Manual lifting vertical column type marking machine

A technology of lifting columns and marking machines, which is applied to typewriters, power transmission devices, printing, etc., and can solve problems such as large volume, difficult handling, and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below by non-limiting embodiment and in conjunction with accompanying drawing, invention is further described:

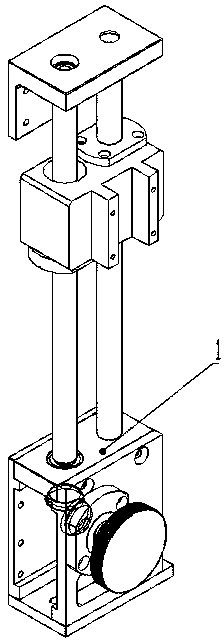

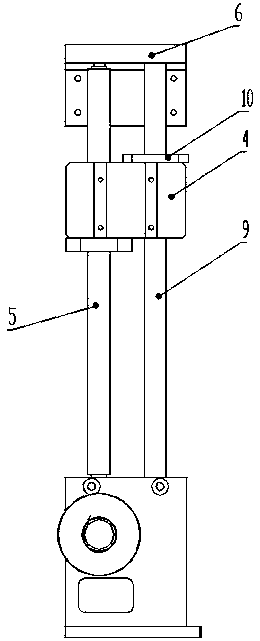

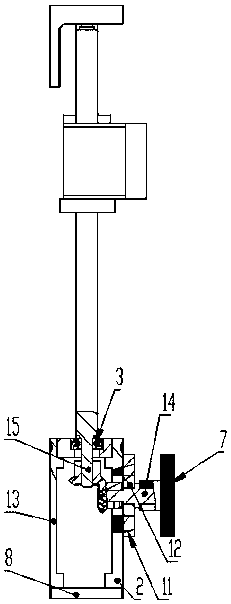

[0013] A manual lifting column marking machine, which includes a manual lifting column, the manual lifting column includes a lower end cover 1, a lifting block 4, a lifting screw 5, an upper end cover 6, a lifting hand wheel 7, a bottom mounting plate 8, a light Shaft 9, linear bearing 10, hand wheel seat 11, lifting bearing 14, the lifting screw 5 and the optical axis 9 are fixed side by side between the upper end cover 6 and the lower end cover 1, and the lifting block 4 is slidably arranged on the lifting screw 5 and the optical axis 9, the lower end cover 1 is surrounded by the gear box panel one 2, the gear box panel two 13, and the bottom mounting plate 8 at the bottom. The lifting handwheel 7 is fixedly installed on the lower end cover 1 through the handwheel seat 11. The lifting handwheel 7 is meshed with the lifting wheel shaft 14 and the bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com