Dual-drive vacuum compression equipment and drive control method

A vacuum compression, dual-drive technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as high noise, and achieve the effect of reducing working noise, reducing working noise, and good compression balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

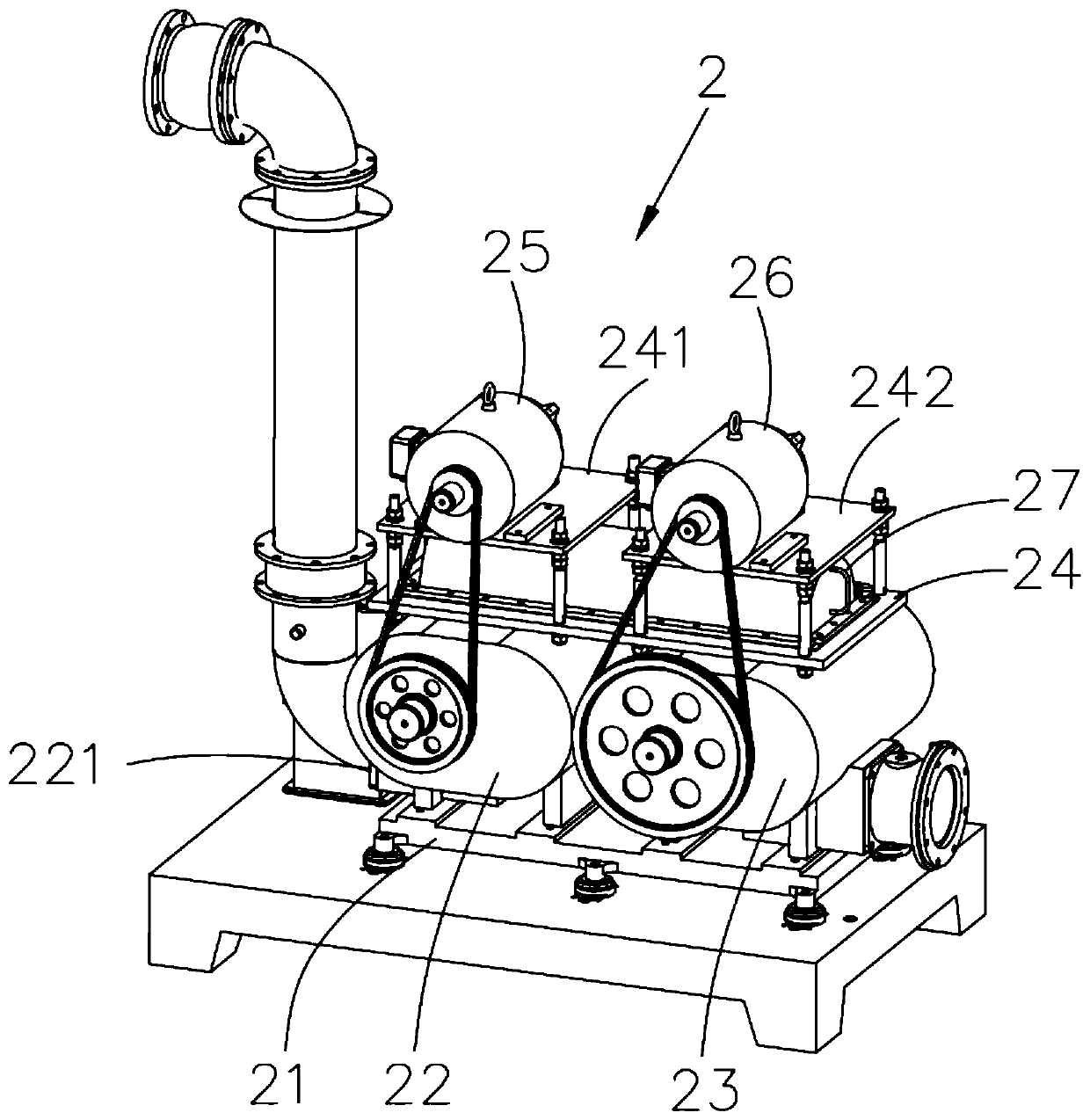

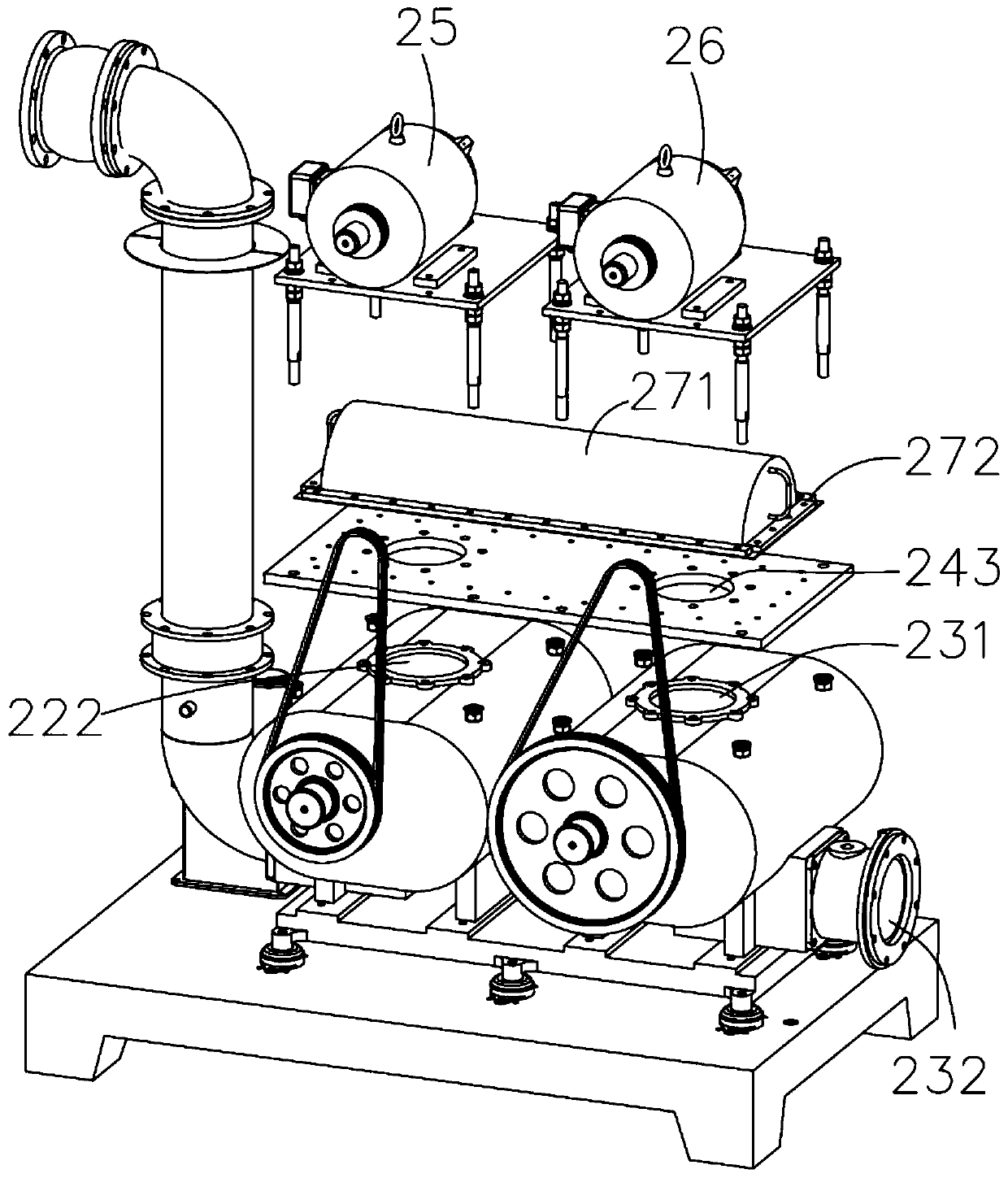

[0032] Attached below Figures 1 to 8 The present invention will be described in detail.

