Rolling testing machine for corner impact strength testing of mould-pressed tray and testing method

A technology of strength testing and rolling test, which is applied in the direction of strength characteristics, using repeated force/pulsation force to test the strength of materials, measuring devices, etc. It can solve the problems that the molded tray can no longer be used for rolling detection, and achieve low production and maintenance costs. , to ensure the safety of detection, and the effect of simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

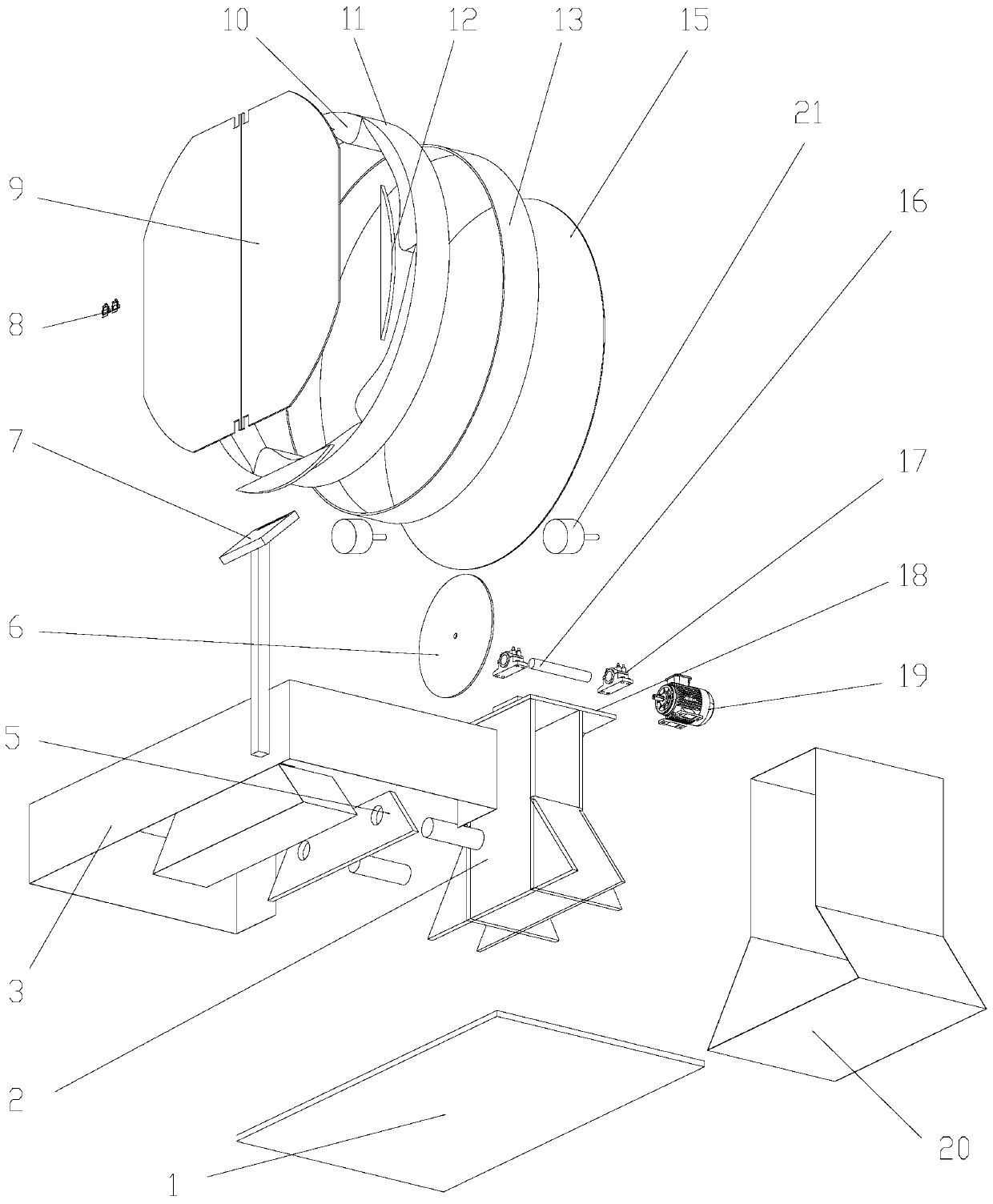

[0036] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0037] Figure 8 , Figure 9 The upper part of the molded tray M shown is the bearing surface, and the lower part of the molded tray is provided with several supporting legs M1 formed by molding (the bottom of the molded tray in the figure has 9 supporting legs, and the bearing surface of the molded tray is used for holding the goods being shipped.

