Multidirectional following type moving mechanism for fat explosion instrument and weight losing device

A mobile mechanism and multi-directional technology, which is applied in the field of fat bursting instrument, can solve the problems of inconvenience, random movement of the fat bursting instrument, etc., and achieve the effect of preventing personal injury, preventing wrong teeth, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

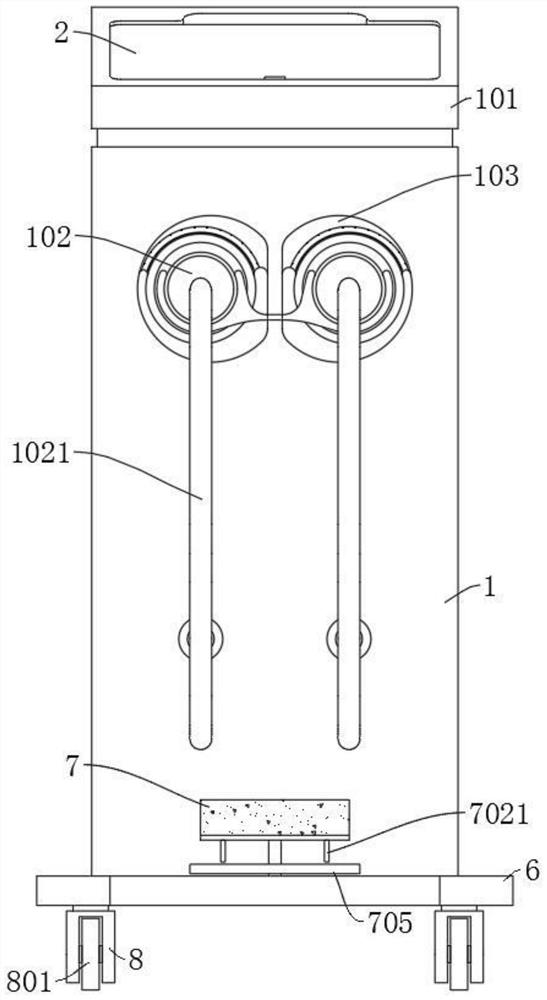

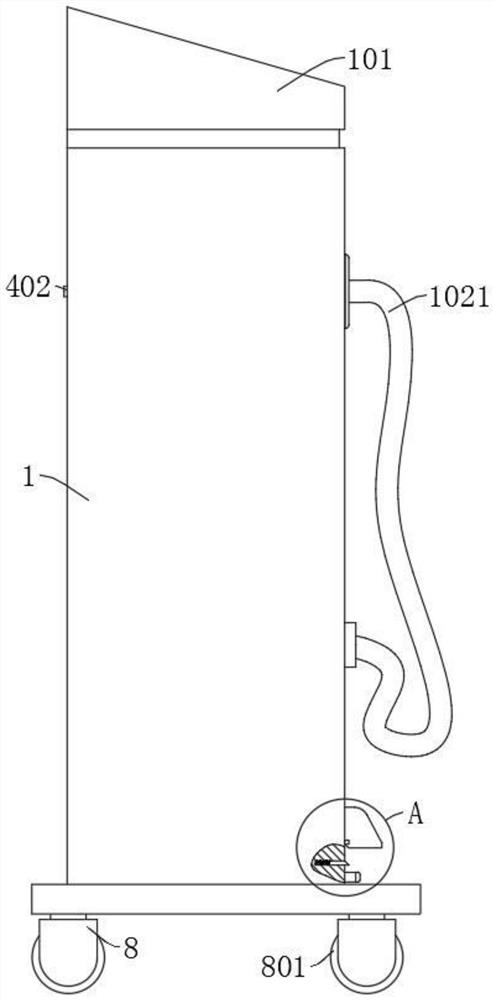

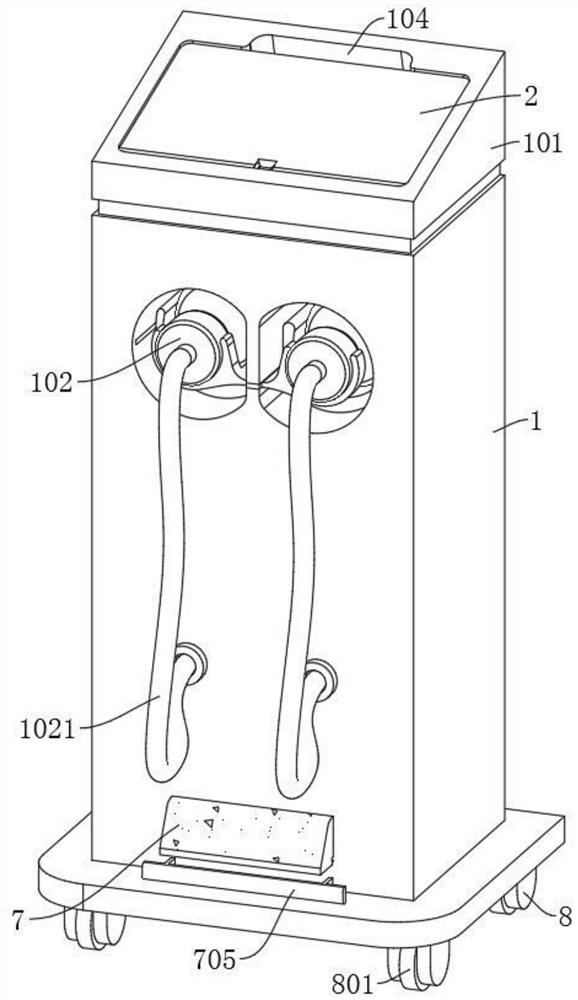

[0037] refer to Figure 1-8, a multi-directional follow-up mobile mechanism for a fat-explosive instrument, comprising a fat-explosive instrument body 1 and a moving wheel 801 rotatably connected to the bottom of the fat-explosive instrument body 1, the bottom of the fat-explosive instrument body 1 is fixedly connected with a mobile seat 6, which moves The bottom of the seat 6 is rotatably connected with a swivel seat 8, the moving wheel 801 is rotatably connected to the swivel seat 8, the swivel seat 8 is slidably connected with a screw mandrel 803, and the working cavity 601 is fixedly connected with a guide rod 804 matched with the screw mandrel 803, The bottom of the screw mandrel 803 is offset against the moving wheel 801, and the moving seat 6 is provided with a working chamber 601, and the working chamber 601 is rotationally connected with a driving shaft 604, and the two ends of the driving shaft 604 are provided with a second worm 6041, and the working chamber 601 is p...

Embodiment 2

