Dual-array package light source structure and packaging method thereof

A light source and installation groove technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of complex LED chip packaging procedures, heat generated by LED chips, and low processing efficiency, so as to improve the dustproof effect and heat dissipation speed , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

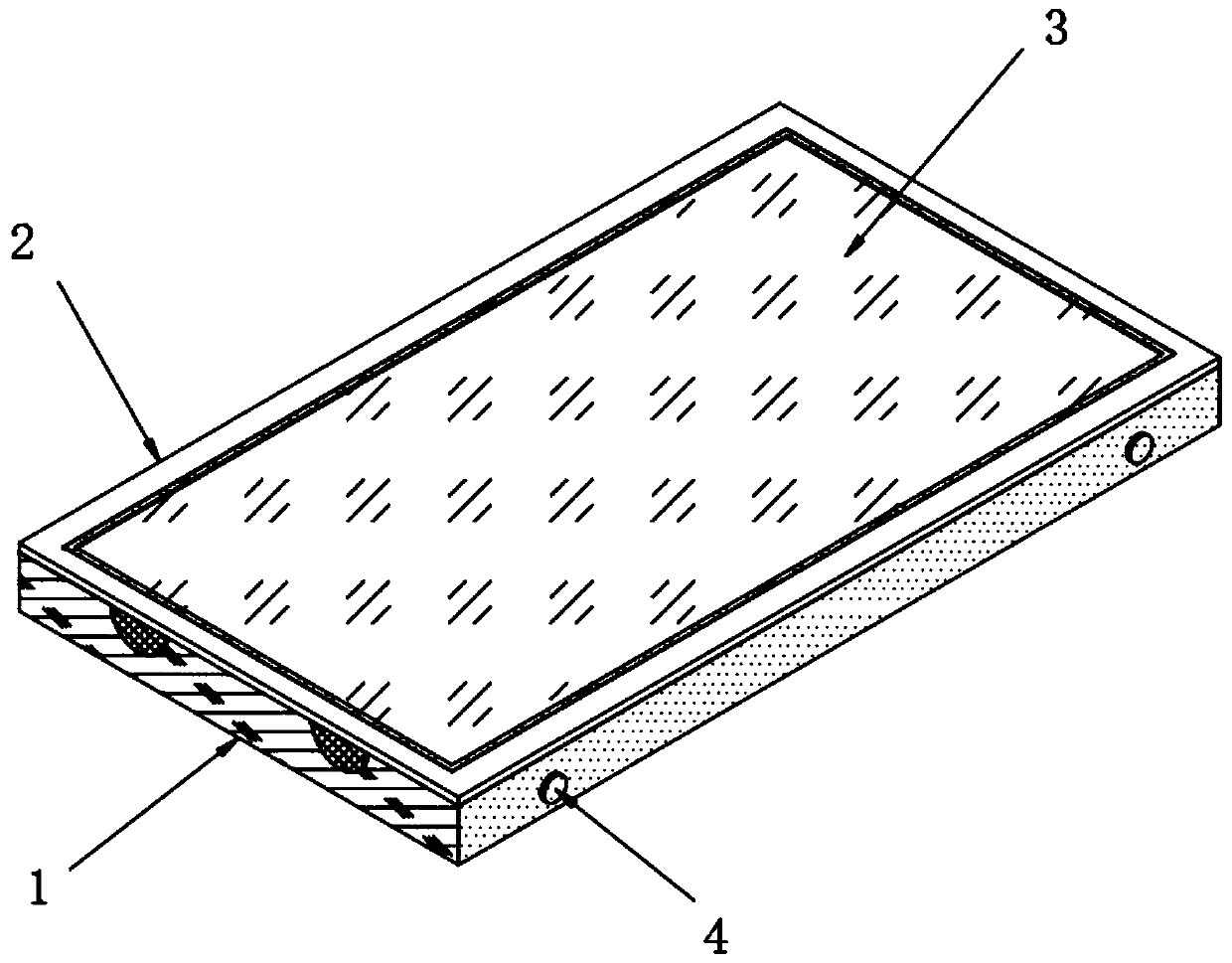

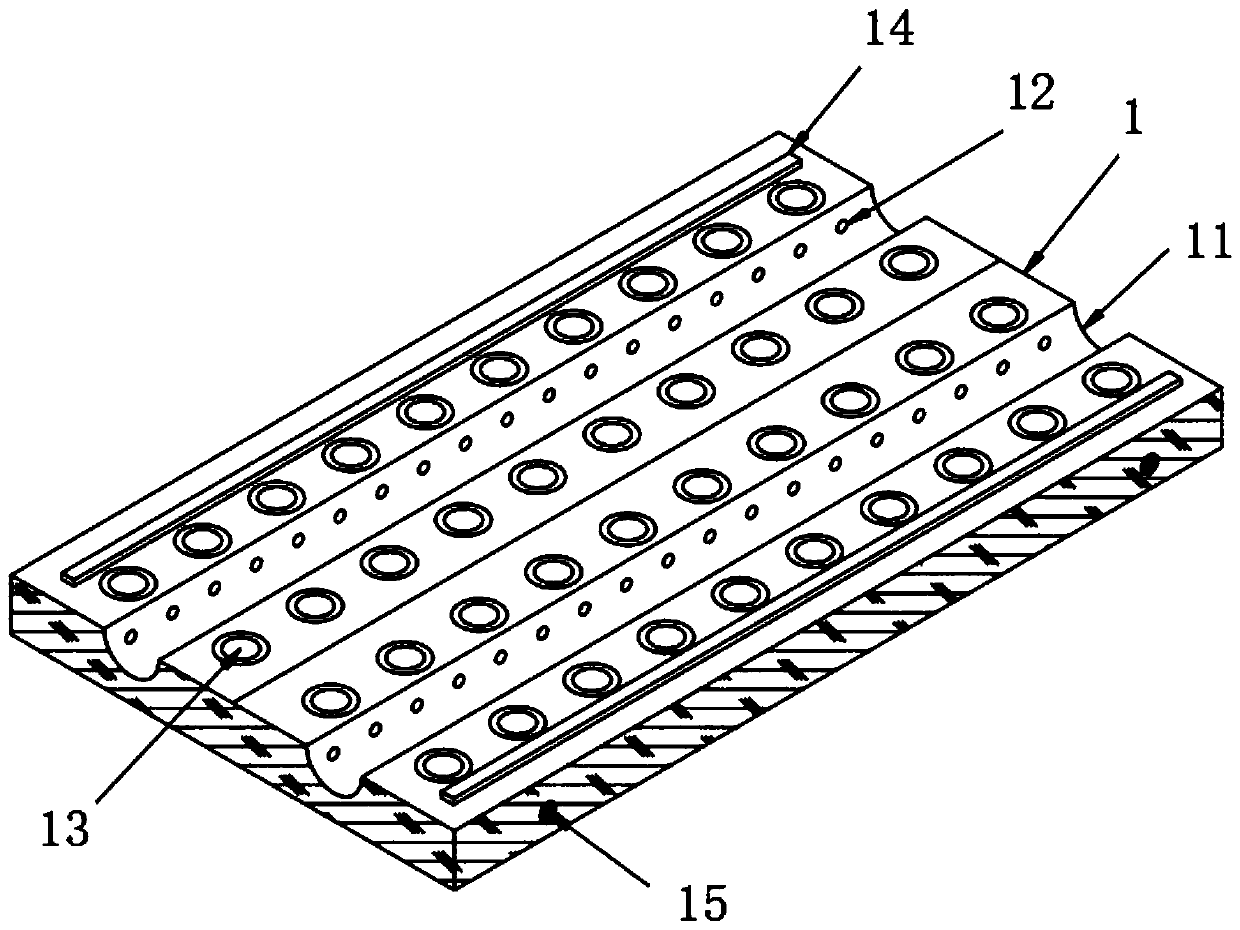

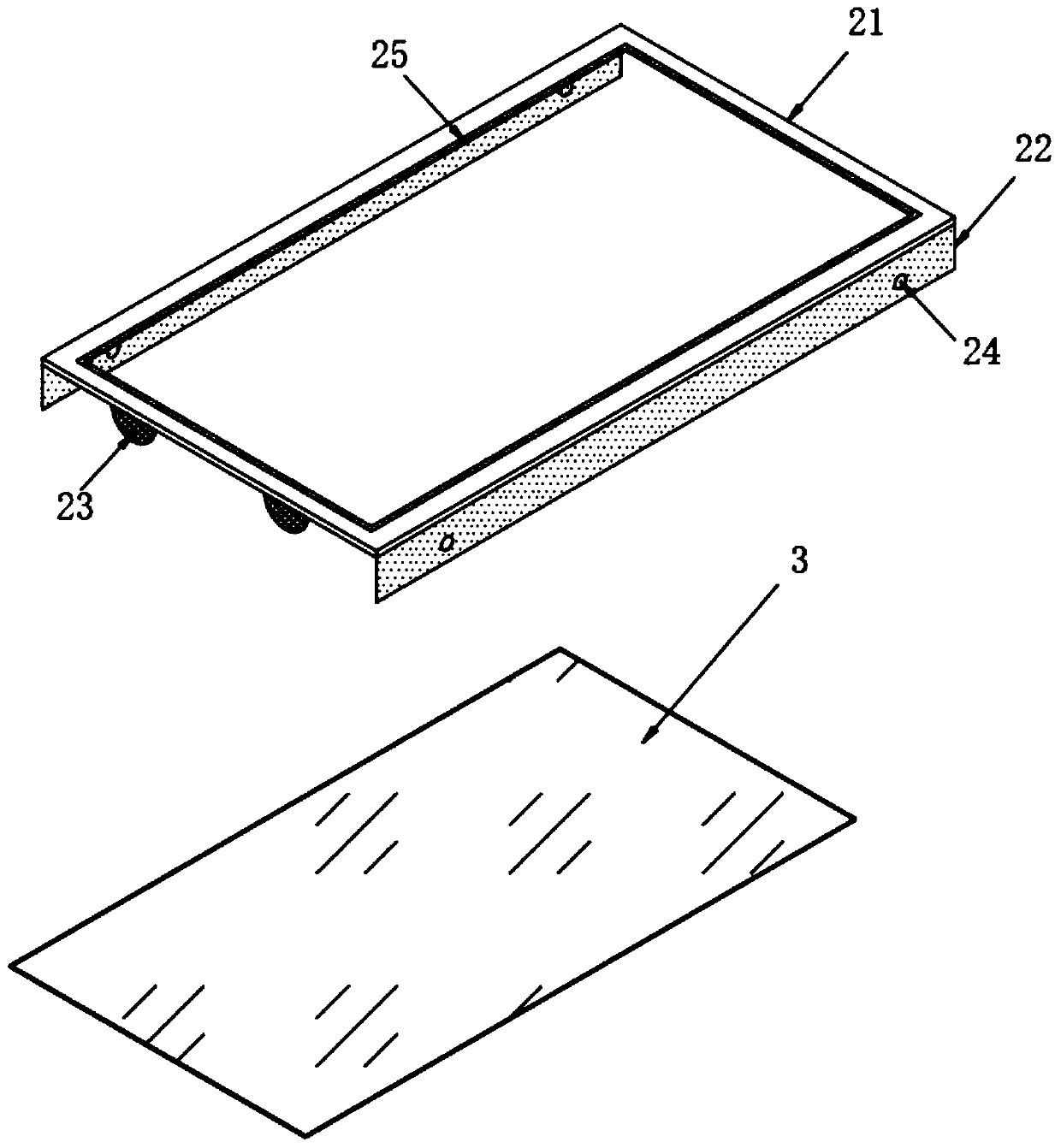

[0031] A double-array packaged light source structure, such as figure 1 and figure 2 As shown, it includes a cuboid substrate 1, two symmetrical cooling grooves 11 are provided on the top surface of the substrate 1, and the cross section of the cooling grooves 