Field reseeding tool

A tool and field technology, applied in the field of field replanting tools, can solve the problems of physical exertion, slow replanting speed, low efficiency, etc., and achieve the effect of reducing labor intensity, convenient use, and ensuring growth safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

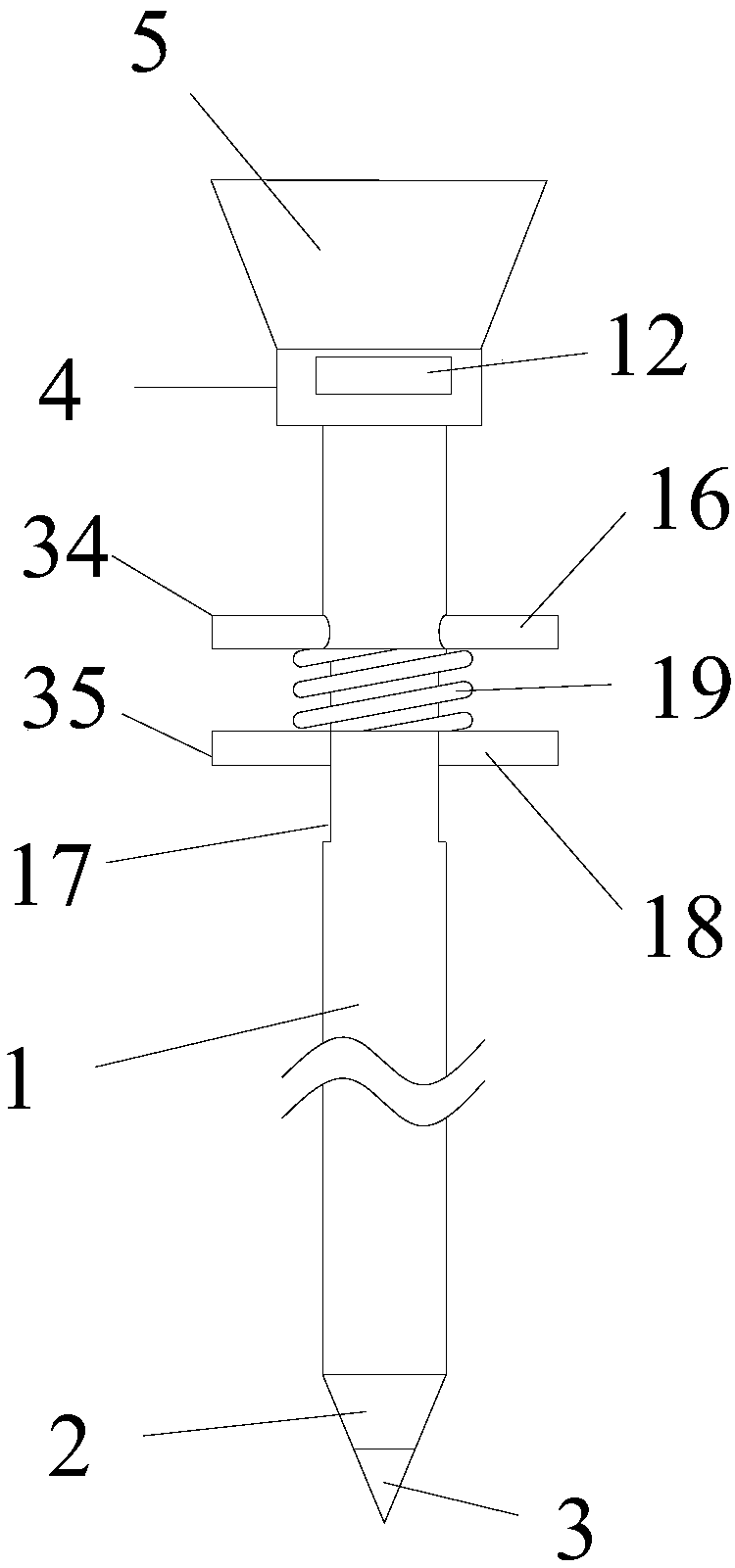

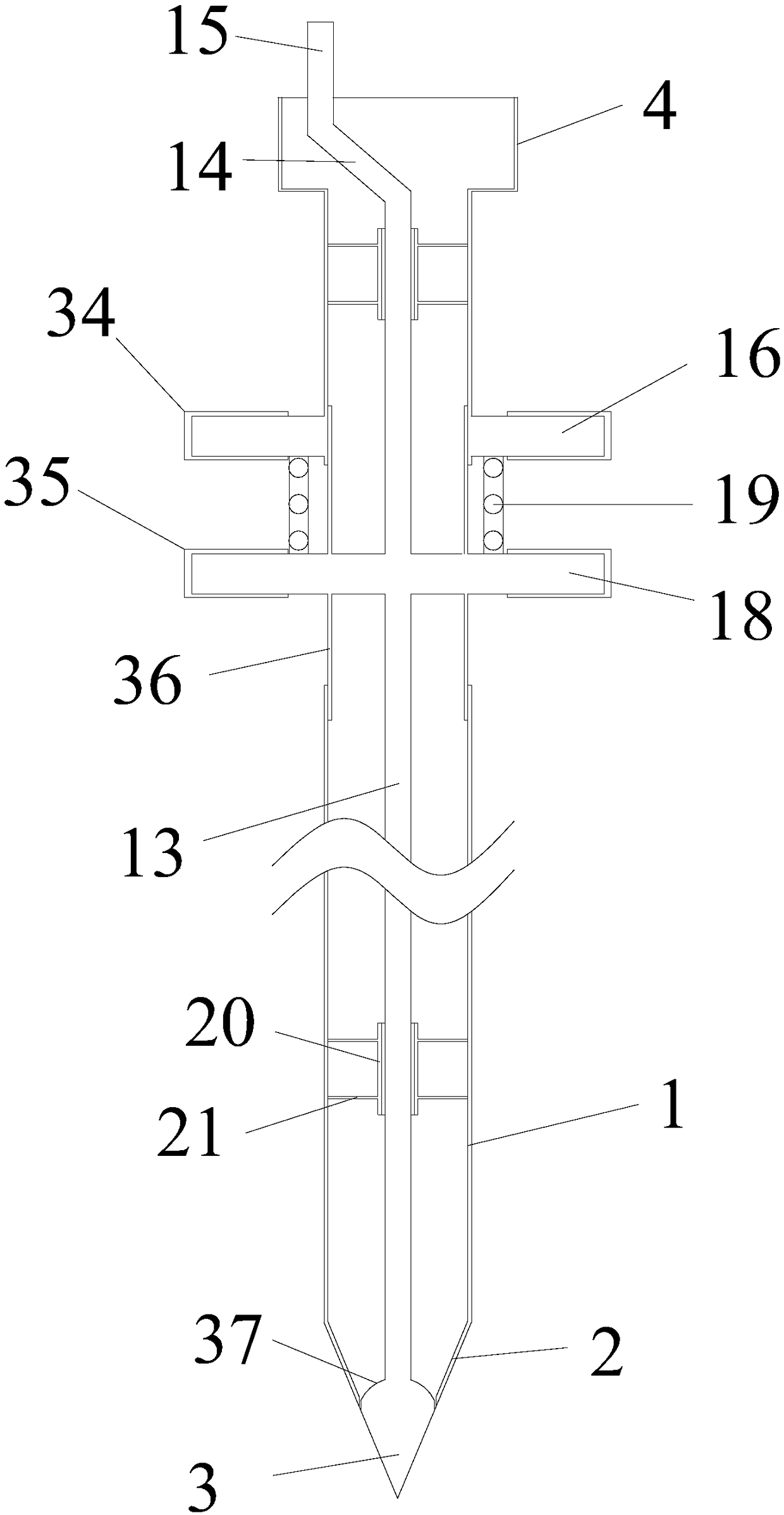

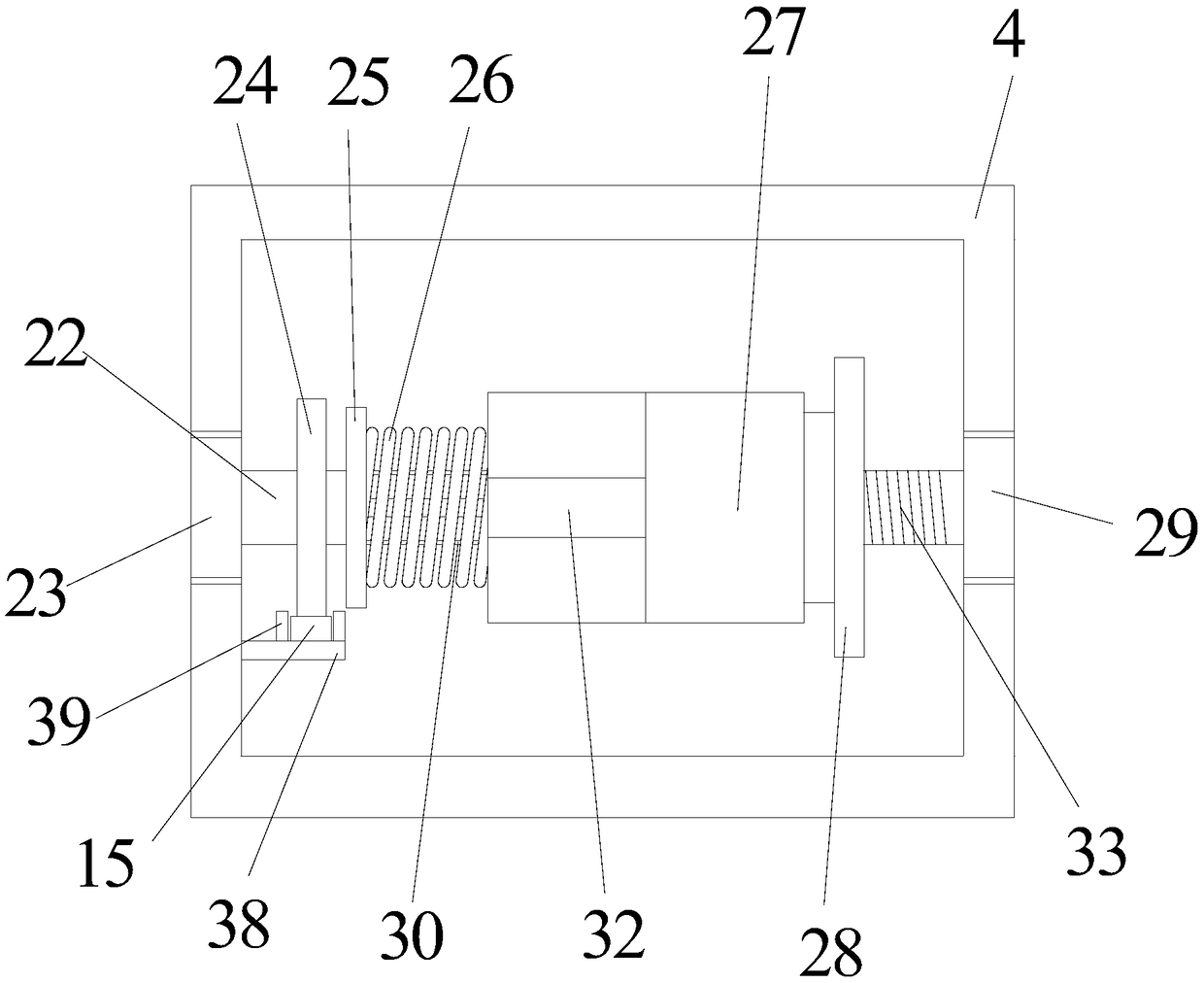

[0032] like Figure 1-7As shown, the field replanting tool according to the embodiment of the present invention includes a planting cylinder 1, a frustum shell 2 is provided on the bottom surface of the planting cylinder 1, and a conical drill bit 3 is provided on the bottom surface of the cone shell 2. The top surface of the seed cylinder 1 is provided with a support platform 