Patents

Literature

39results about How to "Guaranteed engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

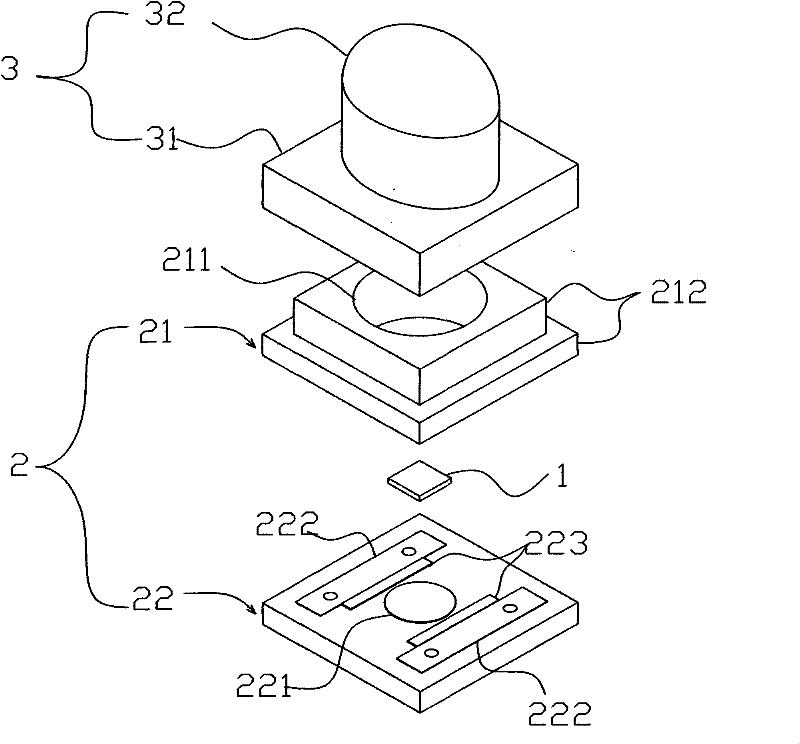

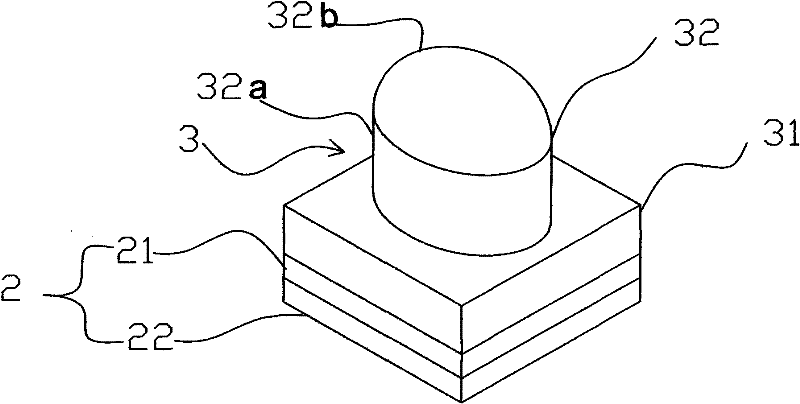

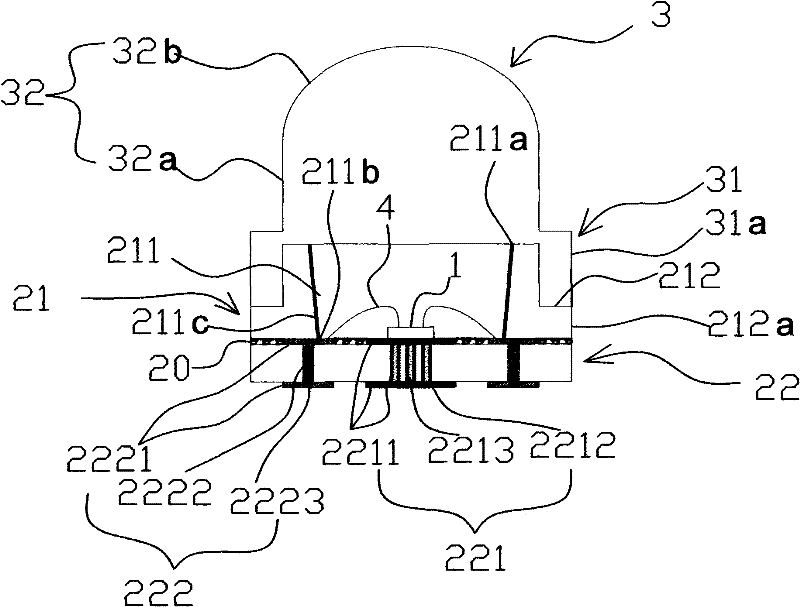

Surface mounted device (SMD) type light emitting diode (LED) device for outdoor display screen and display module using SMD type LED device

InactiveCN102130114AIncrease in sizeIncrease heightSolid-state devicesIdentification meansSurface mountingColloid

The invention relates to a surface mounted device (SMD) type light emitting diode (LED) device for an outdoor display screen, which comprises at least one LED chip, a lower substrate for loading the LED chips, an upper substrate combined with the lower substrate and packaging colloid arranged on the upper substrate, wherein the upper substrate is provided with steps; and the packaging colloid comprises a packaging matrix covering the steps and an optical lens arranged on the packaging matrix. In the SMD type LED device, the stepped upper substrate is combined with the packaging matrix with a certain height to reduce the size of the packaging colloid and optical loss, improve the light extraction efficiency and simplify the structure; moreover, light distribution with a wide viewing angle can be provided and the defects of a through-hole LED and a Top LED can be made up by arranging a stepped structure on the upper substrate and coving the packing colloid with a lens structure. Besides, the invention also provides a display module using the SMD type LED device for the outdoor display screen.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

