Piezoelectric film and method for producing same

A manufacturing method and piezoelectric film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of not obtaining single crystal film, Problems such as inability to apply single crystal film production methods and difficulty in obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

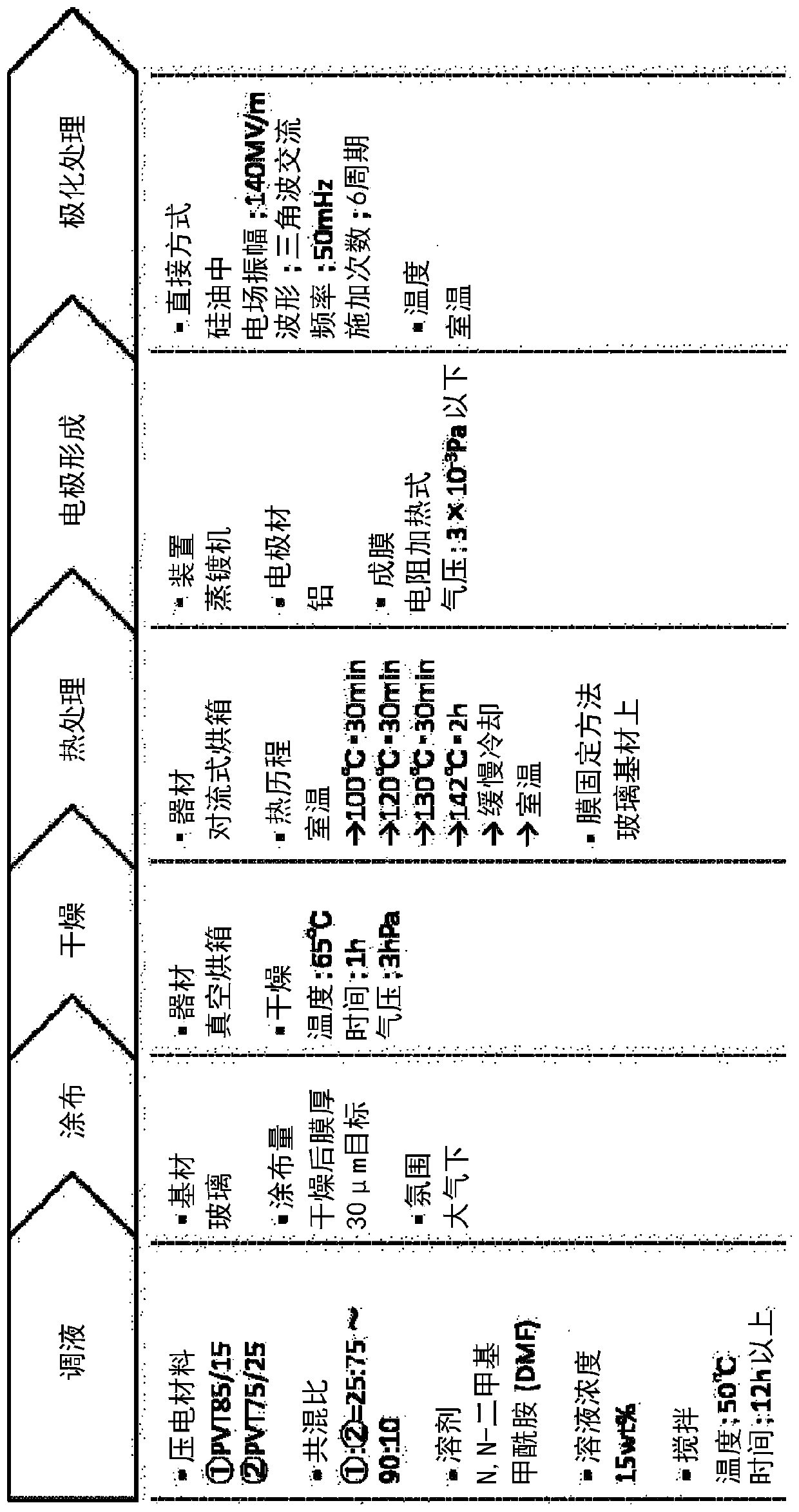

[0068] figure 1 It is a process flow chart of the manufacturing method of the blended lamellar crystal piezoelectric film. The manufacturing process of the piezoelectric film is carried out in the order of liquid adjustment process→coating process→drying process→heat treatment process→electrode formation process→polarization treatment process, and the blended sheet crystal piezoelectric film is produced.

[0069] The detailed description of each process of Example 1-1 is listed below.

