A cam rotor pump rotor remover

A cam rotor pump and disassembler technology, which is applied in the manufacture of tools, hand-held tools, etc., can solve the problems of rotor bending deformation, rotor fixing, and increased maintenance costs, and achieve the effect of saving time and making disassembly work easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

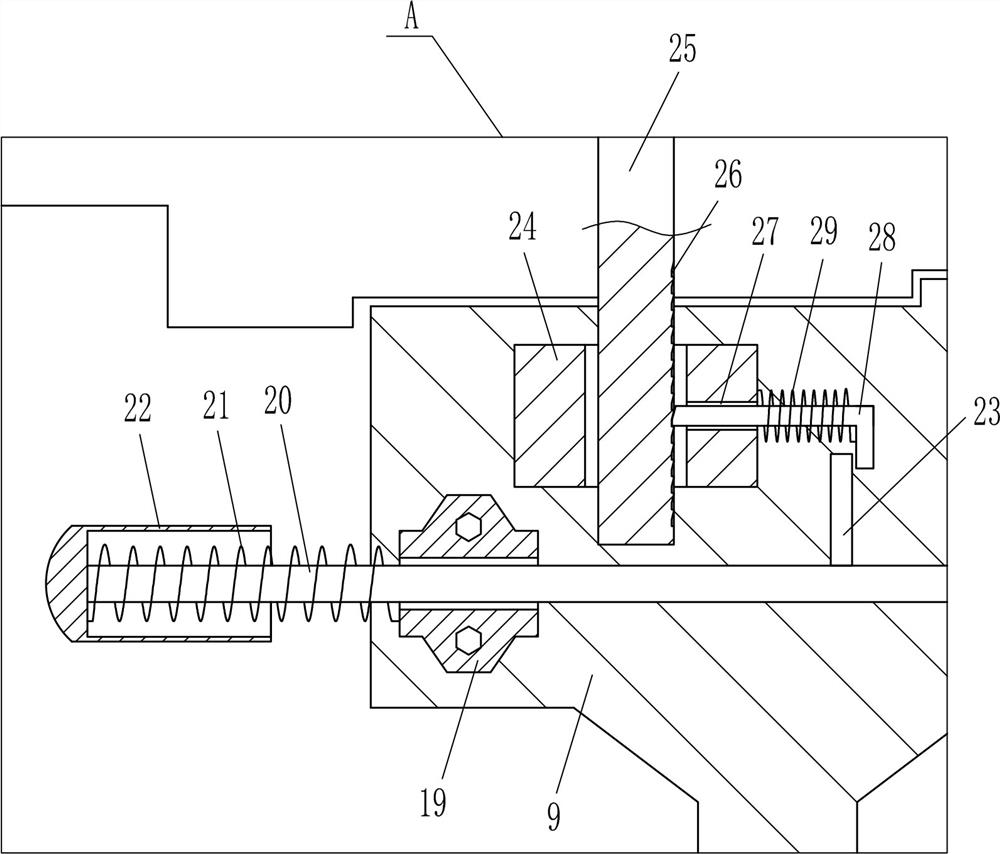

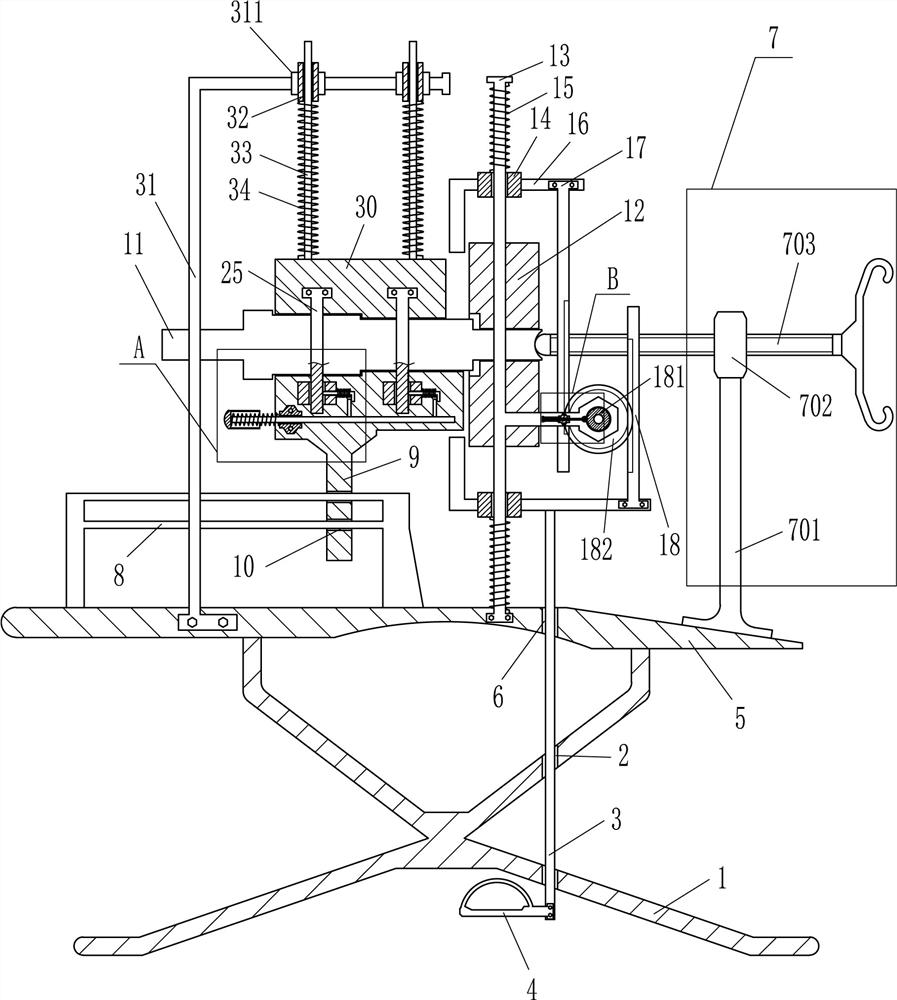

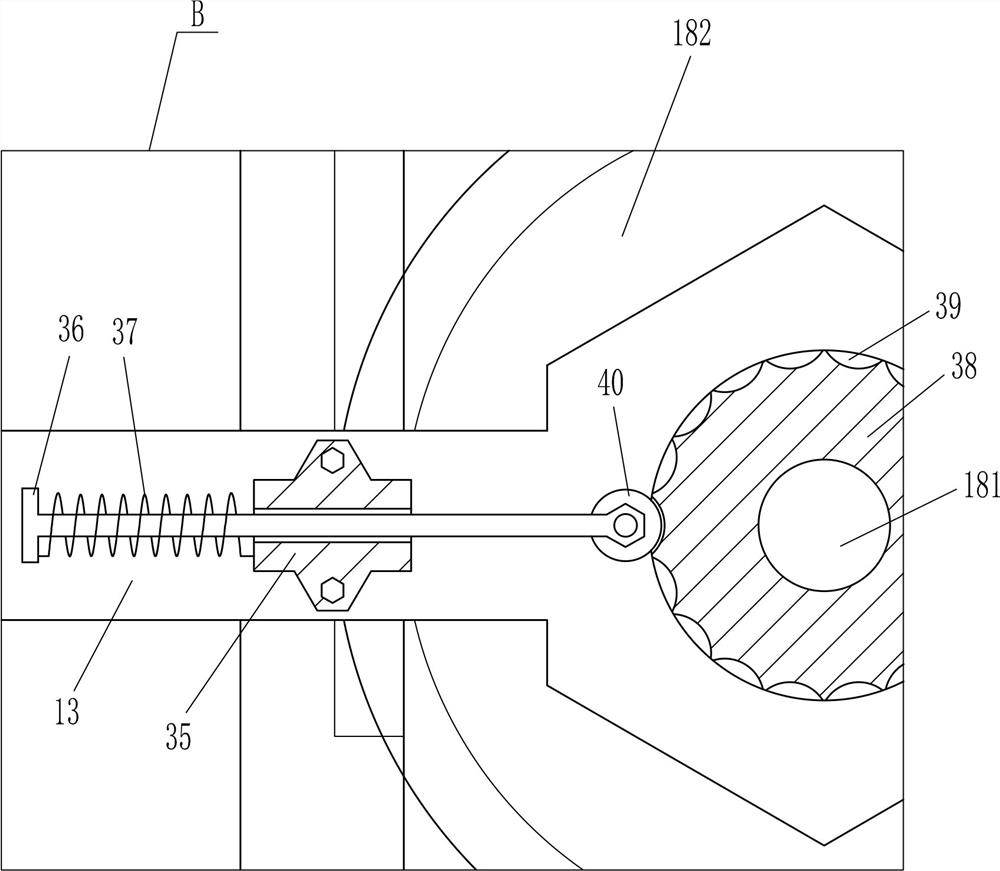

[0016] A rotary lobe pump rotor remover, such as figure 1 As shown, it includes a first bracket 1, a first slide bar 3, a pedal 4, a first support plate 5, an extruding device 7, a second slide bar 8, a second support plate 9, a second pole 13, a first Sliding sleeve 14, first spring 15, splint 16, first rack 17, second rack 18, second rotating shaft 181 and gear 182, the first sliding hole 2 is opened on the lower right side of the first bracket 1, the first bracket 1 There is a first support plate 5 on the top, and the first support 1 is connected to the first support plate 5 by welding. There is a second slide hole 6 on the right side of the top of the first support plate 