A flexible drive fixture for rotating workpieces

A rotating workpiece, flexible technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve problems affecting workpiece processing quality, deformation, etc. The effect of the number of passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

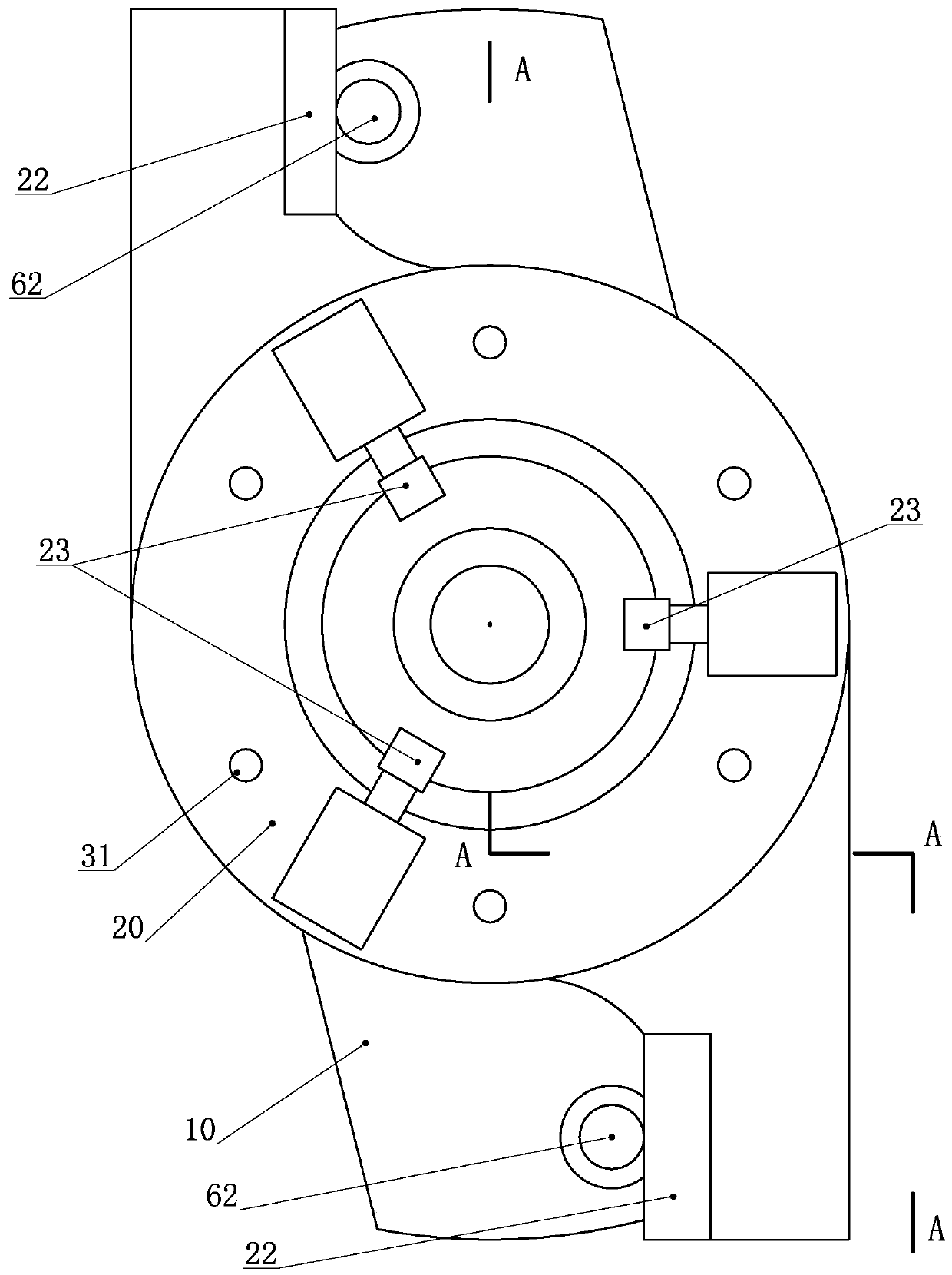

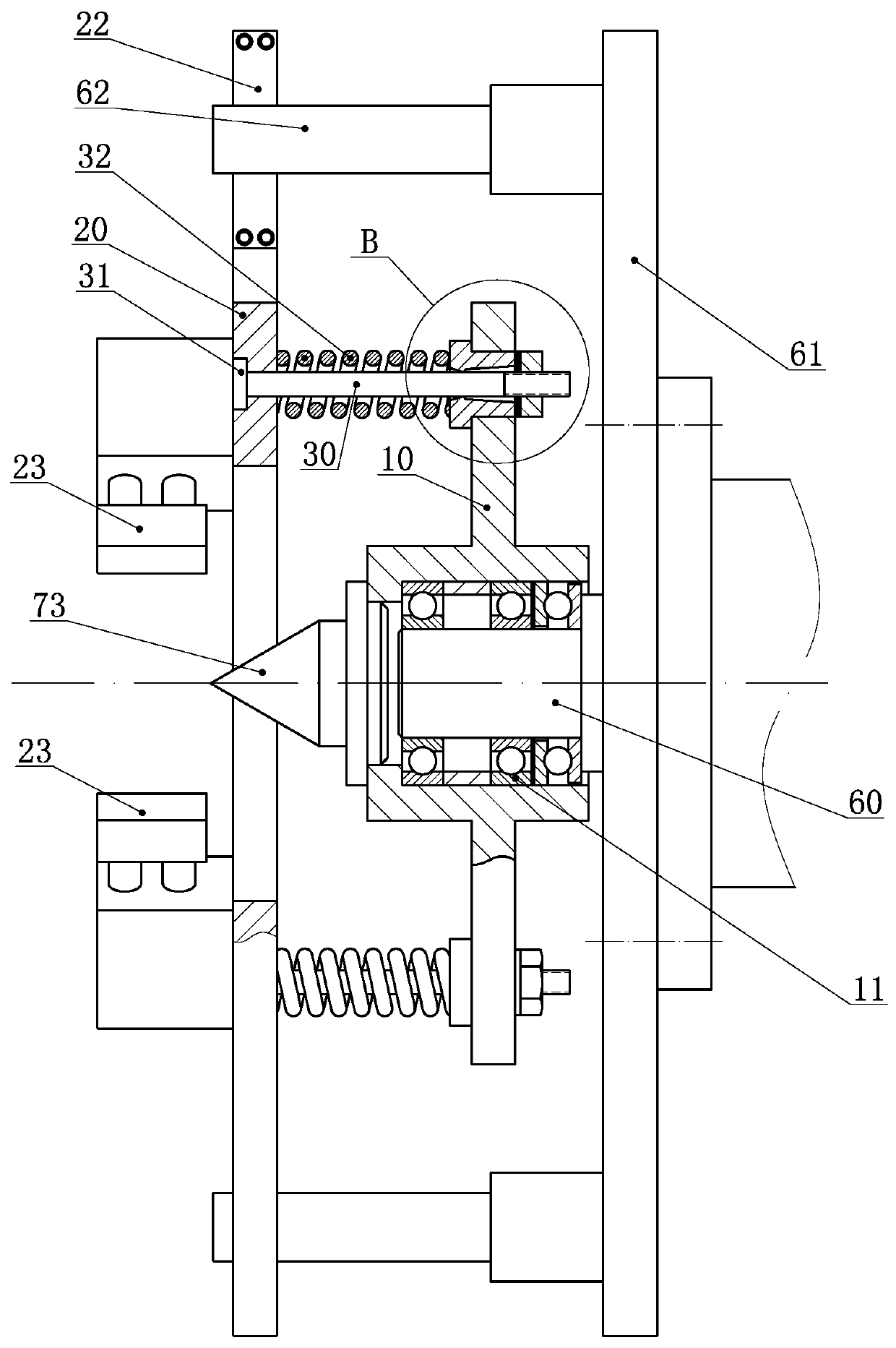

[0028] Such as Figure 1 to Figure 5 , a flexible drive fixture for a rotating workpiece, comprising a rotating chassis 10 , a flexible chuck 20 and a flexible connecting rod 30 .

[0029] The rotating chassis 10 is installed on the machine tool spindle 60 through a group of bearings 11, the rotating chassis is coaxial with the machine tool spindle, the rotating chassis is fixedly connected with the machine tool spindle in the axial direction, and the rotating chassis can rotate relative to the machine tool spindle (that is, it can freely rotate on the machine tool spindle). rotation).

