Display panel and manufacturing method thereof, drive control method, and display device

A technology for display panels and driving substrates, applied in static indicators, instruments, diodes, etc., can solve the problems that affect the display performance of OLED display panels, unsaturated monochrome display, and reduce color gamut, so as to improve display quality and enhance saturation. Intensity and color gamut, the effect of reducing shine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

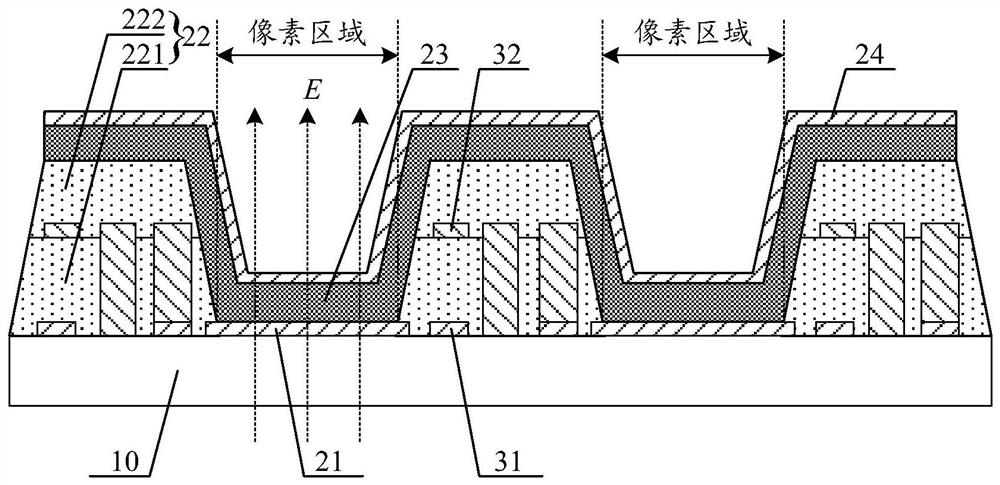

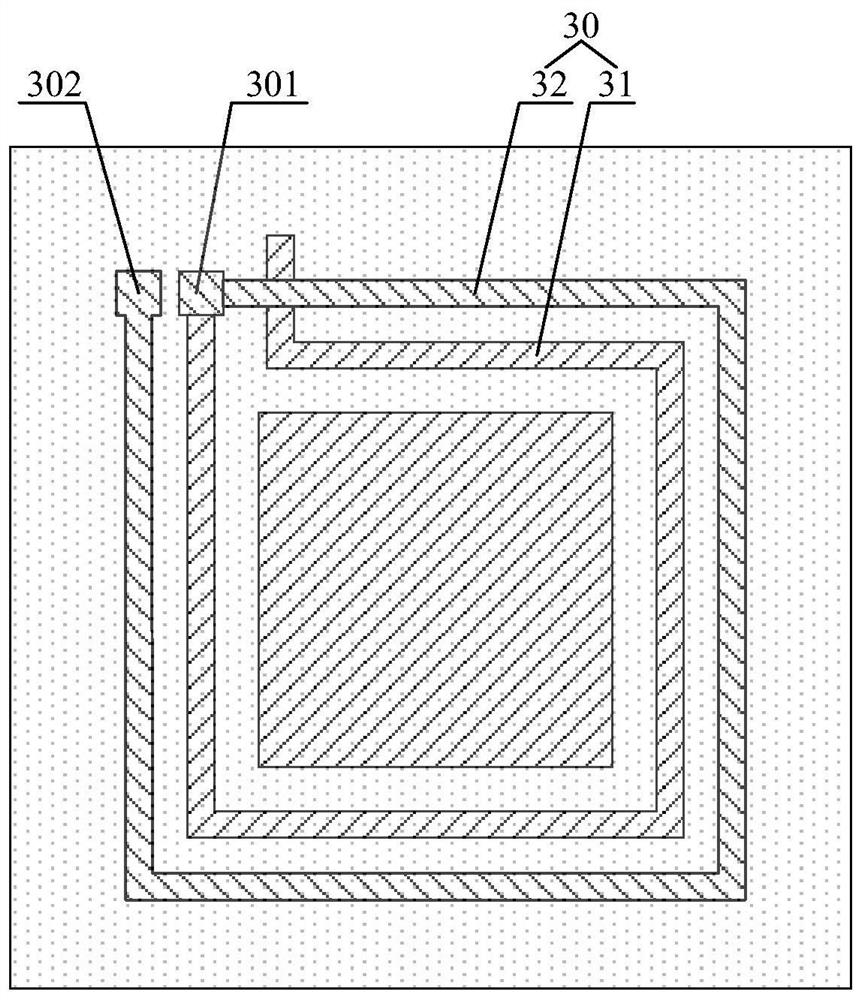

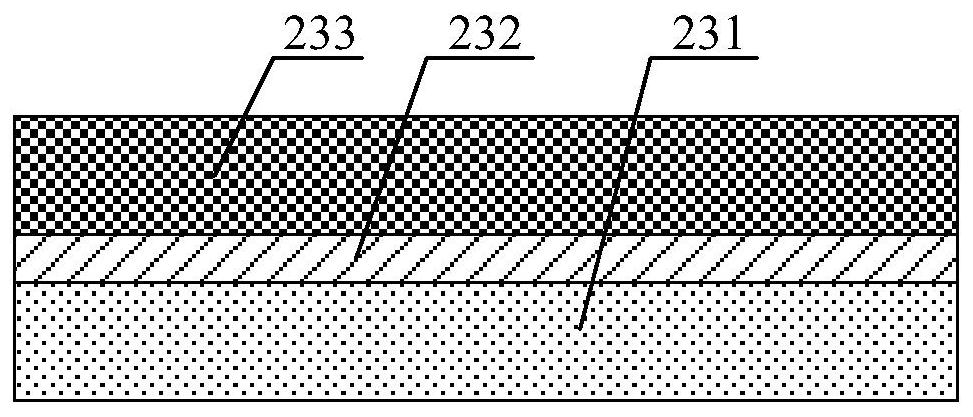

[0048] figure 1 It is a schematic cross-sectional structure diagram of the display panel according to the first embodiment of the present invention. Such as figure 1As shown, the display panel includes a plurality of pixel regions, the display panel includes a driving substrate 10, a first electrode 21 disposed on the driving substrate 10 and located in the pixel region, and a pixel defining layer 22 disposed on the first electrode 21, the pixel defining layer 22 defines a pixel area. The display panel further includes a light emitting structure layer 23 disposed on the pixel defining layer 22 and a second electrode 24 disposed on the light emitting structure layer 23 . The display panel also includes a magnetic field E arranged in at least one pixel area, the direction of the magnetic field forms a certain angle with the plane where the driving substrate 10 is located, and the magnetic field is used to suppress the lateral transfer of charges in the light-emitting structure...

no. 2 example

[0089] Based on the inventive concepts of the aforementioned embodiments, an embodiment of the present invention further provides a display device, which includes the display panel using the aforementioned embodiments. The display device can be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com