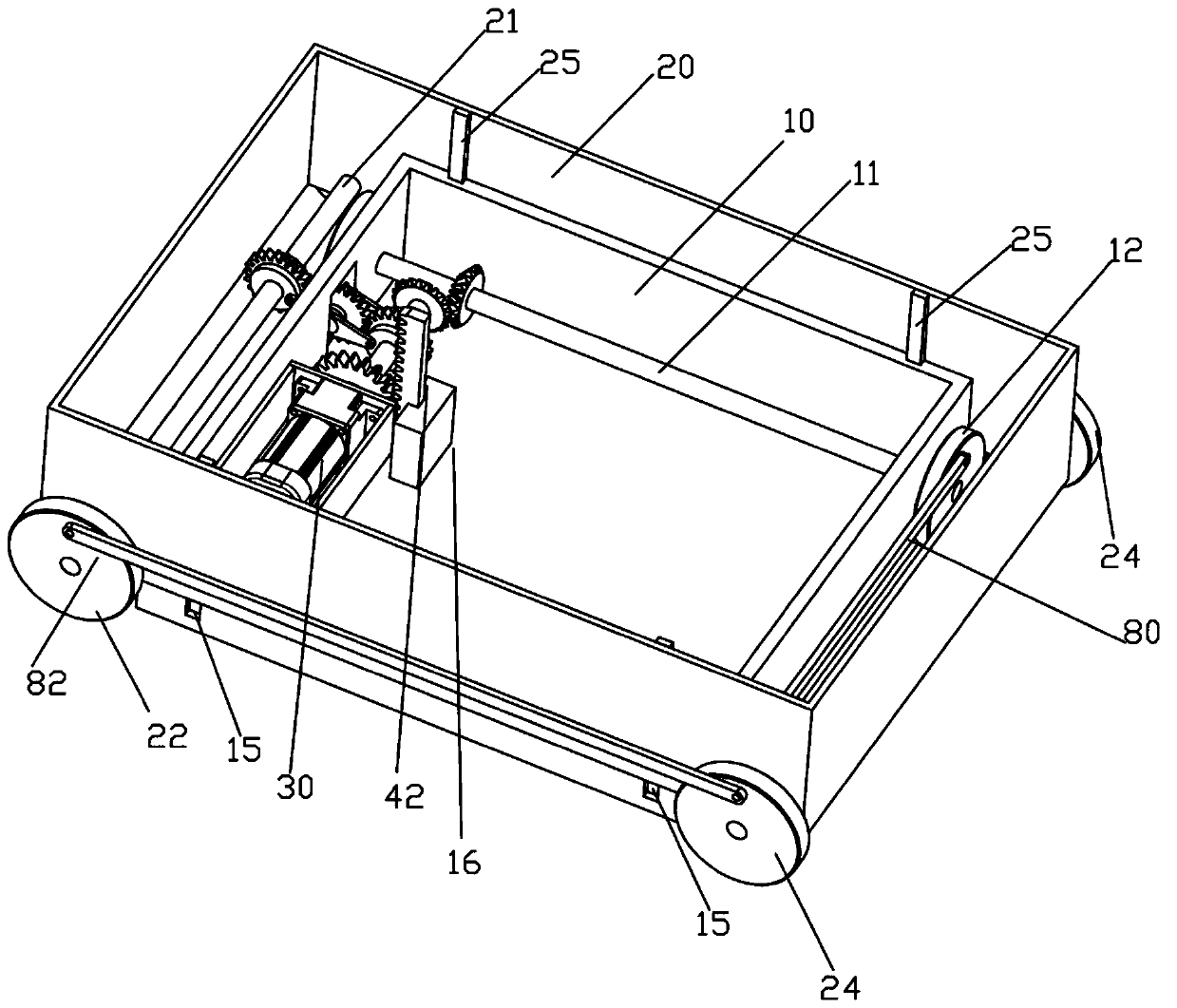

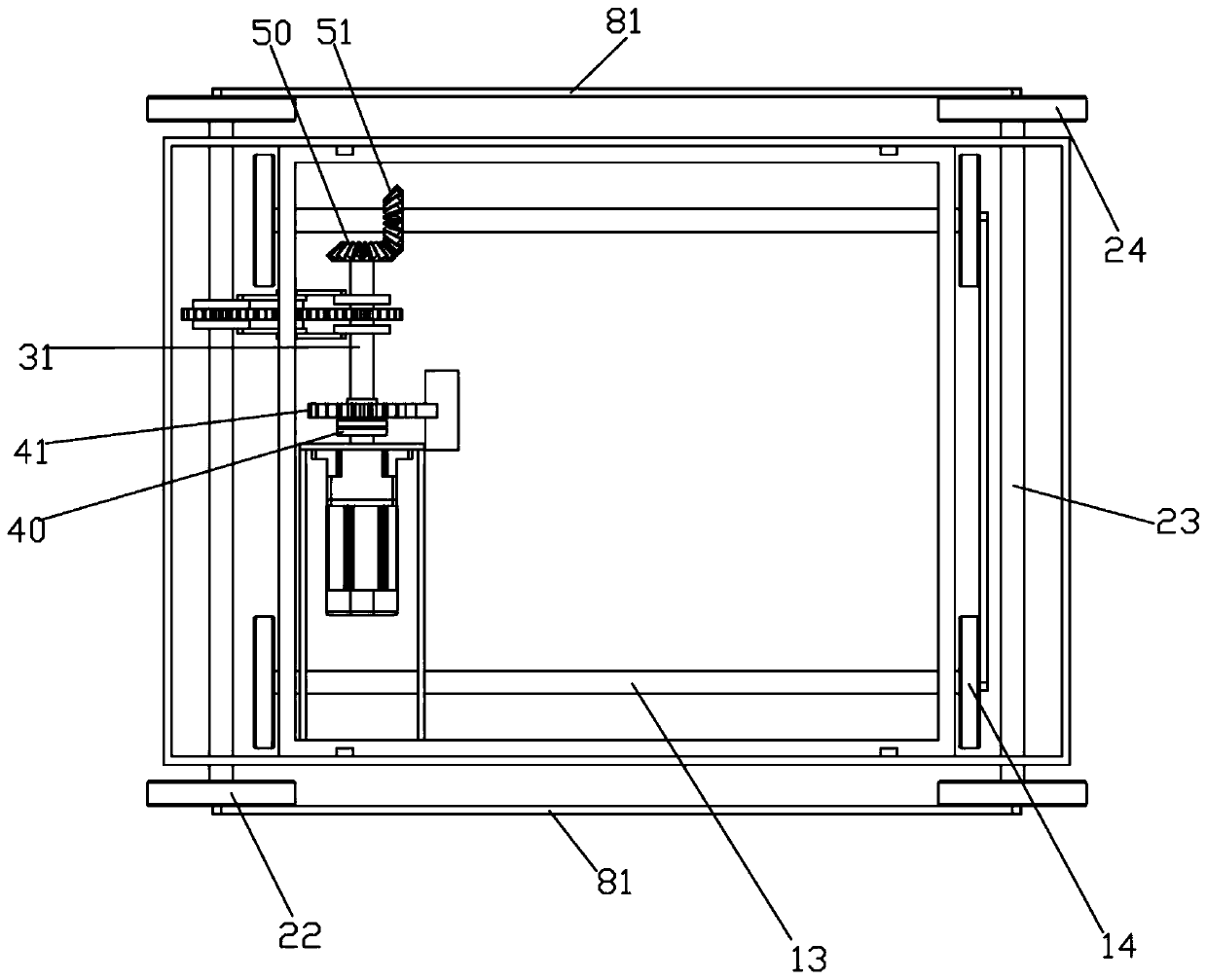

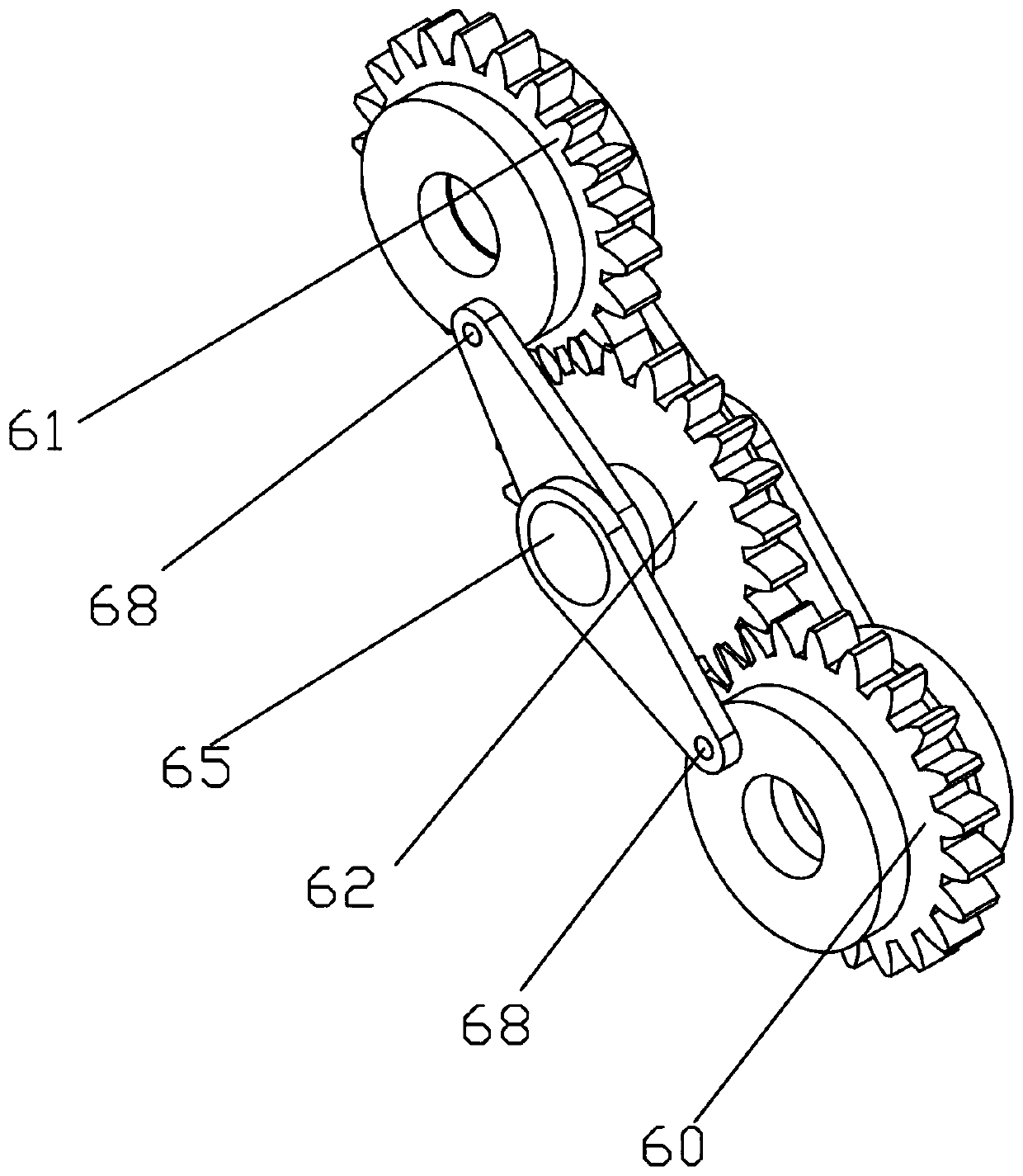

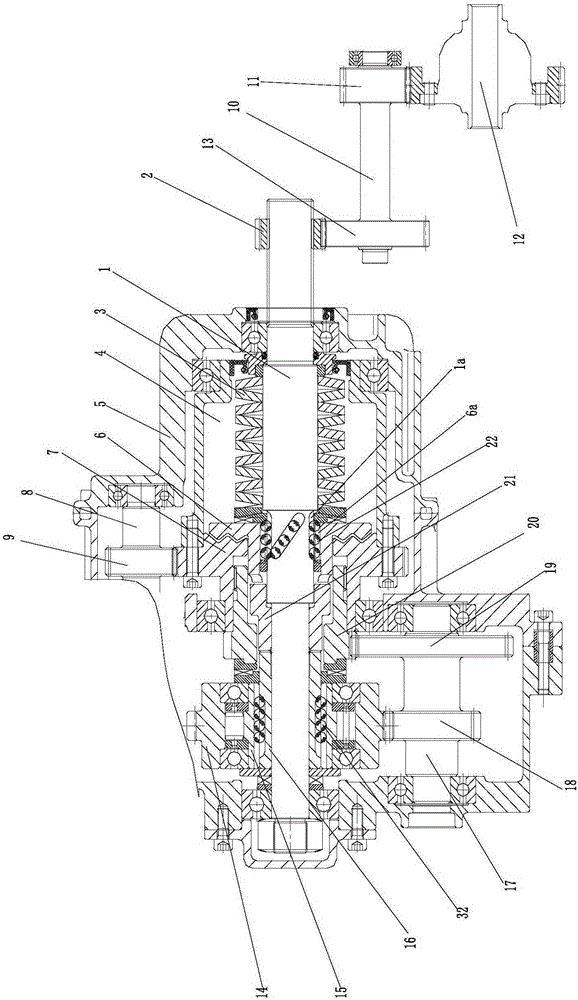

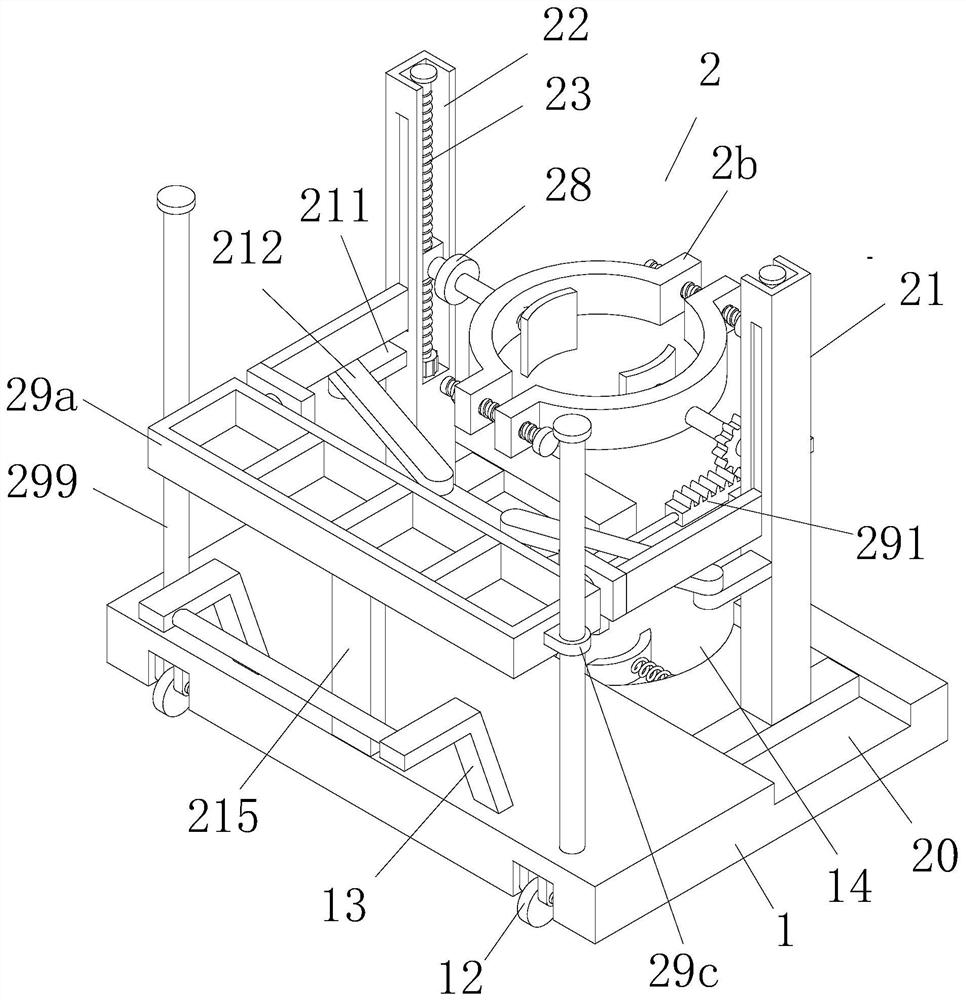

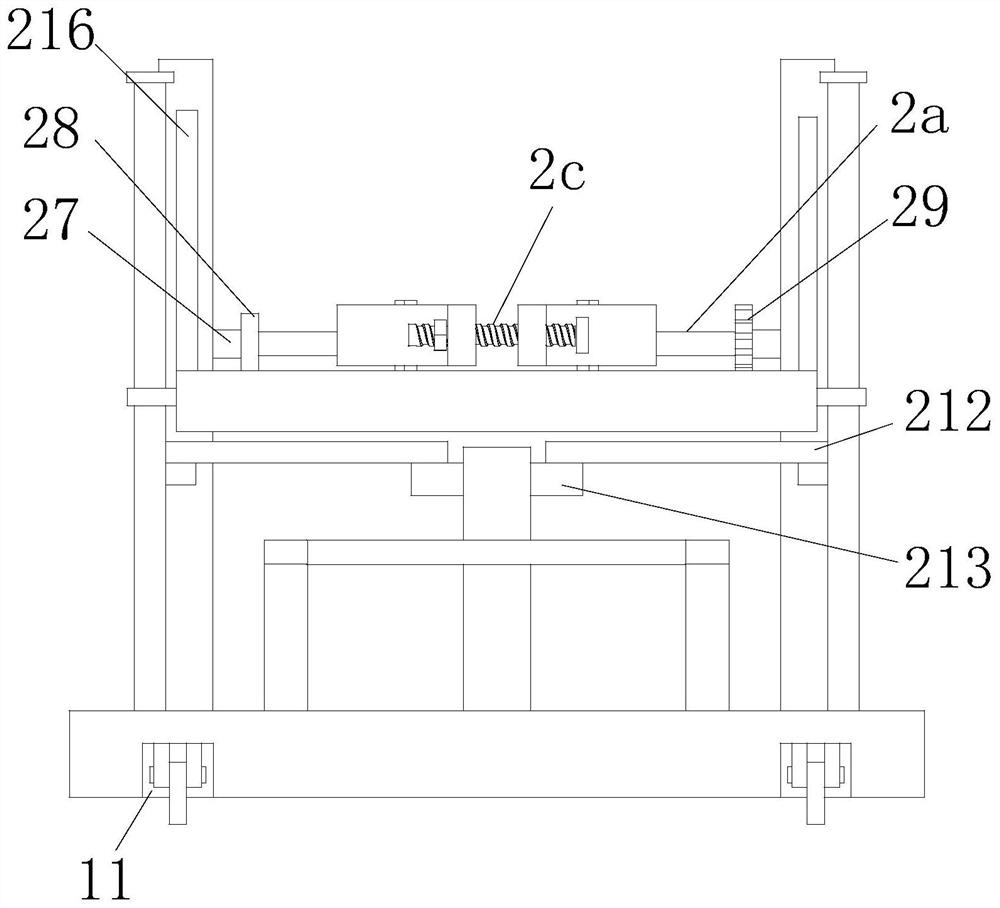

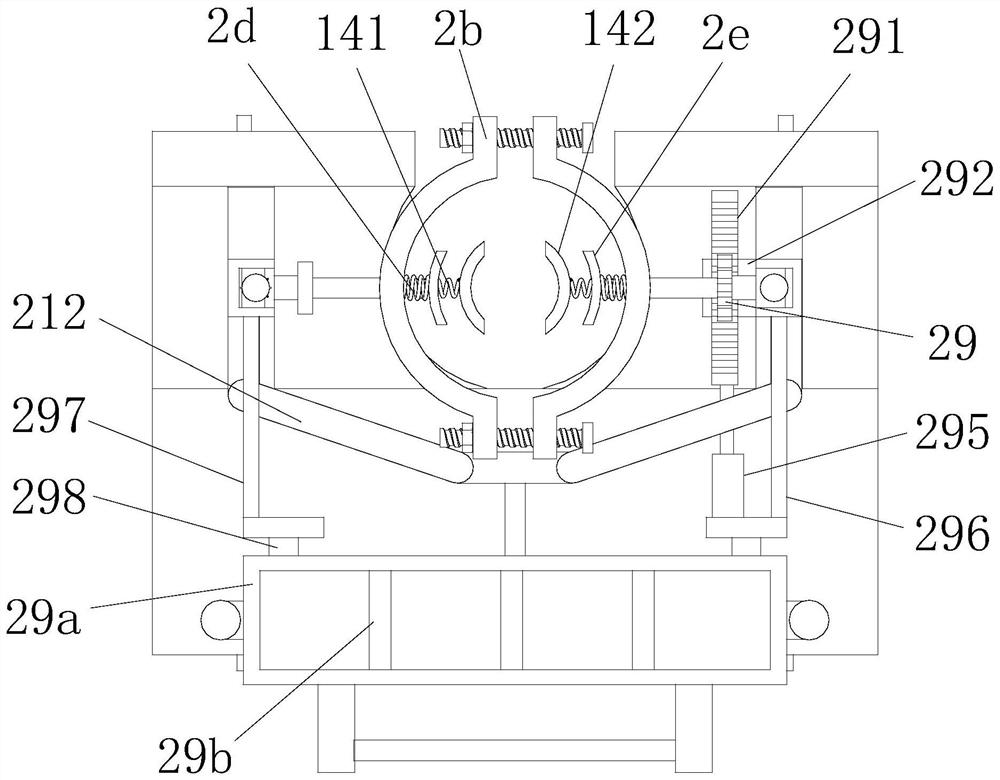

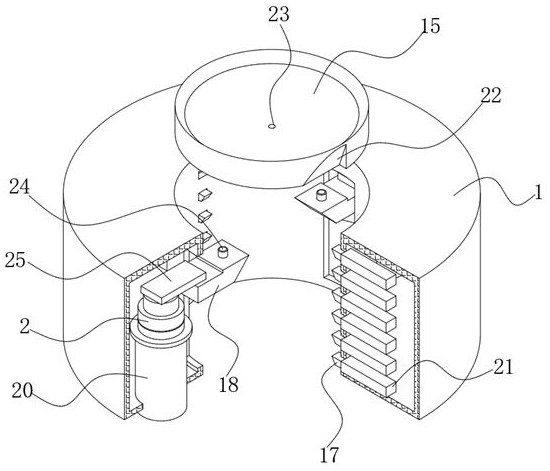

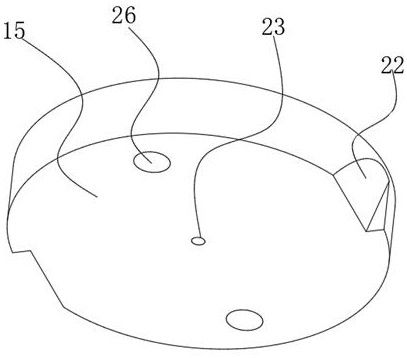

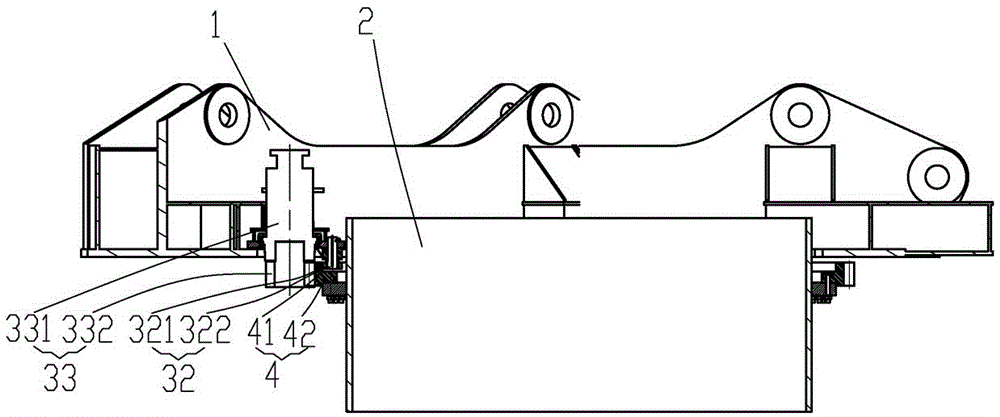

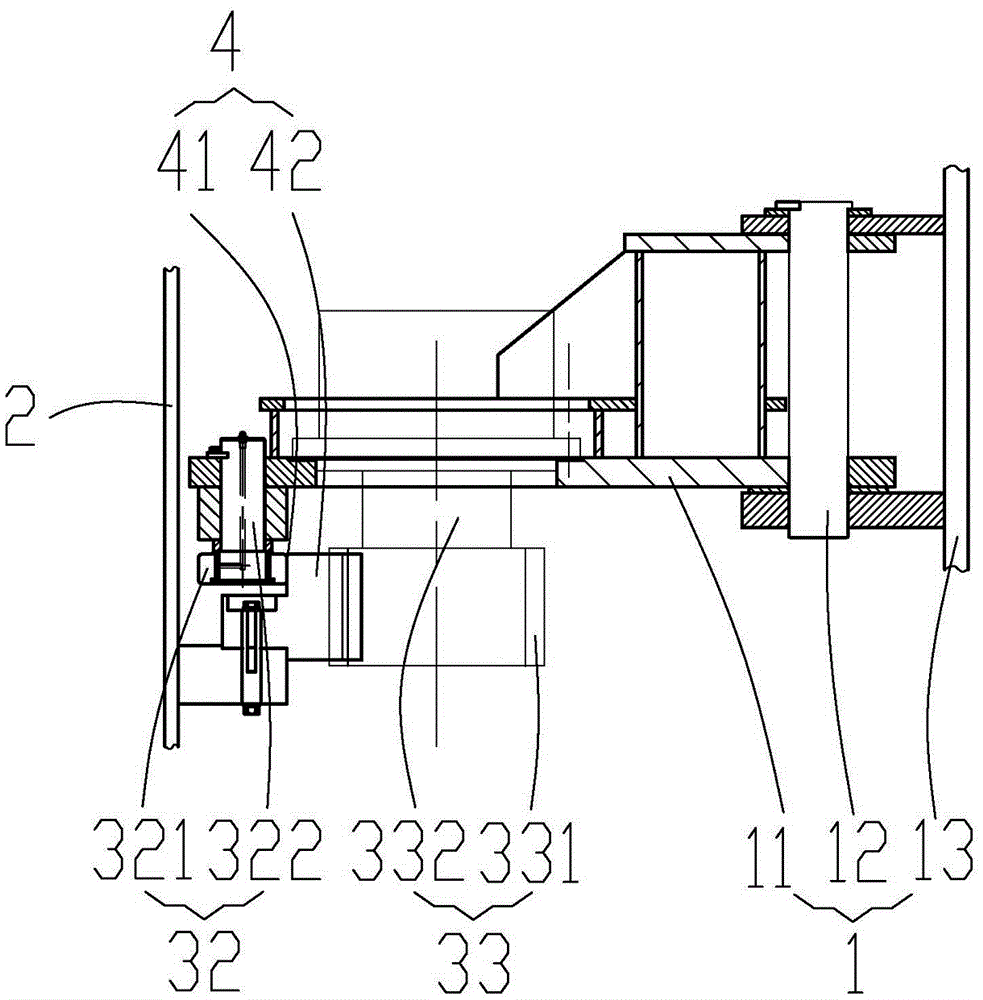

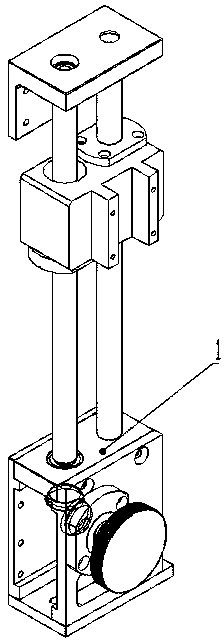

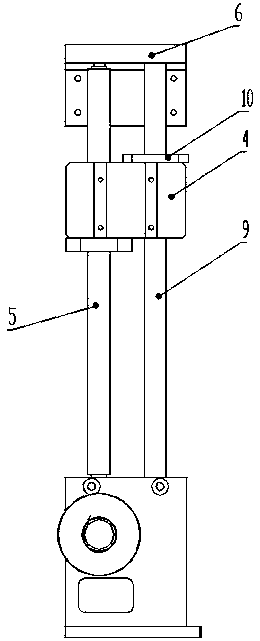

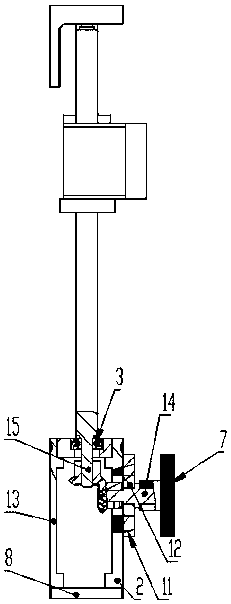

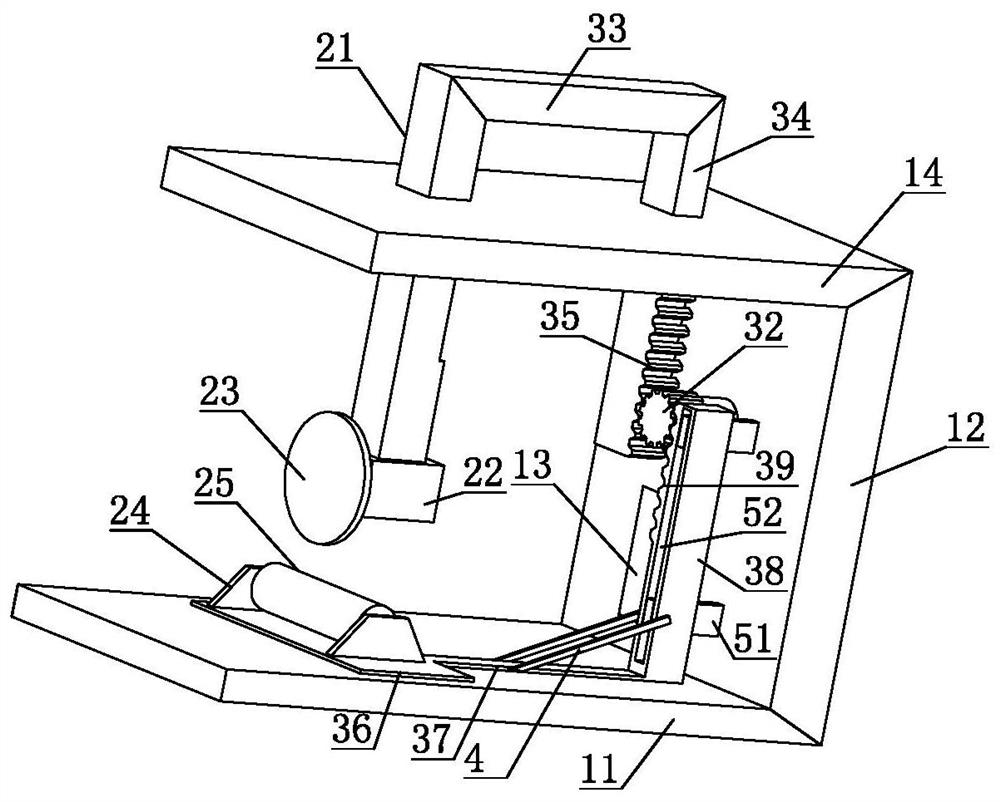

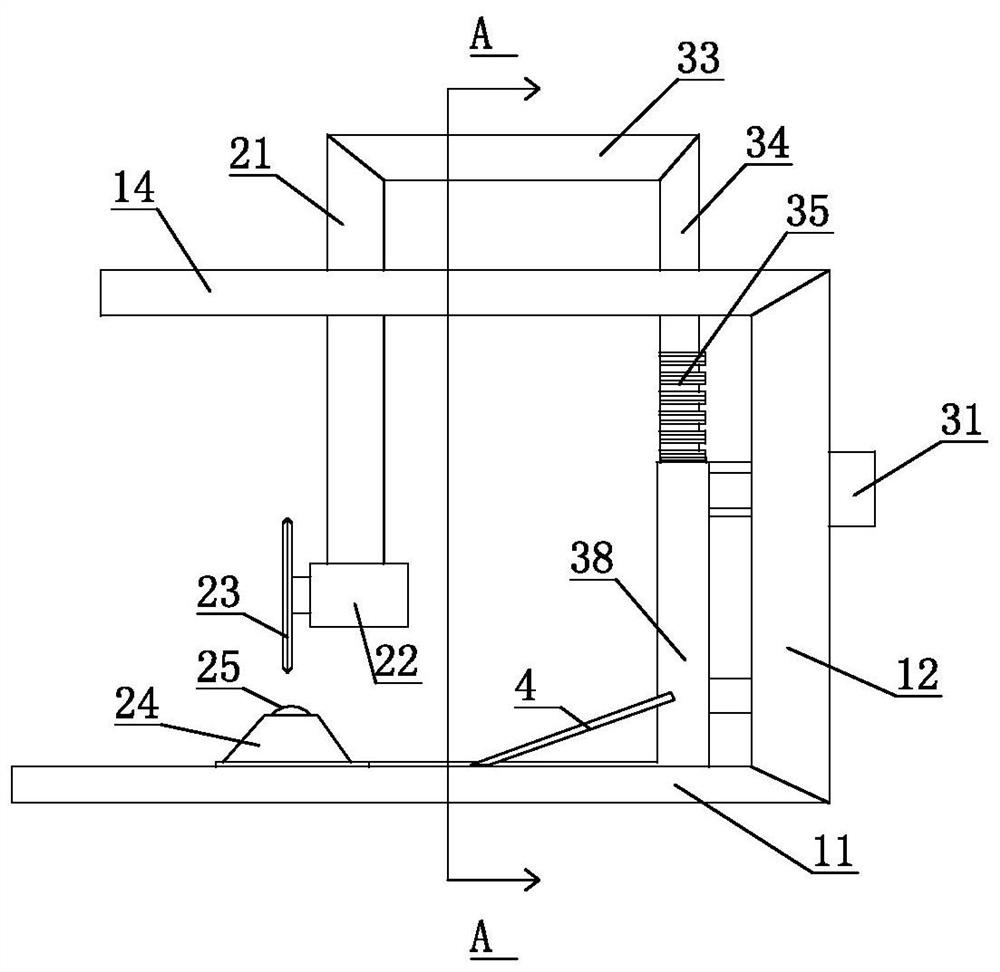

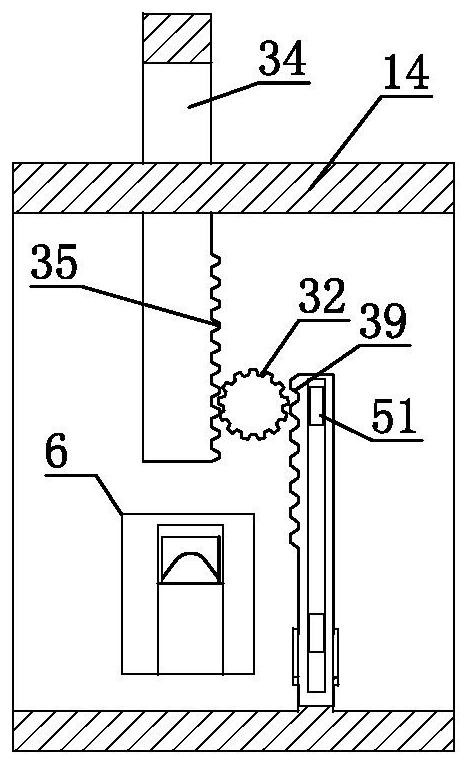

Jacking and walking co-driving type carrying device

PendingCN110733841ARealize lifting functionNot misplacedConveyorsStorage devicesWheel driveBevel gear

The invention relates to the field of transportation equipment, and discloses a jacking and walking co-driving type carrying device. The jacking and walking co-driving type carrying device comprises amain frame body, a lifting frame body, a first transmission shaft, a first rotating wheel, a first driven transmission shaft, a first driven rotating wheel, a driving device, a power output shaft, afirst transmission mechanism and a lifting transmission mechanism, wherein the first transmission shaft provided with the first rotating wheel is arranged on the main frame body, and the first driventransmission shaft provided with the first driven rotating wheel is also arranged on the main frame body; the driving device fixed on the main frame body drives the first transmission shaft to rotatethrough the power output shaft and the first transmission mechanism; and the driving device can drive the lifting frame body to ascend or descend through the lifting transmission mechanism. The poweroutput shaft is not parallel to the first transmission shaft, and the angle can be adjusted by adjusting the tooth ratio of a first bevel gear and a second bevel gear of the first transmission mechanism. According to the carrying device, the jacking and moving functions of the device can be realized only by one driving device.

Owner:北京快仓智能科技有限公司

Holding device for medical purposes

InactiveUS20080272251A1Easy to operateEngagementDiagnosticsIntravenous devicesJoint componentBiomedical engineering

