A fabric winding machine for a manual workshop

A winding machine and fabric technology, which is applied in the direction of thin material processing, coiling strips, transportation and packaging, etc., which can solve problems such as troublesome operation and uneven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

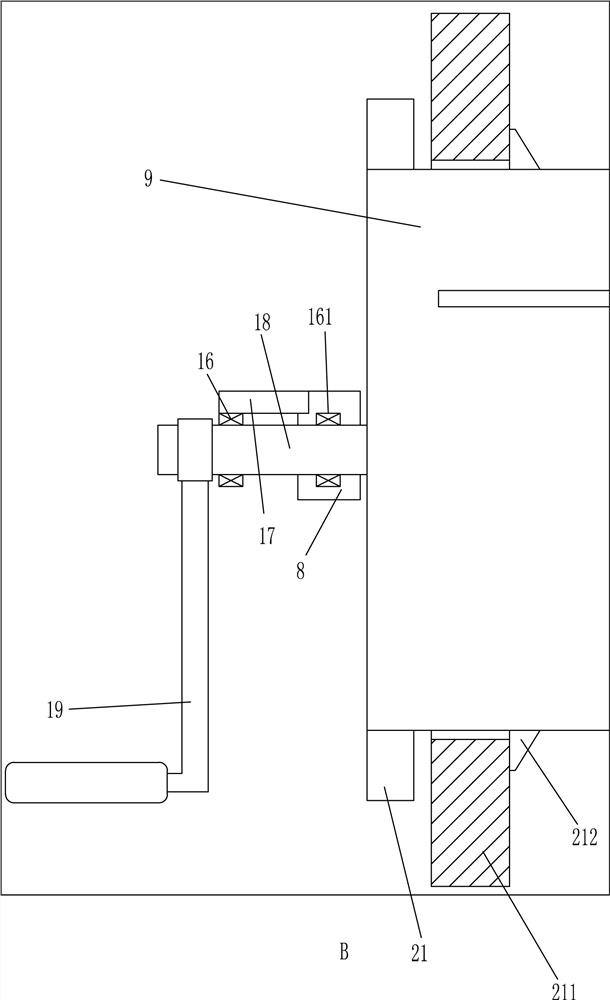

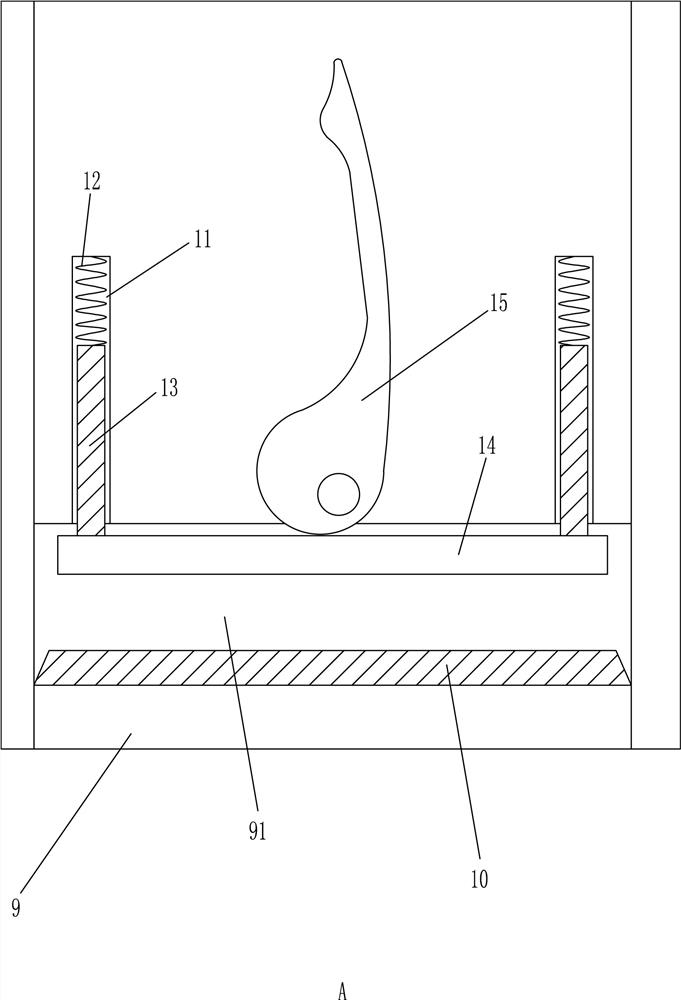

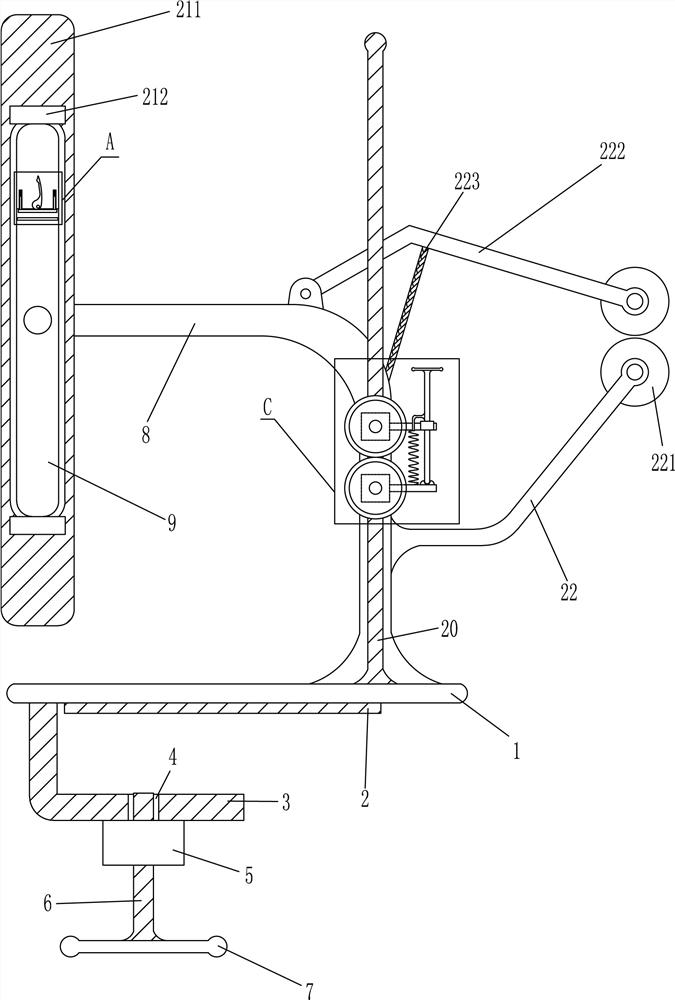

[0018] A hand workshop fabric winder, such as Figure 1-4 As shown, it includes a base 1, a fixing device, a support column 8, a square plate 9, a friction block 10, a first spring 12, a guide rod 13, a pressure plate 14, an eccentric rod 15, a first bearing seat 16, and a second bearing seat 161 , reinforcing rib 17, rotating shaft 18 and rocking handle 19, the left side of the bottom of the base 1 is provided with a fixing device that can fix the device, the right side of the top of the base 1 is fixedly connected with a support column 8, and the base 1 is connected to the support column by welding 8 connection, the middle of the left end of the support column 8 is fixedly connected with the second bearing seat 161, the upper rear side of the left end of the support column 8 is fixedly connected with the reinforcing rib 17, and the rear side of the bottom of the reinforcing rib 17 is fixedly connected with the first bearing seat 16, the first bearing seat 16 and the second b...

Embodiment 2

[0020] A hand workshop fabric winder, such as Figure 1-4 As shown, it includes a base 1, a fixing device, a support column 8, a square plate 9, a friction block 10, a first spring 12, a guide rod 13, a pressure plate 14, an eccentric rod 15, a first bearing seat 16, and a second bearing seat 