5, and the second slide hole 6 is located at the Above the first sliding hole 2, the first sliding hole 2 and the second sliding hole 6 are slidingly provided with a first sliding bar 3, the lower part of the front side of the first sliding bar 3 is provided with a pedal 4, and the right side of the top of...

Embodiment 2

[0018] A rotary lobe pump rotor remover, such as figure 1 As shown, it includes a first bracket 1, a first slide bar 3, a pedal 4, a first support plate 5, an extruding device 7, a second slide bar 8, a second support plate 9, a second pole 13, a first Sliding sleeve 14, first spring 15, splint 16, first rack 17, second rack 18, second rotating shaft 181 and gear 182, the first sliding hole 2 is opened on the lower right side of the first bracket 1, the first bracket 1 There is a first support plate 5 on the top, and a second sliding hole 6 is opened on the right side of the top of the first support plate 5. The second sliding hole 6 is located above the first sliding hole 2. The first sliding hole 2 and the second sliding hole 6 The inner sliding type is provided with a first slide bar 3, the lower part of the front side of the first slide bar 3 is provided with a pedal 4, the right side of the top of the first support plate 5 is provided with an extrusion device 7, and the l...

Embodiment 3

[0021] A rotary lobe pump rotor remover, such as Figure 1-2As shown, it includes a first bracket 1, a first slide bar 3, a pedal 4, a first support plate 5, an extruding device 7, a second slide bar 8, a second support plate 9, a second pole 13, a first Sliding sleeve 14, first spring 15, splint 16, first rack 17, second rack 18, second rotating shaft 181 and gear 182, the first sliding hole 2 is opened on the lower right side of the first bracket 1, the first bracket 1 There is a first support plate 5 on the top, and a second sliding hole 6 is opened on the right side of the top of the first support plate 5. The second sliding hole 6 is located above the first sliding hole 2. The first sliding hole 2 and the second sliding hole 6 The inner sliding type is provided with a first slide bar 3, the lower part of the front side of the first slide bar 3 is provided with a pedal 4, the right side of the top of the first support plate 5 is provided with an extrusion device 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com