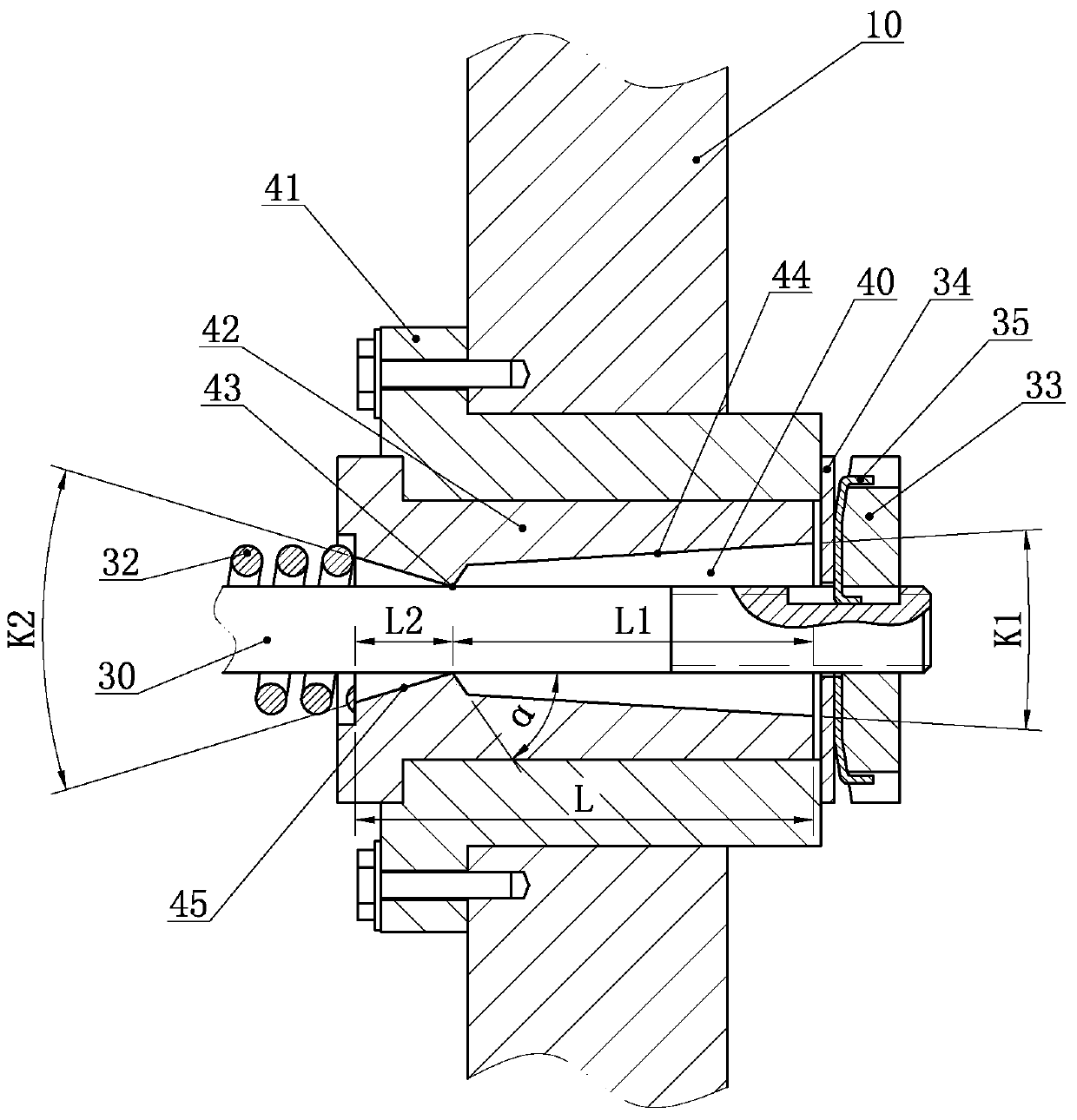

[0030] The rotating chassis is provided with six flexible connecting sleeves, and the six flexible connecting sleeves are equally distributed around the axis of the rotating chassis. The flexible connecting sleeve includes a flexible connecting outer sleeve 41 and a flexible connecting inner sleeve 42. The flexible connecting inner sleeve is arranged in the flexible connecting outer sleeve. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com