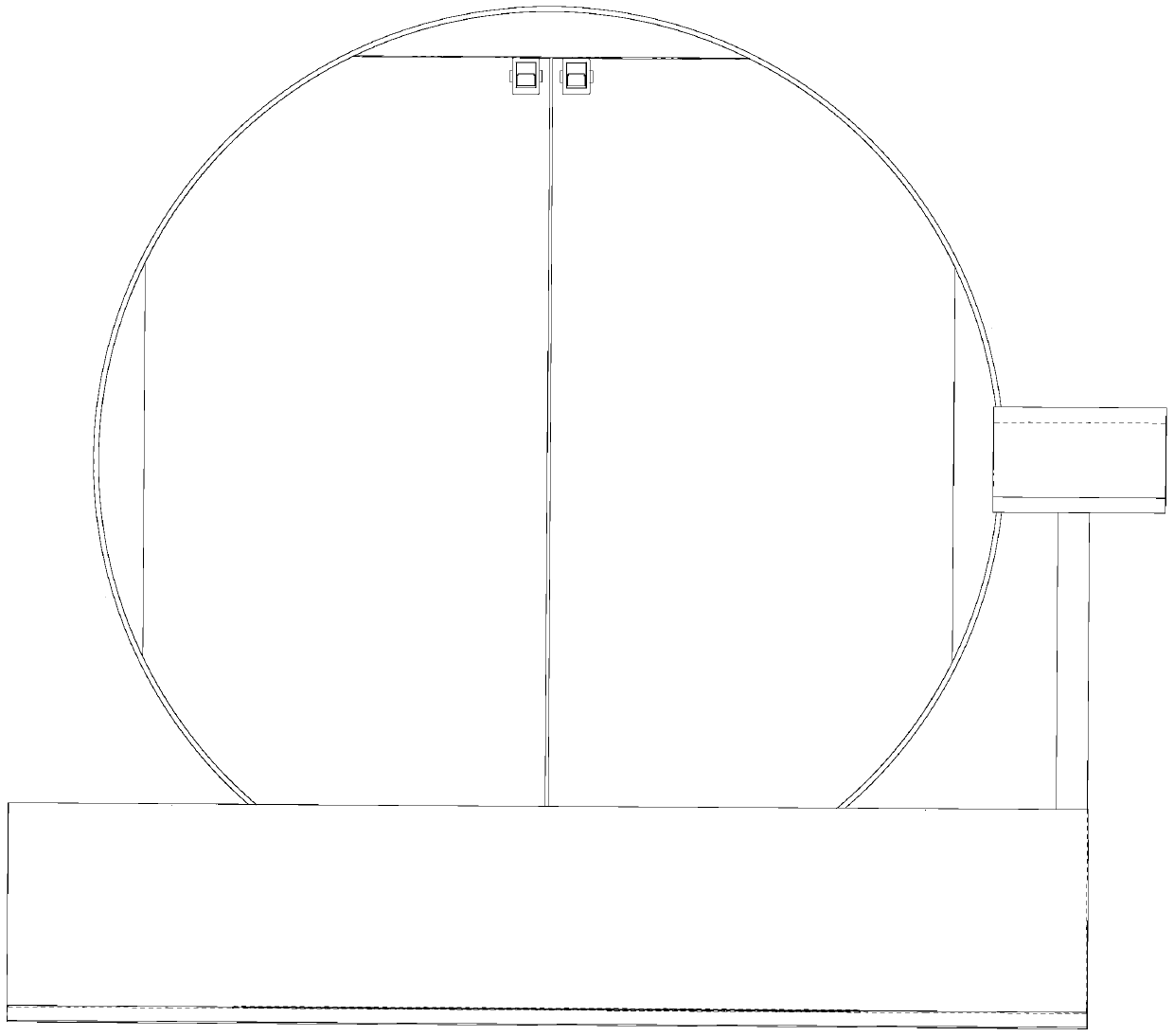

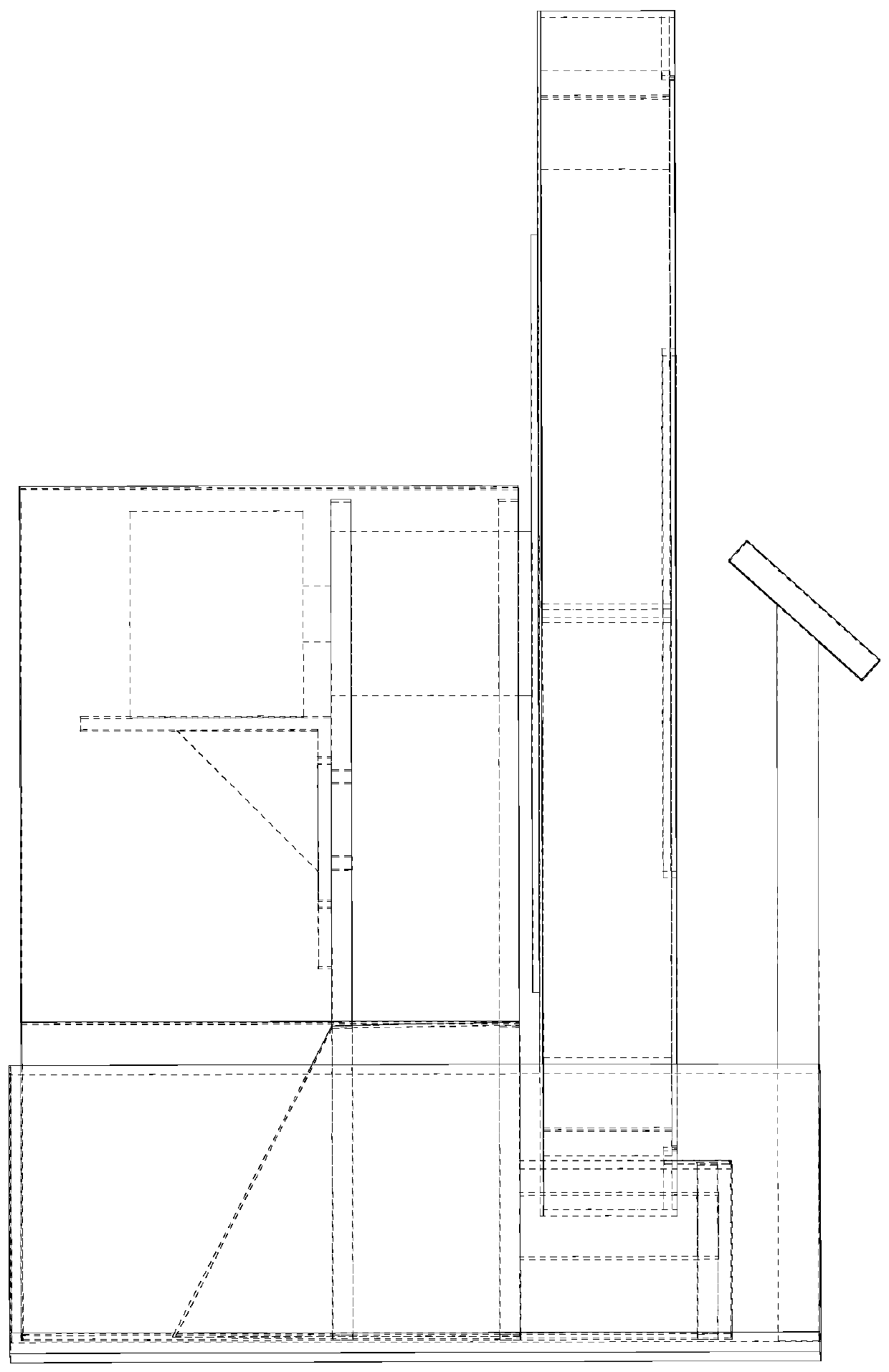

[0038] The molded pallet rolling testing machine provided by the present invention includes a frame 4 standing on a base plate 1 (the base plate is fixed on the ground) and a controller; the frame is formed by a supporting frame 2 and a sealing plate 20 covering the surface of the supporting frame.

[0039] The frame is provided with a test box capable of accommodating molded trays and rotatable around a horizontal axis, and a power mechanism for driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com