Owner:UNIVERSITY OF DUNDEE

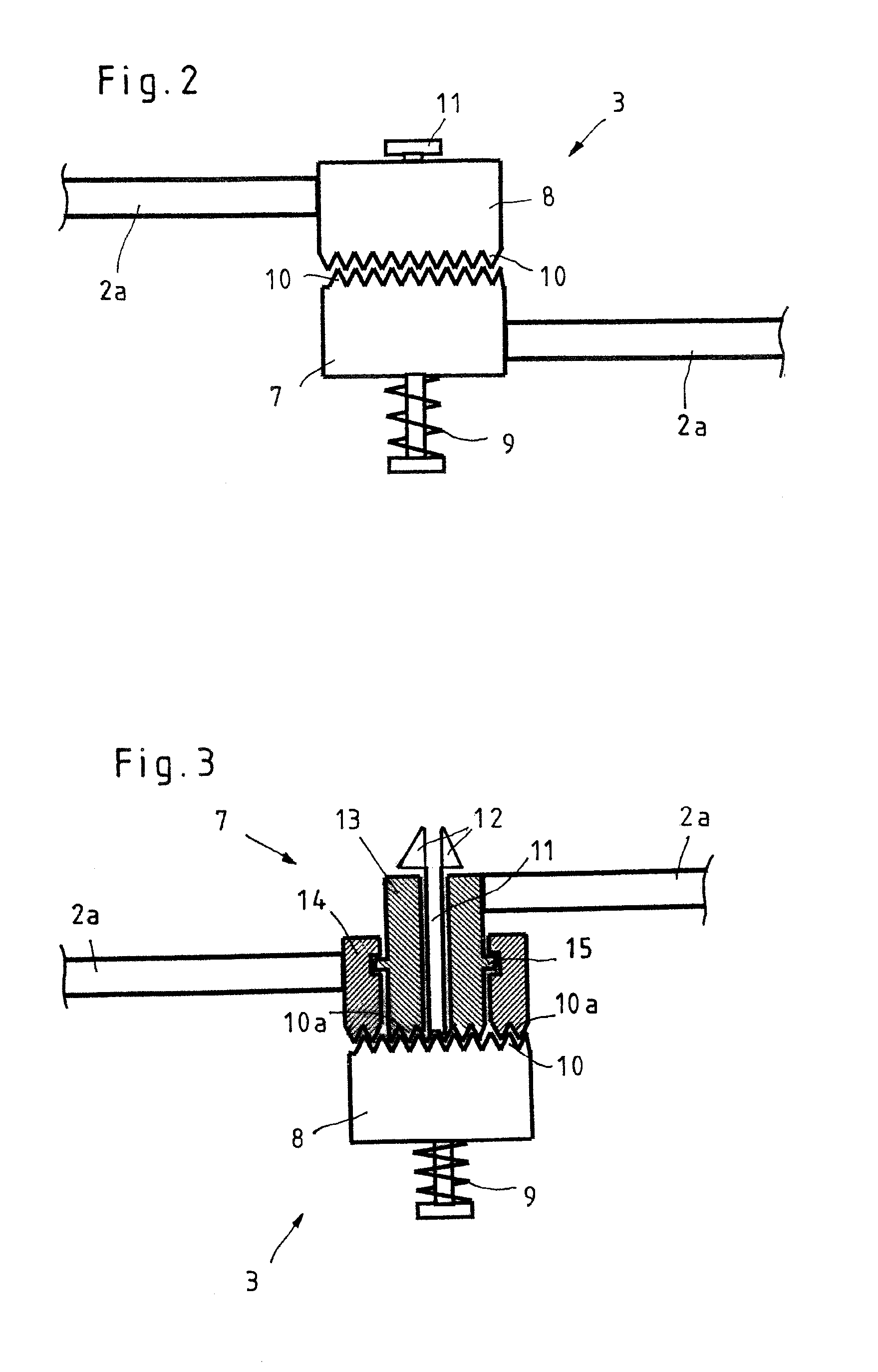

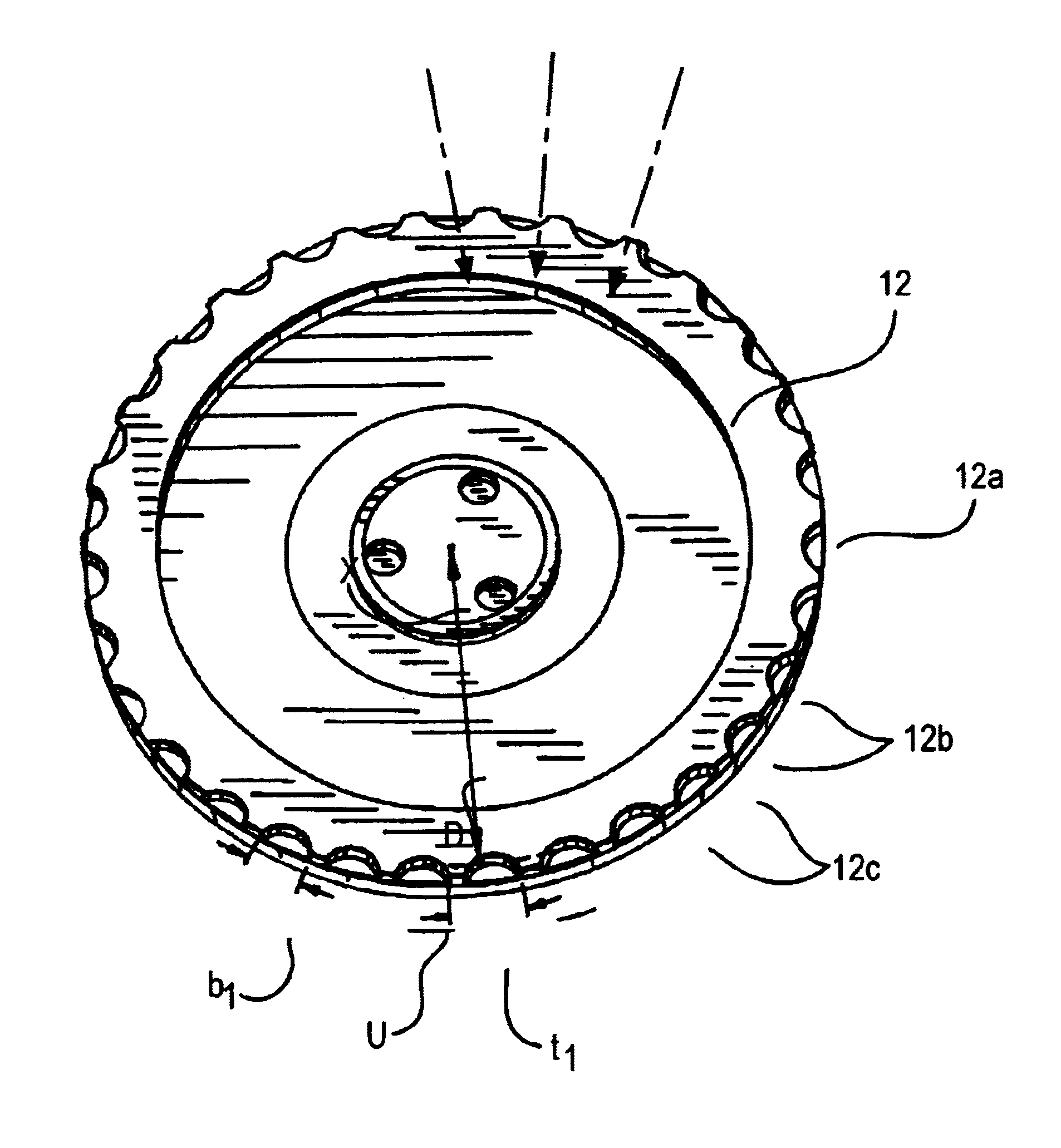

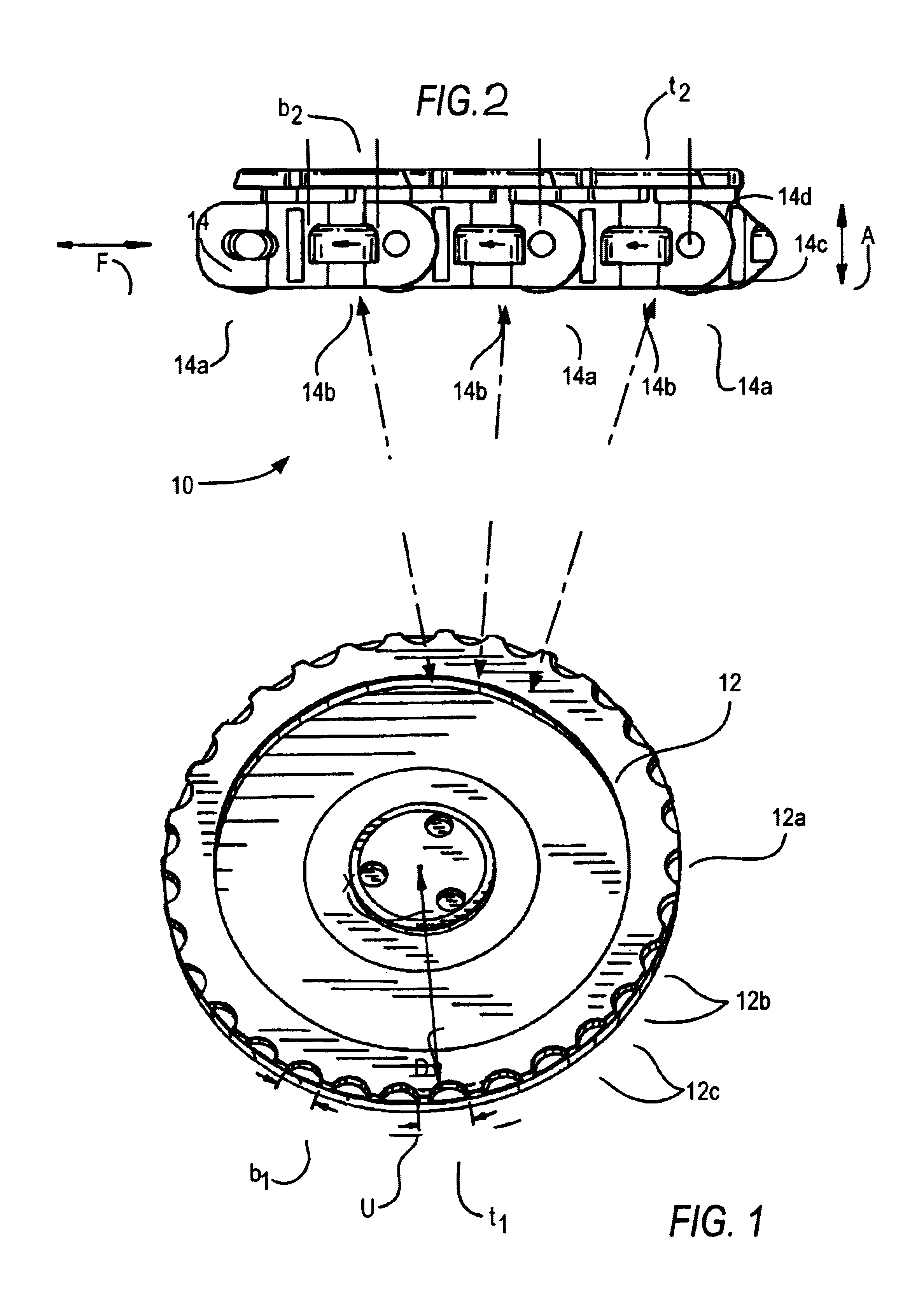

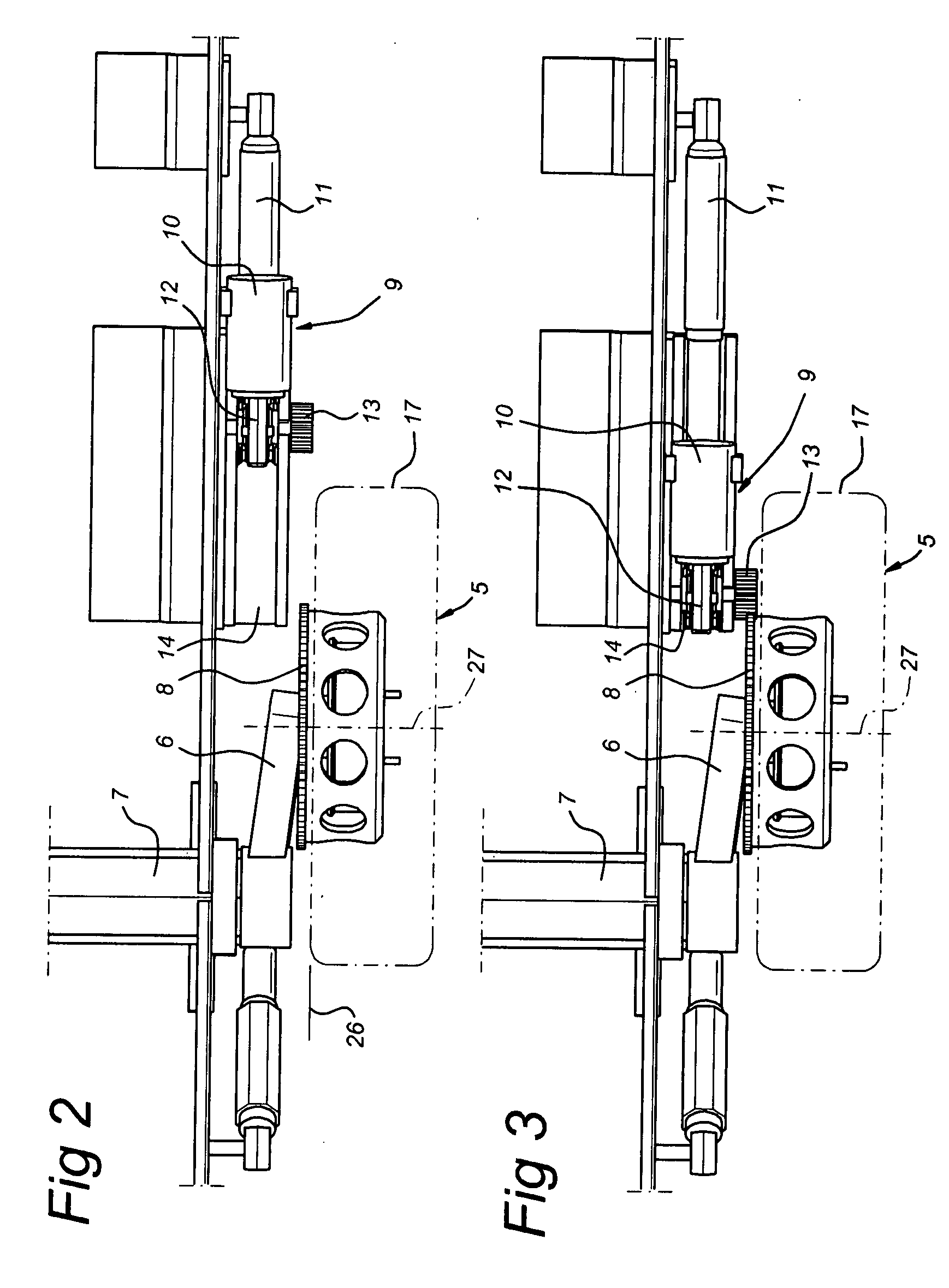

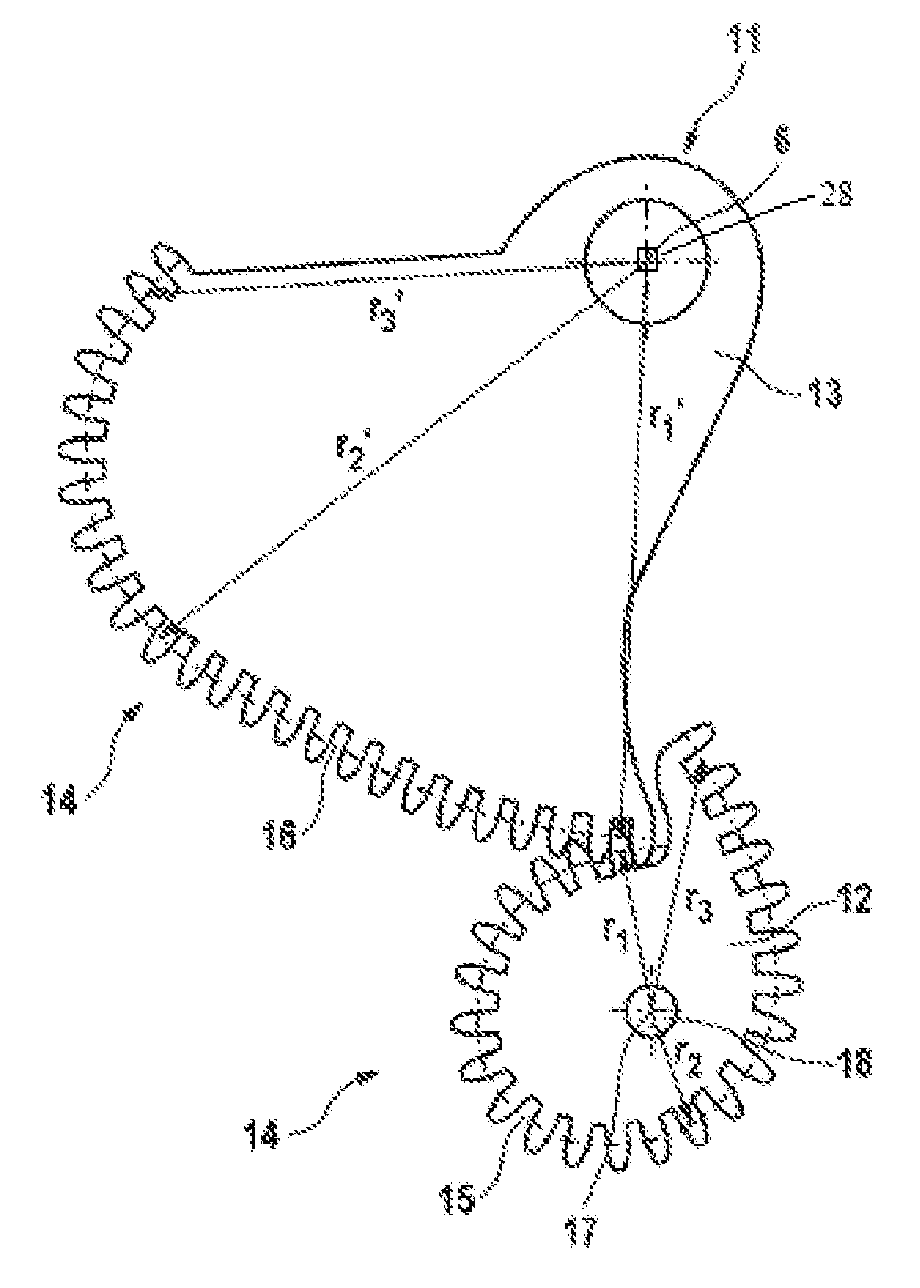

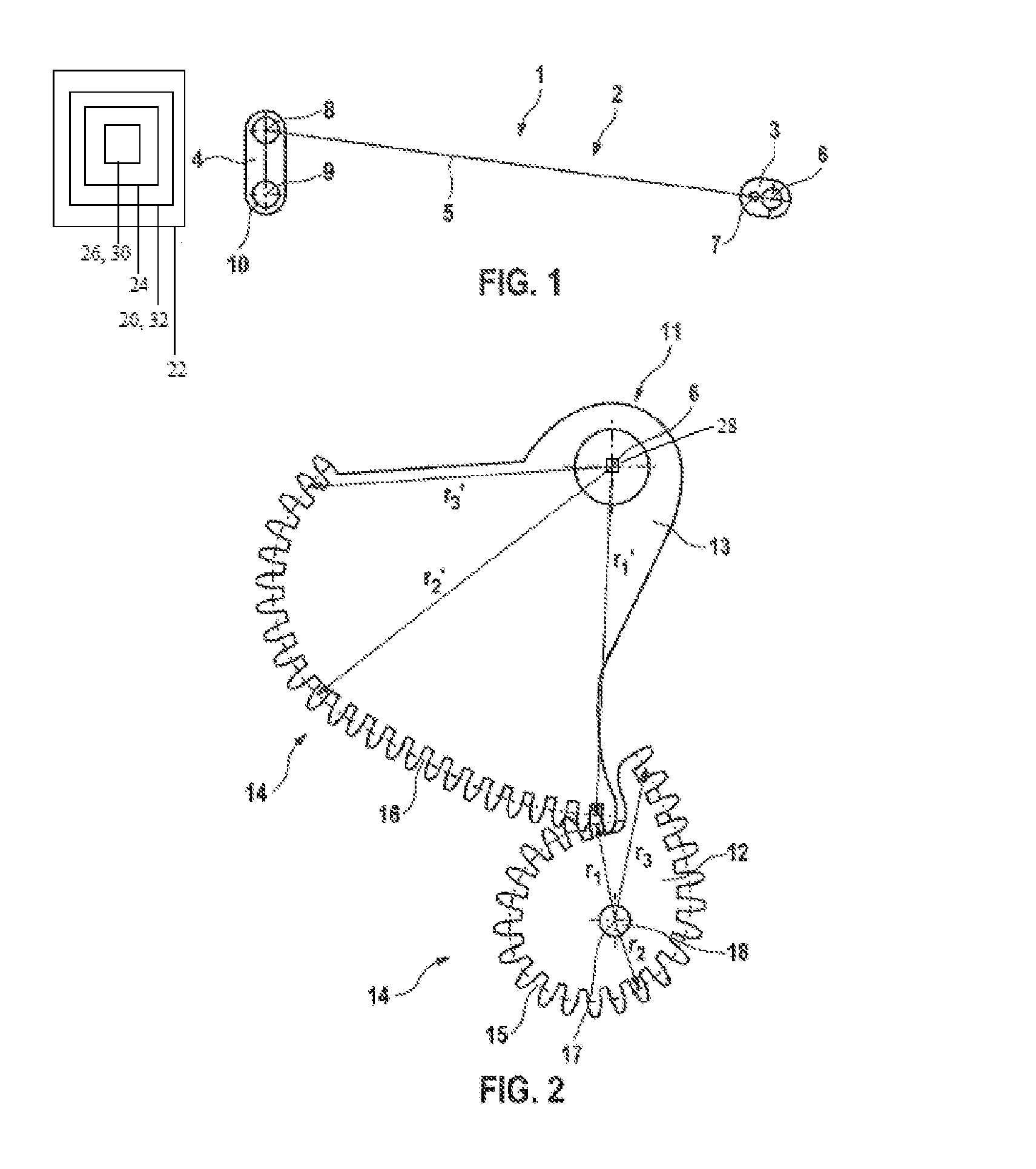

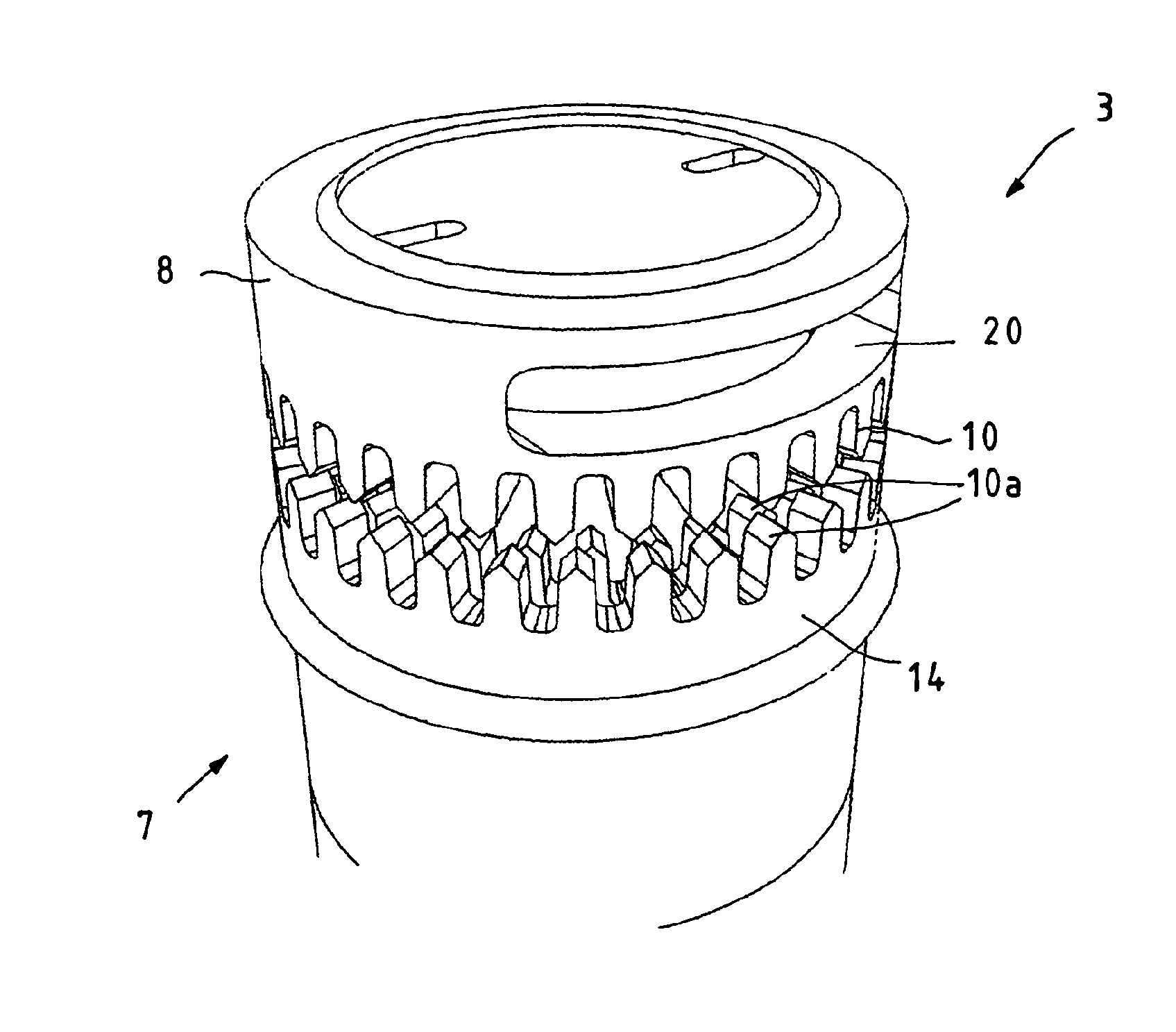

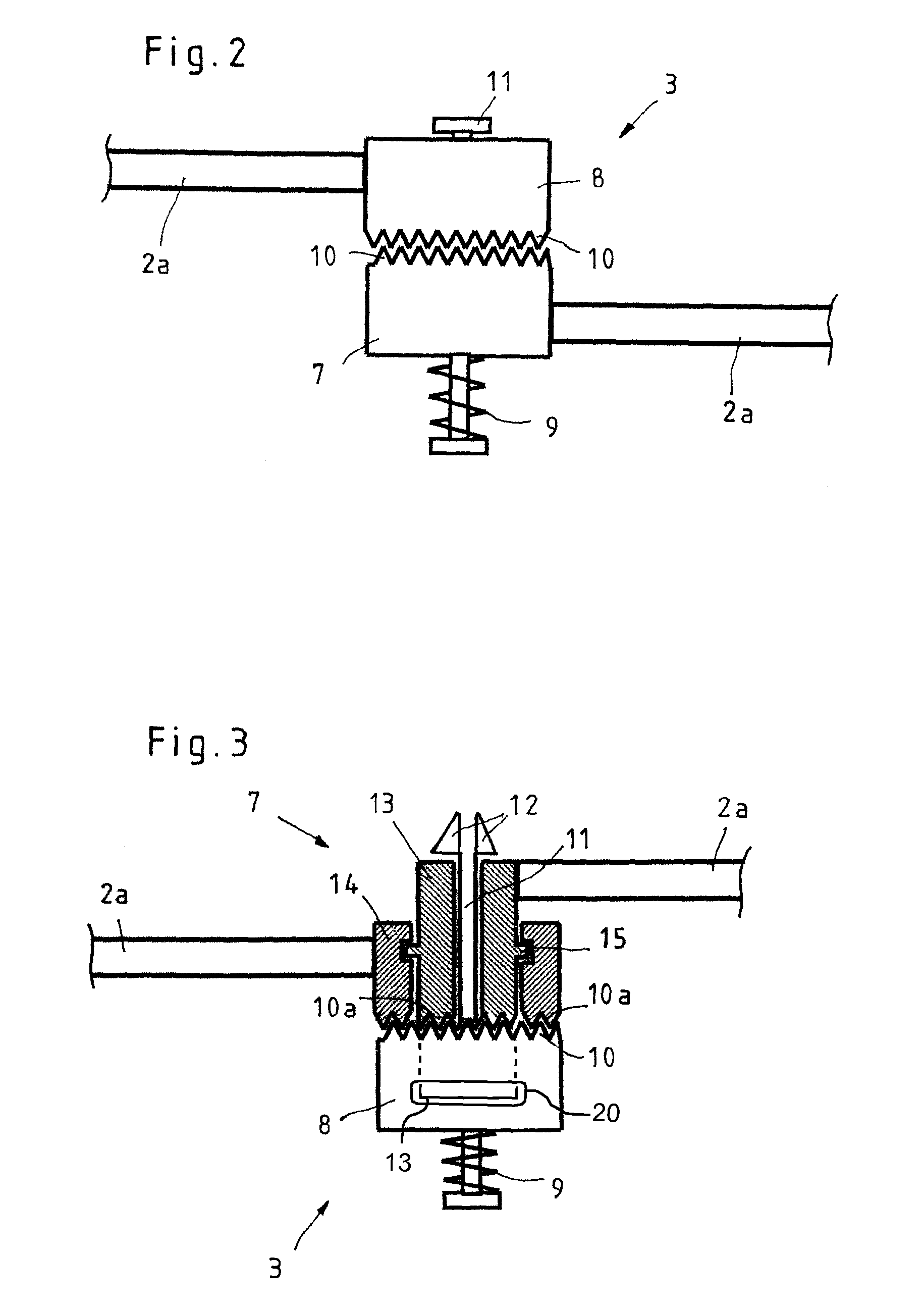

Drive mechanism for a conveyor with stretching compensation means

The drive mechanism (10) has a drive member (12) and a flexible conveying member (14). The engaging elements (12b) of the drive member (12) have an engaging element spacing (t1), while the associated counter elements (14b) of the conveyor member 14 have a counter element spacing (t2). According to the invention the engaging element spacing (t1) of the engaging elements (12b) is larger than the counter element spacing (t2) of the counter elements (14b) of the conveying member in order to compensate for conveyor member stretching in operation. In a preferred embodiment the conveying member is a flexible conveyor chain and the drive member (12) is a toothed drive wheel. In another preferred embodiment the ratio of the engaging element spacing (t1) of the drive member (12) to the counter element spacing (t2) of the conveying member (14) is between about 1.01 and about 1.10.

Owner:BOSCH REXROTH AG

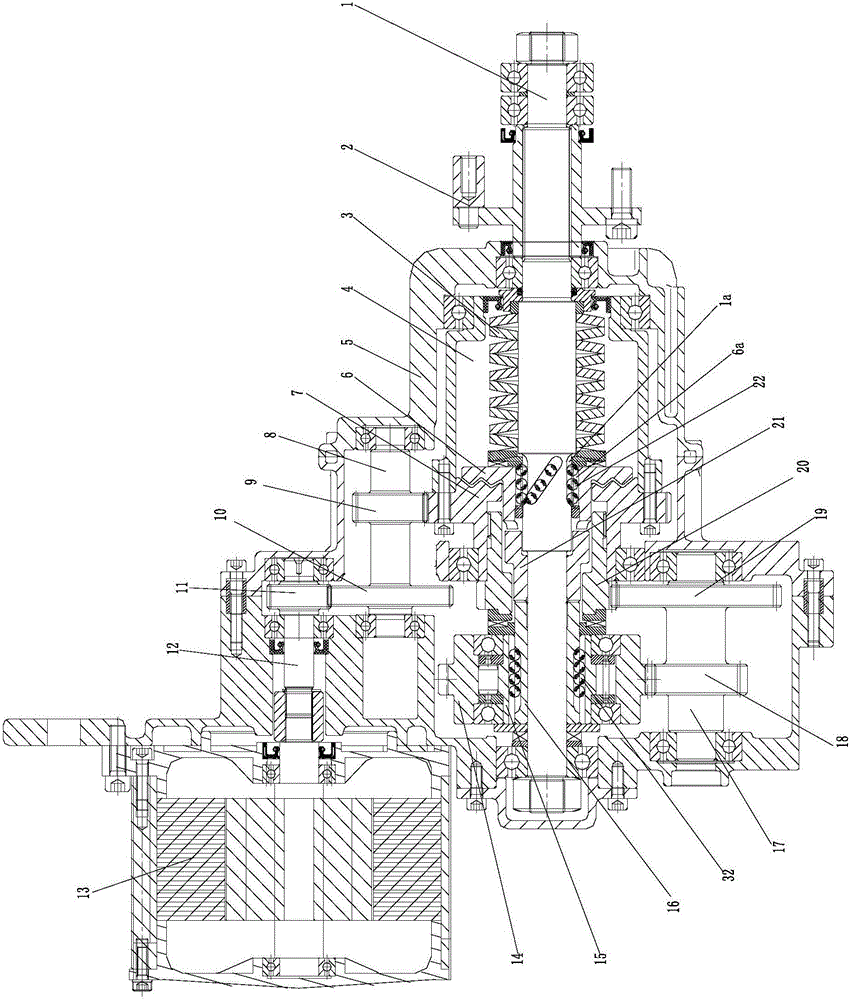

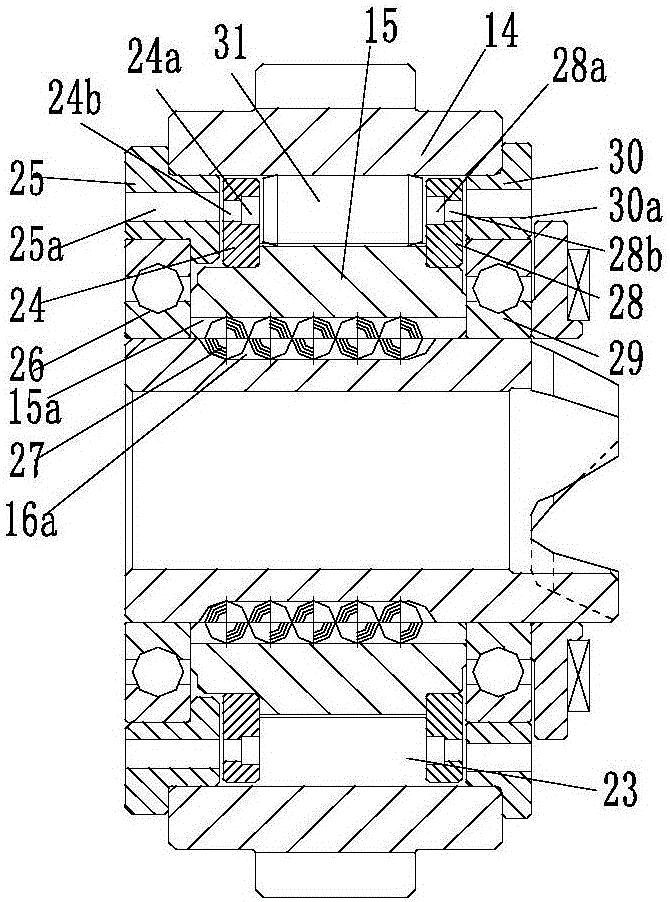

Wavy friction drive self-adaption automatic gearbox for electric cars

The invention discloses a wavy friction drive self-adaption automatic gearbox for electric cars. The gearbox comprises a box, a driving shaft, a slow-gear driving mechanism and a mechanical intelligent self-adaption variable-speed assembly. A wavy friction face friction driving pair is adopted for the friction faces of a drive friction disc and a driven friction disc of the mechanical intelligent self-adaption variable-speed assembly. One end of the driving shaft extends out of the box, and power is transmitted to a car rear axle through an output speed reduction mechanism. The wavy friction drive self-adaption automatic gearbox is of a disengaged and engaged structure by means of the friction discs, has the beneficial effect of flexible response, and is small in axial dimension. Meanwhile, due to embedment of an annular protrusion and an annular groove, with the wavy radial sections, of the friction faces, joint of the friction faces is dispersed, not only the coaxiality of the drive friction disc and the driven friction disc is ensured, but also the friction faces are enlarged, and good driving is maintained on the condition of limited elastic force; and the engagement and disengagement flexibility can be ensured, the driving precision is improved, and the wavy friction drive self-adaption automatic gearbox is suitable for the field of electric cars.