161 , reinforcing rib 17, rotating shaft 18 and rocking handle 19, the left side of base 1 bottom is provided with the fixing device that this device can be fixed, base 1 top right side is affixed with support column 8, and the middle of support column 8 left ends is affixed with second Bearing seat 161, reinforcing rib 17 is fixedly connected to the upper rear side of the left end of support column 8, the first bearing seat 16 is fixedly connected to the rear side of the bottom of reinforcing rib 17, and the rotating shaft 18 is connected between the first bearing seat 16 and the second bearing seat 161 , the square plate 9 that can be rolled up to the cloth is installed on the front end...

Embodiment 3

[0023] A hand workshop fabric winder, such as Figure 1-5 As shown, it includes a base 1, a fixing device, a support column 8, a square plate 9, a friction block 10, a first spring 12, a guide rod 13, a pressure plate 14, an eccentric rod 15, a first bearing seat 16, and a second bearing seat 161 , reinforcing rib 17, rotating shaft 18 and rocking handle 19, the left side of base 1 bottom is provided with the fixing device that this device can be fixed, base 1 top right side is affixed with support column 8, and the middle of support column 8 left ends is affixed with second Bearing seat 161, reinforcing rib 17 is fixedly connected to the upper rear side of the left end of support column 8, the first bearing seat 16 is fixedly connected to the rear side of the bottom of reinforcing rib 17, and the rotating shaft 18 is connected between the first bearing seat 16 and the second bearing seat 161 , the square plate 9 that can be rolled up to the cloth is installed on the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com