Clutch cage arrangement having primary gearwheel and having stamped indentation, projecting into said primary gearwheel, of counterpart plate or of disk

A technology of clutches and components, applied in the direction of elements with teeth, clutches, friction clutches, etc., to achieve the effect of reducing the surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

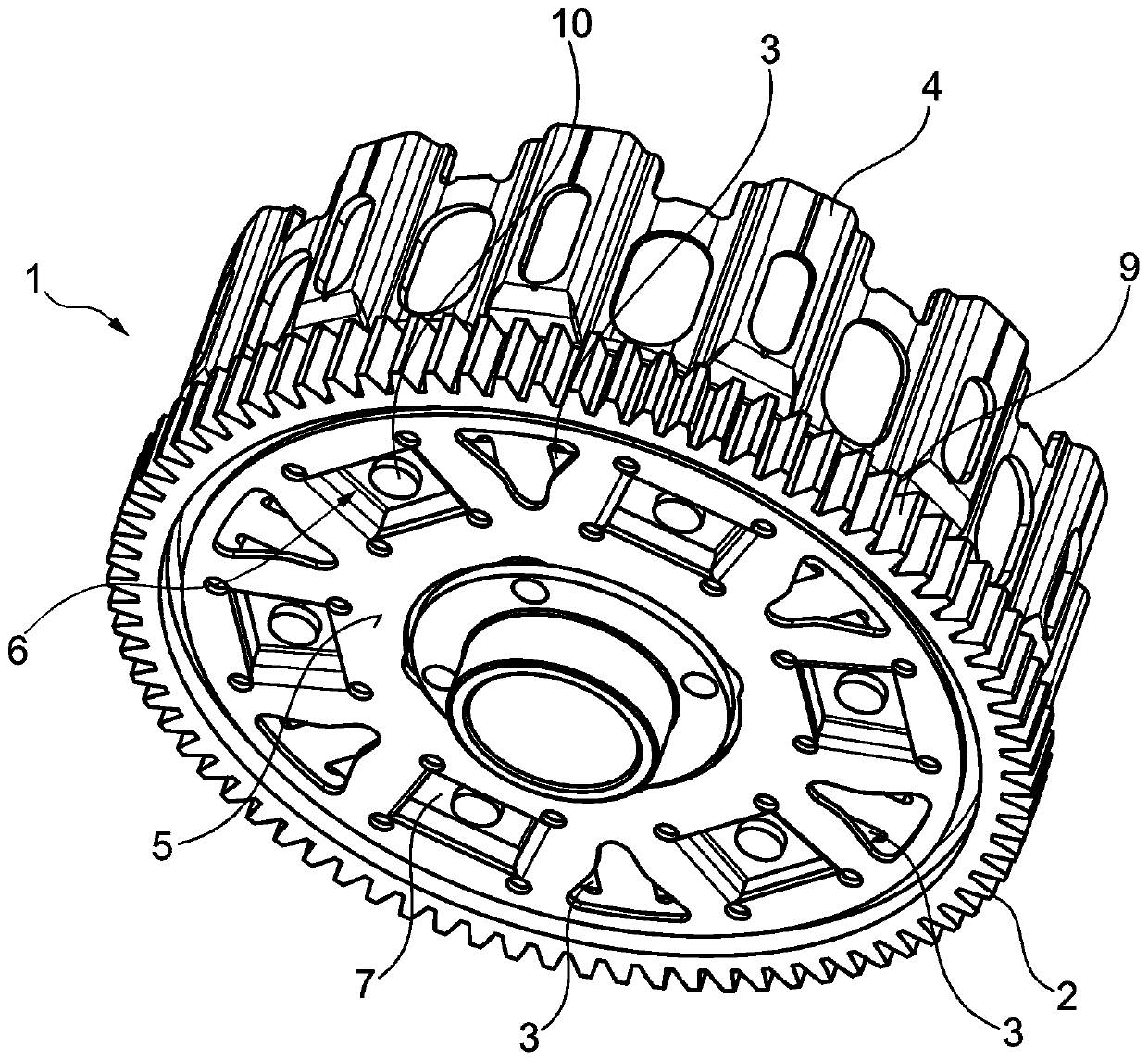

[0034] figure 1 A clutch basket assembly 1 according to the invention is shown, which is mainly used in multi-plate clutches, in particular wet motorcycle clutches. Primary gear 2 is driven by the crankshaft via toothed section 9 . The torque is transmitted from the primary gear wheel 2 to the clutch basket 4 via the intermediate connection of the damping element 3 . Here, a plurality of damping elements 3 are arranged. To fix the damping element 3 in the axial direction, the counter disk 5 , which rotates together with the primary gear 2 , is connected to the clutch basket 4 by means of a riveted connection 6 .

