A lifting unit installation process for self-elevating drilling platform

A lifting unit, drilling platform technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as low efficiency, damage to the pile fixing frame, and inability to achieve smooth installation in sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following specific examples illustrate the implementation of the present invention. Those familiar with the technology can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

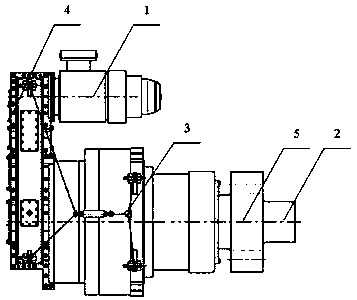

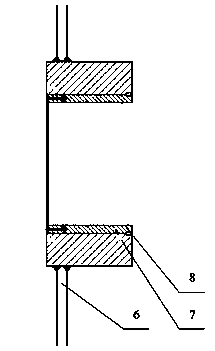

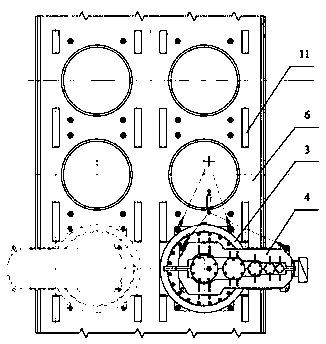

[0035] Such as figure 1 As shown, a lifting unit installation process for a jack-up drilling platform. The lifting unit includes a motor 1 and a gear box arranged front and rear. One end of the motor 1 is flush with one end of the gear box and is driven by a transmission member 4. The gear box includes a gear shaft 2 and a torque plate 3. The gear shaft 2 is arranged horizontally and the torque plate 3 is placed between the gear shaft 2 and the transmission member 4. The torque plate 3 is arranged perpendicular to the gear shaft 2, and the gear shaft 2 is covered with Climbing gear 5, including installation of sliding sleeve 8, cleaning of lifting unit, preliminary installation of lifting unit, cleaning of fixed pile frame 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com