Ultra-thin high-uniformity direct-type plant illumination light source device

A technology for plant lighting and light source devices, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as unscientific light source design, improve lighting uniformity, increase coupling paths, and achieve ultra-thin design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

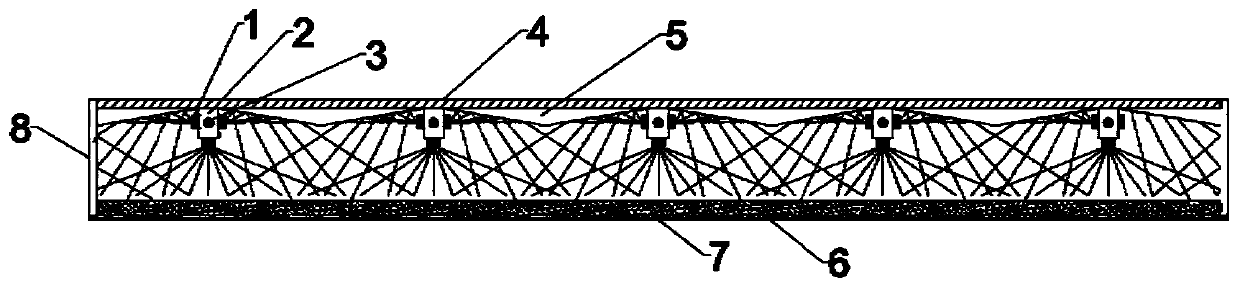

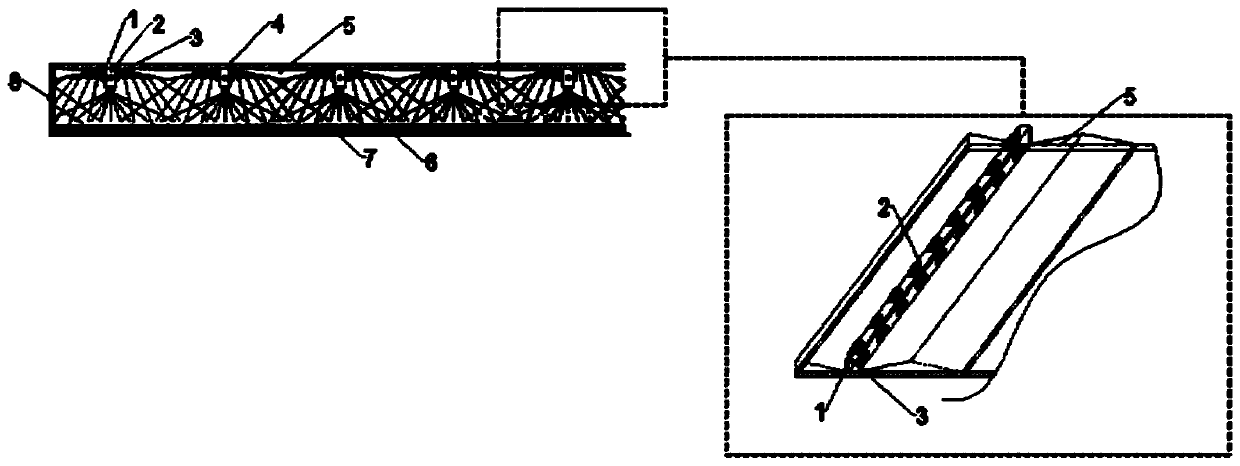

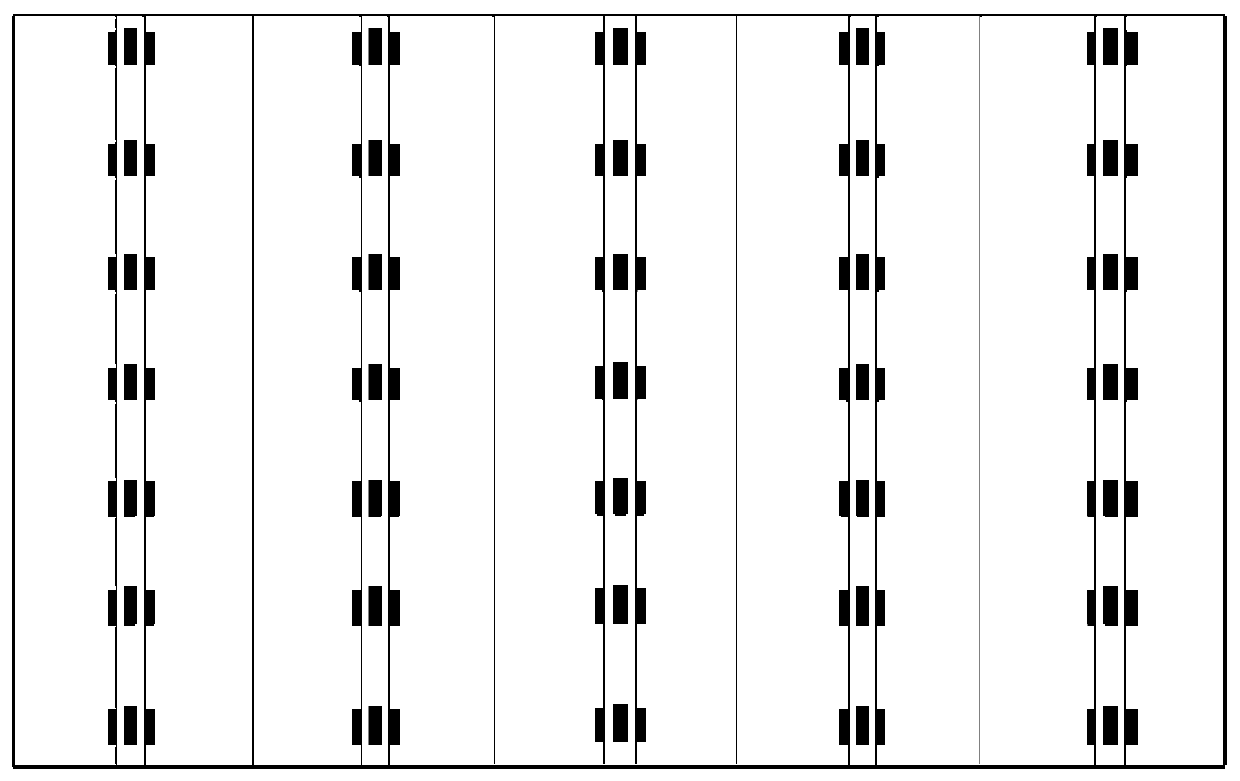

[0027] Such as figure 1 As shown, an ultra-thin and high-uniformity direct-type plant lighting light source device of this embodiment mainly includes several LED lamps 1, bosses 2, direct heat pipes 3, back plates 4, reflective back plates 5, and diffused light panels. 6. Brightness enhancement film 7 and frame 8 . The frame 8 is a rectangular frame with an opening at the top, the brightness enhancement film 7 is located in the bottom of the frame 8, the diffused light panel 6 is located on the surface of the brightness enhancement film 7, the back plate 4 is installed on the top opening of the frame 8, and the top opening is sealed. live. The direct heat pipe 3 is arranged inside the boss 2, the boss 2 and the reflective backboard 5 are alternately arranged on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com