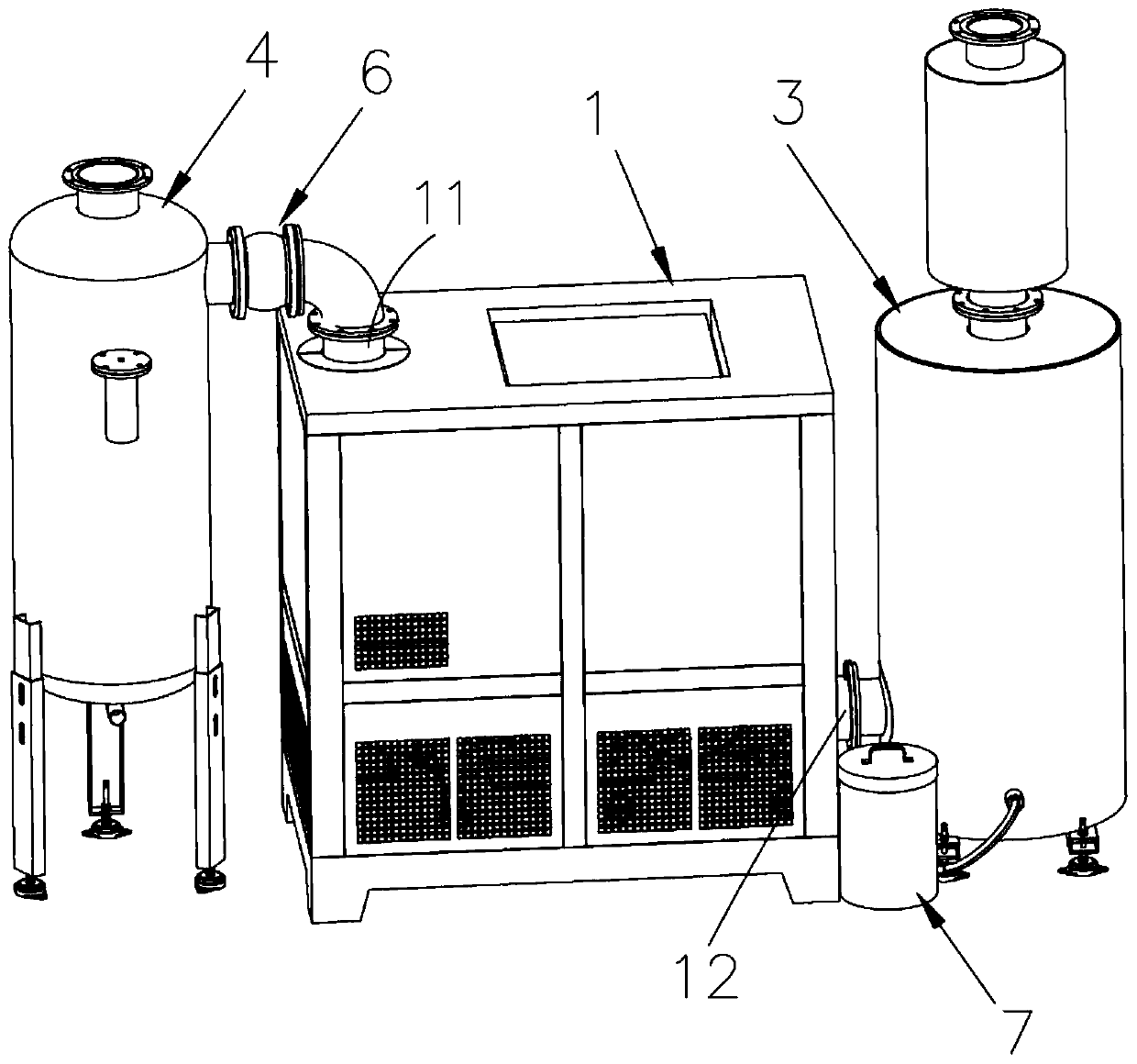

[0033] A dual-drive vacuum compression device of the present invention includes a main engine housing 1, a dual-drive vacuum pump device 2 and an oil-water cooling system 5 are arranged inside the main engine housing 1, a storage tank is arranged on one side of the main engine housing, and the The storage tank 4 is connected to the dual-drive vacuum pump device through the first pipeline 11, and the other side of the host housing is provided with a muffler 3, and the double-drive vacuum pump device 2 is connected to the muffler through the second pipeline 12; it also includes a control device , the dual-drive vacuum pump device is electrically connected to the control device, and the control device includes a display control panel; After the pressure adsorption, the negative pressure value in the storage tank 4 is reduced, and the storage tank can be conveniently connected with the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com