Owner:INST OF OPTICAL MASCH CHONGQING CITY

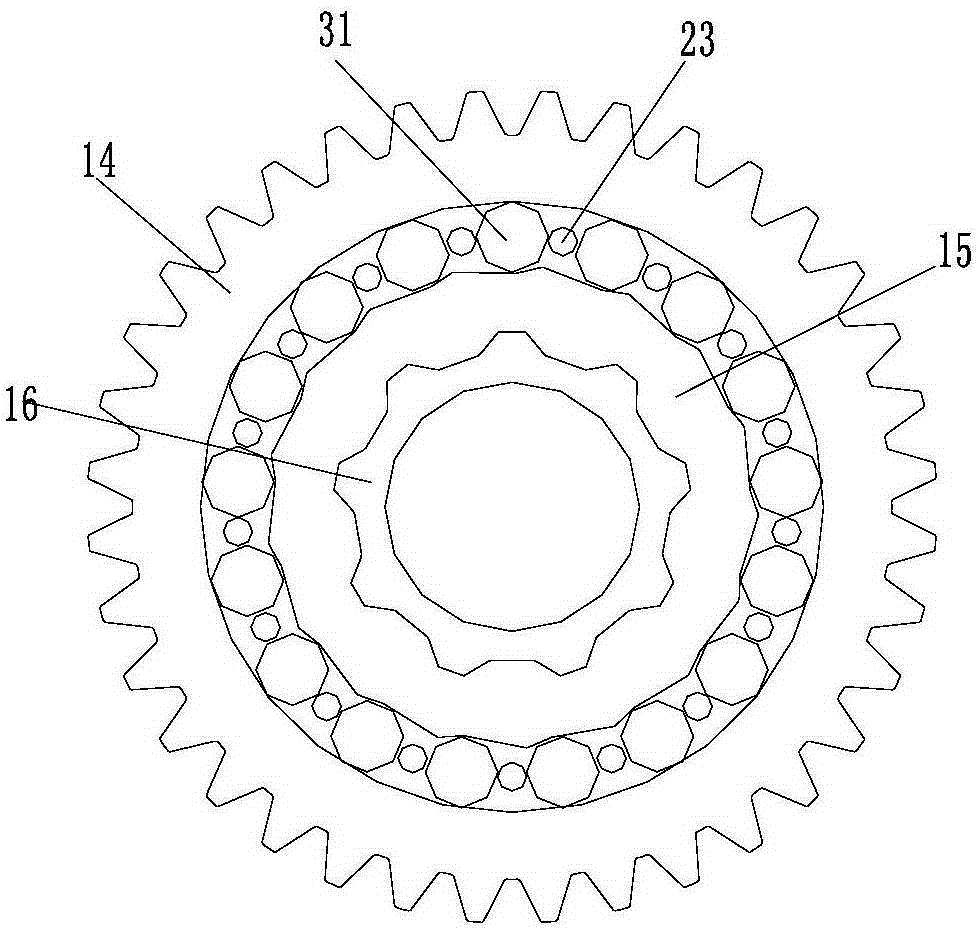

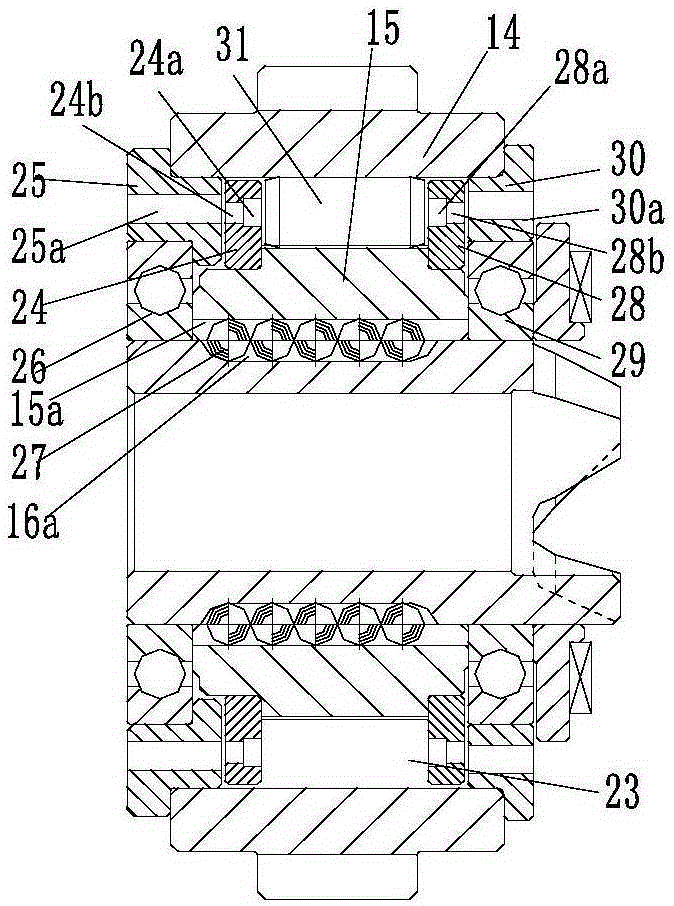

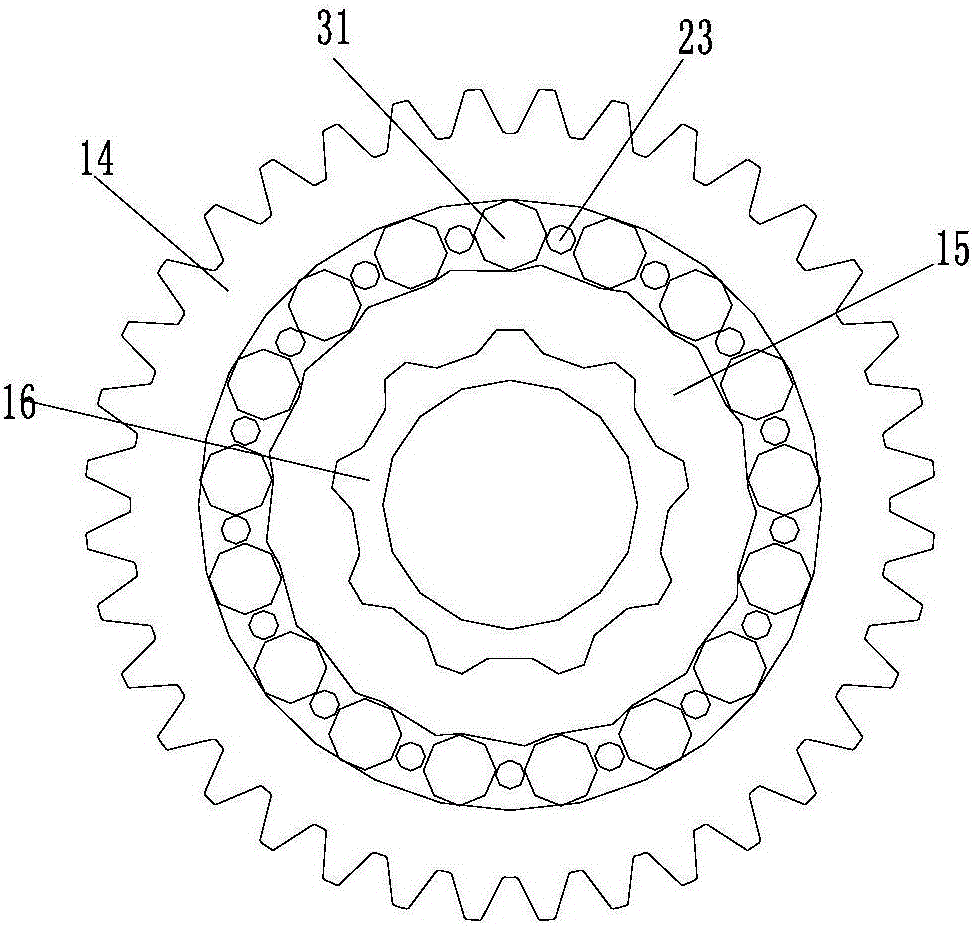

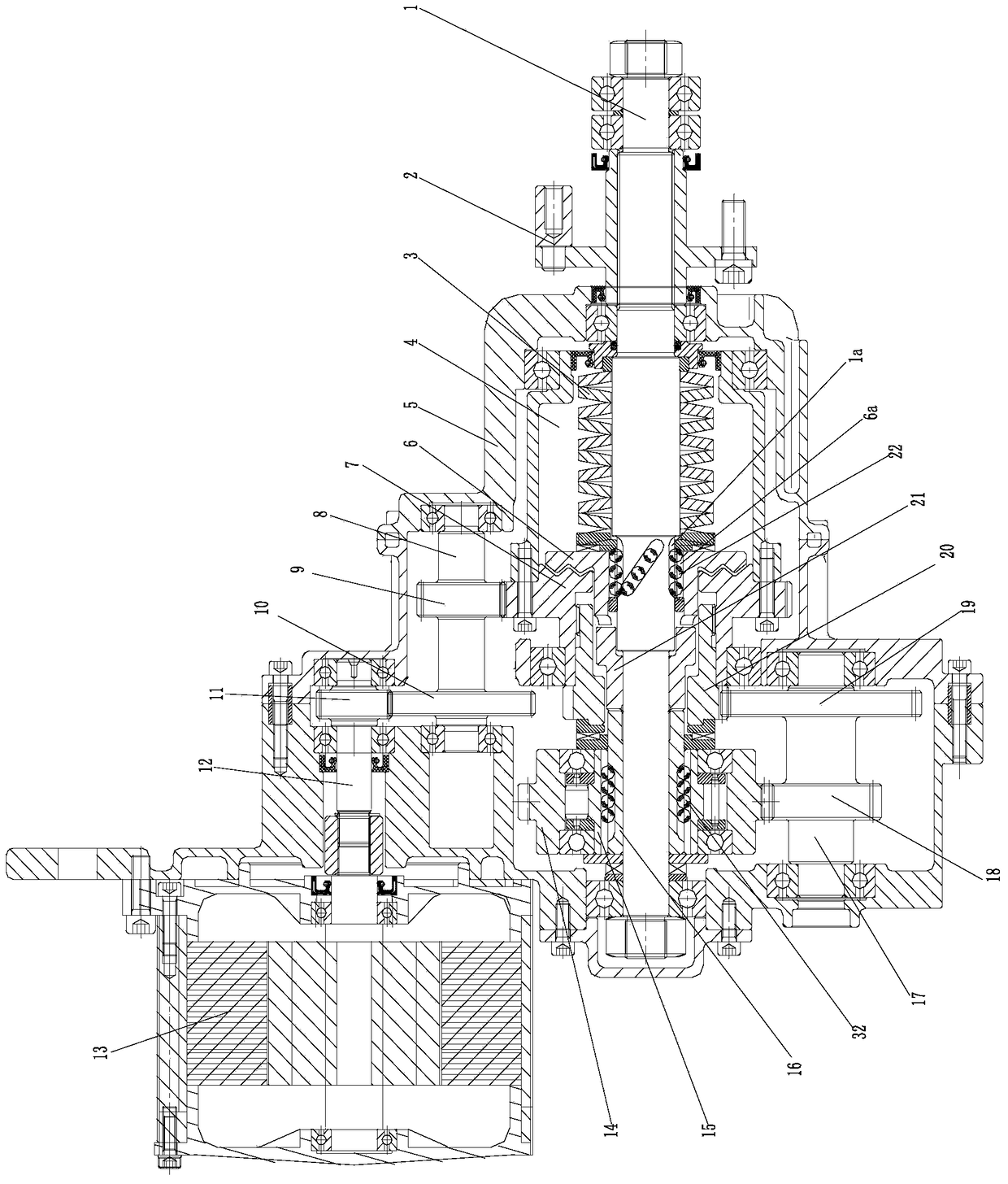

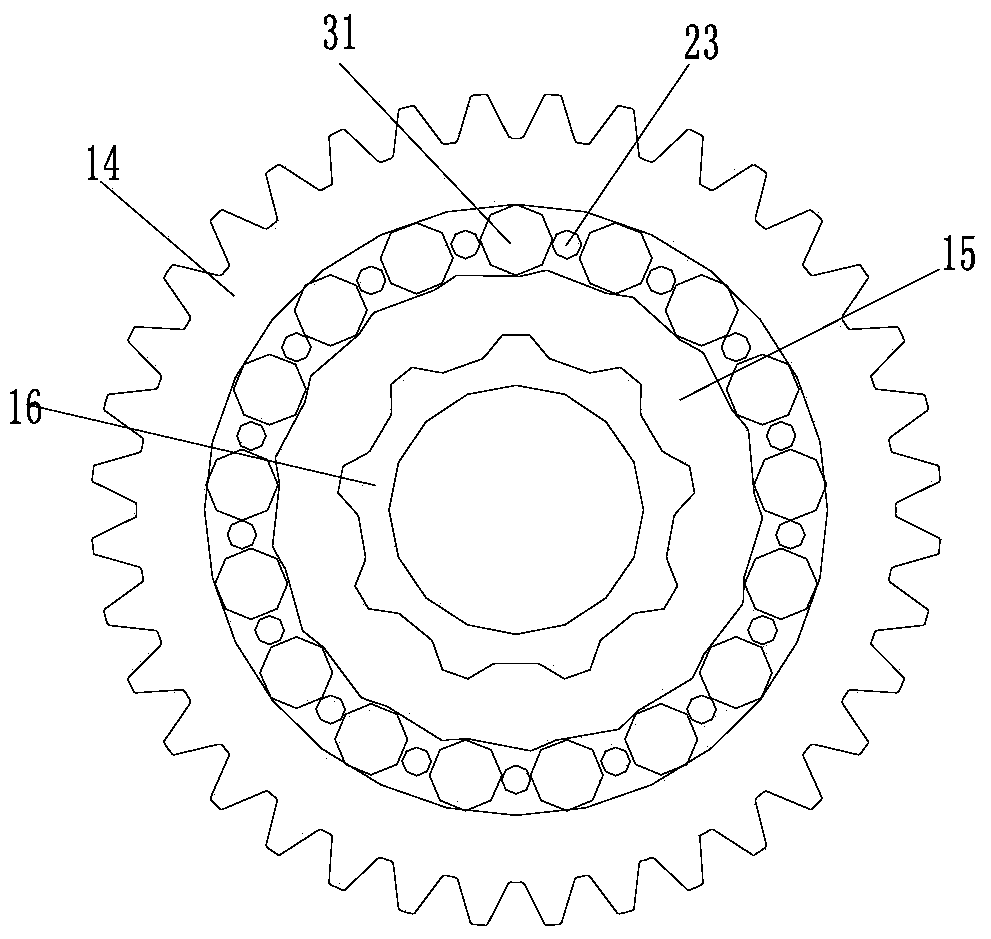

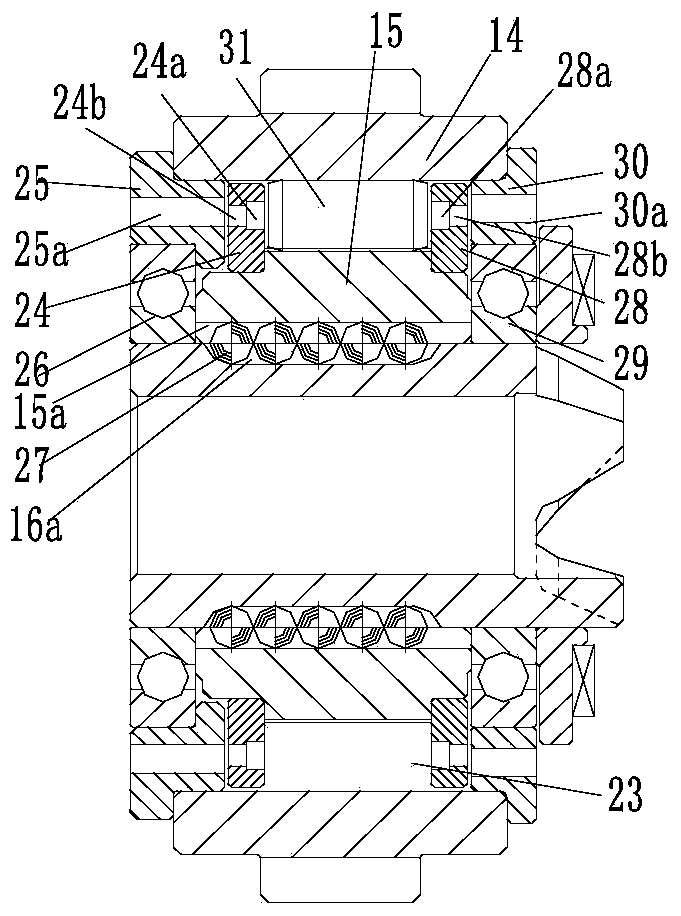

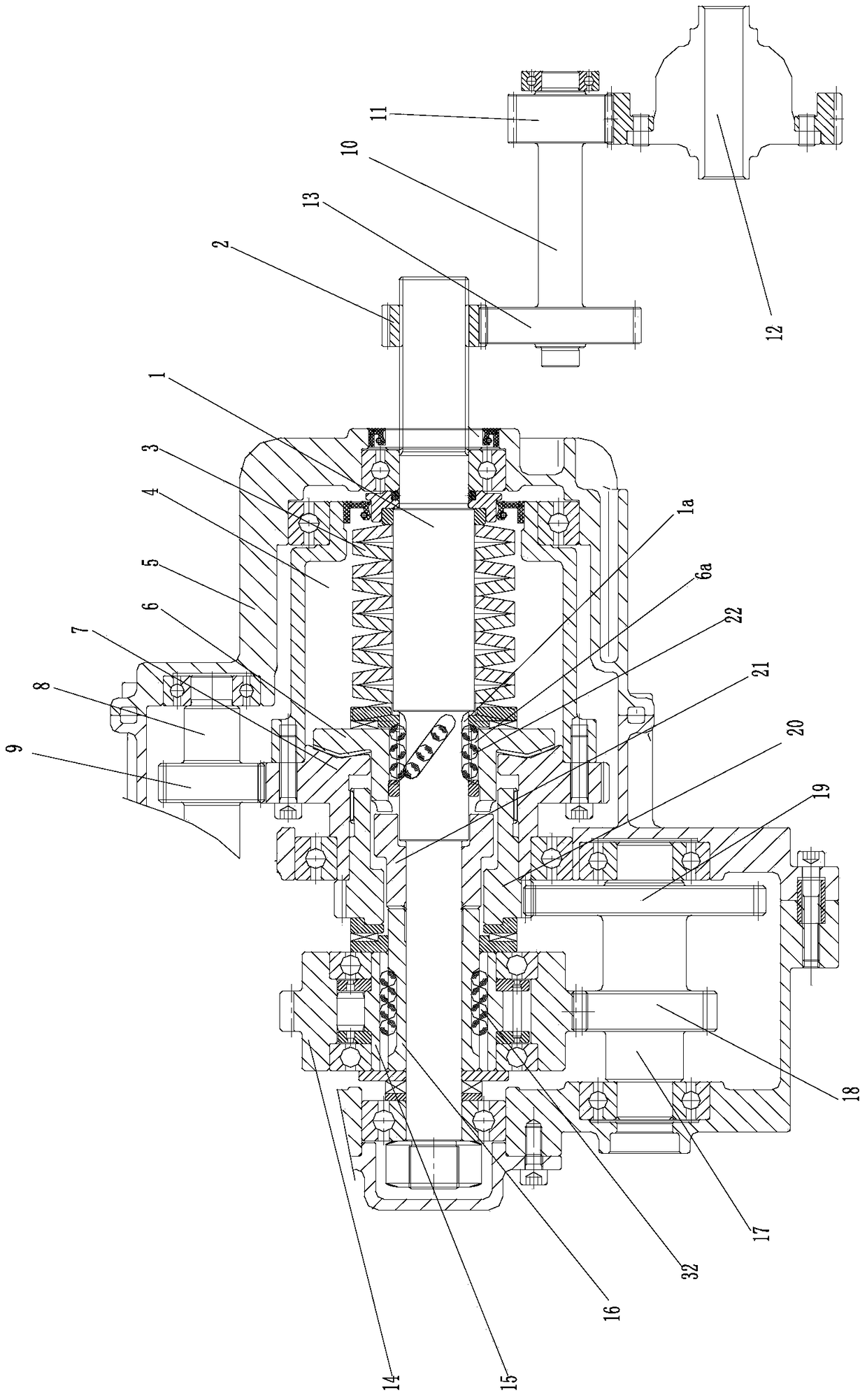

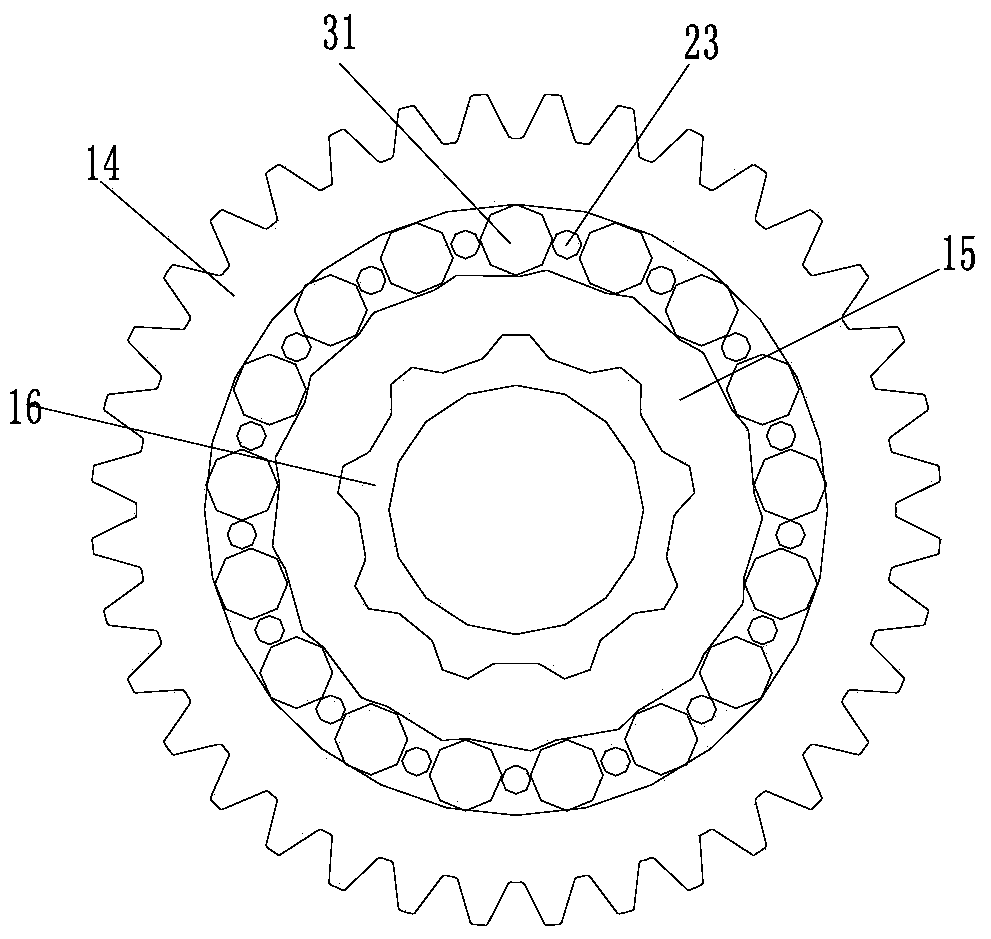

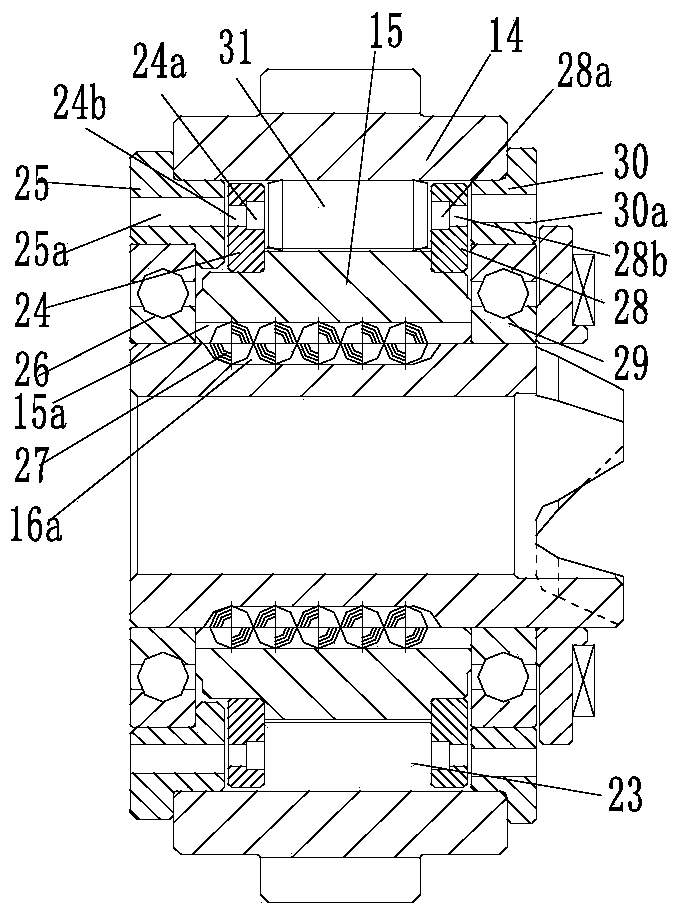

Self-adaptive automatic speed change drive assembly adopting spiral wavy friction transmission for electric motorcycle

ActiveCN105151217ASmooth load changeGuaranteed uptimeWheel based transmissionGearboxesDrive shaftEngineering

The invention discloses a self-adaptive automatic speed change drive assembly adopting spiral wavy friction transmission for an electric motorcycle. The self-adaptive automatic speed change drive assembly comprises a box body, a transmission shaft, a slow-gear transmission mechanism and an intelligent mechanical self-adaptive speed change assembly adopting wavy friction transmission. According to the slow-gear transmission mechanism, the inner ring of an overrun clutch is sleeved with a transmission shaft sleeve and the inner circle of the inner ring is provided with a spiral cam matched with the transmission shaft sleeve. An output structure of the spiral cam is adopted in the inner ring of the overrun clutch and arranged on the transmission shaft sleeve, so that an end face cam is omitted, and the spiral cam is good in smoothness and can sensitively make a response to resistance; and multi-cam transmission is possible for the overrun clutch, wavy friction transmission is adopted for guaranteeing flexibility and stability of disengagement and engagement of friction transmission, the axial size of a speed changer is reduced, the drive assembly is suitable for hubs and the like, and good smoothness and high transmission accuracy are acquired in the speed change process.

Owner:SOUTHWEST UNIVERSITY

Auxiliary equipment for honey pomelo grafting

PendingCN113099865AReduce the possibility of accidentsAct as a supportGraftingCultivating equipmentsFruit treeEngineering

The invention relates to auxiliary equipment for honey pomelo grafting. The auxiliary equipment is characterized in that the lower end of a base is connected with the existing ground, and a supporting device is arranged at the upper end of the base. Through cooperation of T-shaped rods, sliding blocks, discs, gears, cylindrical rods and hoops, fruit trees needing to be grafted can be supported and fixed, the situation that the grafting effect is poor or even fails due to shaking of fruit trees in the grafting process is avoided, the possibility that accidents occur due to the fact that the fruit trees are manually supported in the grafting process is reduced, and through cooperation between first springs and sponge pads, and damage to shells of the fruit trees can be avoided when the fruit trees are supported and fixed through hoops.

Owner:吉安井冈农业园艺科技有限公司

Auxiliary fitness equipment

PendingCN111494896AGuaranteed fitness effectGood for leg clampingGymnastic exercisingGear wheelControl engineering

Owner:程黎杰

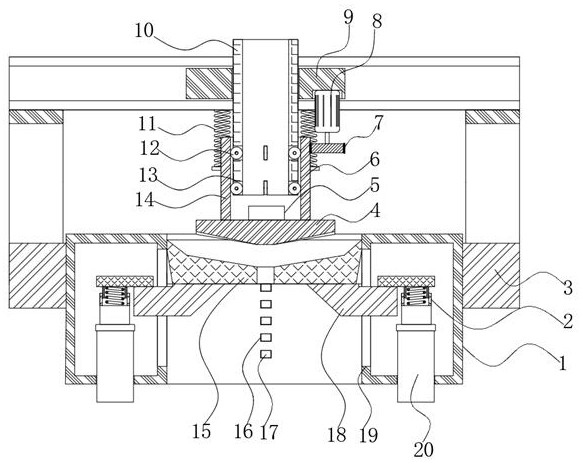

Quartz raw material accurate grinding treatment equipment

The invention belongs to the technical field of quartz processing, particularly relates to quartz raw material accurate grinding treatment equipment, and provides the following scheme aiming at the problem that an existing accurate grinding treatment mechanism is easy to cause ore blockage: the quartz raw material accurate grinding treatment equipment comprises a base which is internally provided with a cavity and is integrally of an annular structure, and the middle of the base is slidably connected with a retainer plate; the lower surface of the retainer plate is provided with a jacking mechanism and a self-locking mechanism which are symmetrical to each other, the upper surface of the retainer plate is of a conical groove structure, a discharging hole is reserved in the middle of the retainer plate, a supporting frame is fixed to the position, close to the top end, of the outer wall of the circumference of the base, and two channel steel beams with opposite openings and parallel to each other are fixed to the top end of the supporting frame. When the quartz ore fine grinding device is used and the conical pressing plate performs fine grinding on quartz raw ore in the material supporting plate, the vibration mechanism located at the top end of the conical pressing plate vibrates the conical pressing plate at the same time, at the moment, quartz sand below the conical pressing plate can be effectively prevented from being blocked in the discharging hole, and the ore blocking possibility is reduced.

