A kind of preparation method of brightener for copper plating

A brightener and copper-plating technology, applied in the preparation of copper-plating brighteners, can solve the problems of low brightness and slow light output, and achieve the effects of increasing dispersibility, increasing brightness, and improving crystal thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

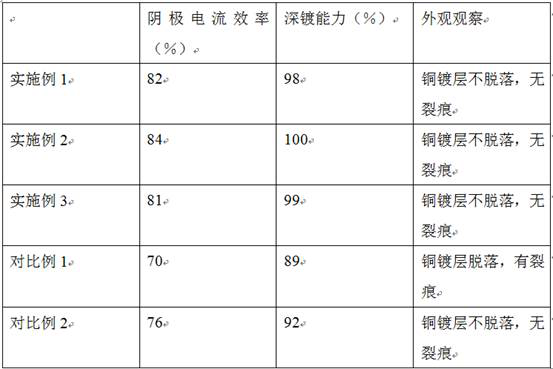

Examples

preparation example Construction

[0031] The preparation method of described catalyst is:

[0032] A. The mixture and ethanol solution were ultrasonically oscillated for 20 minutes according to the mass ratio of 1:5-7, then added acetic acid solution to adjust the pH to 2.0-2.5, left to age for 10 hours, spray-dried, and collected the dry matter;

[0033] B. Ball mill the dried material, collect the ball milled material, put the ball milled material and concentrated sulfuric acid into the reaction kettle according to the mass ratio of 3:6-8 for mixing, then add urea with 10-15% of the ball-milled material, and use nitrogen protection, Stir and react at 125-130°C for 20h;

[0034] C. After the stirring reaction is completed, use sodium hydroxide solution to adjust the pH to 8.0, add auxiliary materials with a mass of 10% to 15% of the ball-milled material, stir, discharge, freeze-dry, and freeze-dried material and synergist by mass ratio 2 ~ 5:7 mixed to get the catalyst.

[0035] The initiator is any one of ...

Embodiment 1

[0043] The additive is formed by mixing cardanol and sorbitol at a mass ratio of 9:2.

[0044] The mixture is formed by mixing epichlorohydrin and ethylene oxide solution at a mass ratio of 5:12.

[0045] The additive is a mixture of alanine and tyrosine in a mass ratio of 5:3.

[0046] The mixture is formed by mixing tetrabutyl titanate and titanium tetrachloride in a mass ratio of 7:2.

[0047] The auxiliary material is ammonium bicarbonate.

[0048] The synergist is urea.

[0049] The preparation method of catalyst is:

[0050] A. The mixture and the ethanol solution were ultrasonically oscillated for 20 minutes according to the mass ratio of 1:5, then the acetic acid solution was added to adjust the pH to 2.0, left to age for 10 hours, spray-dried, and the dry matter was collected;

[0051]B. Ball-mill the dry matter, collect the ball-milled matter, put the ball-milled matter and concentrated sulfuric acid into the reaction kettle at a mass ratio of 3:6 for mixing, the...

Embodiment 2

[0062] The additive is formed by mixing cardanol and sorbitol in a mass ratio of 8:2.

[0063] The mixture is formed by mixing epichlorohydrin and ethylene oxide solution at a mass ratio of 4:11.

[0064] The additive is a mixture of alanine and tyrosine in a mass ratio of 4:2.

[0065] The mixture is formed by mixing tetrabutyl titanate and titanium tetrachloride in a mass ratio of 7:3.

[0066] The auxiliary material is ammonium bicarbonate.

[0067] The synergist is urea.

[0068] The preparation method of described catalyst is:

[0069] A. The mixture and ethanol solution were ultrasonically oscillated for 20 minutes at a mass ratio of 1:6, then acetic acid solution was added to adjust the pH to 2.3, left to age for 10 hours, spray-dried, and the dry matter was collected;

[0070] B. Ball-mill the dry matter, collect the ball-milled matter, put the ball-milled matter and concentrated sulfuric acid into the reaction kettle at a mass ratio of 3:7 for mixing, then add ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com