Plant culture rack system based on natural light source and artificial light source

A technology of artificial light source and natural light source, which is applied in the field of plant cultivation frame system, can solve the problems of low light energy utilization rate, high energy consumption, and unscientific design of plant cultivation lamps, etc., to achieve improved uniformity of illumination, simple installation, and guaranteed lighting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

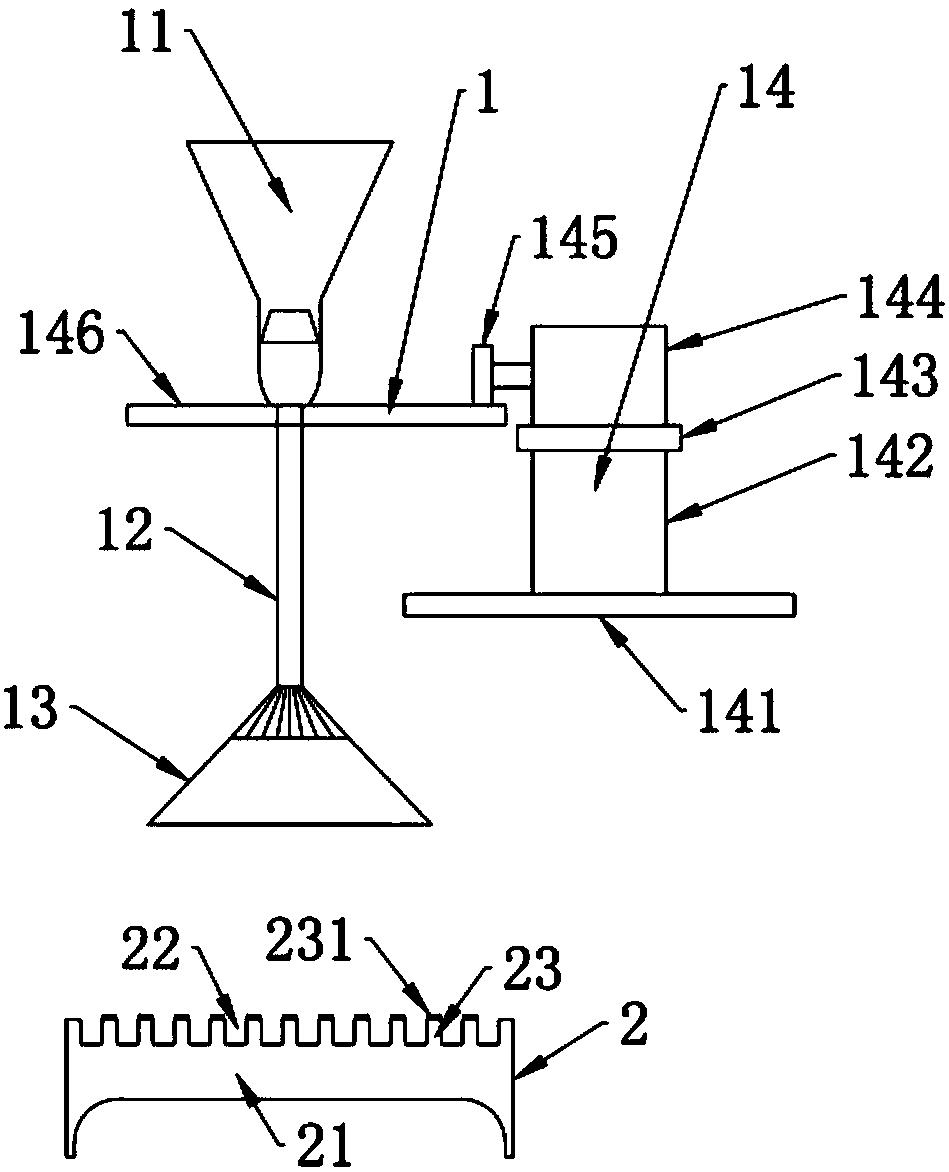

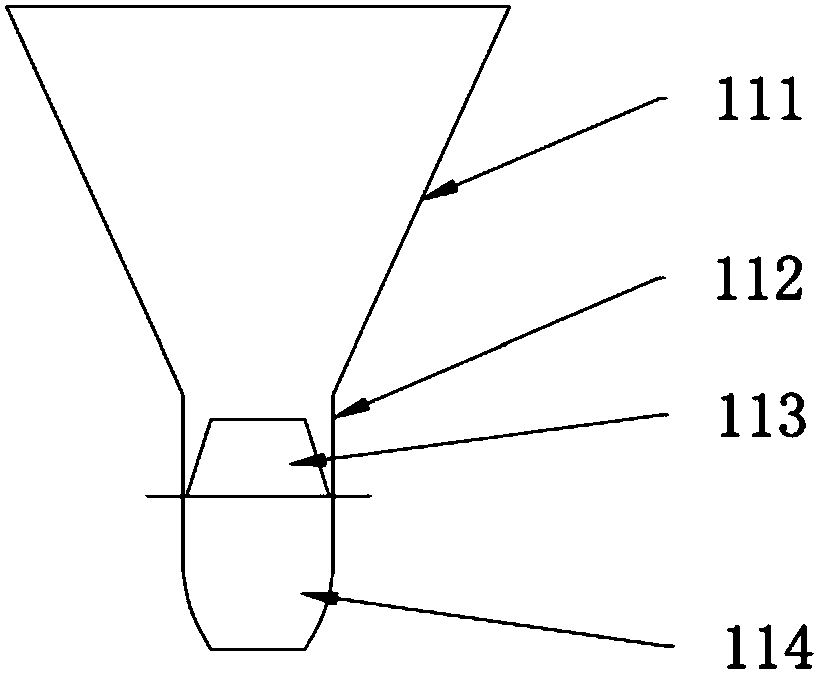

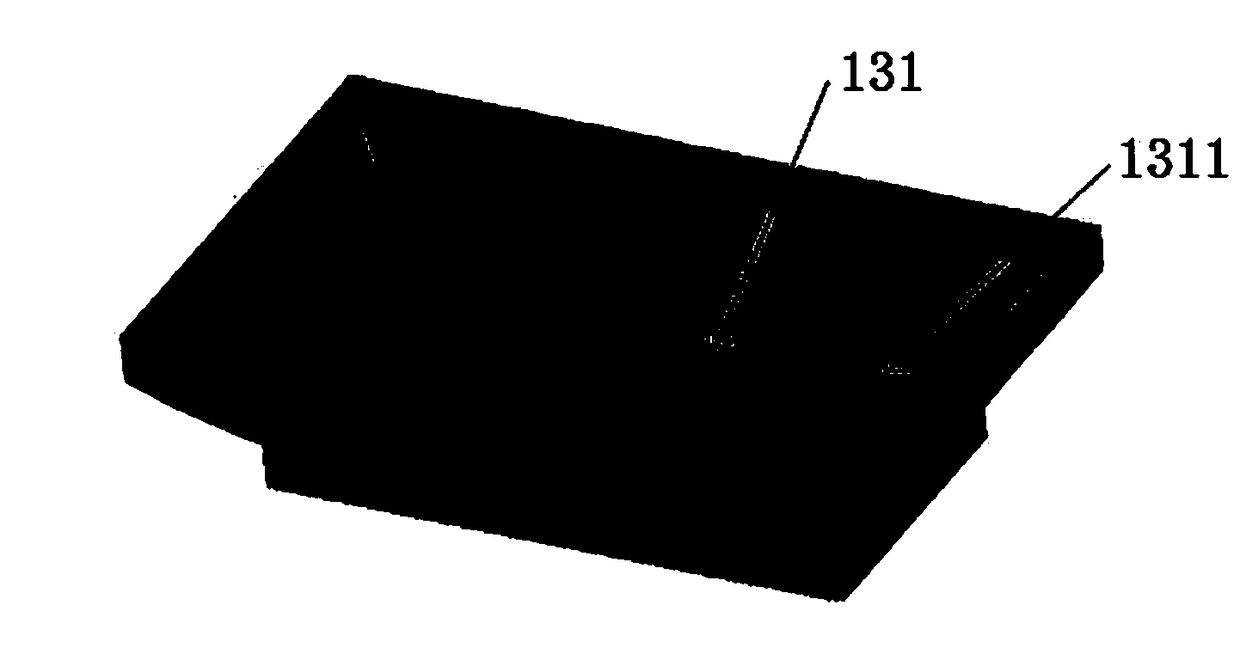

[0025] Such as figure 1 Shown is the plant cultivation rack system in this embodiment, the system includes a natural light collection module 1 and a cultivation rack module 2 , and the natural light collection module 1 is located above the cultivation rack module 2 . The natural light collection module 1 includes a lighting device 11 , a light guiding device 12 , a light output device 13 , and an automatic tracking conversion device 14 . Such as figure 2 As shown, the light-collecting device 11 includes a mirror focus superimposed concentrator 111 , a cylindrical mirror reflector 112 , a parabolic polarizer 113 and a compound parabolic concentrator CPC114 . The light guide device 12 is provided with a fiber coupler and a light guide fiber, the output end of the lighting device 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com