Owner:SINOTENG SILICA MATERIALS TECH (JIANGSU) CO LTD

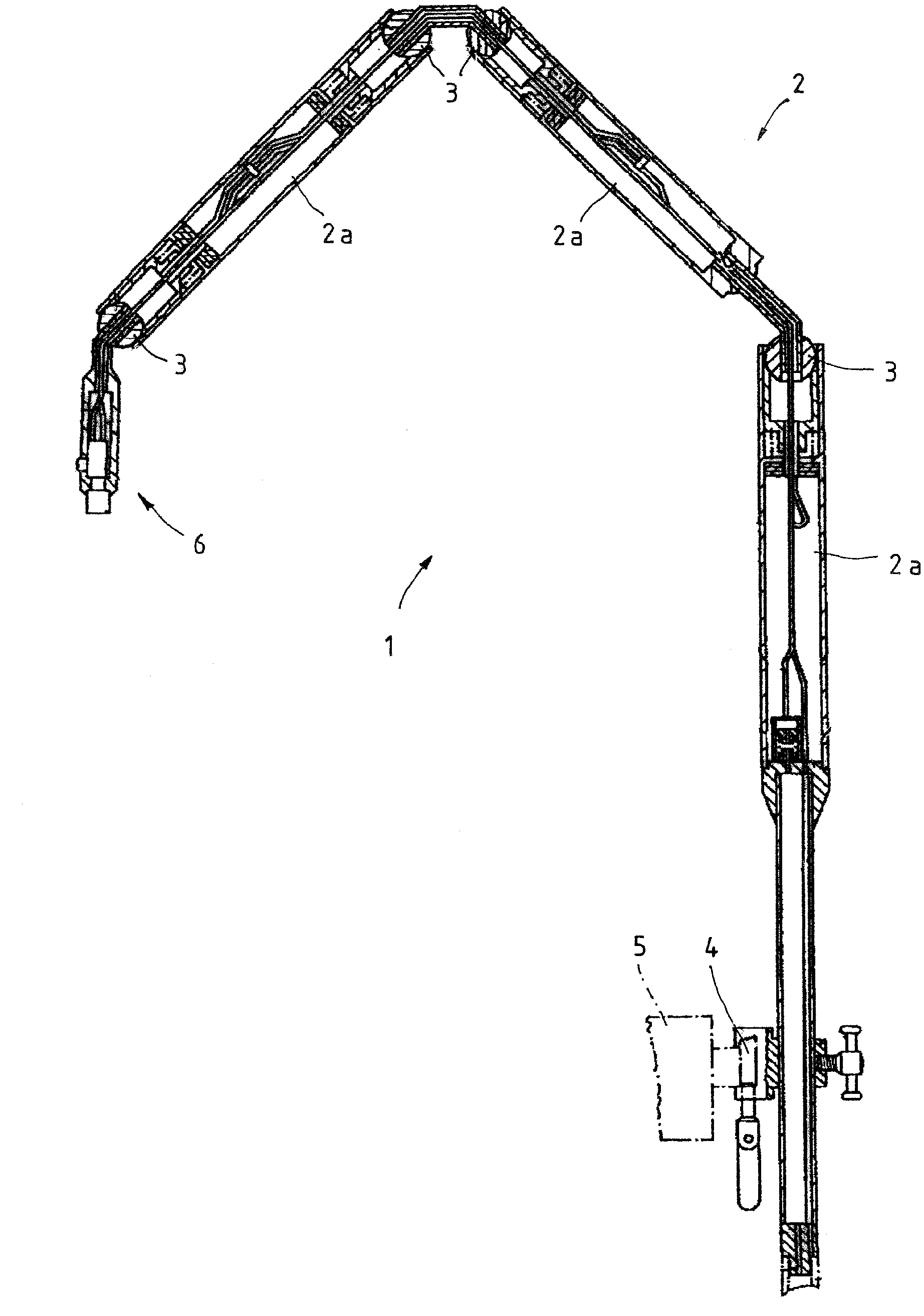

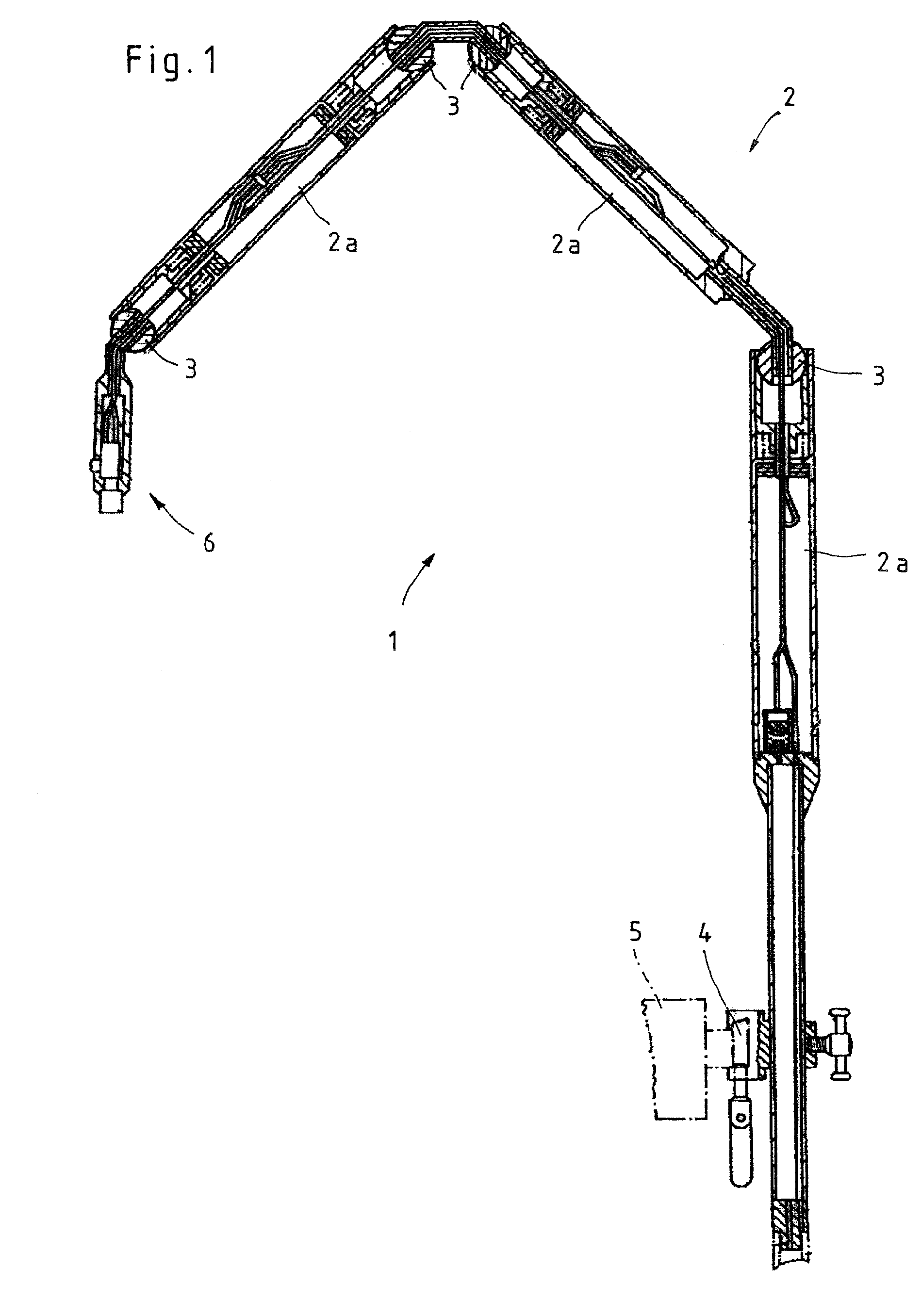

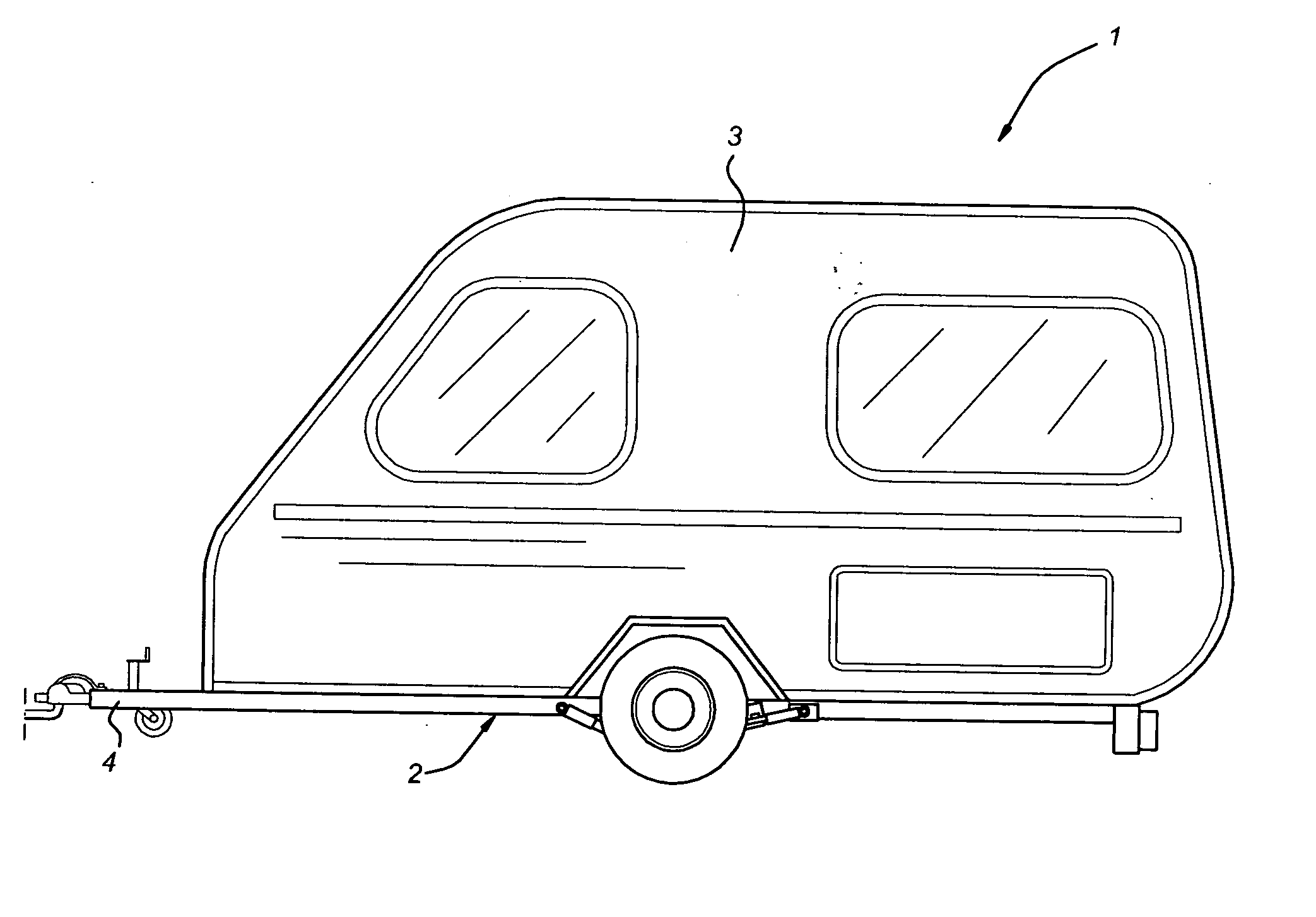

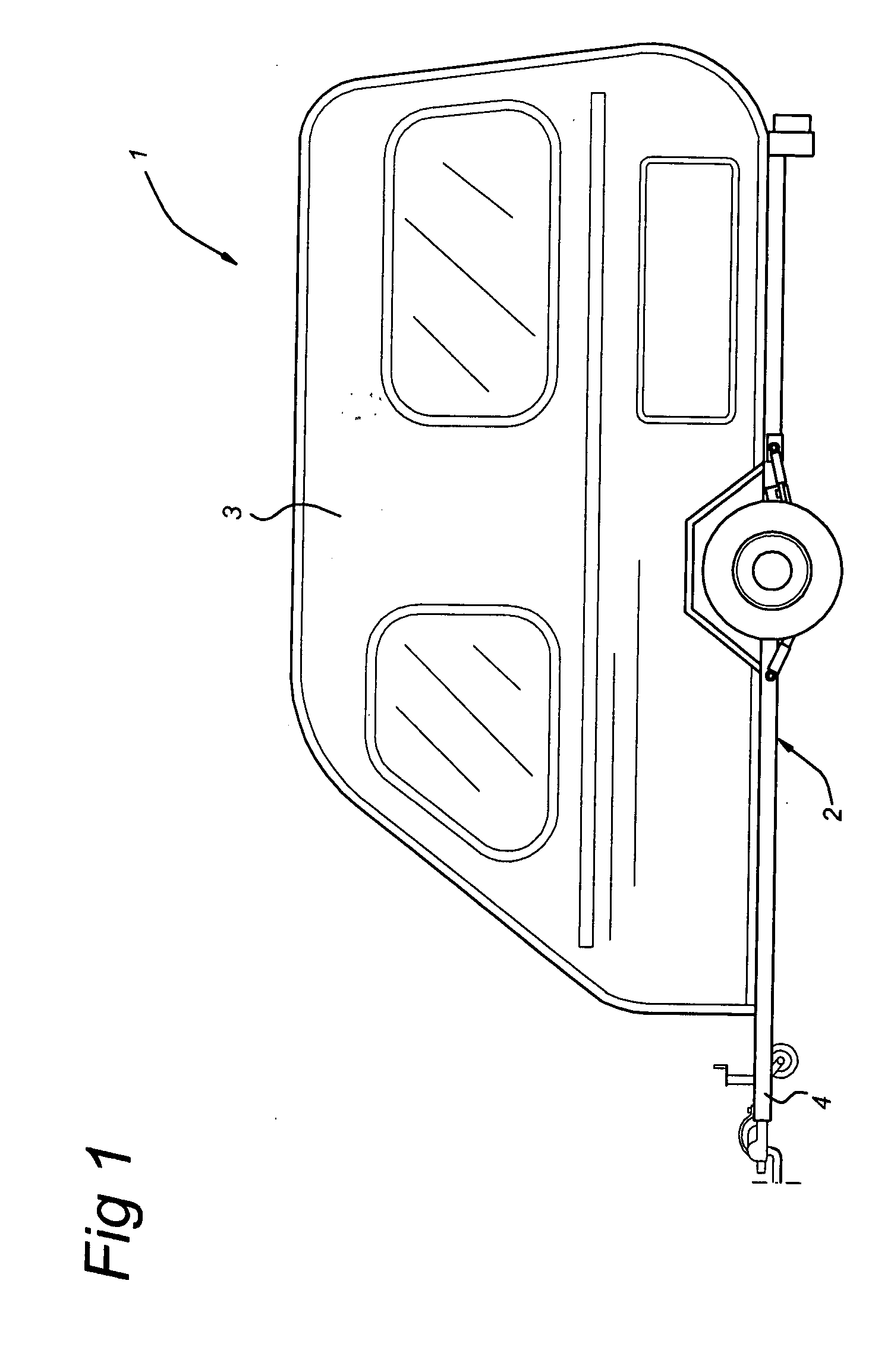

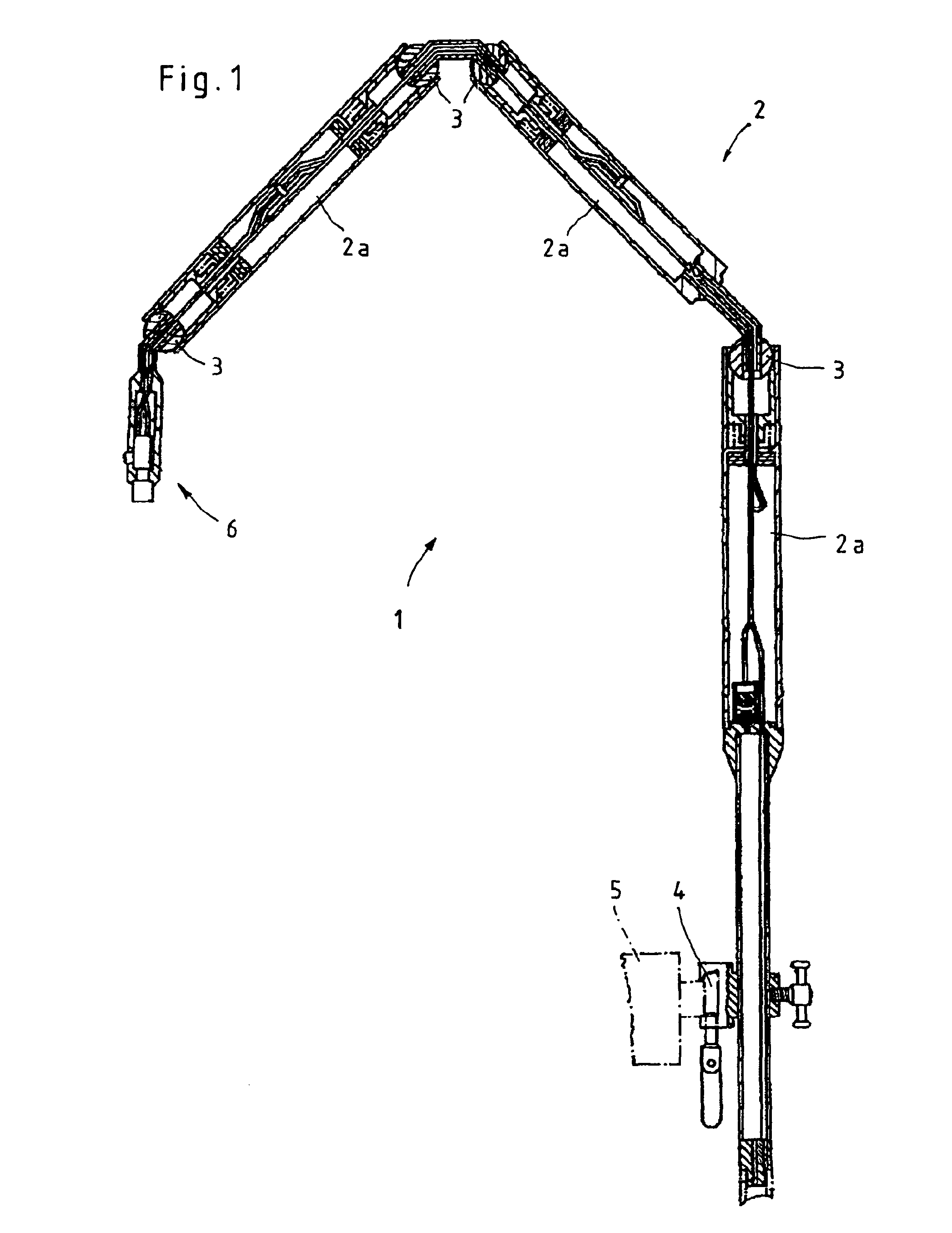

Auxiliary drive for a trailer

InactiveUS20070228811A1Avoid disadvantagesSimple engagementElectric propulsion mountingTractor-trailer combinationsLinear motionEngineering

In an auxiliary drive for a trailer such as a caravan, the drive consists of a drive unit with a gearwheel. Through linear movement of the drive unit relative to the chassis, the gearwheel can be brought into engagement with a ring gear fitted either on the brake drum of a wheel of the vehicle or on an auxiliary part such as a covering drum fitted over the brake drum. The ring gear preferably lies in a plane outside the plane bounded by the inside of the wheel.

Owner:REICH

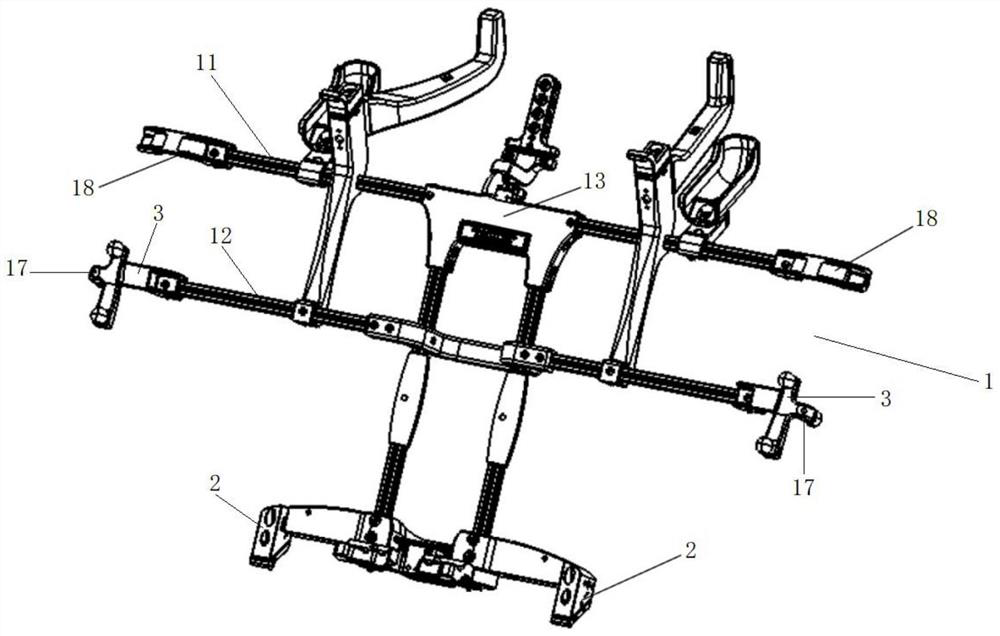

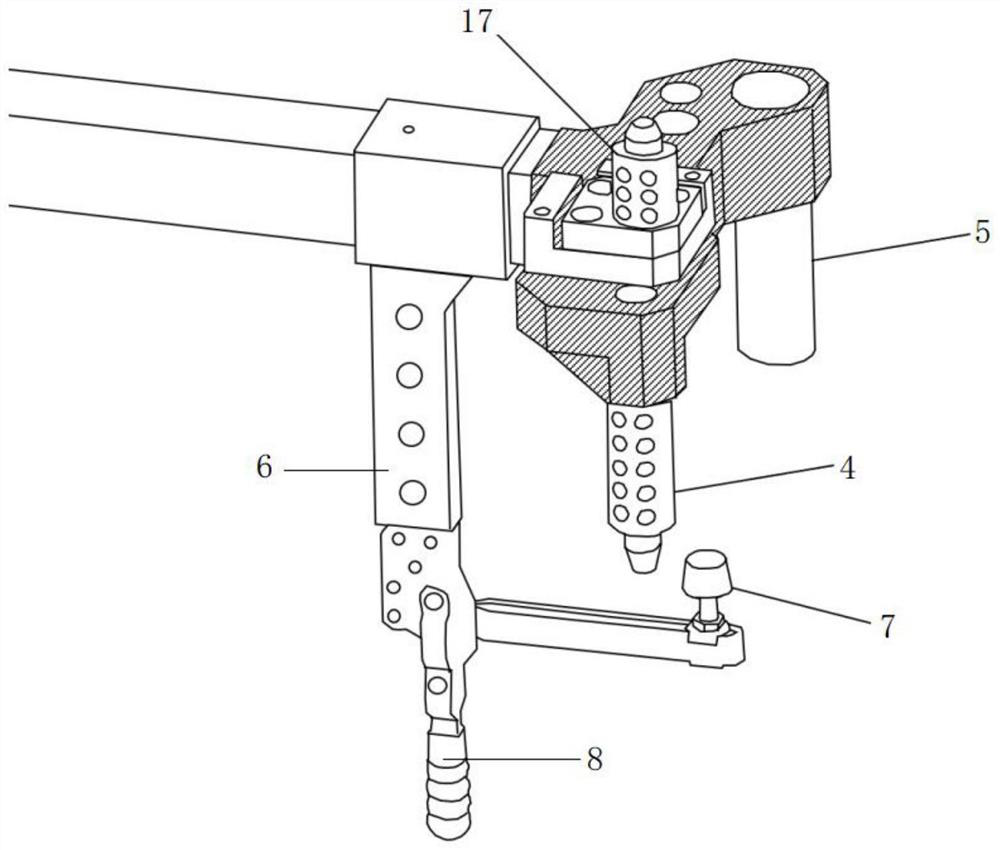

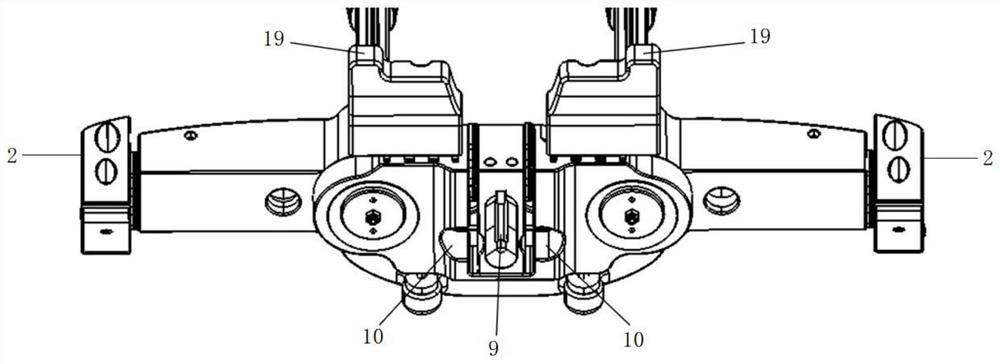

Assembly sample frame and assembly method for ensuring engagement of hatchback door lock and lock catch

PendingCN114789762AAvoid closing difficultiesAvoid issuing cardsWork holdersMetal-working hand toolsBack door

The invention discloses an assembly sample frame and an assembly method for ensuring meshing of a hatchback door lock and a lock catch. The assembly sample frame comprises a sample frame support, and the sample frame support is provided with a sample frame vehicle body fixing structure used for enabling the sample frame support to be installed and fixed on a vehicle body. A sample frame lock catch installation structure used for installing a back door lock catch is arranged on the lower portion of the side, facing the vehicle body, of the sample frame support, and a sample frame back door installation structure capable of enabling a back door to be installed and positioned on the sample frame support is arranged on the side, facing the back door, of the sample frame support. The back door lock catch is installed on the sample frame and then connected with the vehicle body, the relative installation position accuracy of the sample frame and the vehicle body is guaranteed, then the back door is installed on the basis of the sample frame, the relative installation position accuracy of the back door and the vehicle body is guaranteed, the relative position accuracy of the back door and the back door lock catch is guaranteed, and the meshing state of the back door lock and the back door lock catch is guaranteed. And the problems of difficulty in closing the back door, jamming, abnormal sound and the like are avoided. And station arrangement is optimized, and investment and working hours of tools, tightening tools and manpower are reduced.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

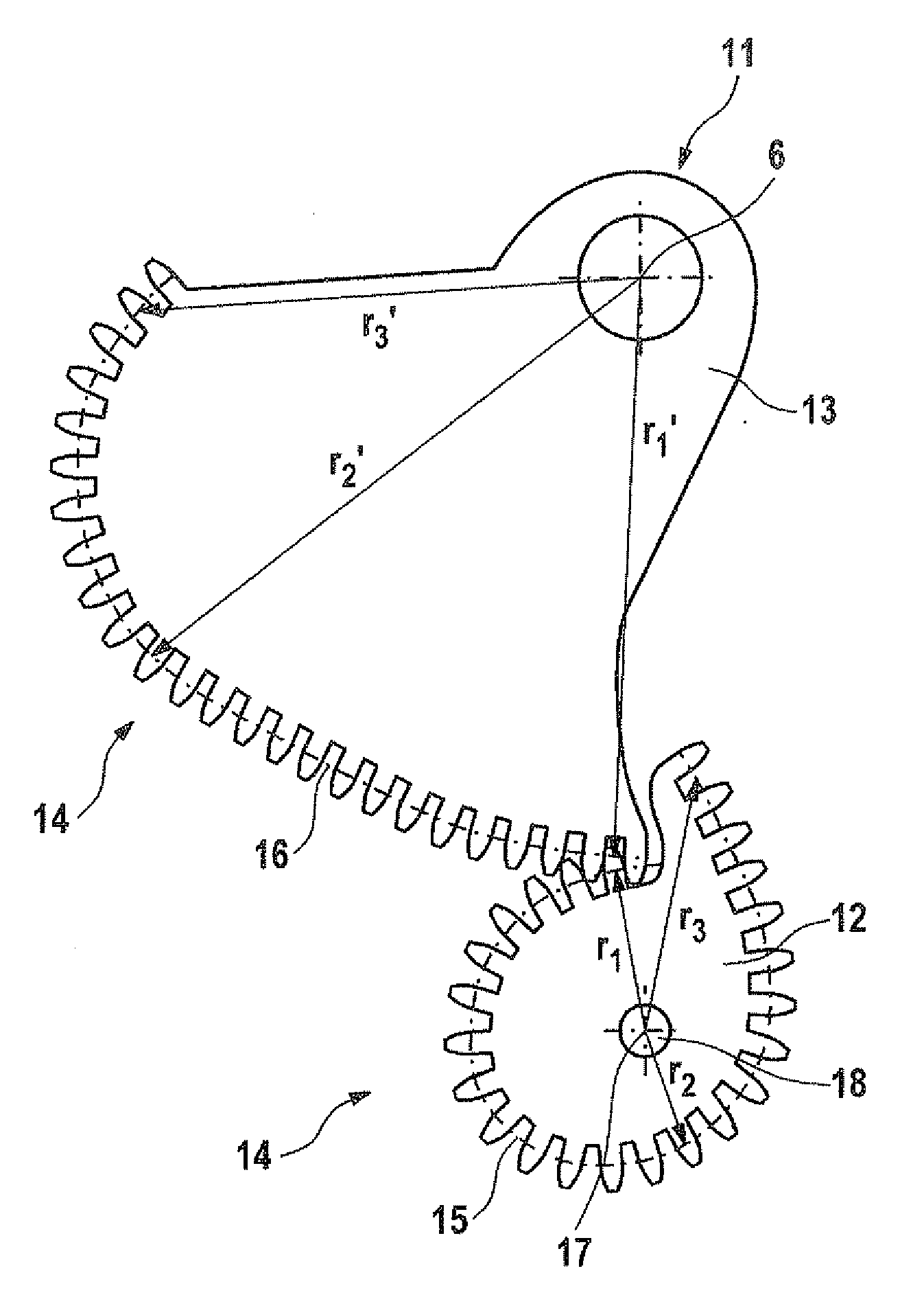

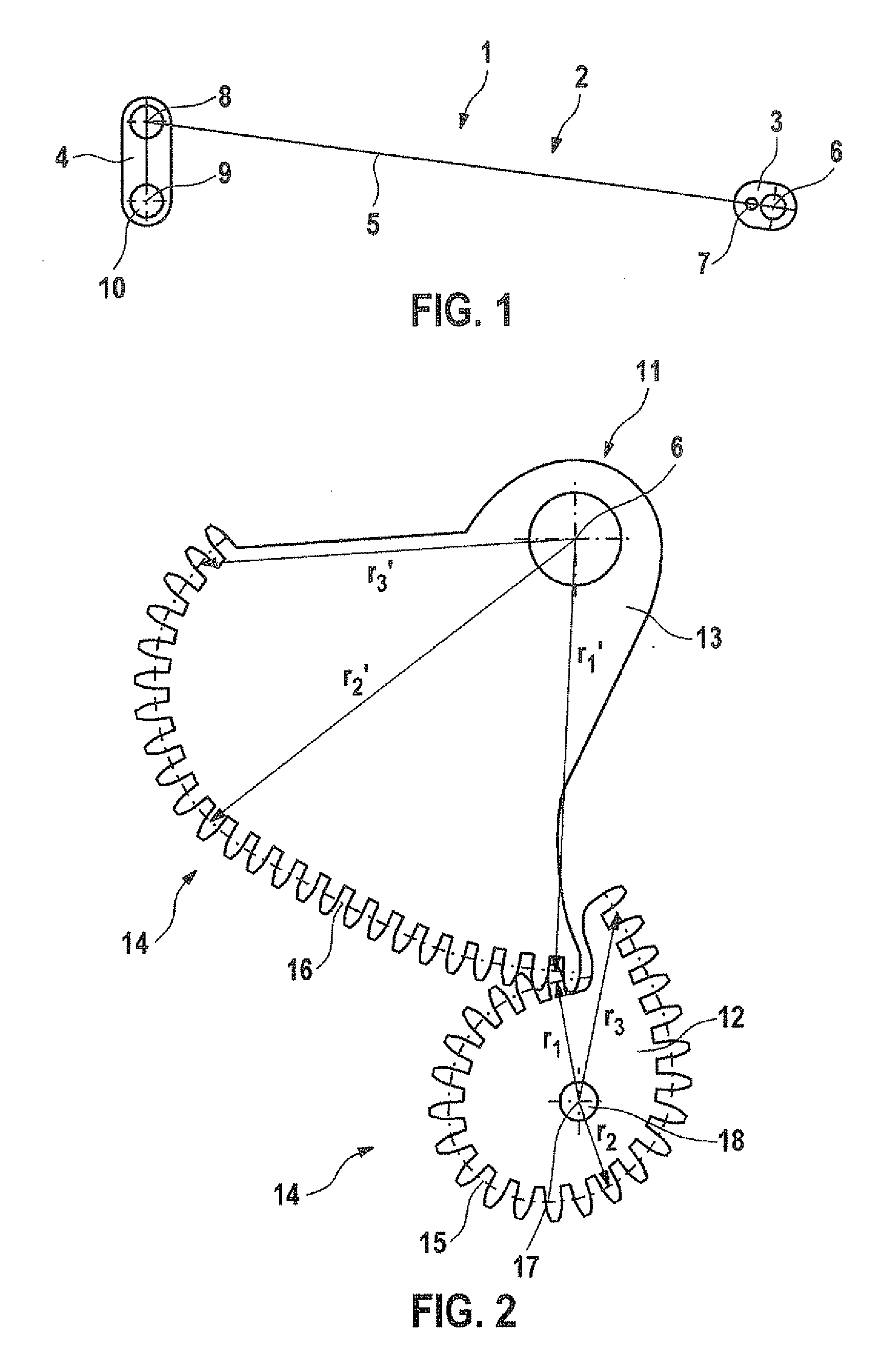

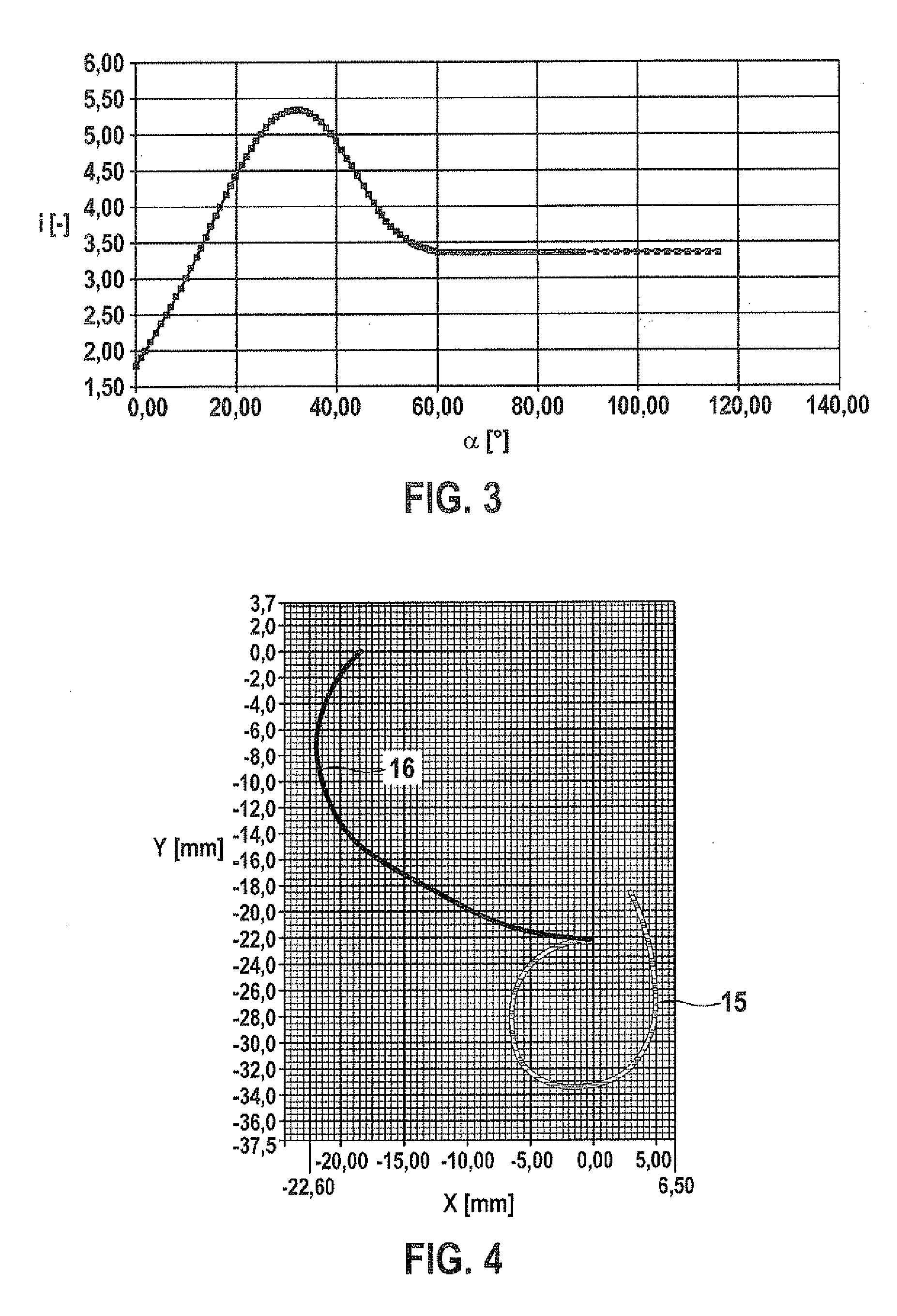

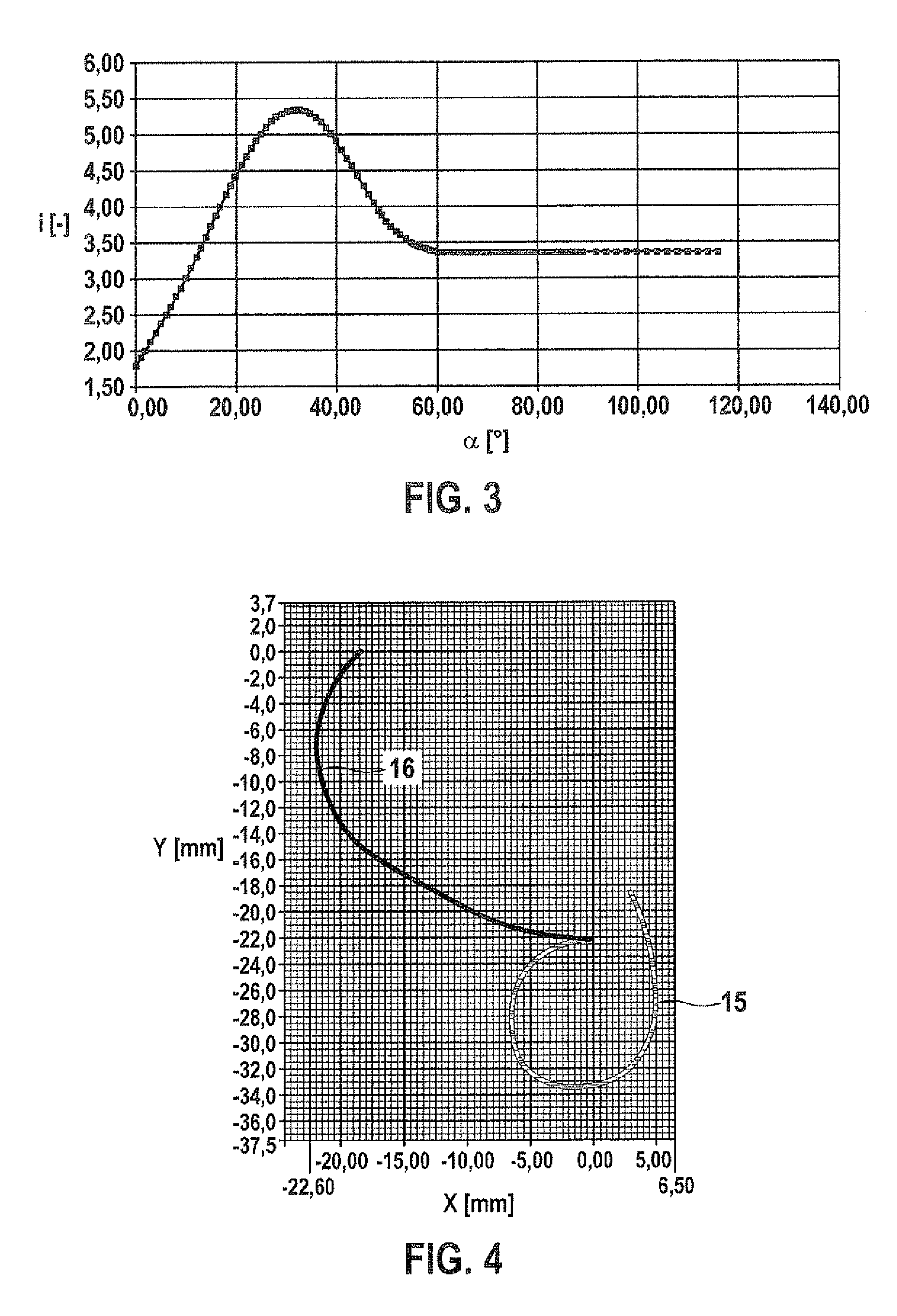

Transmission System and Exhaust Gas Turbocharger

InactiveUS20130028714A1Avoid excessShorten adjustment timeInternal combustion piston enginesWind motor controlTurbochargerCoupling

A transmission system for an adjusting device, of a waste gate of an exhaust gas turbocharger, including a four bar coupling mechanism, a driver arm operatively connected to a drive via a transmission, an output arm and a coupler, operatively connecting the driver and output arms, the transmission having a driving gear, assigned to the drive, and a driven gear, assigned to the driver arm and interacting with the driving gear having a rolling curve radius, which changes over the circumference, the driven gear having a rolling curve radius running complementary to the former. The rolling curve radii is selected in an angle of rotation range about the extended position of the coupling to form at least in regions a first transmission ratio and outside the angle of rotation range to is form at least a second transmission ratio larger than the first ratio. Also described is an exhaust gas turbocharger.

