Fault detection method, device and equipment, and storage medium

A fault detection and fault technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as fault analysis limitations, inability to make maintenance judgments in a timely manner, and make up for the limitations of maintenance experience , The effect of improving the efficiency of fault location

Active Publication Date: 2019-11-19

LAUNCH TECH CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] With the continuous increase in the number of new car models and new fault types, the accessories in the vehicle are constantly enriched, and the types of fault indicators are also increasing. Since the current diagnostic equipment only outputs fault indicators, and the analysis of faults by maintenance technicians There are limitations in experience, so it may not be possible to make timely maintenance judgments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0121] In addition, as a preferred implementation manner, obtaining fault cases includes:

[0122] Acquire the fault cases corresponding to the model of the vehicle to be detected.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

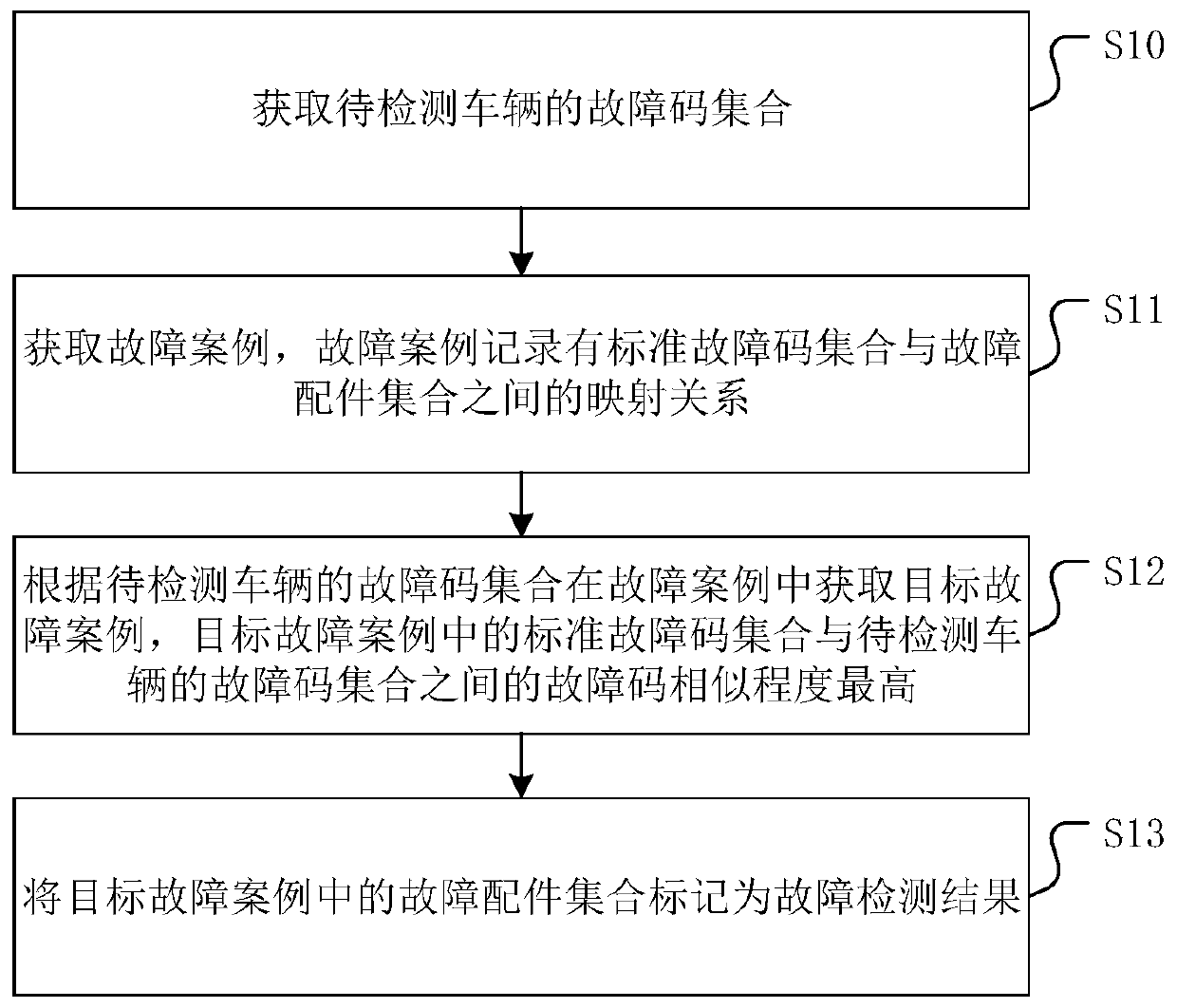

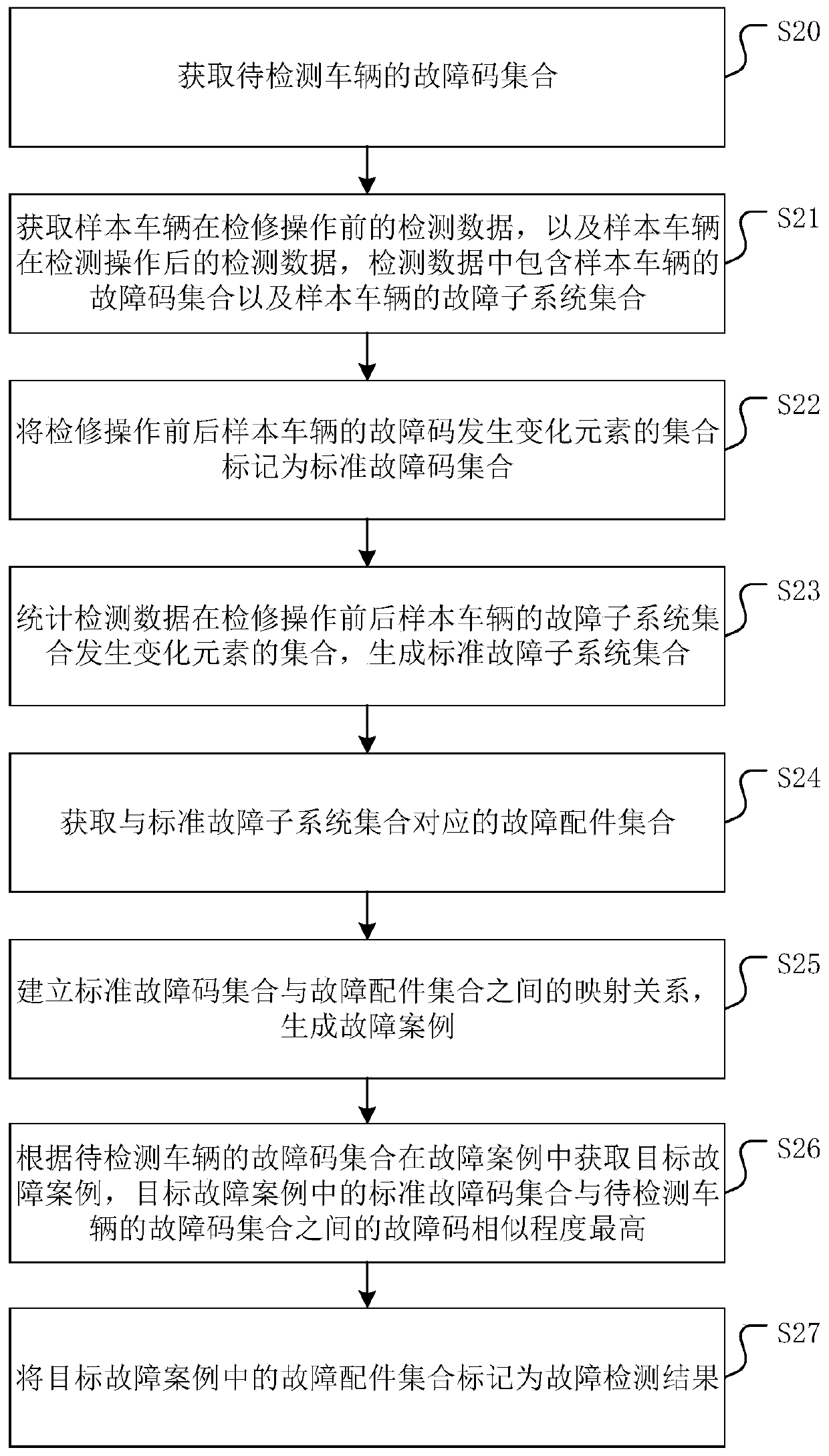

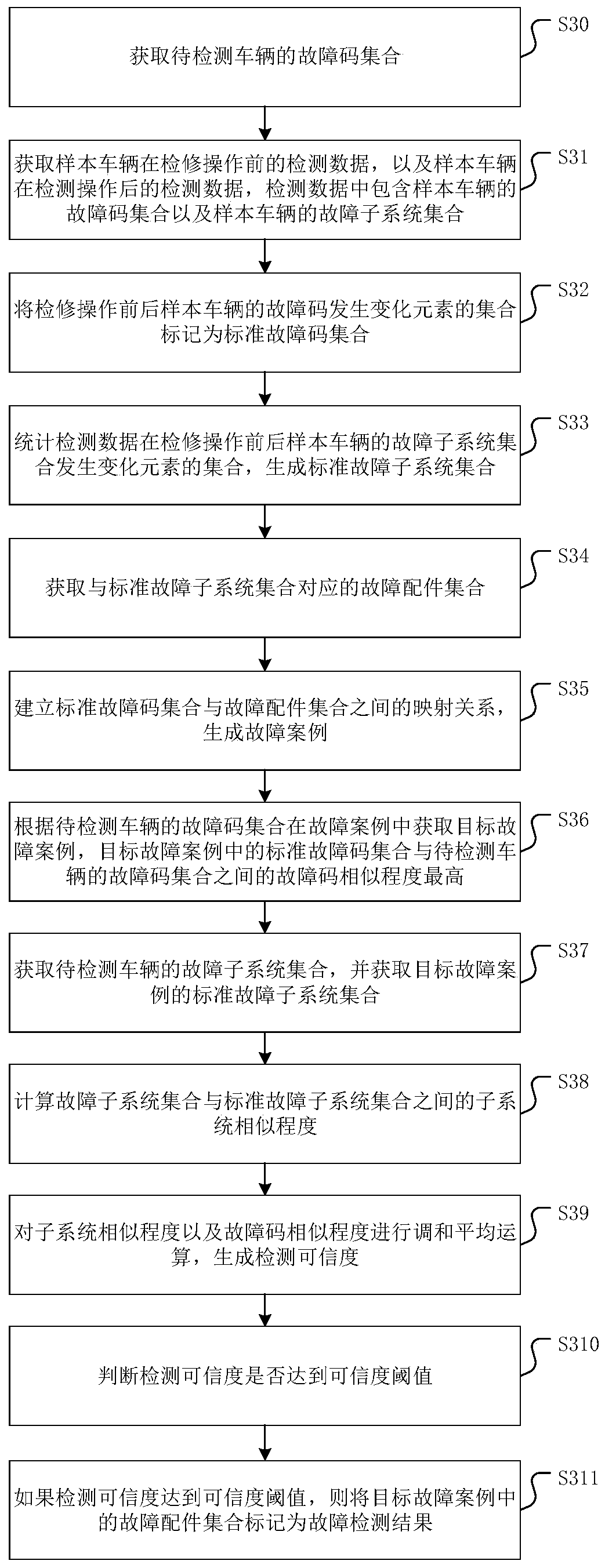

The invention discloses a fault detection method, device and equipment, and a storage medium. The method includes the following steps: obtaining a fault code set of a to-be-detected vehicle; obtaininga fault case, wherein the fault case records, a mapping relationship between a standard fault code set and a fault accessory set; acquiring a target fault case in the fault case according to the fault code set of the to-be-detected vehicle, wherein the similarity degree between the standard fault code set in the target fault case and the fault code set of the to-be-detected vehicle is highest; and marking the fault accessory set in the target fault case as a fault detection result. The method can make up for limitation of maintenance experience of a maintenance technician, thereby improving the positioning efficiency of a vehicle fault. In addition, the invention also provides the fault detection device and equipment, and the storage medium, and beneficial effects are the same as described above.

Description

technical field [0001] The present application relates to the field of vehicle detection, in particular to a fault detection method, device, equipment and storage medium. Background technique [0002] Existing vehicle diagnostic equipment often adopts a detection method similar to that of the on-board automatic diagnostic system OBD, and reads the operating indicators of vehicle system components through sensors of various electrical monitoring systems, and outputs the operating indicators, and then the maintenance technician reads the equipment output indicators data, and use the maintenance experience of maintenance technicians to locate the actual faulty parts. [0003] With the continuous increase in the number of new car models and new fault types, the accessories in the vehicle are constantly enriched, and the types of fault indicators are also increasing. Since the current diagnostic equipment only outputs fault indicators, and the analysis of faults by maintenance te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B23/02

CPCG05B23/0243G05B2219/24065

Inventor 刘新潘洋

Owner LAUNCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com