Isolating switch

A technology for isolating switches and fixing seats, which is applied in the direction of electric switches, air switch components, high-voltage air circuit breakers, etc., and can solve problems such as high force requirements of the driving mechanism, failure of circuit disconnection, and long gear rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

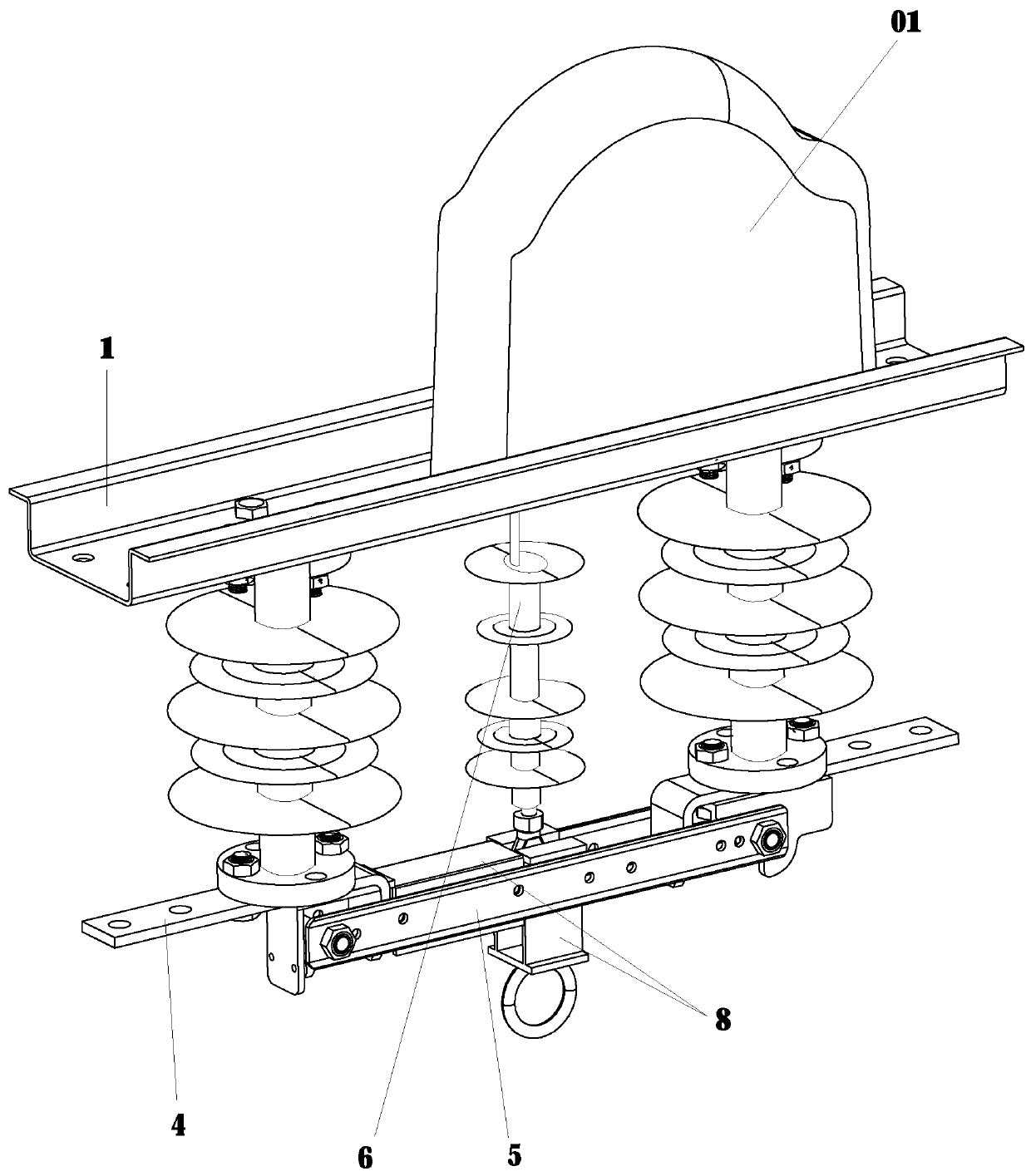

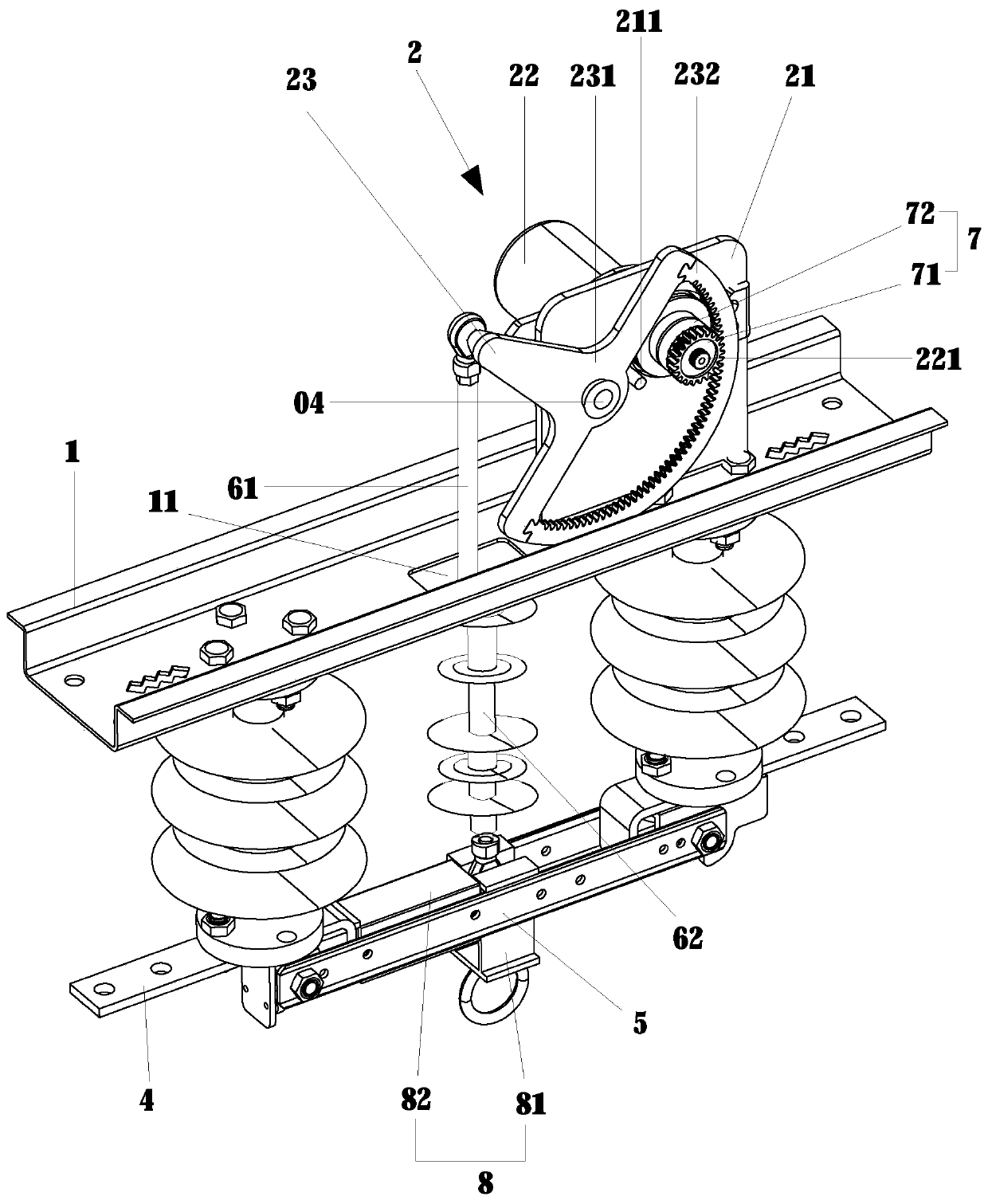

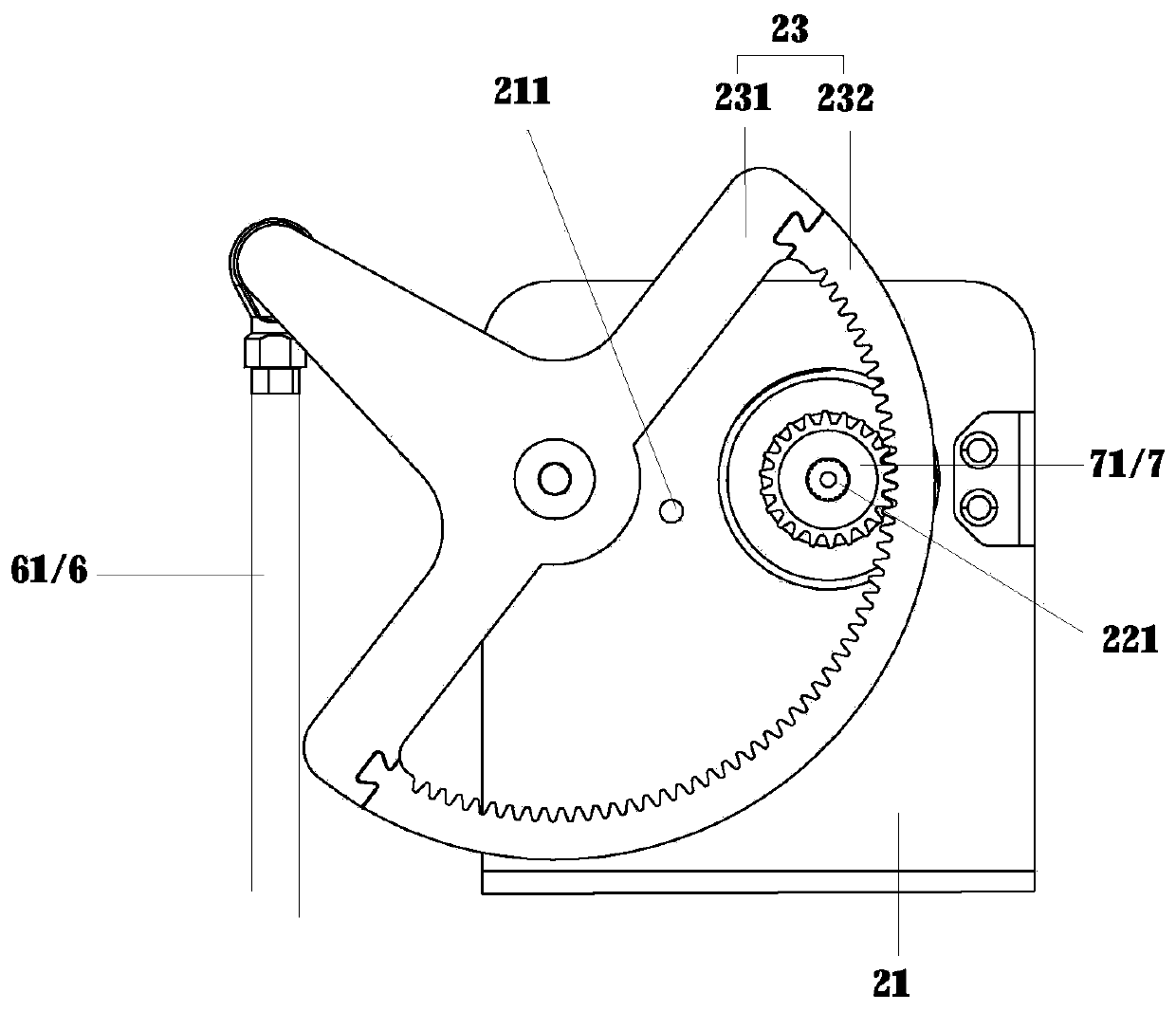

[0029] refer to Figure 1 to Figure 12 It can be seen that the present invention: a disconnector, including a fixed seat 1, a drive mechanism 2 located above the fixed seat 1, two parallel insulators 3 and a knife switch 5 located below the fixed seat 1, one end of the knife switch 5 is hinged to one of the insulators 3 At the end away from the fixed seat 1, the ends of the two insulators 3 away from the fixed seat 1 are fixed with lugs 4, and the two lugs 4 are turned on or off through the swing of the knife switch 5, and the driving mechanism 2 passes through the connecting rod. 6. Connect and drive the knife switch 5 to swing. The driving mechanism 2 includes a fixed plate 21, a motor 22 and a bracket 23. The motor 22 is connected to an output shaft 221. The bracket 23 includes a body 231 and an arc-shaped rack 232. The arc-shaped rack 232 Mesh with the output shaft 221 through the buffer assembly 7, the buffer assembly 7 includes a gear 71 and a transition wheel 72, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com