Owner:ROBERT BOSCH GMBH

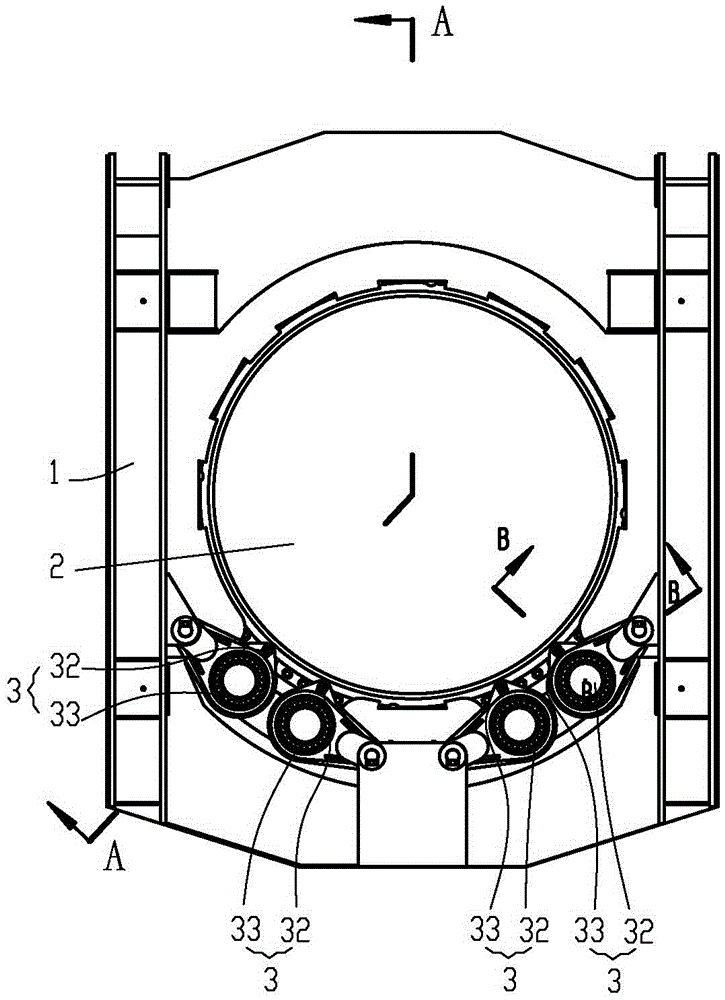

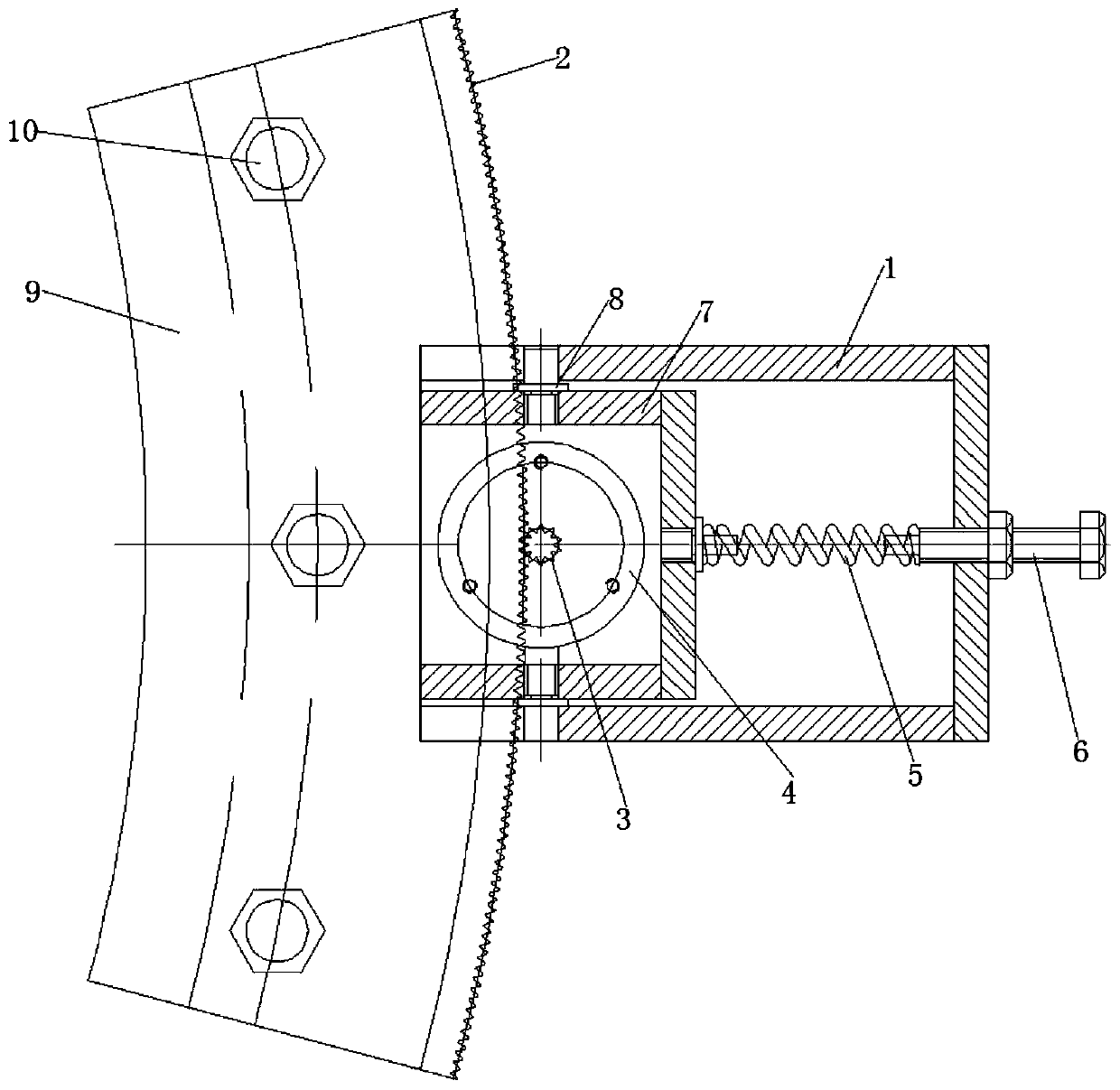

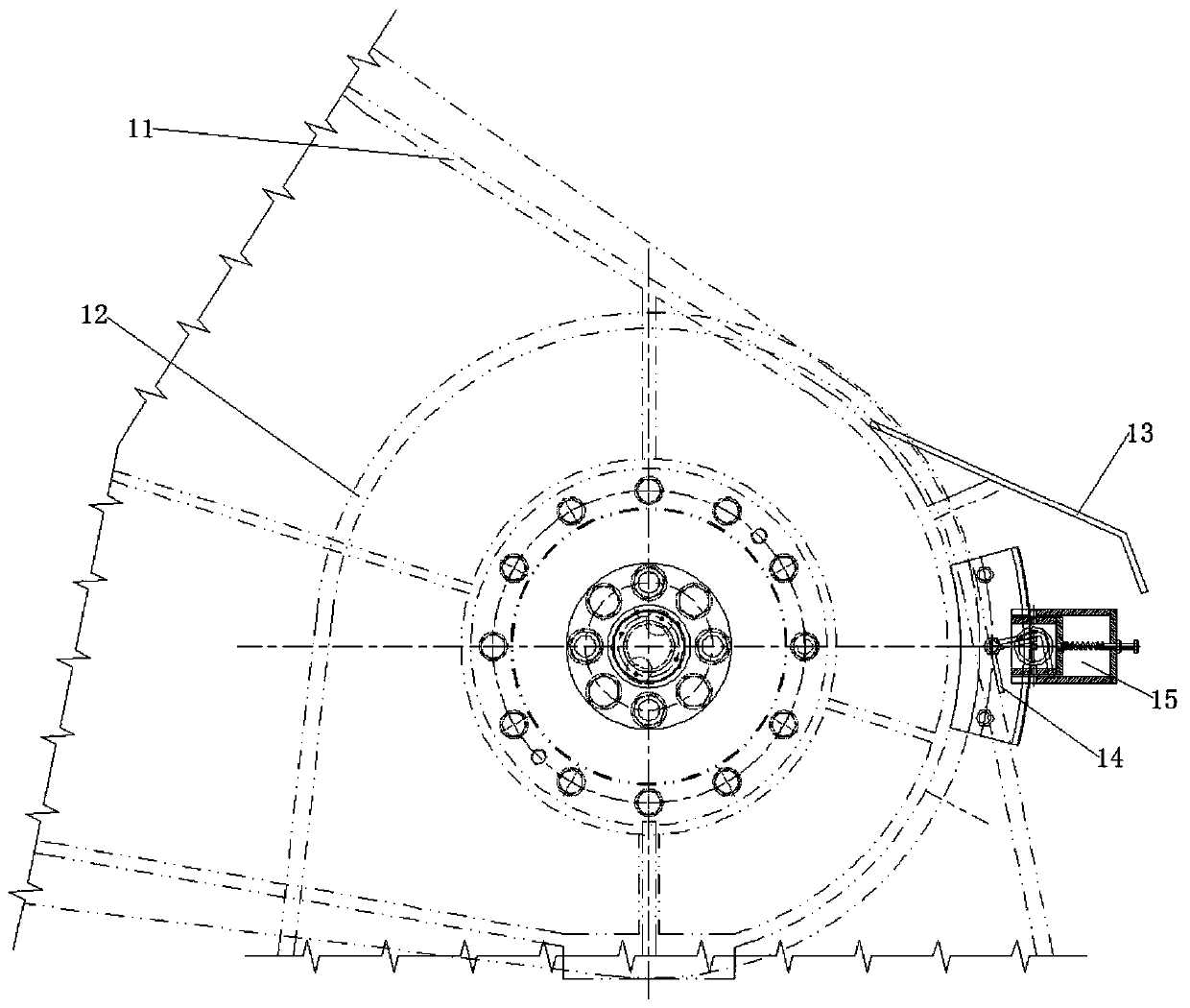

Rotation device

The invention relates to the field of engineering equipment, and specifically relates to a rotation device. The rotation device comprises a support device, a drive device, a rotation device and a large gear, wherein the drive device is connected with the support device; the rotation device is connected with the support device; the large gear is connected with the rotation device; the large gear comprises a circumferential surface; the drive device comprises a pinion and a rolling mechanism; the pinion is engaged with the large gear; and the rolling mechanism moves along the circumferential surface of the large gear. In this way, instable working caused by separation of the pinion and the large gear due to the engagement can be avoided, an impact is avoided, a weight is reduced, the stress condition of the engagement of the pinion and the large gear is improved, the service life is prolonged, and the purposes of reducing cost and increasing efficiency are achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Angle measuring device and equipment with the same

PendingCN110793469AEasy to useAvoid over-tighteningUsing optical meansMechanical measuring arrangementsGear wheelControl theory

The invention relates to the technical field of angle measurement, in particular to an angle measuring device and equipment with the same. The angle measuring device includes: a first support; a driving gear suitable for being fixedly connected with a rotating part of to-be-detected equipment; a driven gear meshed with the driving gear; an encoder comprising an encoder body and an encoder rotatingshaft, wherein the encoder rotating shaft is fixedly connected with the driven gear, and the encoder rotating shaft is suitable for driving the driving gear to rotate to drive the driven gear to rotate under the driving of the to-be-detected equipment so as to drive the encoder rotating shaft to rotate relative to the encoder body; at least one elastic piece, wherein one end of the at least one elastic piece is connected with the encoder body, and the other end of the at least one elastic piece is connected with the first support. By arranging the at least one elastic piece, when the drivinggear and the driven gear are abraded and the axis deviates, the at least one elastic piece can drive the encoder to drive the driven gear to be automatically adjusted to be in the meshed state that the driven gear is matched with the driving gear, the two gears are prevented from being meshed too tightly or not tightly, and normal use of the angle measuring device is guaranteed.

Owner:HUADIAN HEAVY IND CO LTD

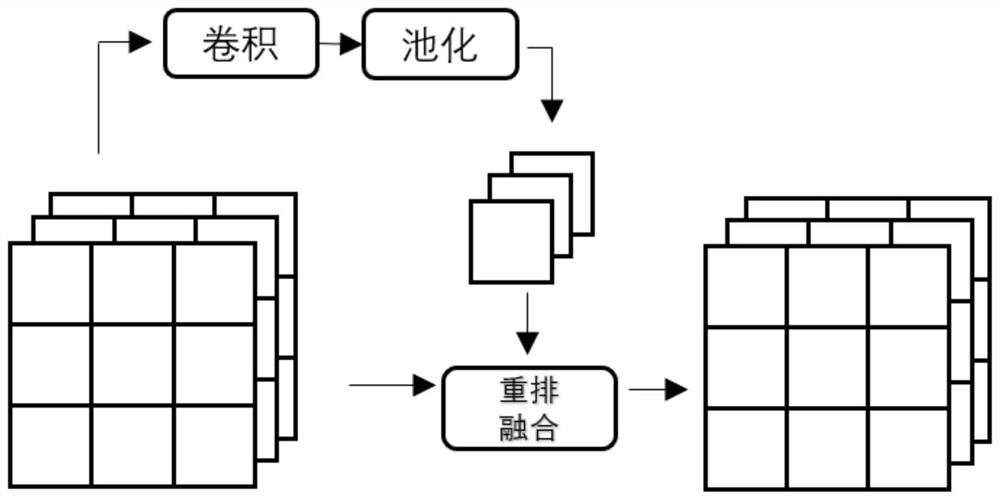

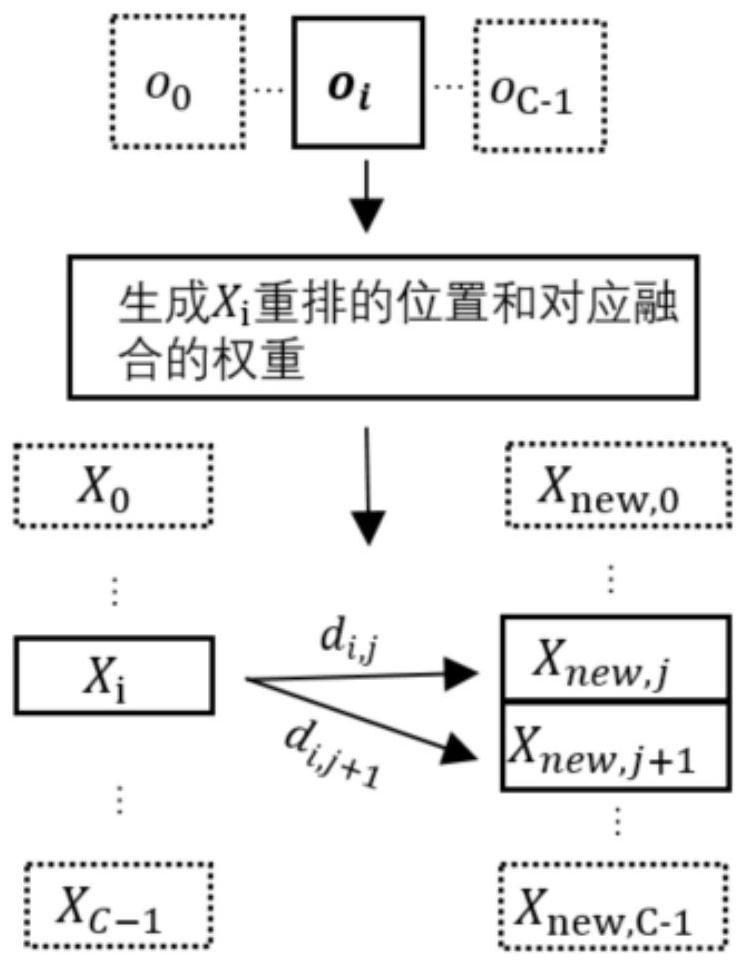

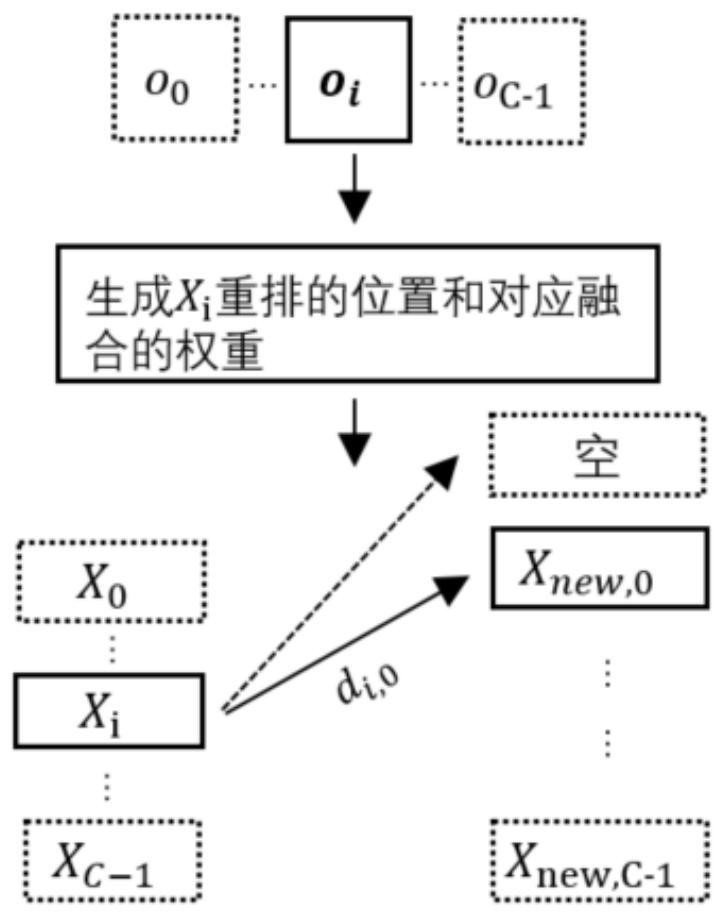

Implementation method of convolutional neural network module for enhancing channel rearrangement and fusion

PendingCN112801275AImprove the problem of insufficient integrationGuaranteed engagementCharacter and pattern recognitionNeural architecturesEngineeringNeural network nn

The invention discloses an implementation method of a convolutional neural network module for enhancing channel rearrangement and fusion. The method comprises the following steps: extracting features of a feature map of a certain level through a convolutional layer, and generating a transitional feature map; carrying out pooling on the generated transition feature map in a spatial dimension to obtain a rearrangement fusion vector with the same size as a channel; and calculating a new rearranged and fused channel and a corresponding weight by using the obtained rearranged and fused vector, accumulating a feature map of a certain channel to the new channel and an adjacent channel according to the calculated weight, traversing all channels, and obtaining a fused feature map after all channels are subjected to weighted accumulation. The module provided by the invention can be seamlessly inserted into any convolutional neural network, enhances communication of information of different channels, and can be applied to a network of image classification and a backbone network of tasks such as target detection, semantic segmentation and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

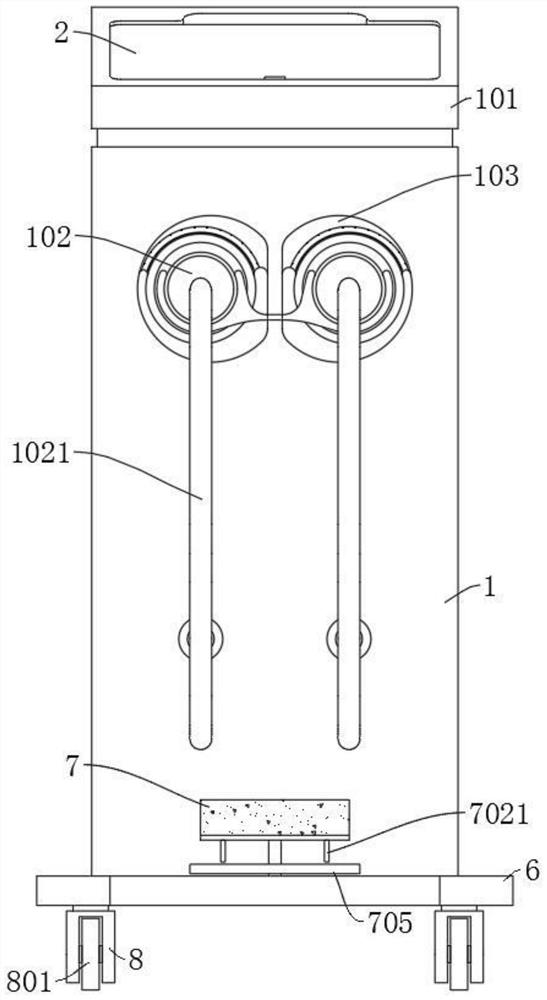

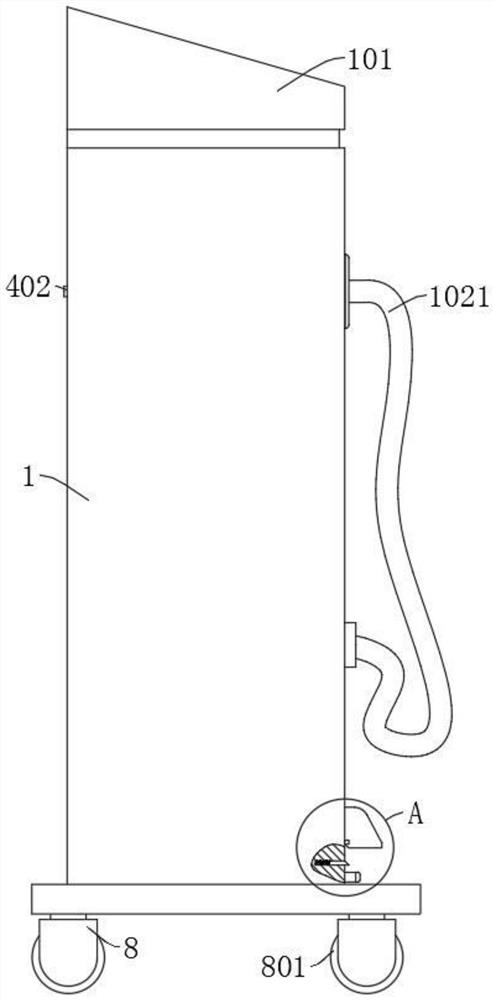

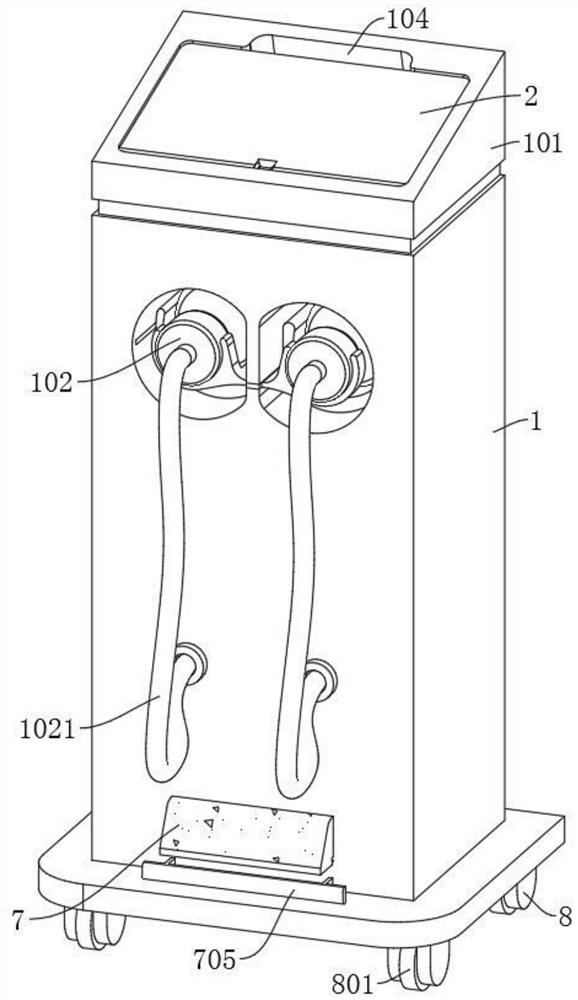

Multidirectional following type moving mechanism for fat explosion instrument and weight losing device

InactiveCN111839852AGuaranteed steering flexibilityWill not affect up and downUltrasound therapyNon-surgical orthopedic devicesDrive shaftControl theory

Owner:吴岩

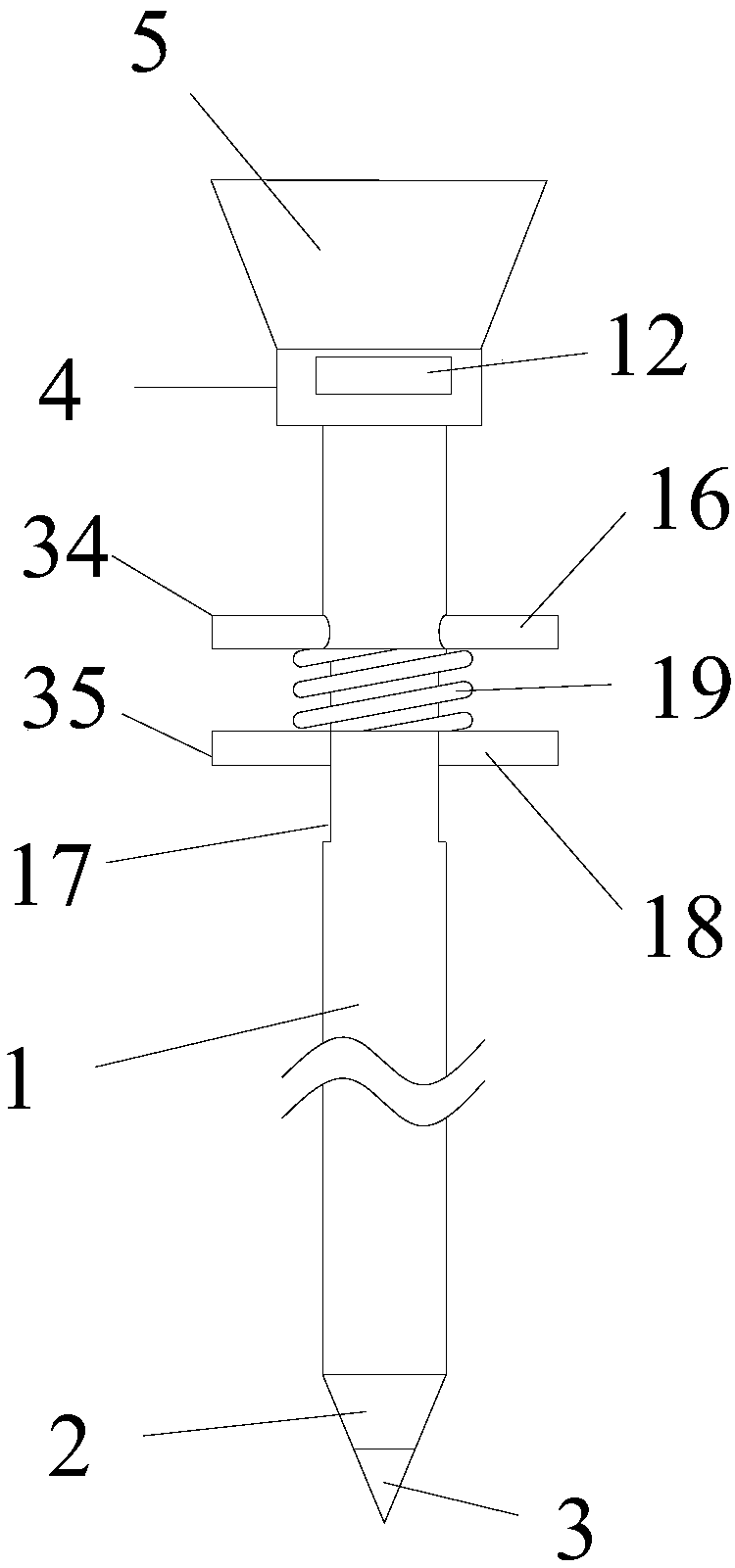

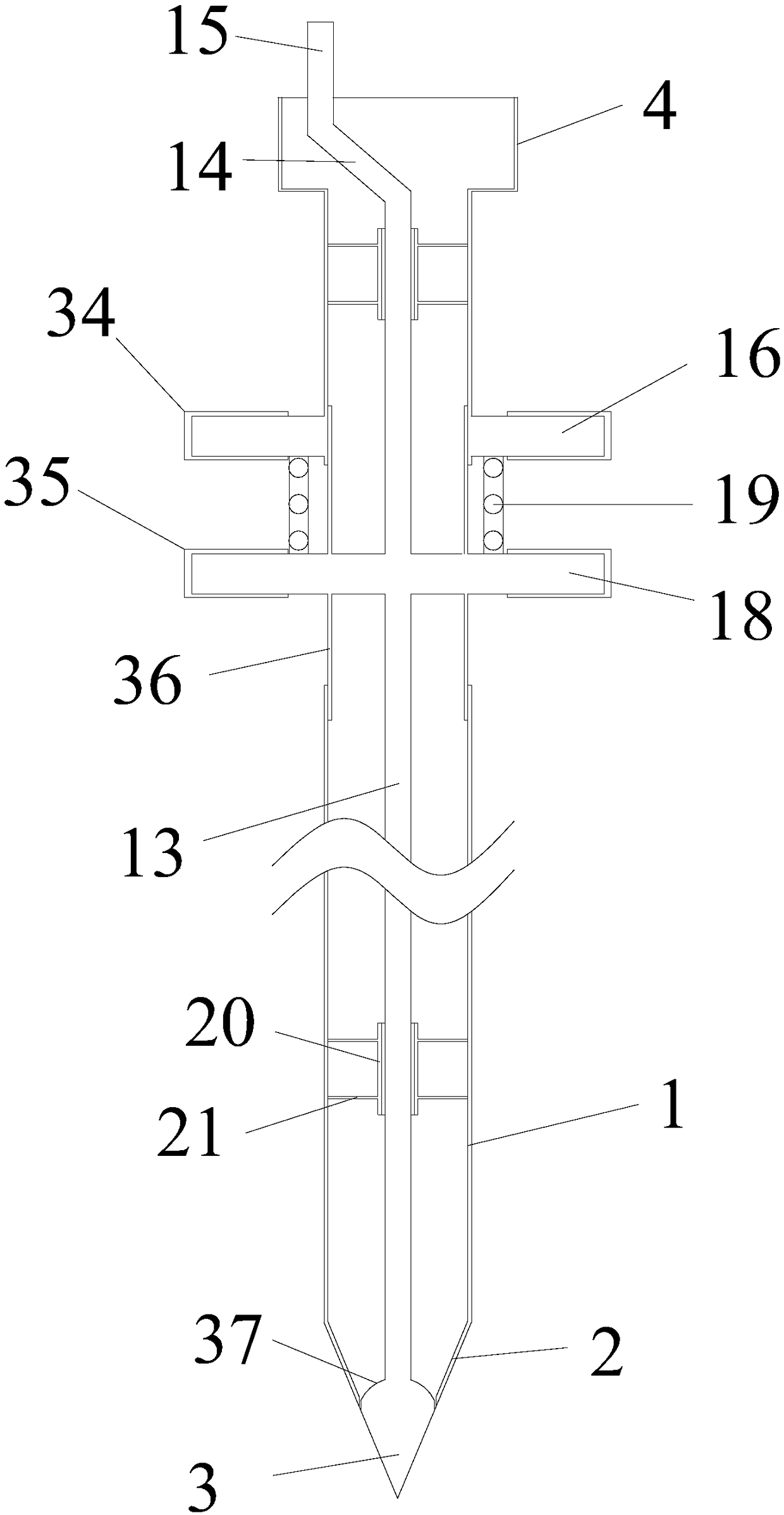

Field reseeding tool

PendingCN109258013AWide range of reseedingReduce labor intensitySeed depositing seeder partsHand sowing implementsRound tableEngineering

The invention discloses a field reseeding tool, which comprises a seeding cylinder, wherein the bottom surface of the seeding cylinder is provided with a round table shell and a conical drill bit, thetop surface of the seeding cylinder is provided with a support table, the top surface of the support table is provided with a seeding hopper, the side face of the seeding hopper is provided with a support rod arranged at the edge of the top surface of the support table, the bottom face of the seeding hopper is provided with a rectangular discharge port, the opposite side faces of the rectangulardischarge port are provided with round through holes, the side face of one round through hole is provided with a round groove, the round groove is internally provided with an annular baffle fitting thereto, the inner round side face of the annular baffle is provided with a stop block, a seeding adjustment device is penetrated between the corresponding round through hole and the annular baffle, theseeding adjustment device is fixed on the side wall of the support table, the top end of the cone drill bit is provided with a support column located in the seeding cylinder, the top end of the support column is provided with a correcting rod, and the top end of the correcting rod is provided with a straight rack. The field reseeding tool greatly improves the reseeding speed and efficiency of a laborer.

