Positioning support guiding frame for offshore wind turbine generator

A positioning support, offshore wind power technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of complex adjustment mechanism and exceeding the standard, it must be shut down, and the structure complexity is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

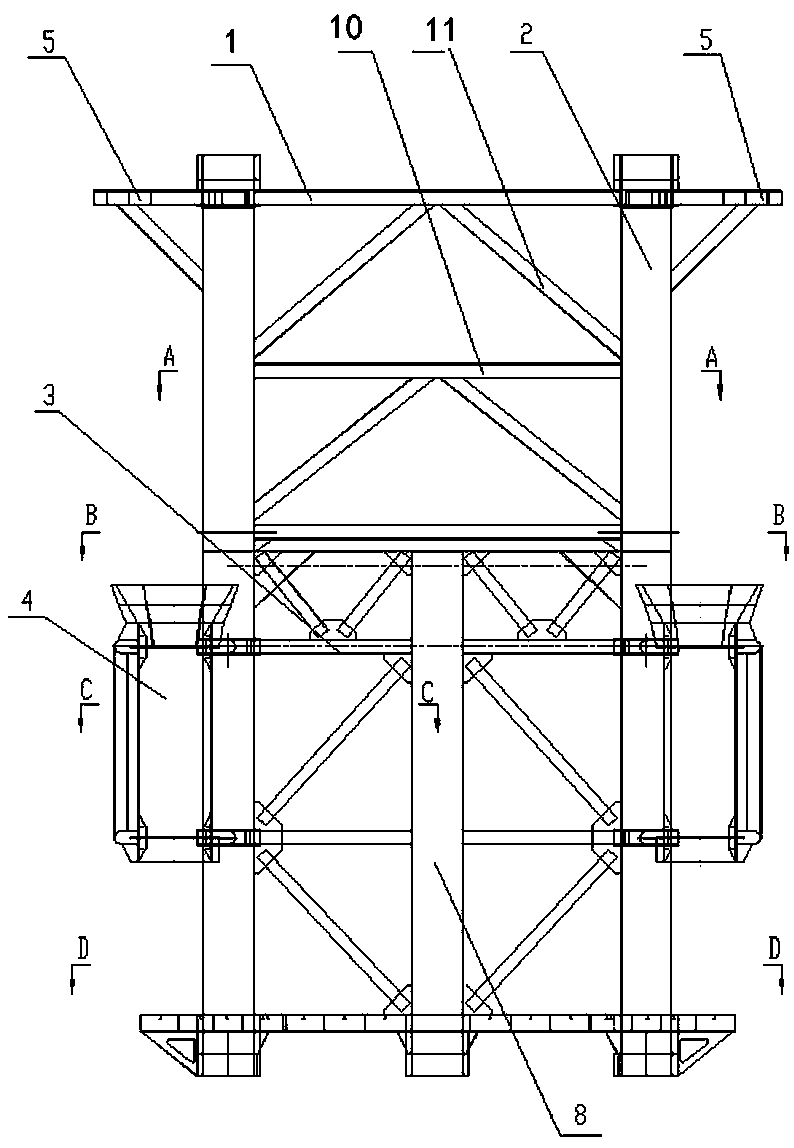

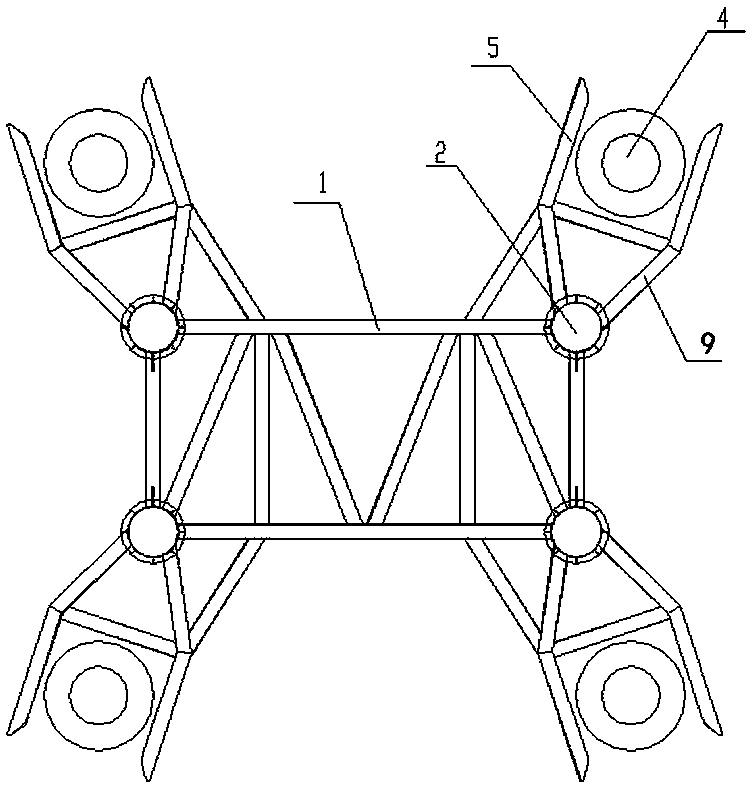

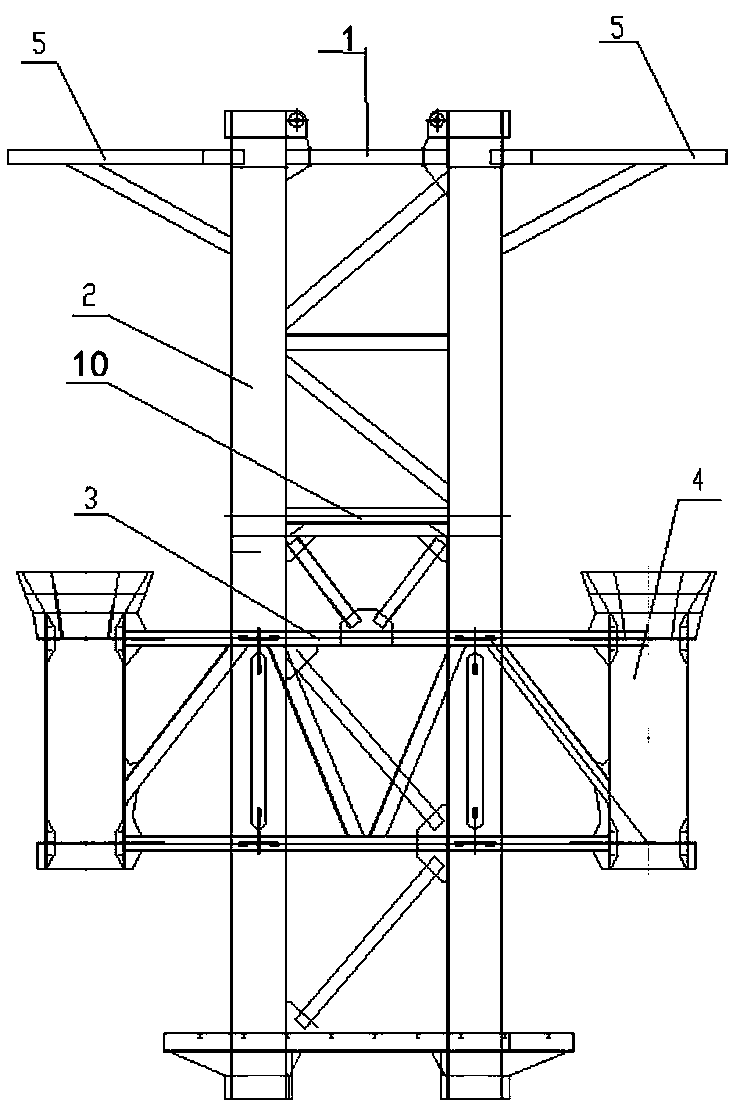

[0015] An offshore wind turbine positioning support guide frame, such as Figure 1 to Figure 8 As shown, it includes a plurality of positioning pile guide pipes 2 arranged in a matrix, and the tops of adjacent positioning pile guide pipes 2 are connected as a whole through connecting rods 1, and engineering piles immersed in seawater are installed in the middle of each positioning pile guide tube 4. In this embodiment, four positioning pile guide pipes 2 are used to achieve sufficient supporting strength and rigidity and simplify the structure.

[0016] The top of the engineering pile guide pipe 4 is in the shape of a trumpet expanding outwards, which is convenient for guiding the insertion of engineering piles.

[0017] At the junction of each positioning pile guide tube 2 and the connecting rod 1, a guide frame is provided to guide the positioning pile to move down and insert into the engineering pile guide tube 4, which is used to guide the engineering pile to move down an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com