4, and the top surface of the support platform 4 is provided with a seed hopper 5, and the side of the seed hopper 5 and the edge of the top surface of the support platform 4 are provided with a support rod 6. The bottom surface of the next seed hopper 5 is provided with a rectangular discharge port 7, and the opposite sides of the rectangular discharge port 7 are provided with a circular through hole 8, and one of the circular through hole 8 sides is provided with a circular groove 9, so that The inside of the circular groove 9 is provided with an annular baffle 10 corresponding to it, and the inner cir...

Embodiment 2

[0044] The difference from Example 1 is that, if Figure 8 and Figure 9 As shown, the reset member in this embodiment is a reset elastic sleeve 40, which is a plastic elastic sleeve, and the top of the reset elastic sleeve 40 extends outward to form an upper flange 41, which is close to the bottom of the fixed handle 16 , the plastic layer one 34 is sleeved on the periphery of the upper flange 41 . The bottom of reset elastic sleeve 40 extends outwards to form lower flange 42, lower flange 42 is close to the top of movable handle 18, plastic layer 2 35 is socketed on the periphery of lower flange 42, upper flange 41 and lower flange 42 The radial lengths are equal to A, and A is between 10mm-40mm, which can prevent soil and the like from entering the reset elastic sleeve 40, so as to affect the elastic reset effect of the reset elastic sleeve 40. In order to continuously maintain the elastic reset effect of the reset elastic sleeve 40, an elastic member is embedded around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com