Wavy friction drive self-adaption automatic gearbox for electric cars

A technology of automatic transmission and friction transmission, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as tolerances, and achieve the effects of improving safety, increasing friction surfaces, and small axial dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

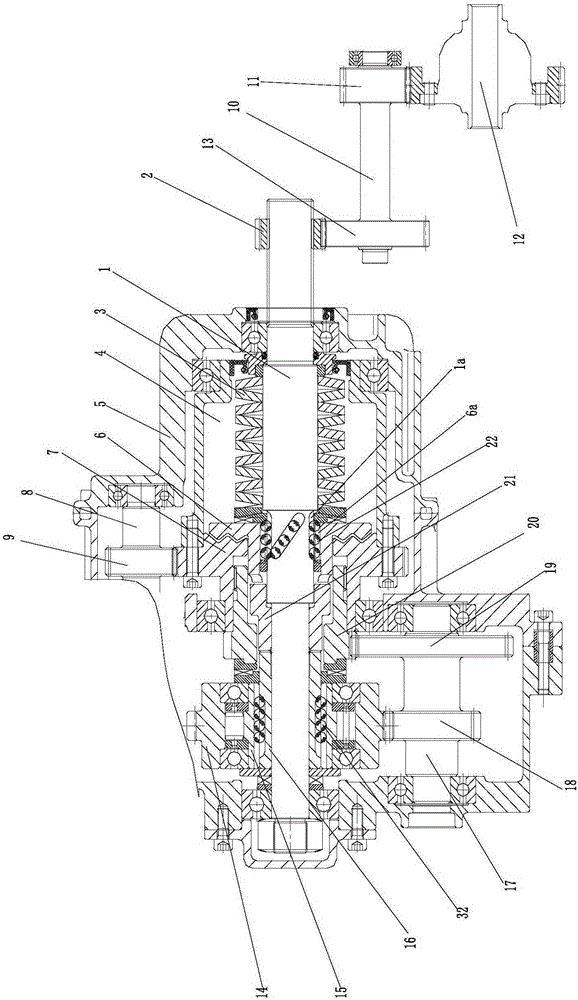

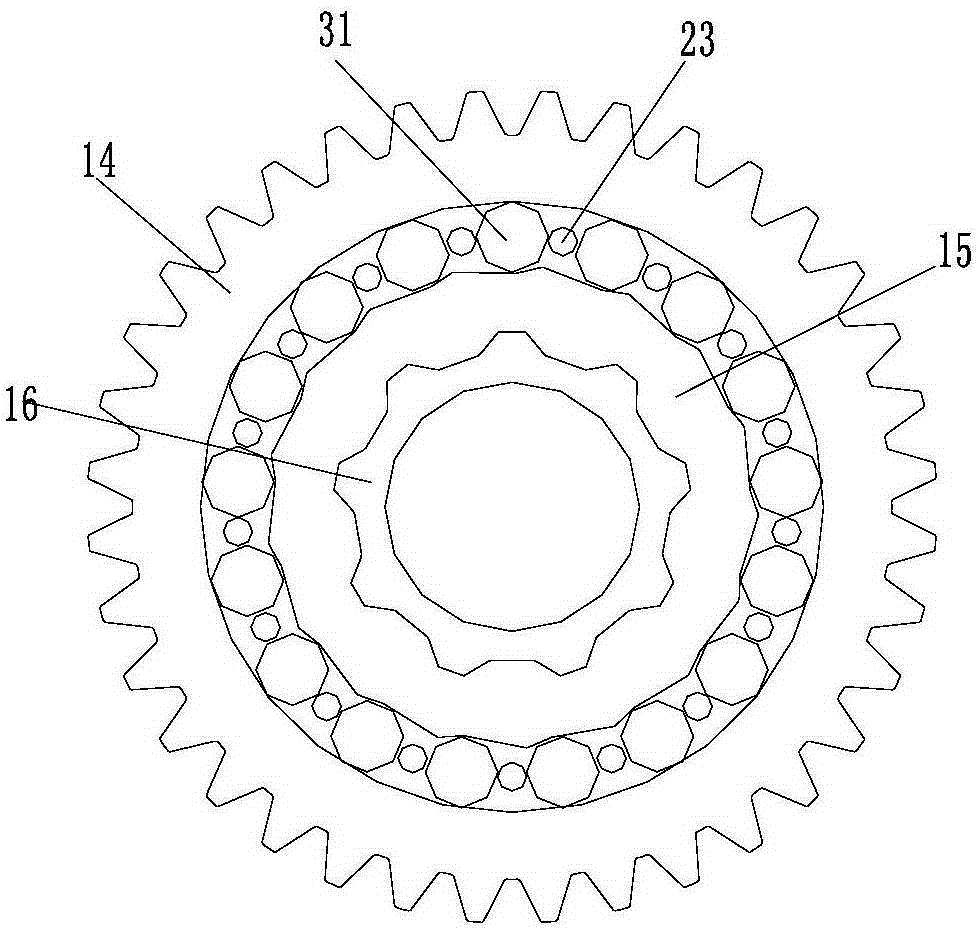

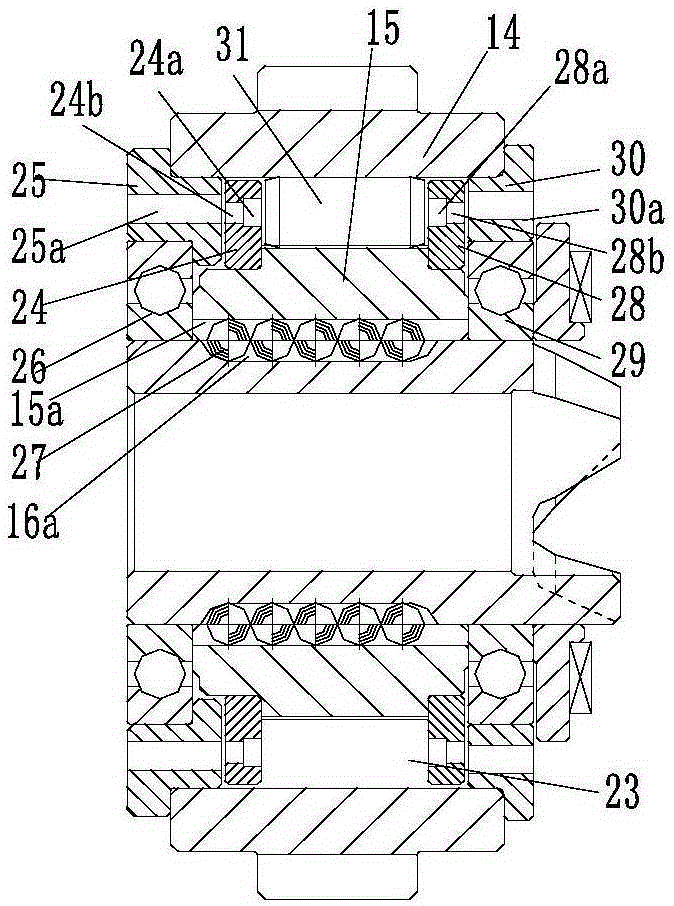

[0026] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 Schematic diagram of the structure of the overrunning clutch, image 3 It is an axial sectional view of an overrunning clutch, as shown in the figure: the wave-shaped friction transmission adaptive automatic transmission for electric vehicles of the present invention includes a casing and a transmission shaft 1 that is rotatably matched with the casing and outputs power; it also includes a slow transmission The mechanism and the mechanical intelligent adaptive transmission assembly arranged on the transmission shaft 1;

[0027] The mechanical intelligent adaptive transmission assembly includes driven friction disc 6, active friction disc 7 and transmission elastic element;

[0028] The active friction disc 7 and the driven friction disc 6 form a disc-type friction transmission pair that transmits fast gears in the way that the friction surfaces cooperate with each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com