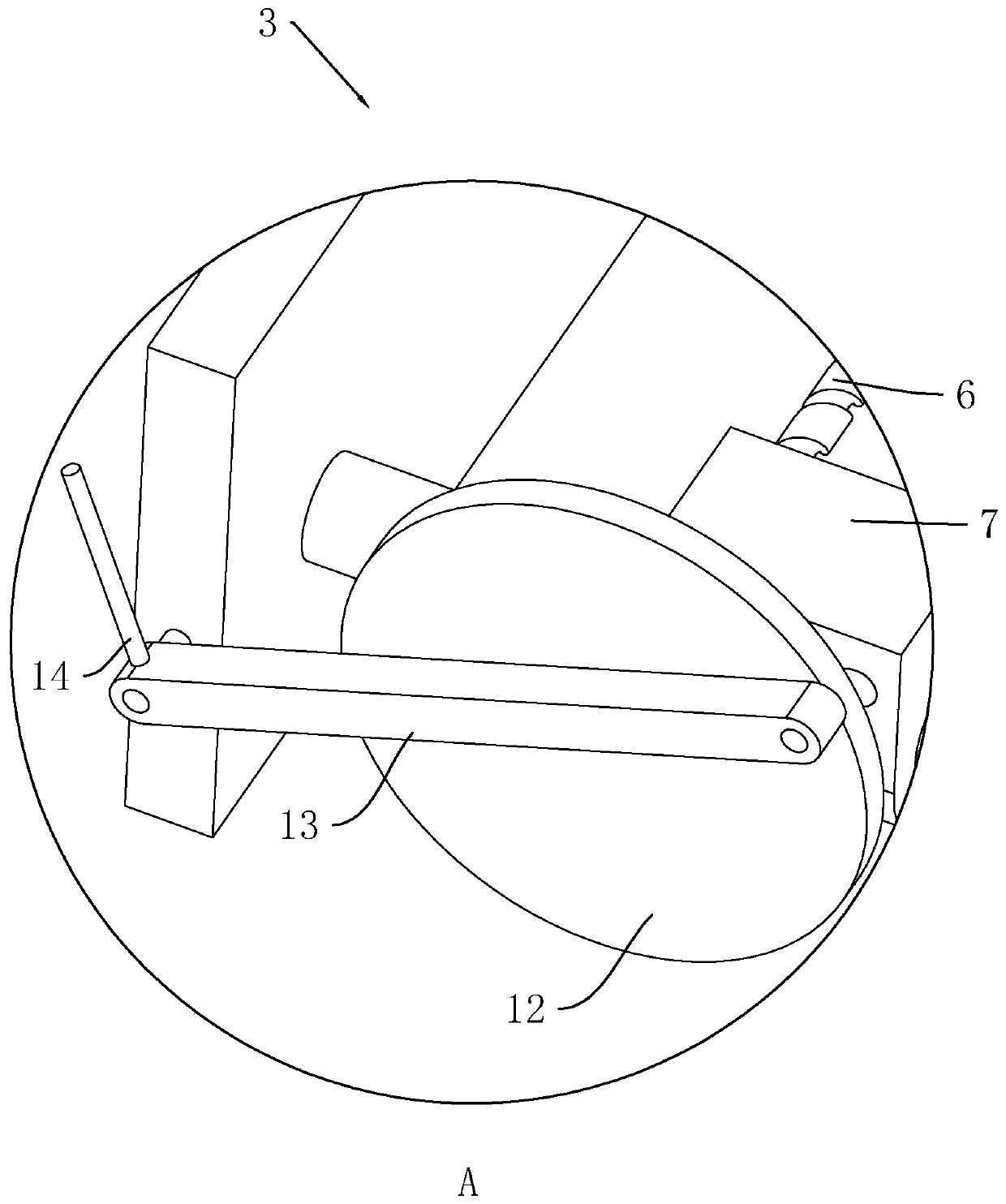

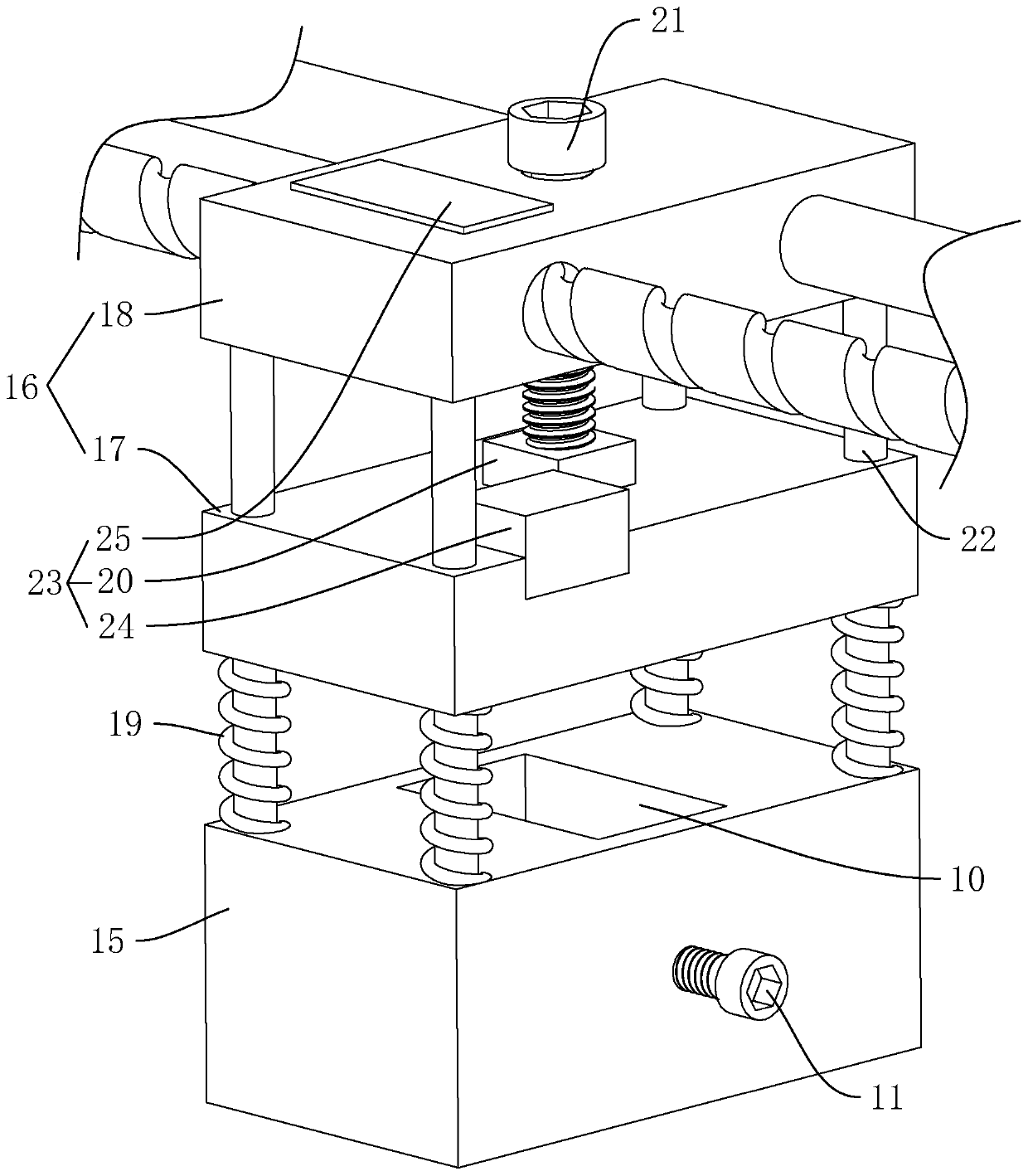

[0036] Embodiment: a kind of ultrasonic probe operating device with pressure sensor, such as figure 1 As shown, it includes a frame 1, a sliding structure 2, a driving structure 3 and a probe base 8. The probe base 8 is used to install the probe, the probe base 8 is slidably connected to the sliding structure 2, the sliding structure 2 is slidably connected to the frame 1, and the driving structure 3 drives the sliding structure 2 to slide, thereby driving the probe to slide.

[0037] Such as figure 1 As shown, the frame 1 includes two side plates 4 and two sliding bars 5, the two side plates 4 are vertically arranged and both are parallel, and the two sliding bars 5 are fixedly connected to the two side plates 4 horizontally between, and the sliding rods 5 are parallel to each other.

[0038] Such as figure 1 As shown, the sliding structure 2 includes a threaded rod 6 , a sliding seat 7 and a guide rod 9 . There are two sliding seats 7 and they are sleeved on two guide ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com