[0039] refer to Figure 4 with Image 6 , is basically the same as Embodiment 1, furthermore, the top of the rotating seat 8 is fixedly connected with a second rotating ring 802, and the bottom of the moving seat 6 is provided with a fourth rotating groove matched with the second rotating ring 802, and the second worm wheel The bottom of 605 is fixedly connected with a third swivel 6051, and the bottom wall of the working chamber 601 is provided with a third swivel groove matched with the third swivel 6051, which can ensure that the swivel seat 8 has 180° of turning flexibility when moving, and the When it is not moving, it will not affect the up and down movement of the screw rod 803, and the second worm gear 605 can ensure the degree of engagement with the second worm screw 6041 when it rotates, preventing wrong teeth.

Embodiment 3

[0041] refer to Image 6 , which is basically the same as in Embodiment 1, furthermore, the cross section of the guide rod 804 is specifically rectangular, the bottom of the screw rod 803 is fixedly connected with a rubber block, and the rubber block is offset against the moving wheel 801, and the guide rod 804 mainly prevents the screw rod 803 from Rotate, thereby guarantee its lifting up and down, so here, the cross-section of 804 of guide rod is not limited to rectangle, can be the non-circular cross-section that prevents screw mandrel 803 from rotating on it, and rubber block is mainly used to increase wire rod here. The friction force with the outer surface of the moving wheel 801 when the rod 803 is pressed down prevents slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com