Rail set railway fixing device

A technology of fixing device and fastening device, applied in the direction of fixing rails, roads, rails, etc., can solve the problems of high production cost, complicated design, inability to place four fasteners, etc., and achieves low maintenance cost and high manufacturing precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

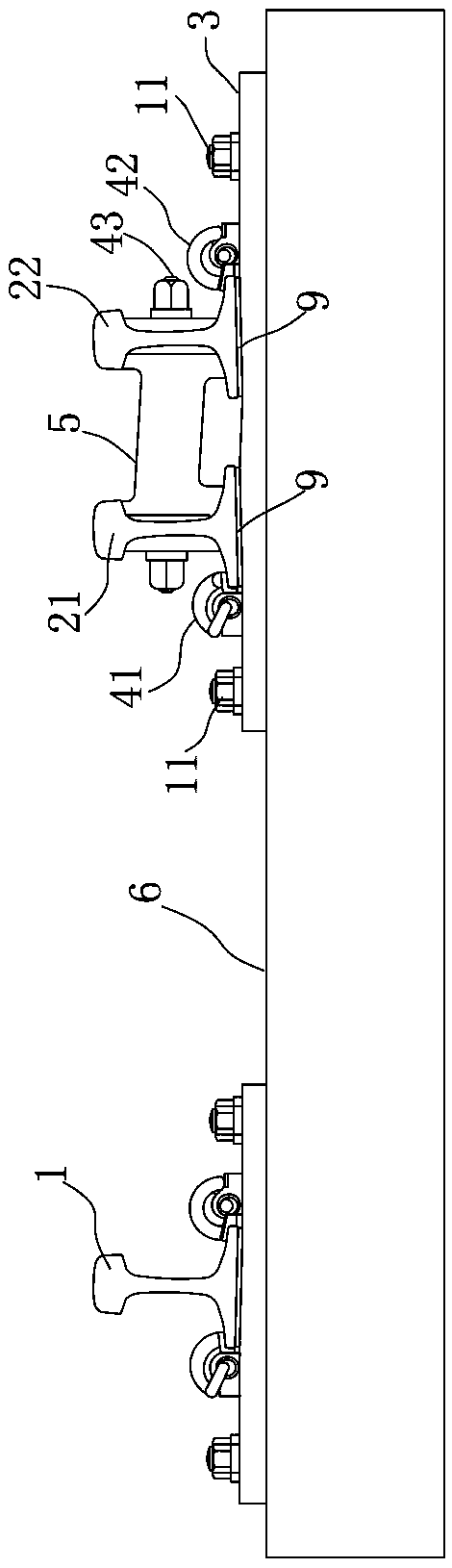

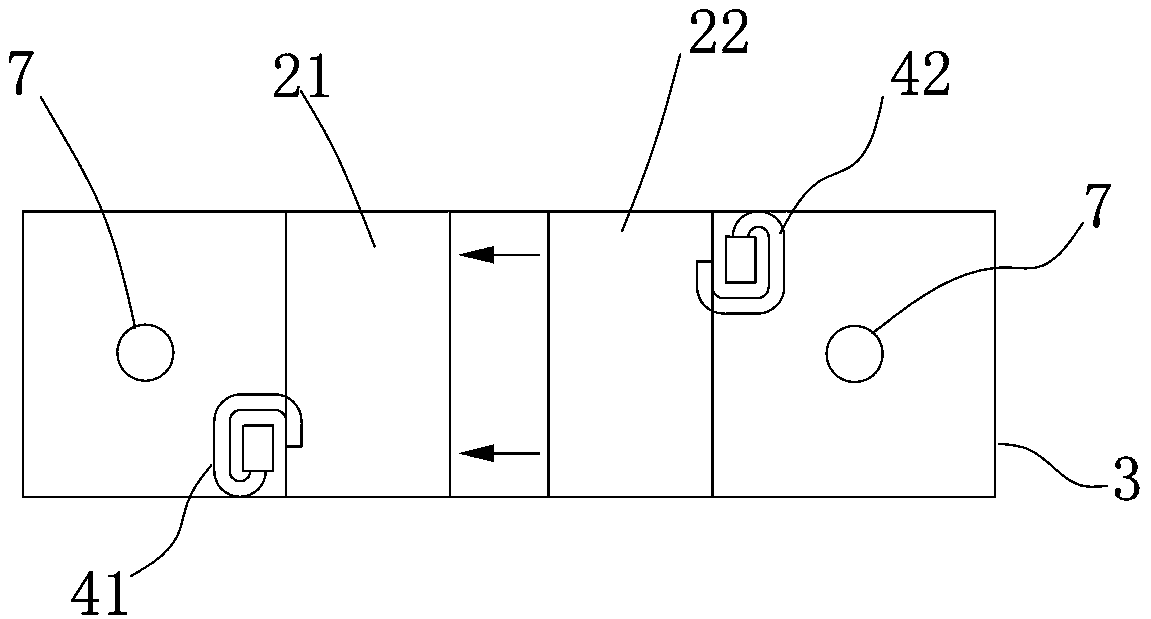

[0025] as attached figure 1 , 5 As shown, the track of the present invention is a three-wire track, which includes a common rail 1, adjacent left non-common rail 21 and right non-common rail 22, at the bottom of the left non-common rail 21 and right non-common rail 22 An iron backing plate 3 is installed between the sleeve rail sleeper 6, and the top surface of the iron backing plate 3 is stepped; a fastening device is fixedly installed between the left non-common rail 21 and the right non-common rail 22; Fastener A41 is installed on the outside of the rail bottom of 21, and fastener B42 is installed on the outside of the rail bottom of the right non-common rail 21. The fasteners A41 and fasteners B42 are arranged in a staggered or symmetrical manner; both fasteners A41 and fasteners B42 are III Type elastic fasteners.

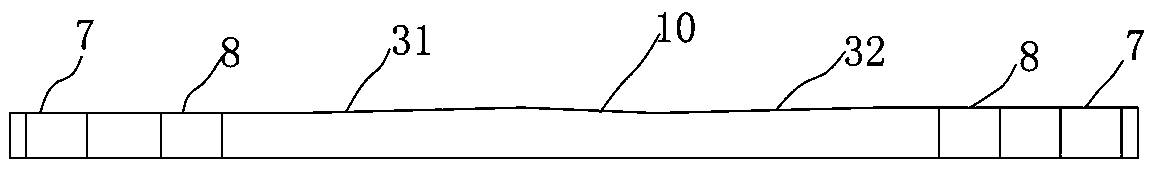

[0026] as attached figure 1 , 2 As shown, the present invention sets a rail bottom slope A 31 on the left side of the top surface of the iron backing plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com