11 is semicircular. A distance from the LED chips 13 arranged linearly, a heat dissipation through hole 12 is opened on the inner wall of each heat dissipation groove 11, and each LED chip 13 is provided with a mounting groove, and the LED chip 13 is snap-fitted with the mounting groove, and the heat dissipation through hole 12 communicates with the inside of the installation groove, and both sides of the substrate 1 are symmetrically provided with threaded holes 15; the top of the substrate 1 is provided with an isolation frame 2, and a glass sheet 3 is arranged between the isolation frame 2 and the substrate 1, such as image 3 As shown, the isolation frame 2 includes a frame 21, the frame 21 is a square ring structu...

Embodiment 2

[0045] As a second embodiment of the present invention, both sides of the top surface of the substrate 1 are symmetrically provided with damping strips 14 , and the sum of the thicknesses of the damping strips 14 and the glass sheet 3 is equal to the thickness of the frame 21 .

[0046] Further, the shock absorbing strip 14 is made of high temperature resistant rubber material.

[0047] Specifically, the width between the two damping strips 14 is smaller than the width of the glass sheet 3 .

[0048] In the double-array packaged light source structure of this embodiment, shock absorbing strips 14 are arranged symmetrically on both sides of the top surface of the substrate 1 , so that the structure of the glass sheet 3 is more stable when installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com