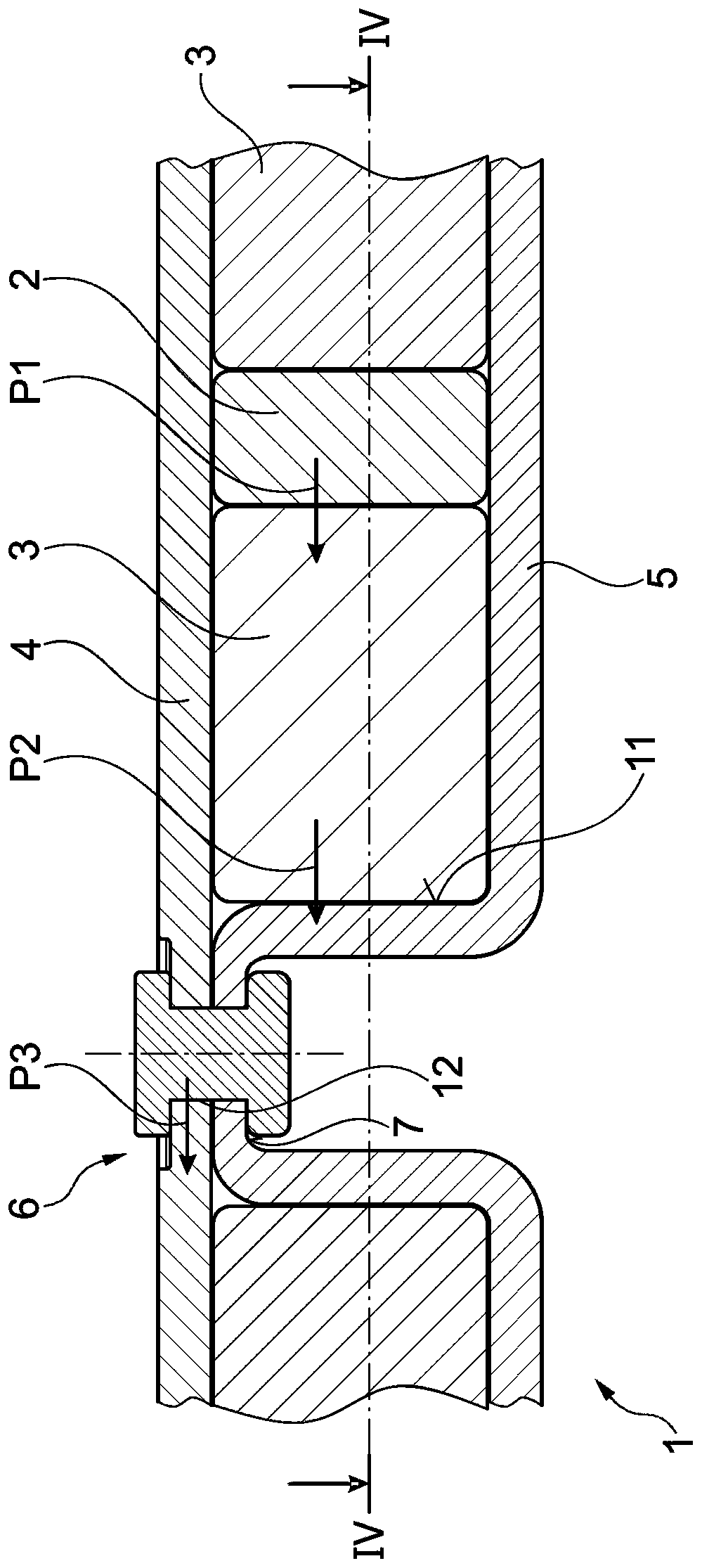

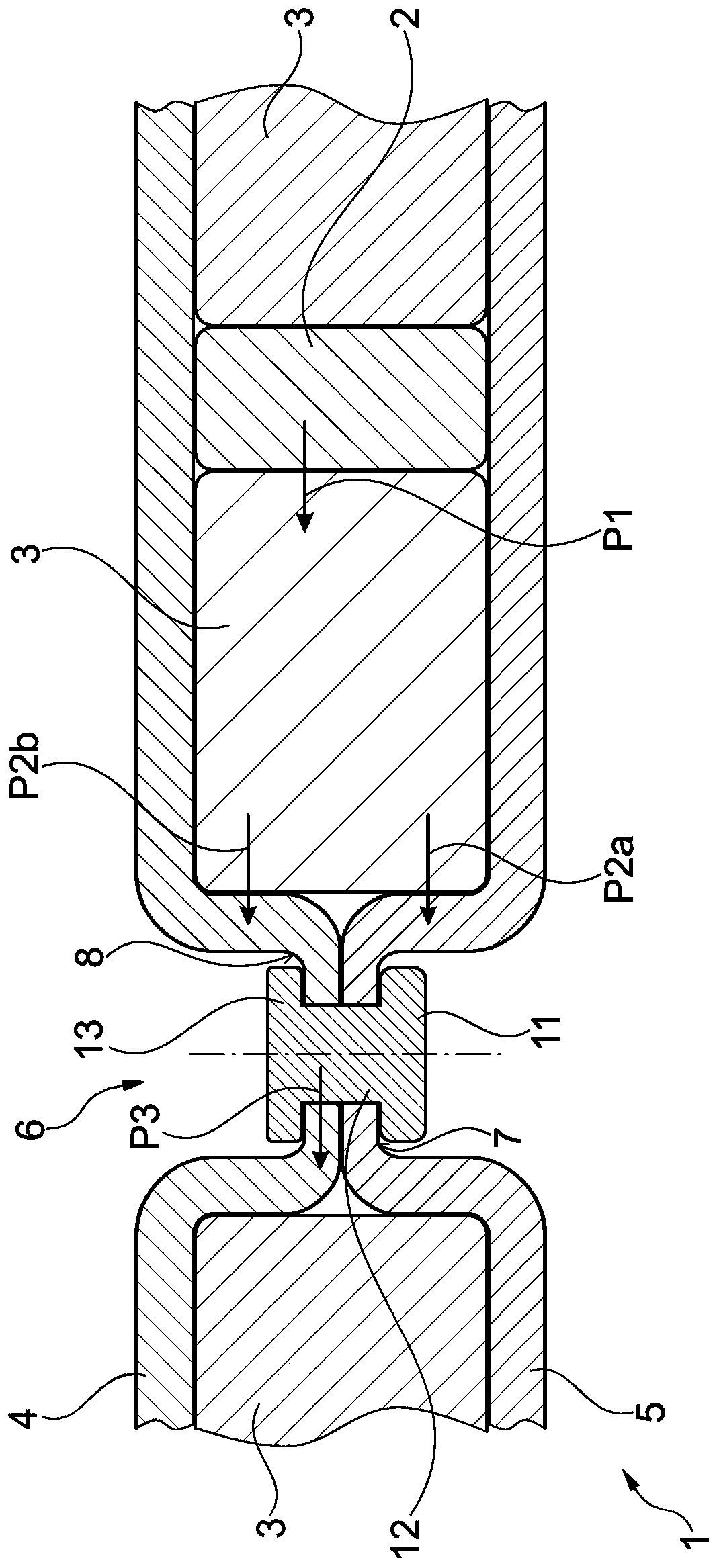

[0035] The counter-disk embossing 7 is introduced into the counter-disk / counter-plate 5 by punching / embossing, so that the disc-side rivet head 10 has a predetermined contact surface. The counter-disc impression 7 protrudes towards the clutch basket 4 in the axial direction.

[0036] Depend on figure 2 The functions realized by the corresponding disc embossing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com