Clamping jaw based on gel driver

A driver and gel technology, applied in the field of intelligent structure, can solve the problems of inability to realize flexible clamping of objects, occupy a large space, and single clamping force, and achieve suitable for promotion and application, wide clamping angle, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

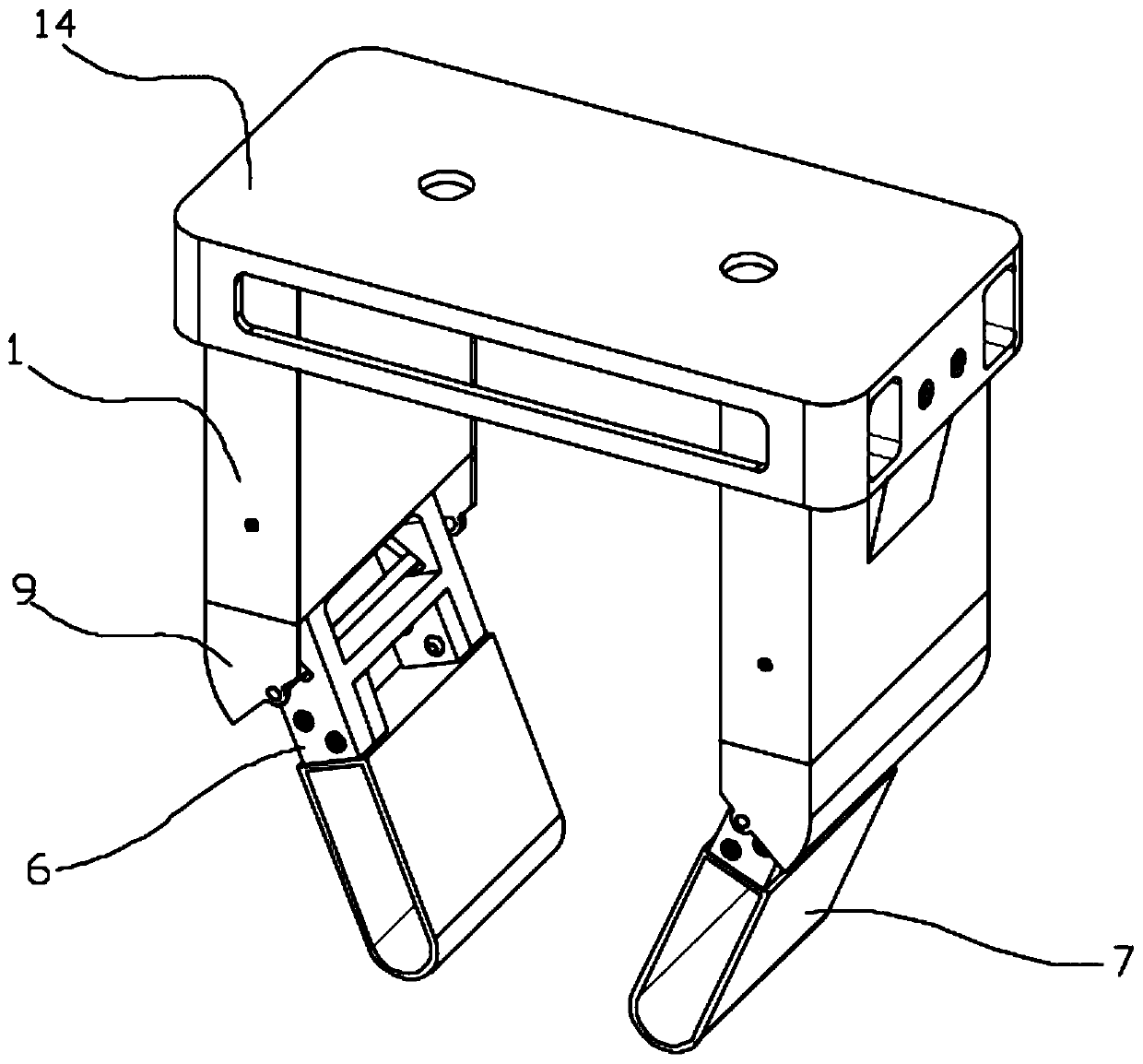

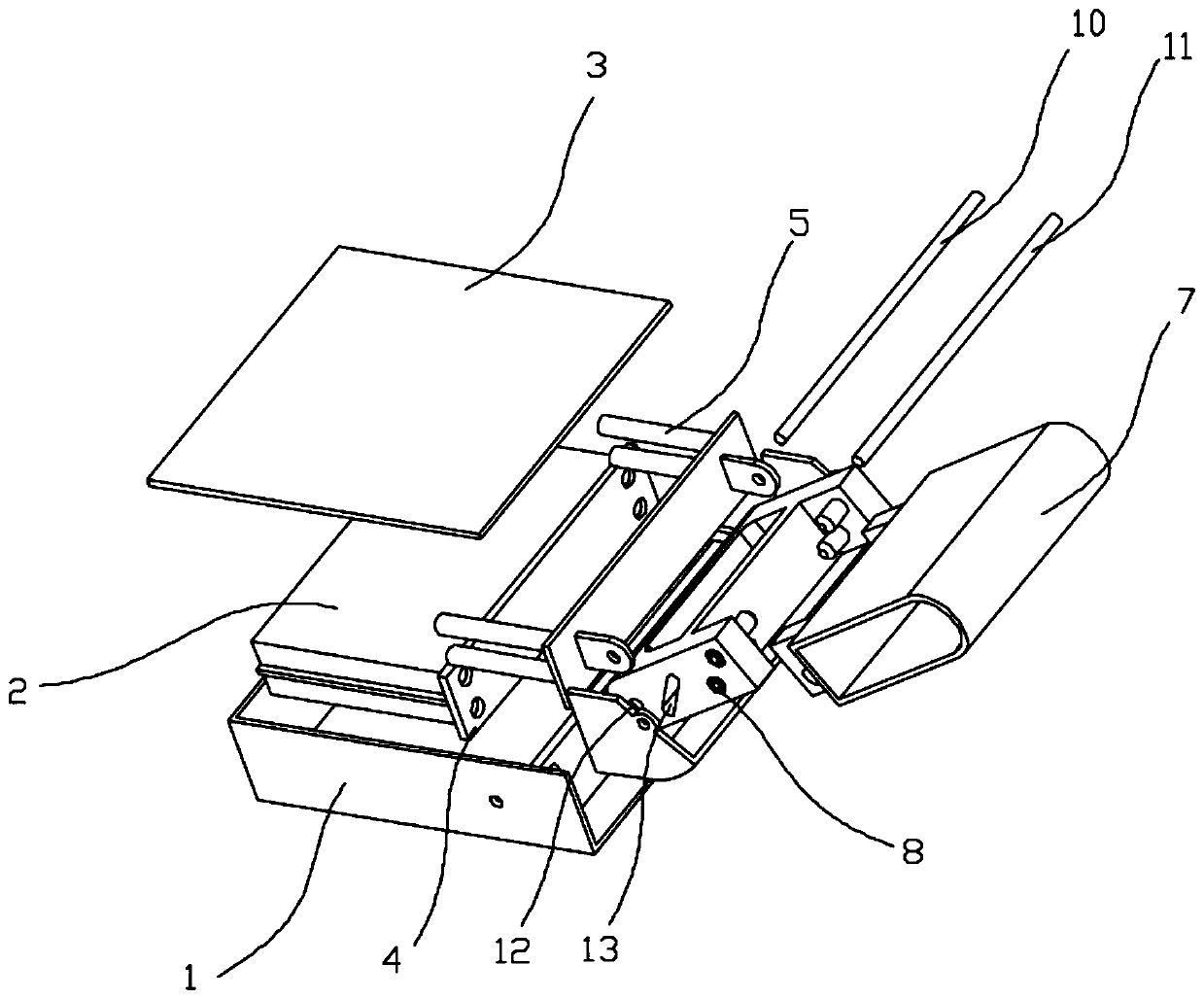

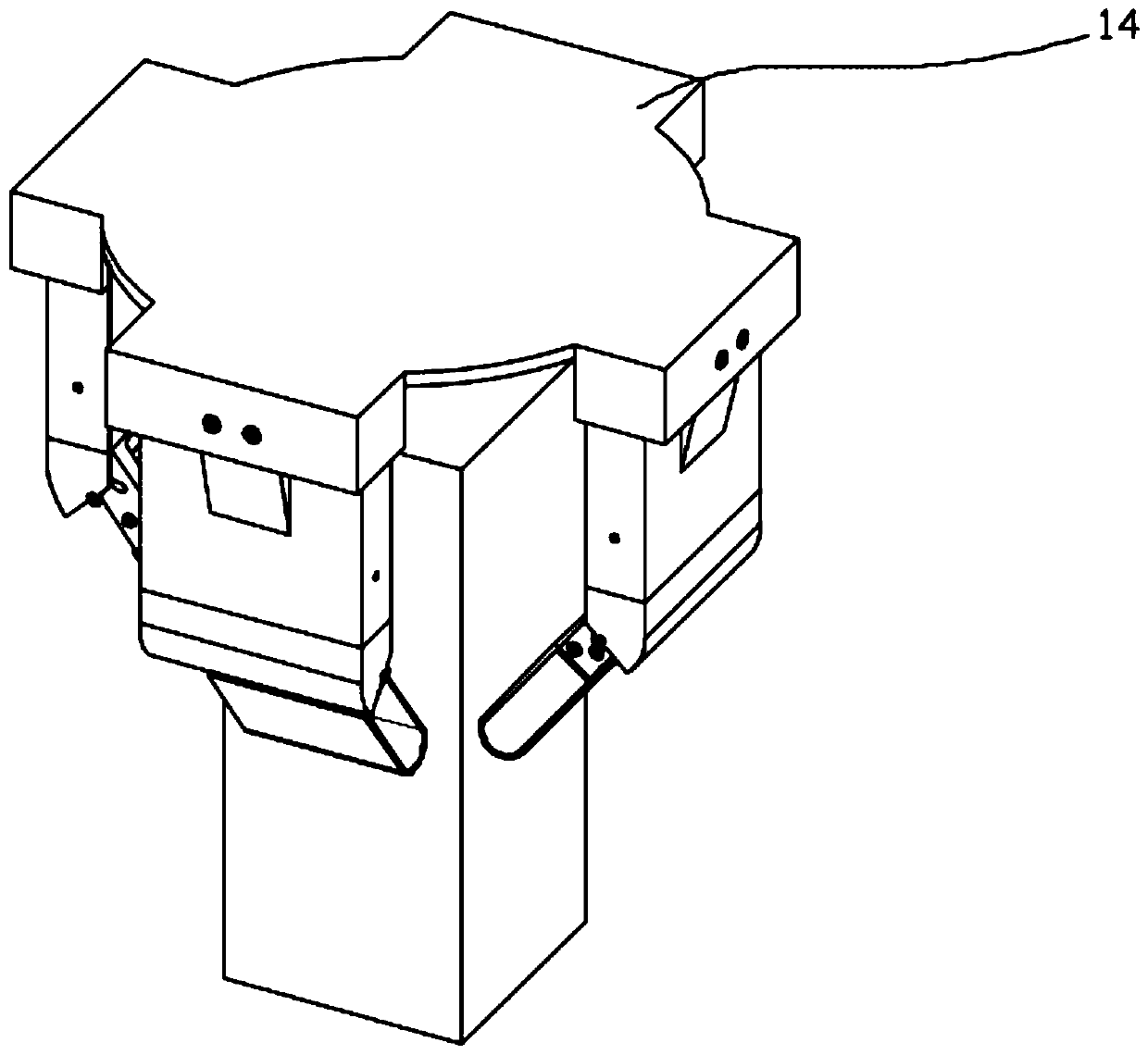

[0021] The specific embodiment of the specific solution of the present invention will be further elaborated in conjunction with the accompanying drawings.

[0022] The gel driver 2 of the present invention refers to the gel driver 2 disclosed in the patent CN109524538A.

[0023] The jaw based on the gel driver 2 includes a support connecting plate 14 and the gel driver 2, the supporting connecting plate 14 is used to connect with an external mechanism, and the jaw also includes a clamping mechanism connected to the supporting connecting plate 14, The clamping mechanism includes a sliding mechanism driven by a gel driver 2, a rotating mechanism 6 and clamping fingers 7, the sliding mechanism is connected to the rotating mechanism 6 in rotation, and the end of the rotating mechanism 6 is connected to the clamping fingers 7, The gel driver 2 shrinks or returns to drive the rotating mechanism 6 to drive the clamping fingers 7 to clamp or loosen. The rotation angle of the gripping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com