Owner:王芳

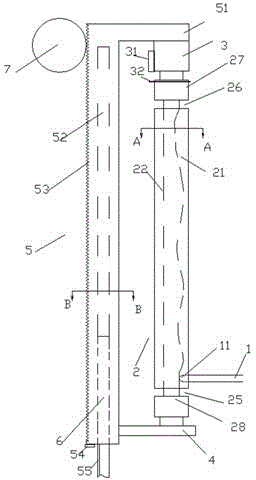

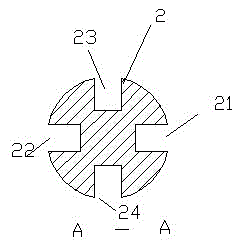

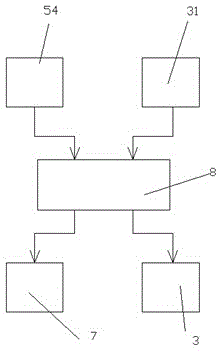

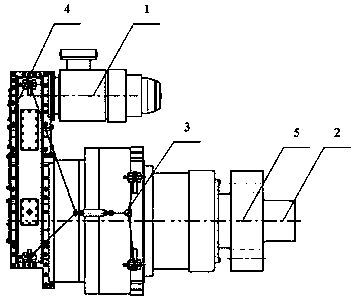

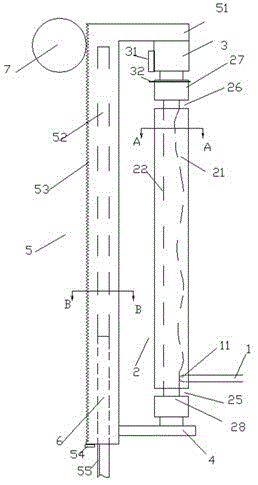

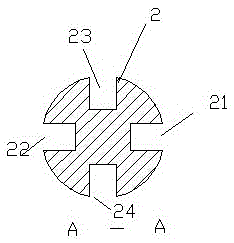

Tool profiling control system

InactiveCN104084845AStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

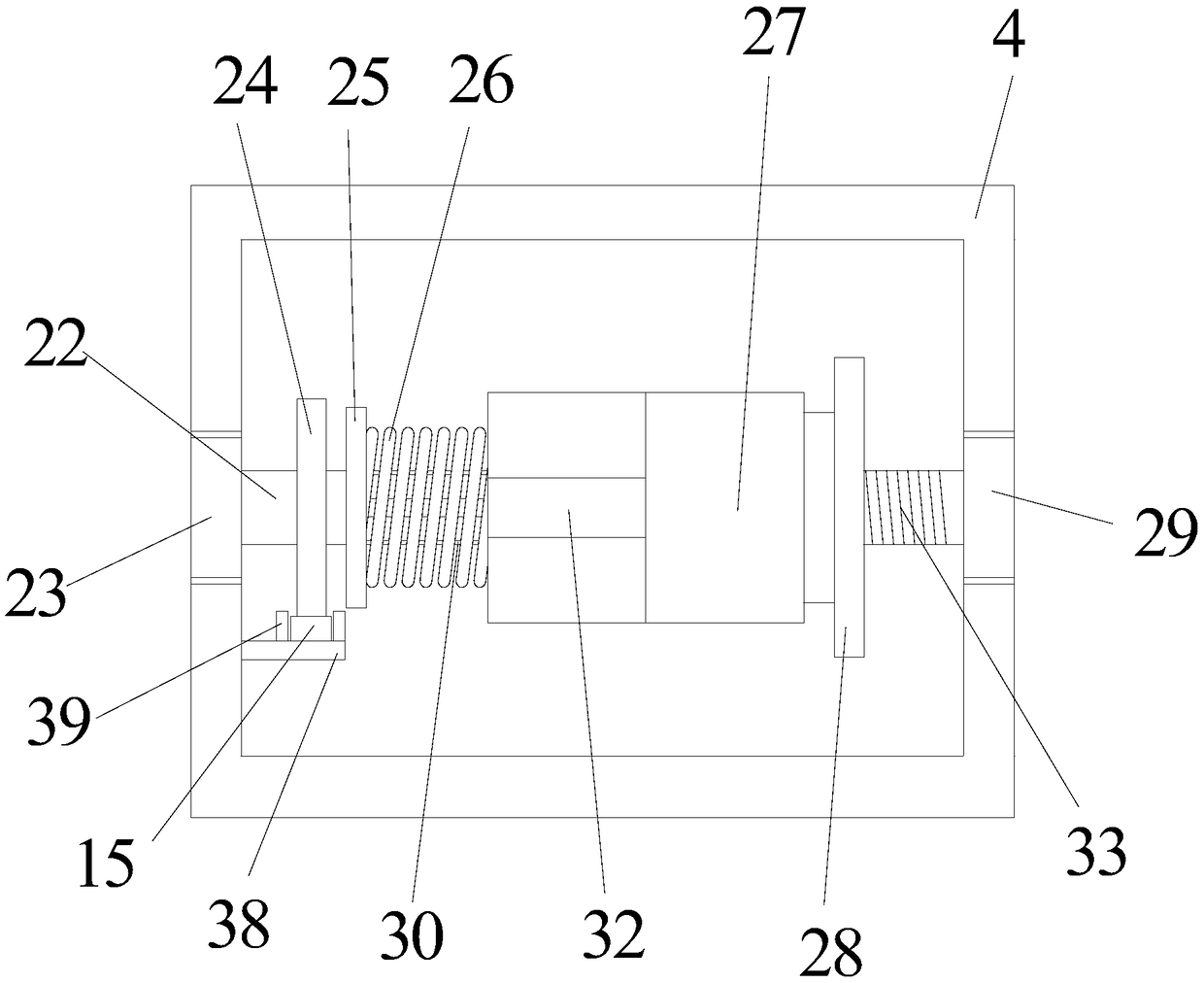

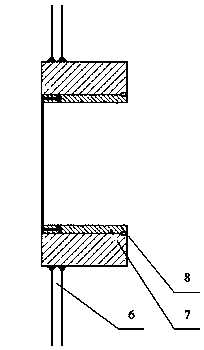

A mounting process of a lifting unit for a jack-up drilling platform

ActiveCN108894202APrevent deviationPrevent deviation from setting of pile fixing frameArtificial islandsUnderwater structuresFixed frameEngineering

The invention discloses a mounting process of a lifting unit for a jack-up drilling platform, the lifting unit comprises a motor and a gearbox arranged in front and back, one end of the motor is arranged flush with one end of the gearbox, A gearbox includes a gear shaft, a torque plate disposed transversely and horizontally of the gear shaft and disposed between the gear shaft and the transmissionmember, the torque plate is arranged perpendicular to the gear shaft, The outer sleeve of the gear shaft is provided with a climbing gear, which is characterized in that the climbing gear comprises asliding shaft sleeve, a cleaning lifting unit, a preliminary installation lifting unit, a pile fixing frame cleaning, a lifting unit traction device positioning, a lifting unit traction device removing, a lifting unit torque plate mounting, a bearing seat cover plate mounting, a lifting unit adjustment pad mounting, and a lubrication pipeline arranging. The invention has the advantages of simpleand orderly steps, improving working efficiency, and ensuring the firmness and stability of the connection between the lifting unit and the pile fixing frame.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

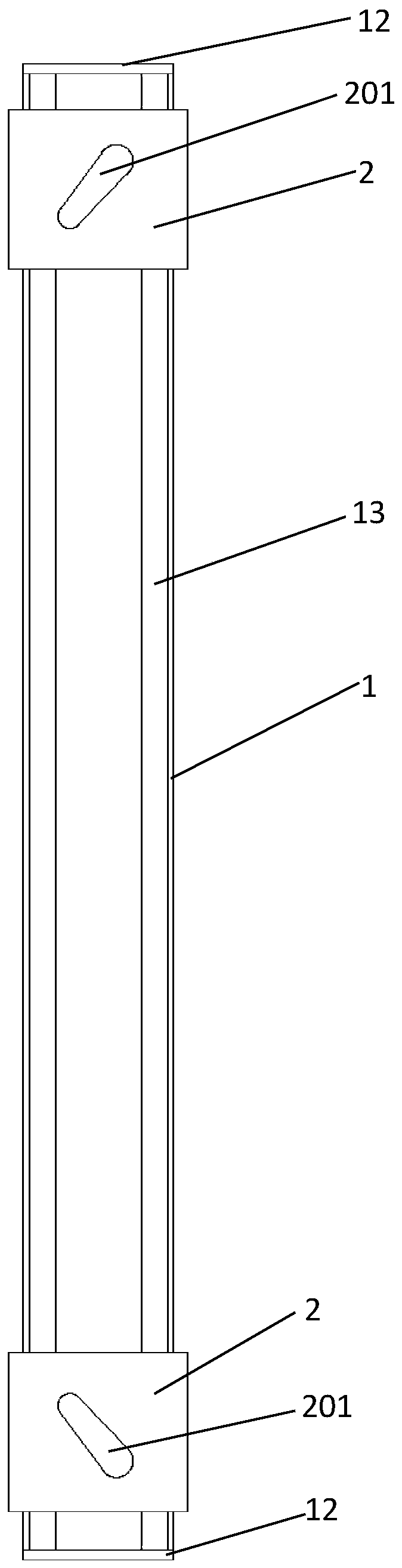

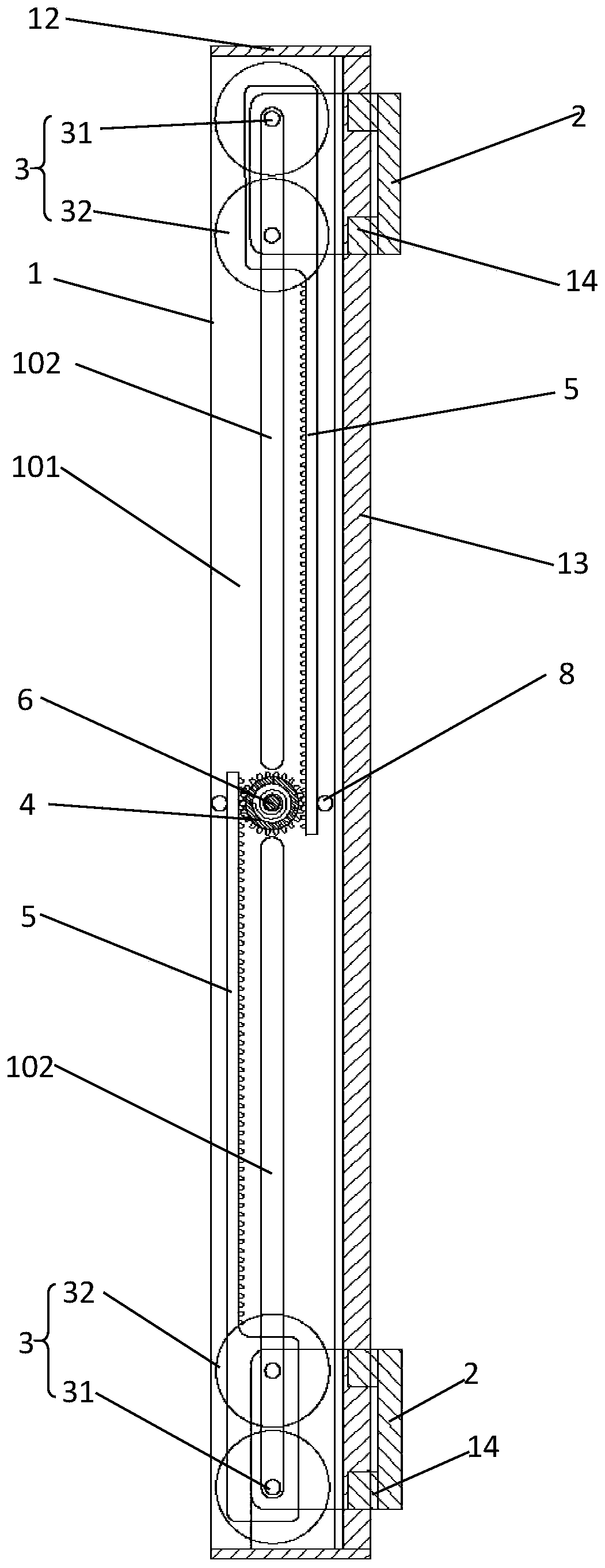

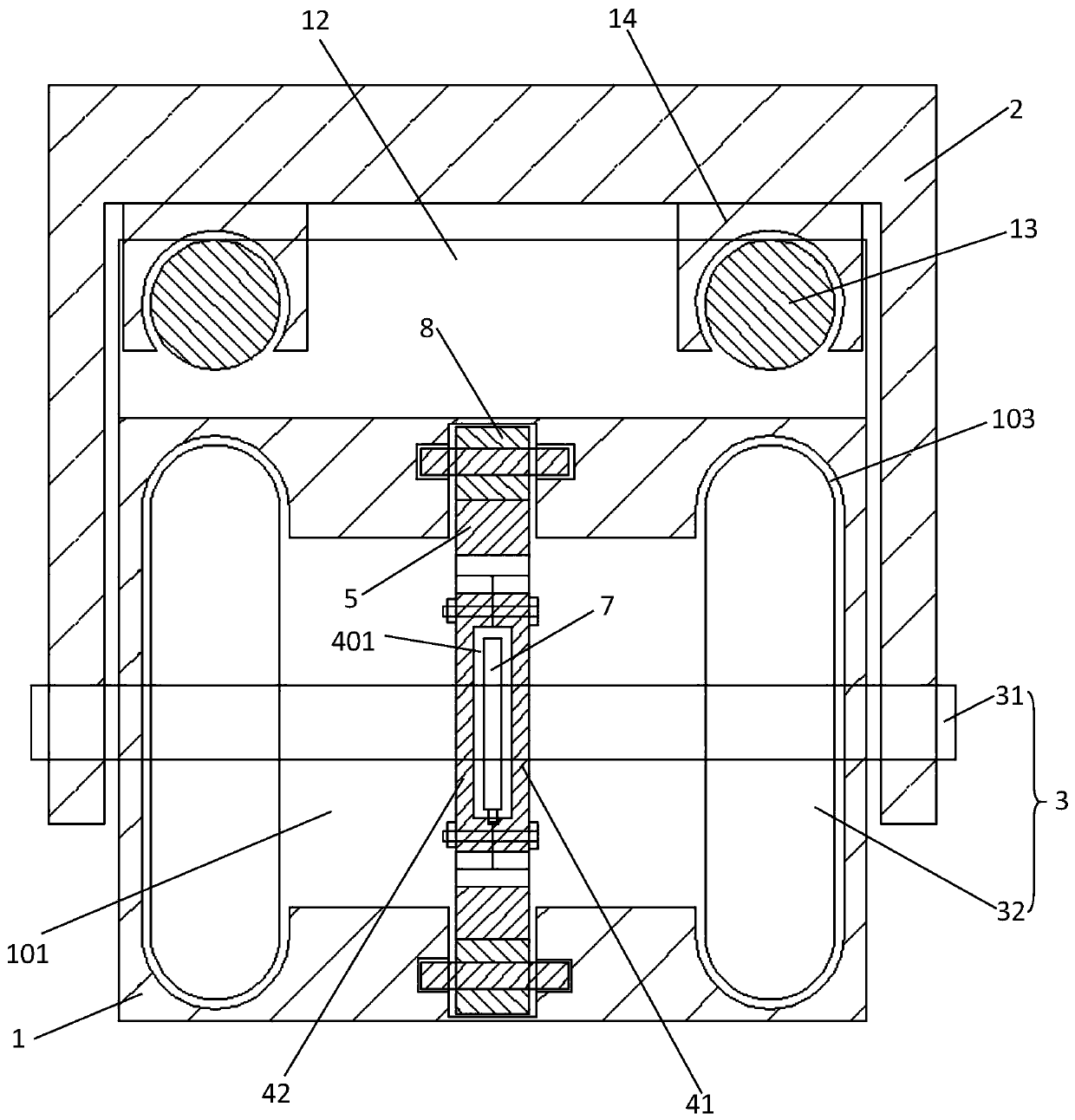

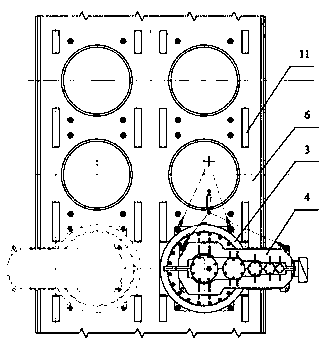

Manual lifting vertical column type marking machine

InactiveCN107804073AEnables side mountingGuaranteed engagementTypewritersPower drive mechanismsGear wheelOptical axis

The invention discloses a manual lifting column marking machine, which includes a manual lifting column, and the manual lifting column includes a lower end cover, a lifting block, a lifting screw, an upper end cover, a lifting hand wheel, a bottom mounting plate, an optical axis, Linear bearings, hand wheel seats, lifting bearings, the lifting screw and the optical axis are fixed side by side between the upper end cover and the lower end cover, the lifting block is slidably arranged on the lifting screw and the optical axis, and the lower end cover is formed by the surrounding The gearbox panel and the bottom mounting plate at the bottom are enclosed. The lifting handwheel is fixedly installed on the lower end cover through the handwheel seat. The lifting handwheel is engaged with the lifting wheel shaft and the bevel gear, and the lower end of the lifting screw is meshed with the bevel gear. , the linear bearing is slidably installed on the upper end of the lifting block and meshed with the optical axis.

Owner:张卓琳

Electric Motorcycle Helical Wave Friction Transmission Adaptive Automatic Transmission Drive Assembly

ActiveCN105151217BSmooth load changeGuaranteed uptimeWheel based transmissionGearboxesDrive shaftEngineering

The invention discloses a self-adaptive automatic speed change drive assembly adopting spiral wavy friction transmission for an electric motorcycle. The self-adaptive automatic speed change drive assembly comprises a box body, a transmission shaft, a slow-gear transmission mechanism and an intelligent mechanical self-adaptive speed change assembly adopting wavy friction transmission. According to the slow-gear transmission mechanism, the inner ring of an overrun clutch is sleeved with a transmission shaft sleeve and the inner circle of the inner ring is provided with a spiral cam matched with the transmission shaft sleeve. An output structure of the spiral cam is adopted in the inner ring of the overrun clutch and arranged on the transmission shaft sleeve, so that an end face cam is omitted, and the spiral cam is good in smoothness and can sensitively make a response to resistance; and multi-cam transmission is possible for the overrun clutch, wavy friction transmission is adopted for guaranteeing flexibility and stability of disengagement and engagement of friction transmission, the axial size of a speed changer is reduced, the drive assembly is suitable for hubs and the like, and good smoothness and high transmission accuracy are acquired in the speed change process.

Owner:SOUTHWEST UNIV

Arc Friction Drive Adaptive Automatic Transmission for Electric Vehicles

The invention discloses an arc-shaped friction transmission self-adaptation automatic transmission used for an electric automobile. The automatic transmission comprises a box body, a transmission shaft, a low-speed gear transmission mechanism and a mechanical intelligentized self-adaptation variable speed assembly, an arc-shaped friction face friction transmission pair is adopted for the friction face of a driving friction disc and the friction face of a driven friction disc of the mechanical intelligentized self-adaptation variable speed assembly, one end of the transmission shaft extends out of the box body, and the power is output to a rear axle of the automobile through an output reducing mechanism. According to the automatic transmission, a separated combination structure is formed through the friction discs, the automatic transmission has the advantage of being sensitive in reaction, and the axial dimension is small; meanwhile, the structure that radial cross section arcs of the friction faces are inlaid in each other is adopted, connection of the friction faces is dispersed, it is facilitated to guarantee the coaxiality of the driving friction disc and the driven friction disc, it is also facilitated to enlarge the friction faces, and it is guaranteed to maintain good transmission under the condition of limited elastic force; it is also facilitated to guarantee the sensitivity of the separation and connection, the transmission precision is improved, and the automatic transmission is applicable to the field of electric automobiles.

Owner:INST OF OPTICAL MASCH CHONGQING CITY

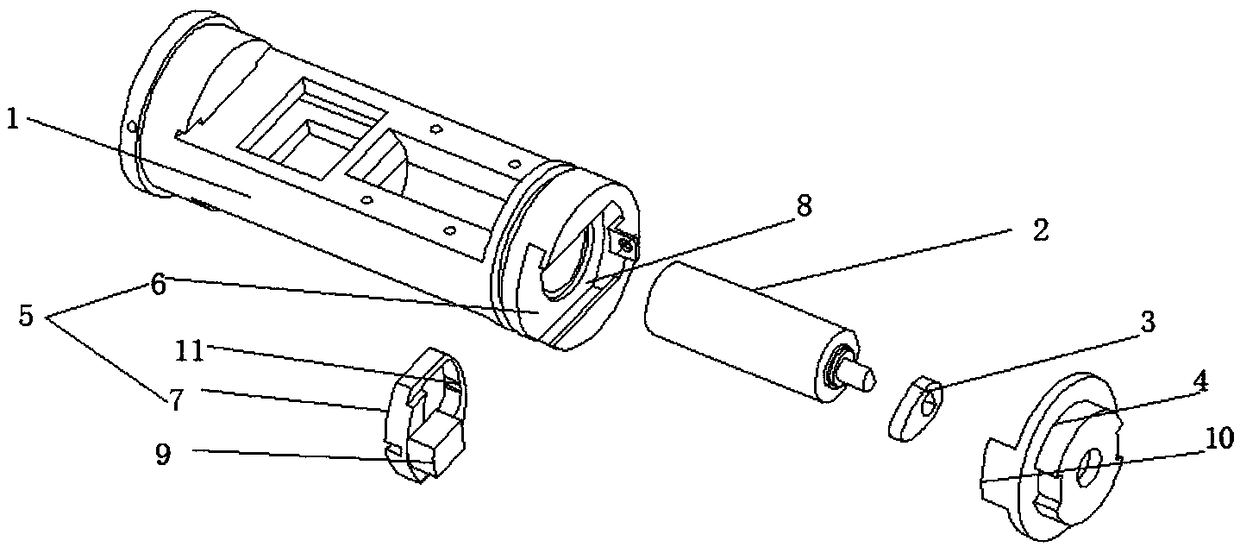

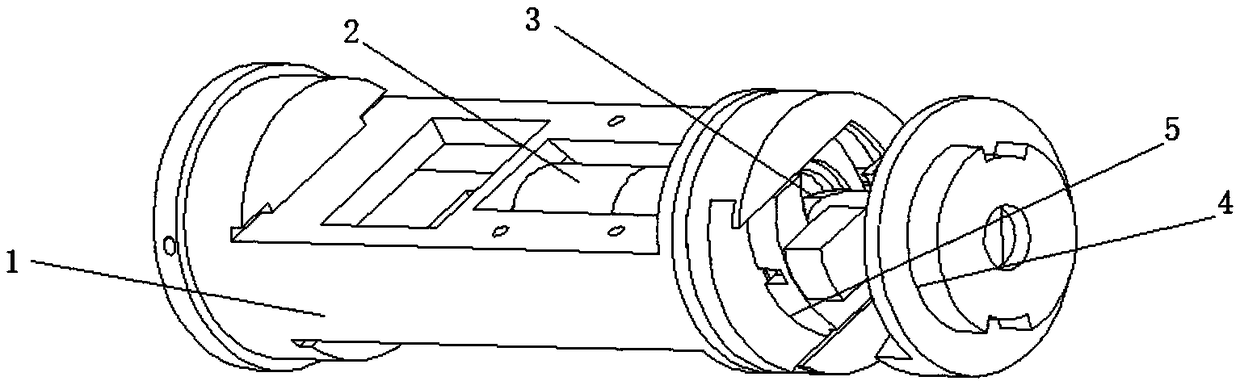

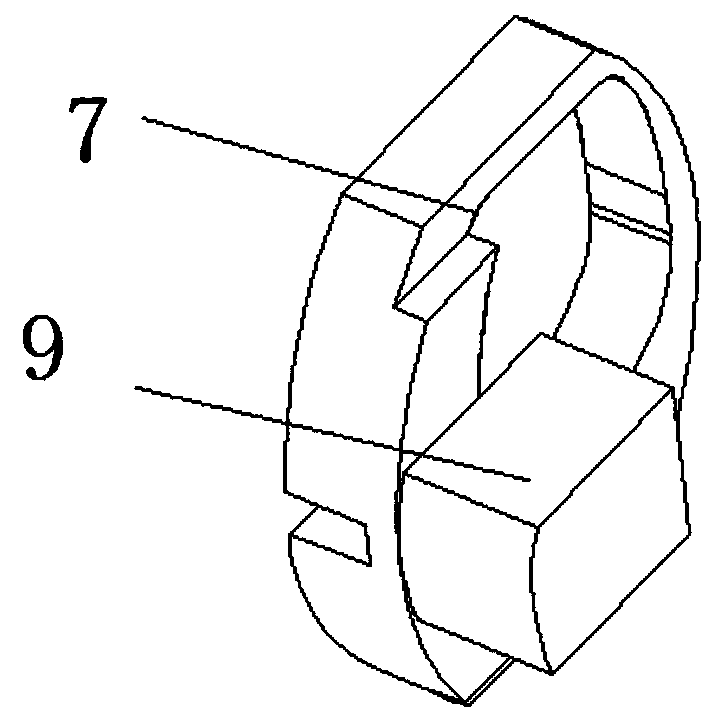

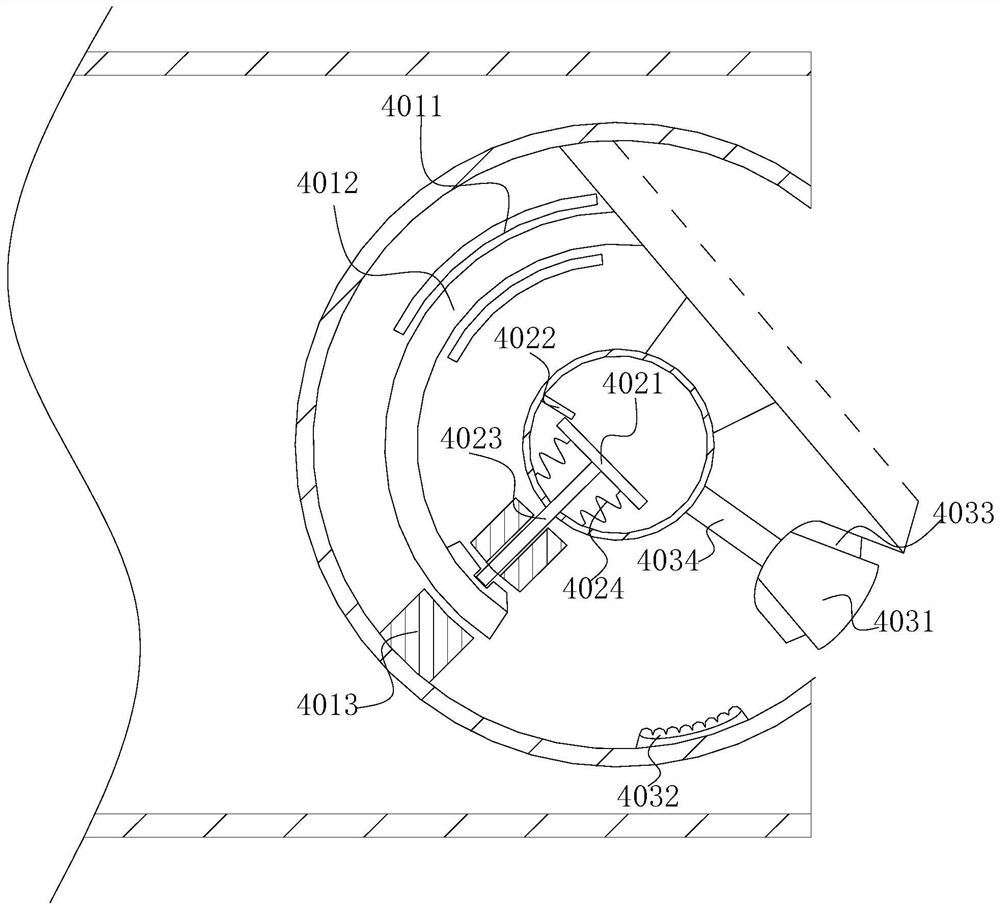

Electronic locking core limiting self-locking clutch device

The invention discloses an electronic locking core limiting self-locking clutch device. The electronic locking core limiting self-locking clutch device comprises a locking core, a driving device, a pushing block and a pushing tongue. A driving device is arranged inside the locking core, and a clutch mechanism is arranged on the end portion of the locking core. The pushing block is installed on theend portion of the driving device, and the pushing block is located inside the clutch mechanism. The pushing tongue is installed on the end portion of the locking core, and the pushing tongue is located on the outer side of the clutch mechanism. The electronic locking core limiting self-locking clutch device solves the technical problem that a clutch and a pushing tongue cannot be well connectedin the prior art.

