A kind of FA optical fiber end face coating fixture and using method thereof

A technology of optical fiber end face and fixture, which is applied in the direction of injection device, etc., can solve the problems of unsuitable FA optical fiber end face coating, etc., and achieve the effect of improving coating quality, ensuring consistency, and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

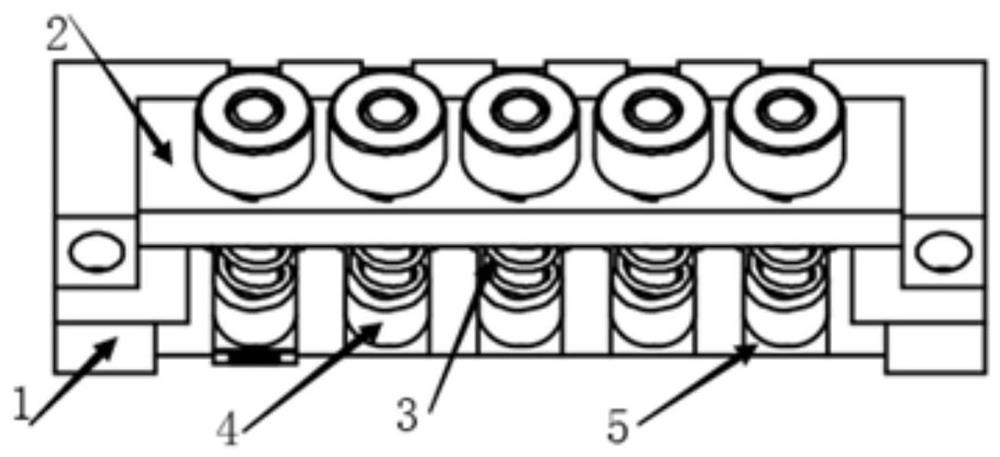

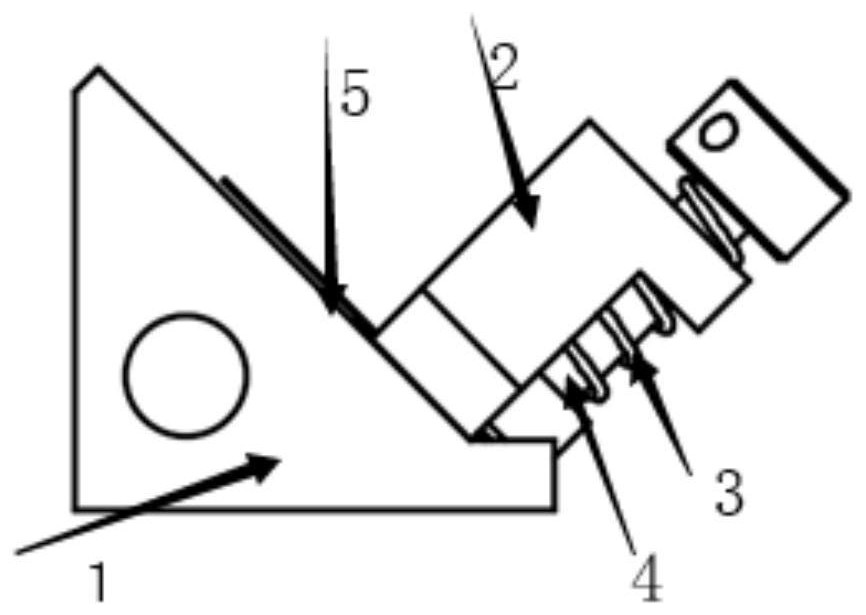

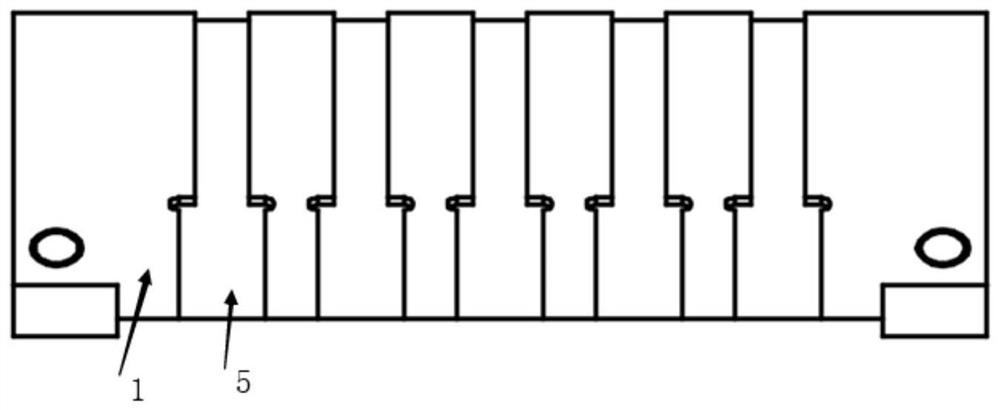

[0036] As an implementation manner, the FA optical fiber end surface coating fixture is connected to a feeding tool, and several V-shaped grooves are arranged in the feeding tool.

[0037] Specifically, a fixed knob is provided on one side of the loading tool, and the FA optical fiber end surface coating fixture is detachably connected to the V-shaped groove by rotating the fixed knob. When loading is required, loosen the fixing knob of the loading tool, put the fixture into the V-shaped groove of the loading tool, and lock the fixing knob to make the positioning surface of the fixture horizontal; after the loading is completed, loosen the fixing of the loading tool Turn the knob, take out the jig, put the FA fiber end-face coating jig and FA fiber into the coating machine to complete the coating.

[0038] As an implementation manner, the positioning groove is composed of a first area and a second area, and the width of the first area is larger than that of the second area. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com