[0070] Liquid adjustment process

[0071] Select PVT85 / 15 as PVT1, PVT75 / 25 as PVT2, use N,N-dimethylformamide (DMF) as the solvent, and make the mixing weight ratio of PVT1 and PVT2 within the range of 25:75 to 90:10 and 7 different solutions.

[0072] Coating process

[0073] A glass substrate to be a substrate is prepared, and the above-mentioned solution is applied on the above-mentioned glass substrate.

[0074] drying process

[0075] The applied film was dried in a vacuum oven at ...

Embodiment 1-2

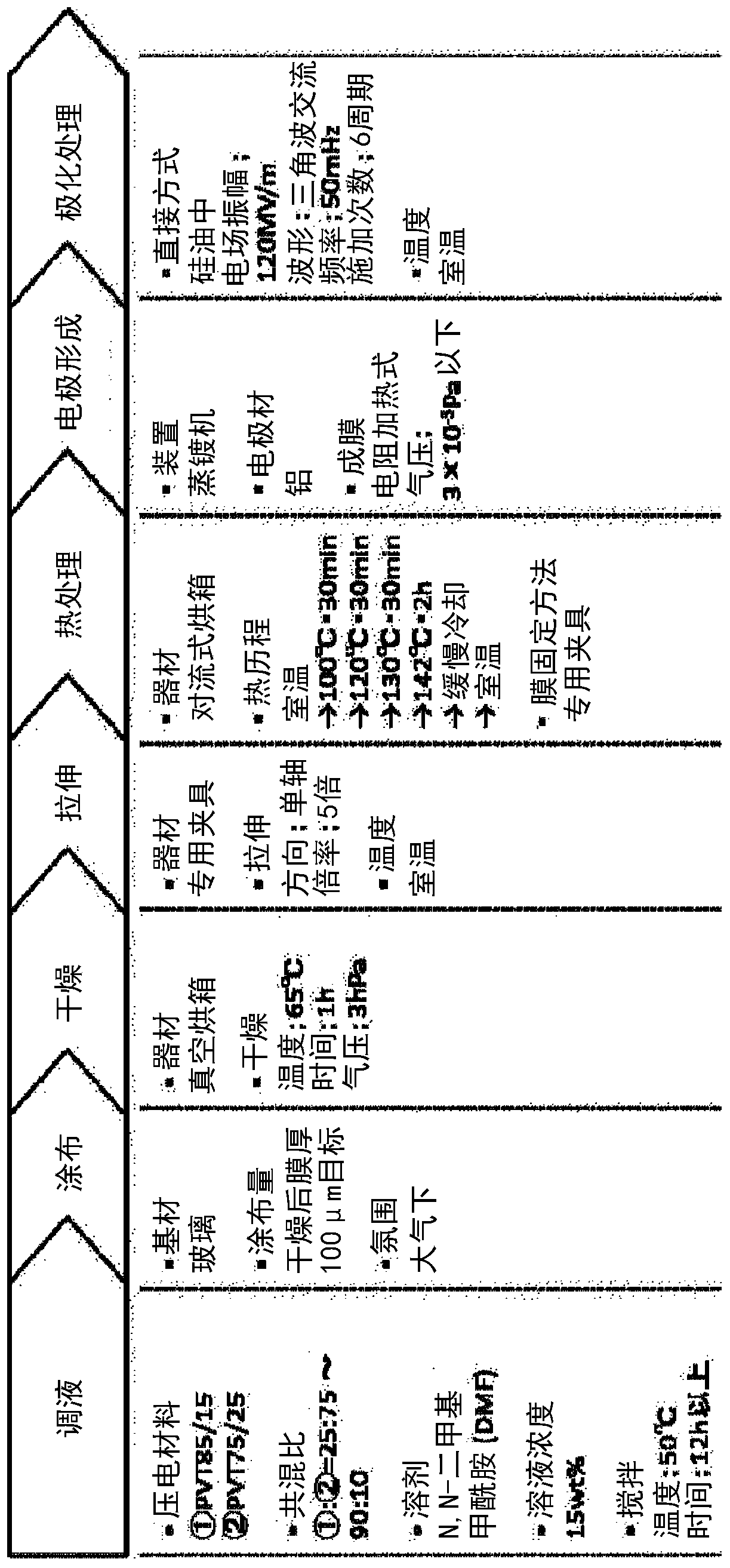

[0083] figure 2 It is a process flowchart of the manufacturing method of the blend single crystal piezoelectric film. The manufacturing process of the piezoelectric film is carried out in the order of liquid adjustment process→coating process→drying process→stretching process→heat treatment process→electrode formation process→polarization treatment process to produce a blended single crystal piezoelectric film.

