A cable cutting device

A cutting device and cable technology, which is applied in the field of electric auxiliary equipment, can solve problems such as discharge at the tip of the cable cut, difficulty in controlling the depth and stability of the cut, and insufficient tightness of the cable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

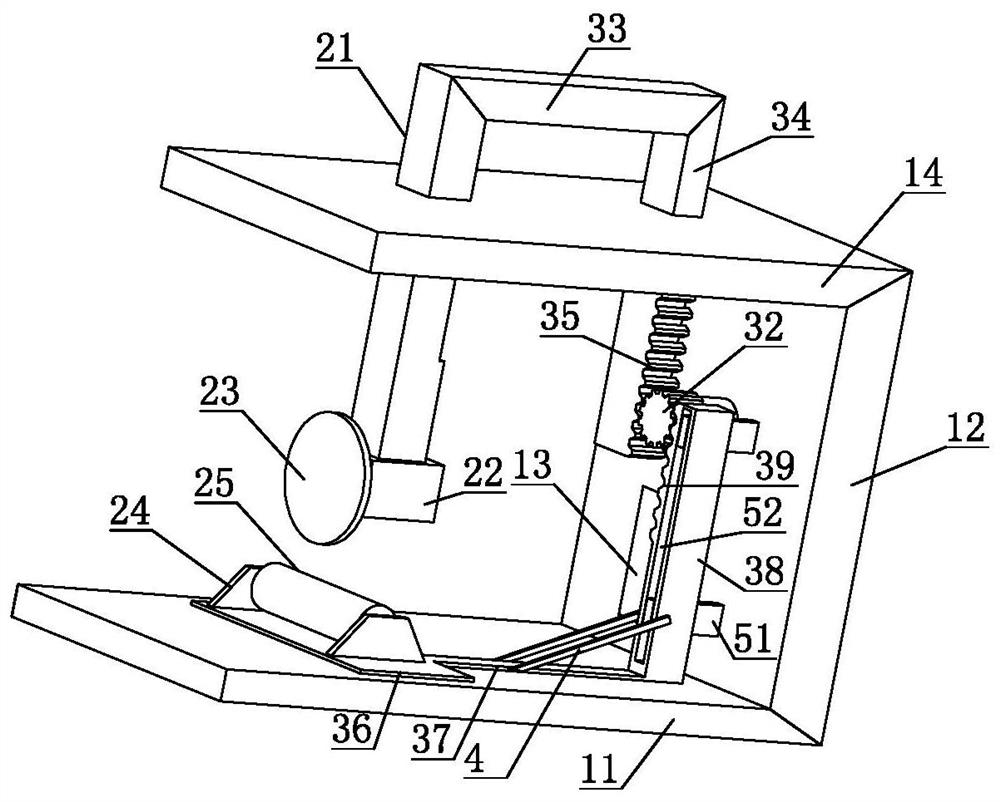

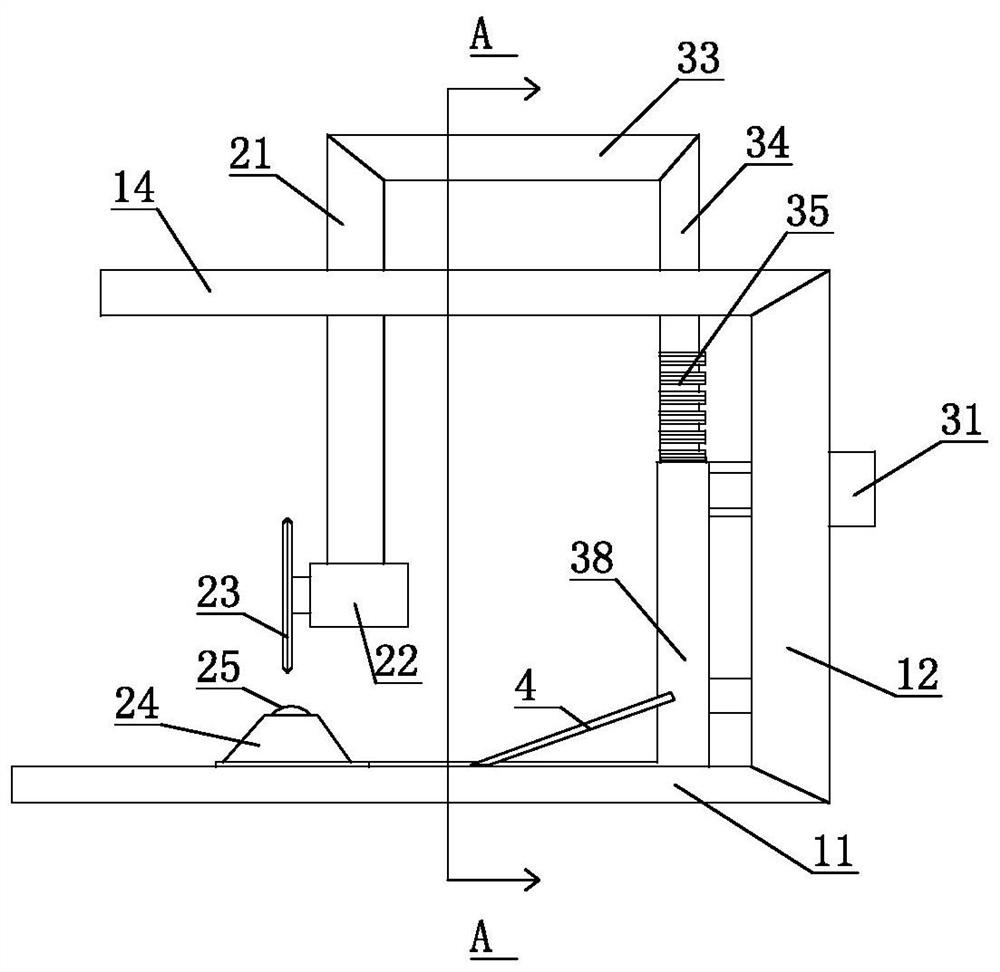

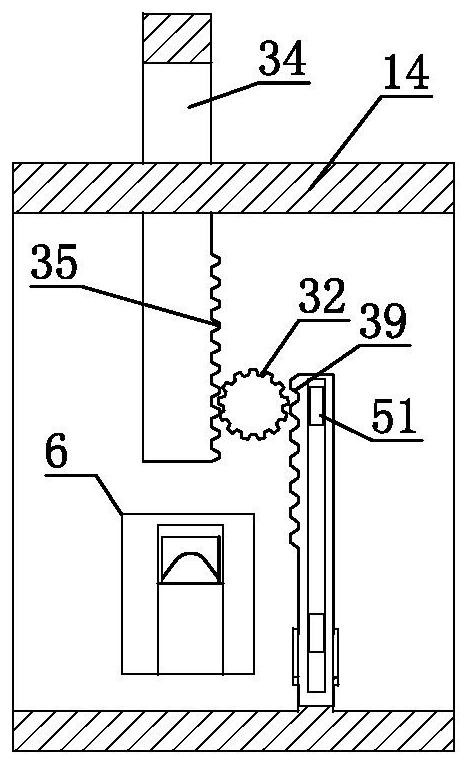

[0029] The present invention is a cable cutting device, comprising a base 11, a support 12 is provided on the upper part of the base 11, an outlet 13 is provided at the bottom of the support 12, a side support plate 14 is provided on the support 12, the Side support plate 14 is provided with elevating rod 21, and described elevating rod 21 is slidably connected with side support plate 14, and the end portion of described elevating rod 21 is fixedly connected with first motor 22, and the output end of described first motor 22 is provided with There is a cutter 23, the base 11 is provided with a support frame 24, and the support frame 24 is rotatably connected with a roller 25. When cutting the cable, the cable is placed on the roller 25, and the place to be cut on the cable is Mark and align the mark with the cutter 23. At this time, the roller 25 pushes the cable to be cut to the highest point, and the cutter 23 runs downward. The cutter 23 will cut the protruding part of the c...

Embodiment 2

[0034] The present invention is a cable cutting device. On the basis of Embodiment 1, in order to ensure the stability in the cutting process, a cable fixing mechanism 6 is provided on the base 11 and in the outlet 13, and the cable fixing Mechanism 6 comprises fixed frame 61, and described fixed frame 61 interior is provided with chute 62 and moving block 63, and described moving block 63 is provided with cable fixing opening 64, and described moving block 63 bottom is provided with spring 65, and described spring 65 is fixedly connected with the base 11, and the cable fixing mechanism 6 can fix the state of the two ends of the cable to prevent the cable from slipping during the cutting process and ensure the stability during the cutting process.

[0035] In order to further ensure the stability of the operation of the whole device, the roller 25 is provided with a plurality of transverse grooves 66, and the transverse grooves 66 cooperate with the cutter 23 to prevent the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com