Owner:YANGZHOU ANXINZHI TECH CO LTD

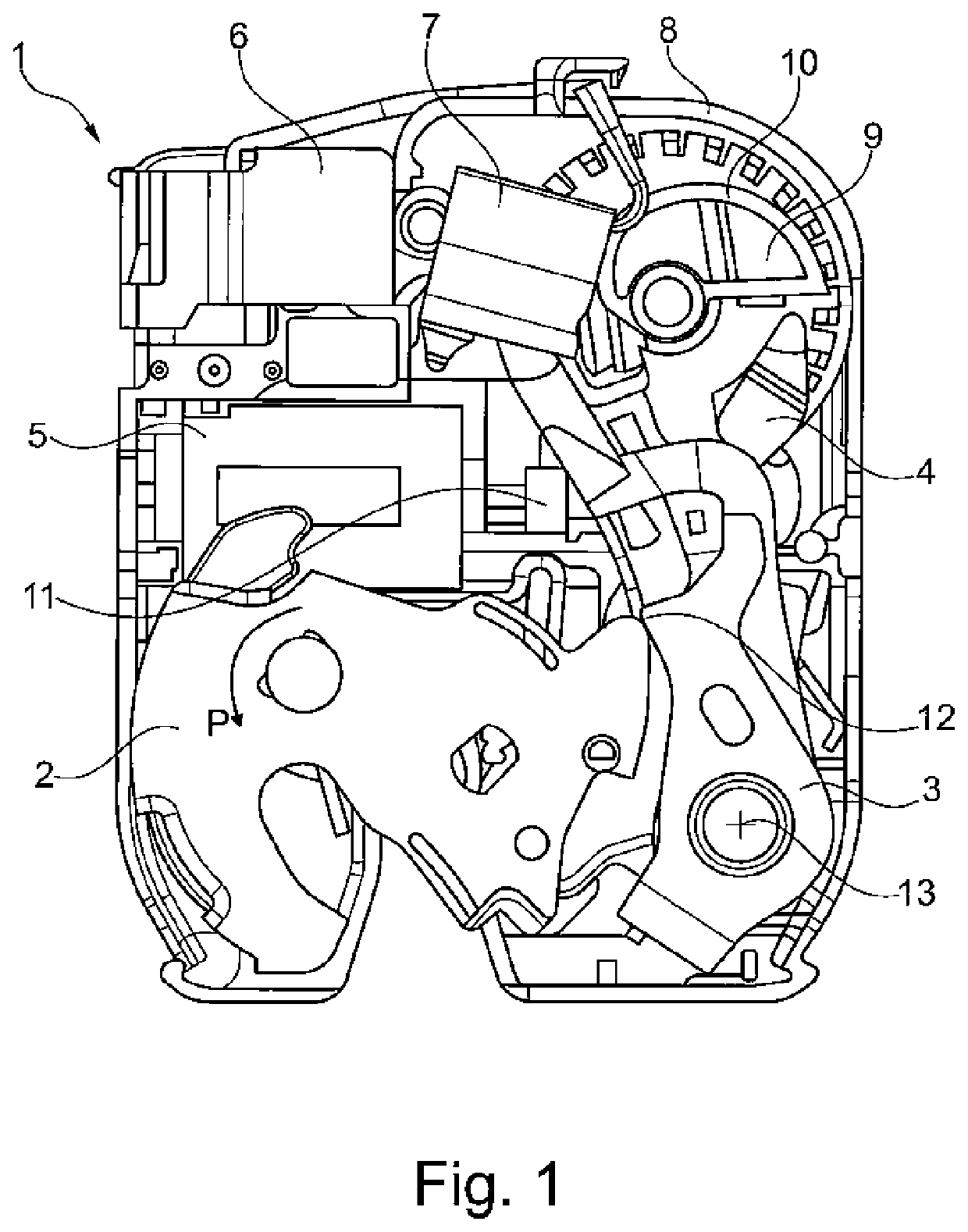

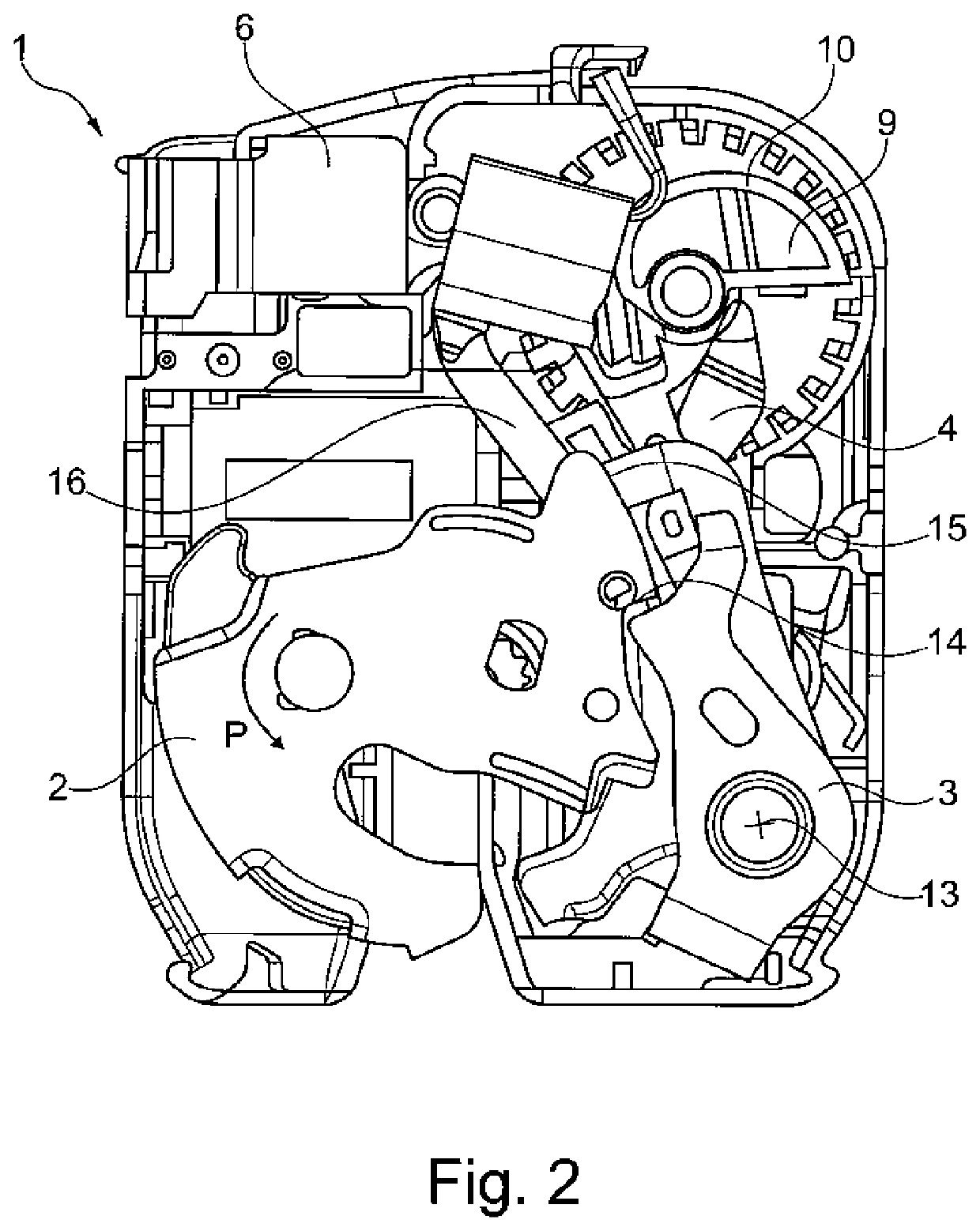

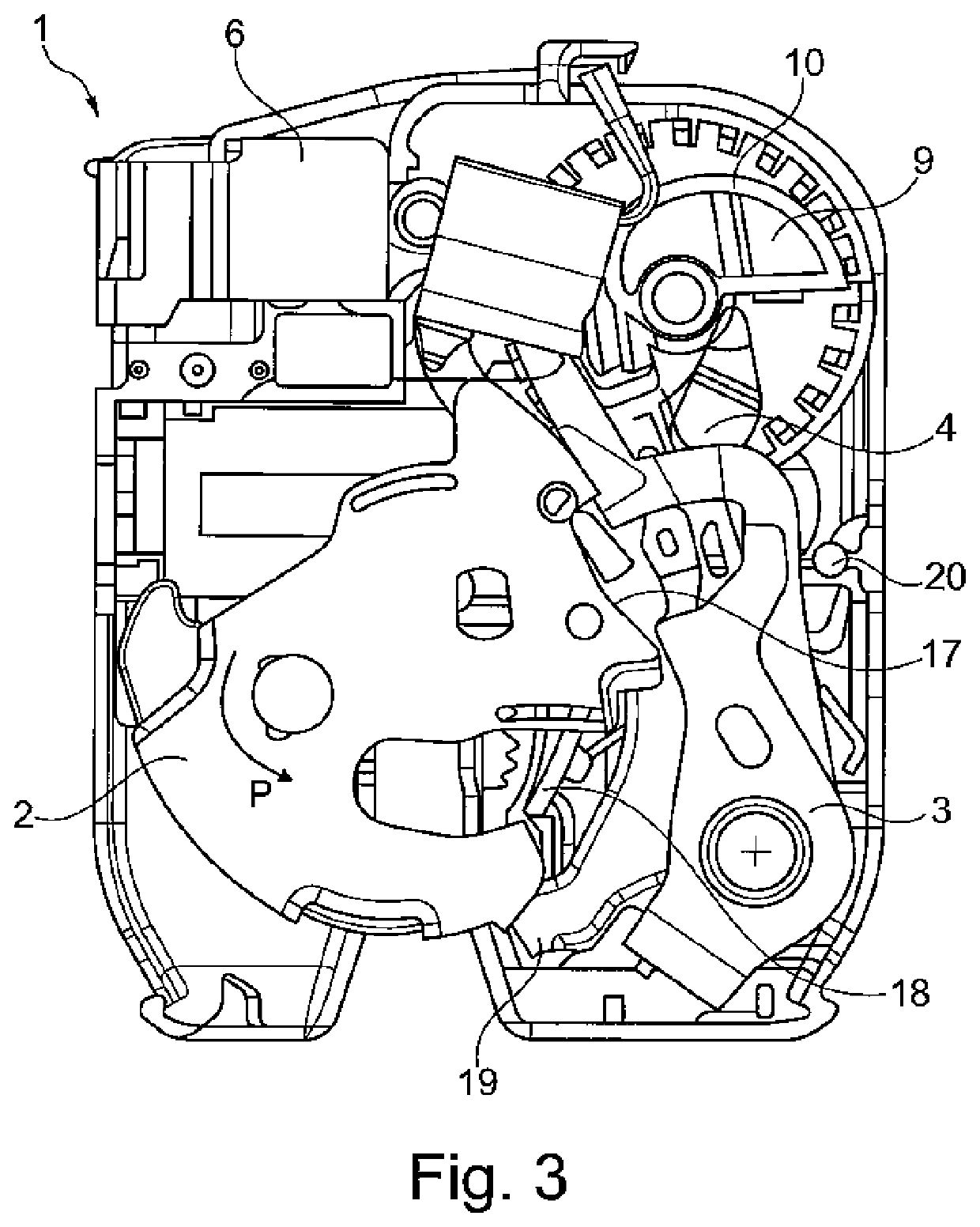

Motor vehicle lock

ActiveUS11098508B2Improve functional safetyEasy constructionElectrical locking circuitsMechanical engineeringElectrical and Electronics engineering

The invention relates to a motor vehicle lock (1) comprising a locking mechanism that includes a rotary latch (2), at least one pawl (3), a triggering lever (4) that allows the pawl (3) to disengage from the rotary latch (2), and a latching lever function that allows the triggering lever (4) which is actuated for disengaging the rotary latch (2) to be secured in an actuated position; the triggering lever can be guided by the rotary latch (2) only in some sections.

Owner:KIEKERT AG

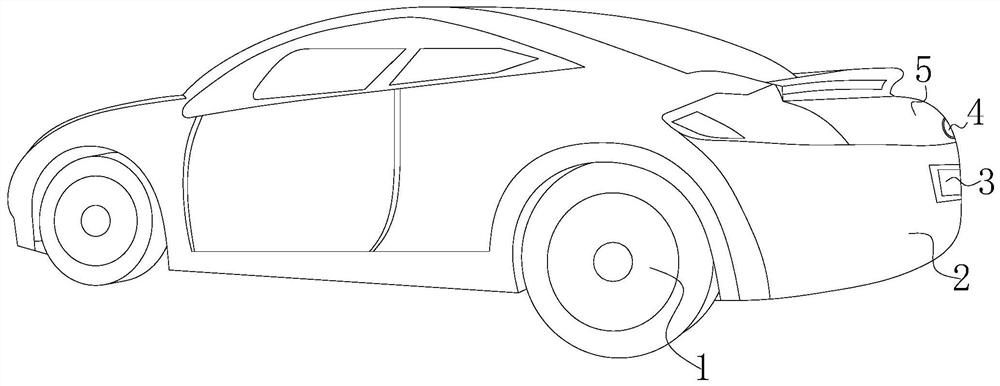

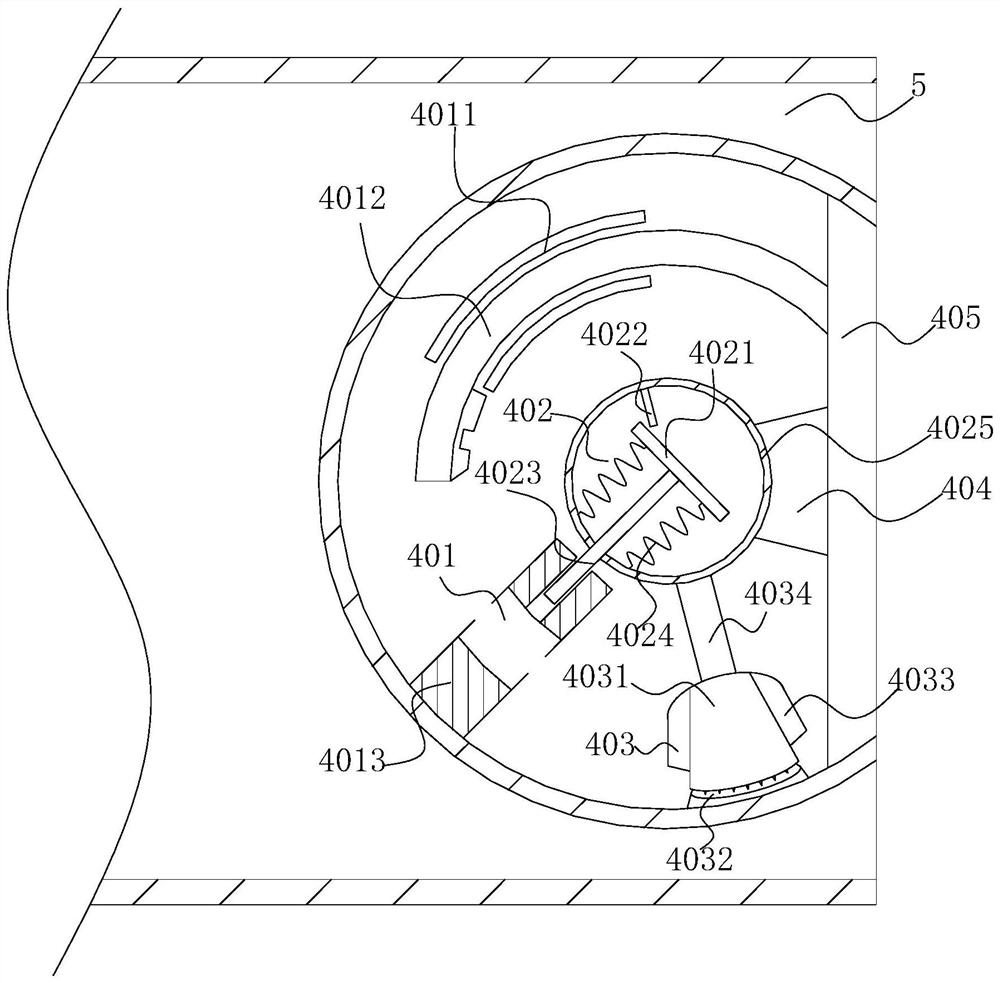

Built-in swivel-open car reversing camera mount protection device

ActiveCN110154930BGuaranteed engagementGuaranteed matchTelevision system detailsColor television detailsCamera lensRotational axis

The invention discloses an embedded rotating and opening car reversing camera installation and protection device. The structure includes wheels, a car body, a license plate installation groove, a camera installation device, and a back cover. There are four wheels and are fixedly installed on the car body. Beneficial effects: by controlling the clockwise and counterclockwise rotation of the rotating shaft, the camera can be controlled to switch between closing or opening, and the movable clamping rod is engaged with the groove on the extension block to realize the rotation of the circular clamping rod. The positioning makes it possible to stably display the picture behind the car when the camera is turned on. The extension block is stuck on the outside of the guide track, thereby controlling the position of the ring clamp lever when it is reset, ensuring that the cushion and the camera are matched, and it is convenient for the cushion to wrap the camera. Cover the camera to avoid dust falling on the camera or the vibration caused by the vehicle passing through the uneven road, which will make the lens unstable or even wear, so as to protect the lens.

Owner:山东远腾环保设备有限公司

A tool profiling control system

InactiveCN104084845BStable mold changeMachining shape influenceCopying process control systemsControl systemEngineering

Disclosed is a tool profiling control system. The tool profiling control system comprises a tool profiling device and a control processor (8). The tool profiling device comprises a tool (1) and a profiling column (2), wherein the profiling column (2) is integrally in a cylindrical shape, and both ends of the cylindrical shaped are provided with an upper plug (27) and a lower plug (28); a middle profiling unit is formed between the upper plug (27) and the lower plug (28) and circumferentially and uniformly provided with four longitudinal profiling grooves (21, 22, 23 and 24) which are connected with the connecting end (11) of the tool (1); at least one of the four longitudinal profiling grooves is a return groove (22), the profiling contour of the return groove (22) is of a flat type, the other profiling grooves are curved grooves and are used for performing feeding control on the tool (1), and meanwhile, the curved grooves are different in curved surface shape.

Owner:AIRUI KETE TIANJIN PRECISION METAL TOOL CO LTD

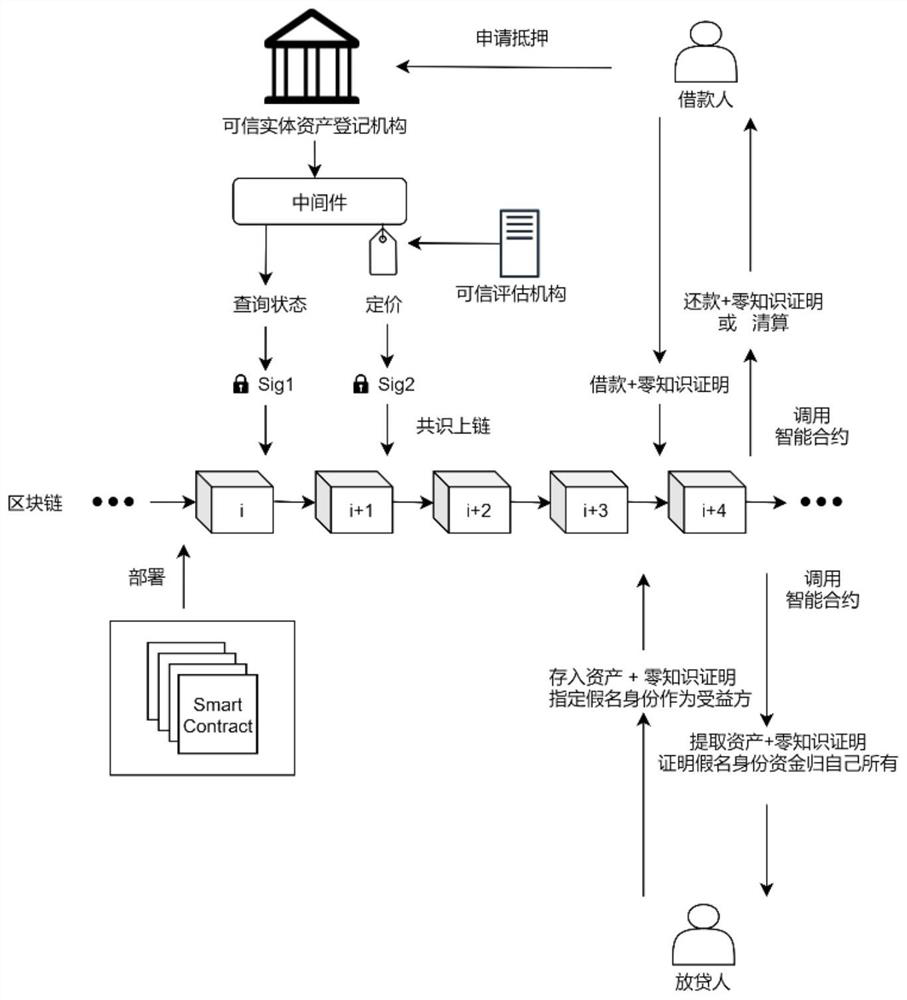

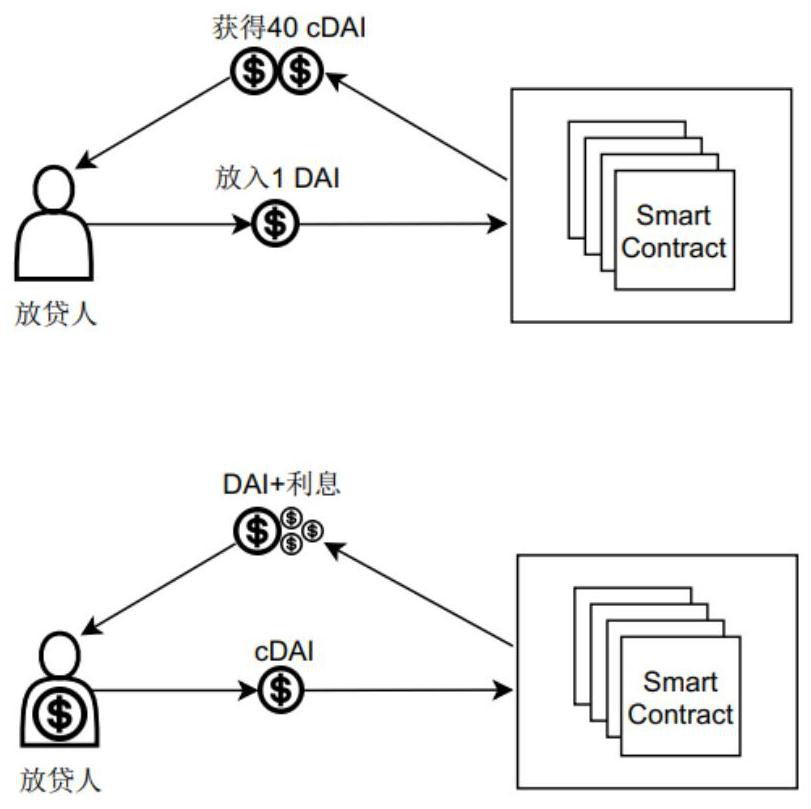

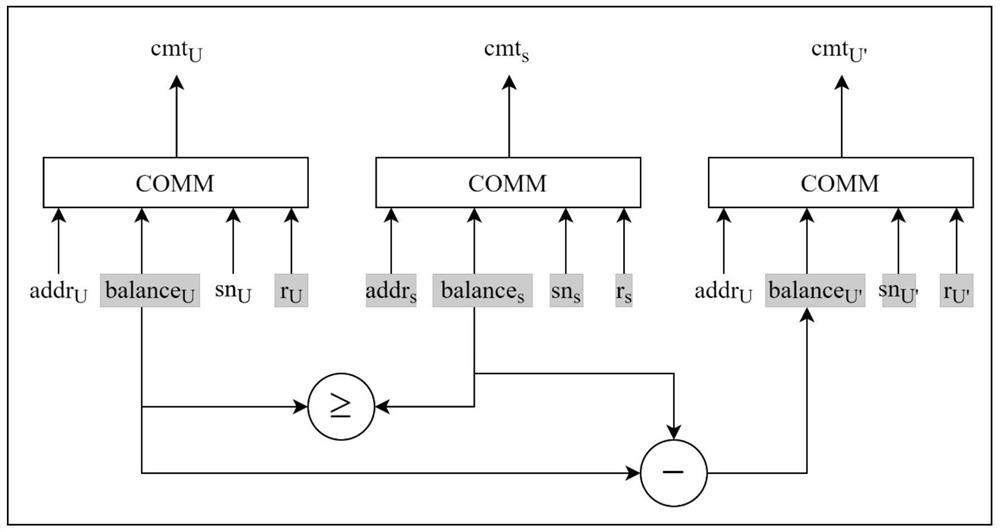

Block chain-based entity mortgage lending method

PendingCN113689282AEnsure fairnessSimplify the transaction processFinanceUser identity/authority verificationZero-knowledge proofBlockchain

Owner:ZHEJIANG LAB

Transmission system and exhaust gas turbocharger

InactiveUS9587555B2Shorten adjustment timeReduce the ratioInternal combustion piston enginesWind motor controlTurbochargerCoupling

A transmission system for an adjusting device, of a waste gate of an exhaust gas turbocharger, including a four bar coupling mechanism, a driver arm operatively connected to a drive via a transmission, an output arm and a coupler, operatively connecting the driver and output arms, the transmission having a driving gear, assigned to the drive, and a driven gear, assigned to the driver arm and interacting with the driving gear having a rolling curve radius, which changes over the circumference, the driven gear having a rolling curve radius running complementary to the former. The rolling curve radii is selected in an angle of rotation range about the extended position of the coupling to form at least in regions a first transmission ratio and outside the angle of rotation range to form at least a second transmission ratio larger than the first ratio. Also described is an exhaust gas turbocharger.

Owner:ROBERT BOSCH GMBH

Holding device for medical purposes

InactiveUS8668684B2Easy to operateEngagementDiagnosticsIntravenous devicesSacroiliac jointBiomedical engineering

Owner:UNIVERSITY OF DUNDEE

A cable cutting device

The invention discloses a cable cutting device and relates to the technical field of electric power auxiliary equipment. Including the base, the upper part of the base is provided with a support, the bottom of the support is provided with an outlet, the support is provided with a side support plate, the side support plate is provided with a lifting rod, and the end of the lifting rod is provided with A first motor, a cutter is provided at the output end of the first motor, a support frame is provided on the base, and rollers are rotatably connected to the support frame. The beneficial effect of the present invention is that it can ensure that a large number of burrs will not appear at the cut of the cable when the cable is cut.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com