[0084] The detailed description of each process of Example 1-2 is listed below.

[0085] Liquid adjustment process

[0086] Choose PVT85 / 15 as PVT1, choose PVT75 / 25 as PVT2, use N,N-dimethylformamide (DMF) as the solvent, and make the mixing weight ratio of PVT1 and PVT2 in the range of 25:75 to 90:10 and 7 different solutions.

[0087] Coating process

[0088] A glass substrate to be a substrate is prepared, and the above-mentioned solution is applied on the above-mentioned glass substrate.

[0089] drying process

[0090] The applied film was dried in a vacuu...

Embodiment 2

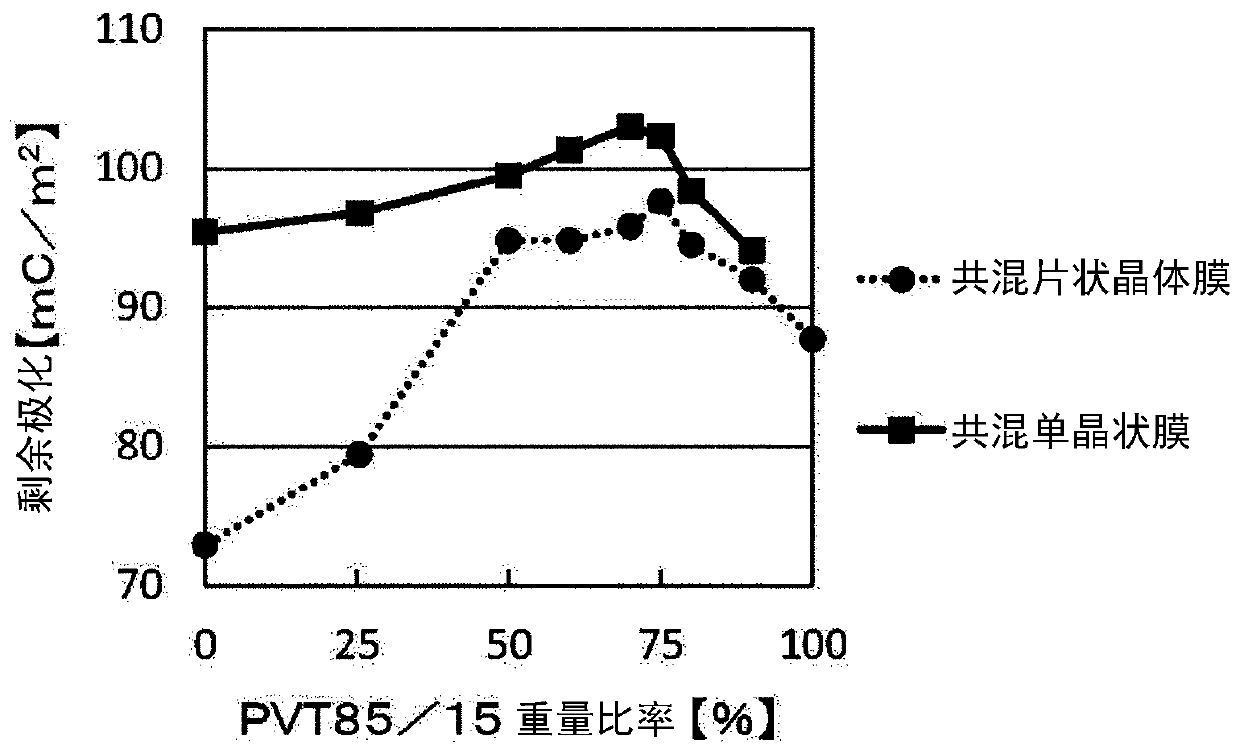

[0100] Table 1 shows the measurement results of remanent polarization Pr, coercive electric field Ec, electromechanical coupling coefficient kt and Comparison table of measurement results of remanent polarization, coercive electric field, and electromechanical coupling coefficient kt of piezoelectric films of comparative examples (1, 2, 3).

[0101] The remanent polarization Pr and the coercive electric field Ec are read from the D (electric displacement)-E (electric field) hysteresis curve measured in the polarization process. Regarding the D-E hysteresis curve, as E, 140MV / m is applied for 6 cycles with a 50mHz triangular wave AC for the flake crystal film, and 6 cycles of 50mHz triangular wave AC are applied for the single crystal film. 120MV / m, the D-E hysteresis curve is obtained from the waveform of the sixth cycle output by the charge amplifier.

[0102] The electromechanical coupling coefficient kt is obtained by washing the polarized sample with hexane and cutting it...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap