One-step forming scallion shredder

A technology of shredded green onion and linkage shaft, which is applied in metal processing and other directions, and can solve problems such as time-consuming and laborious shredded green onion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

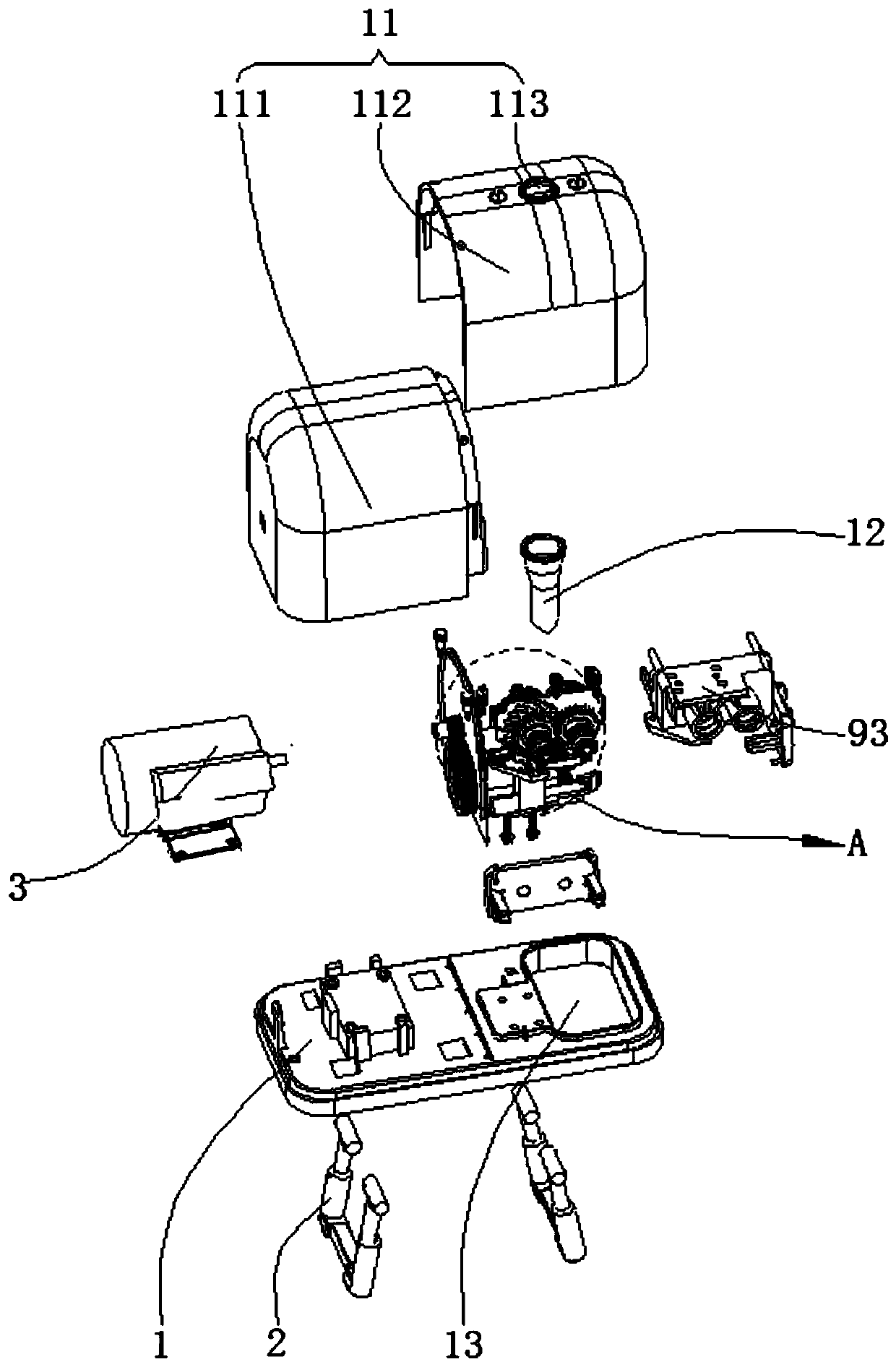

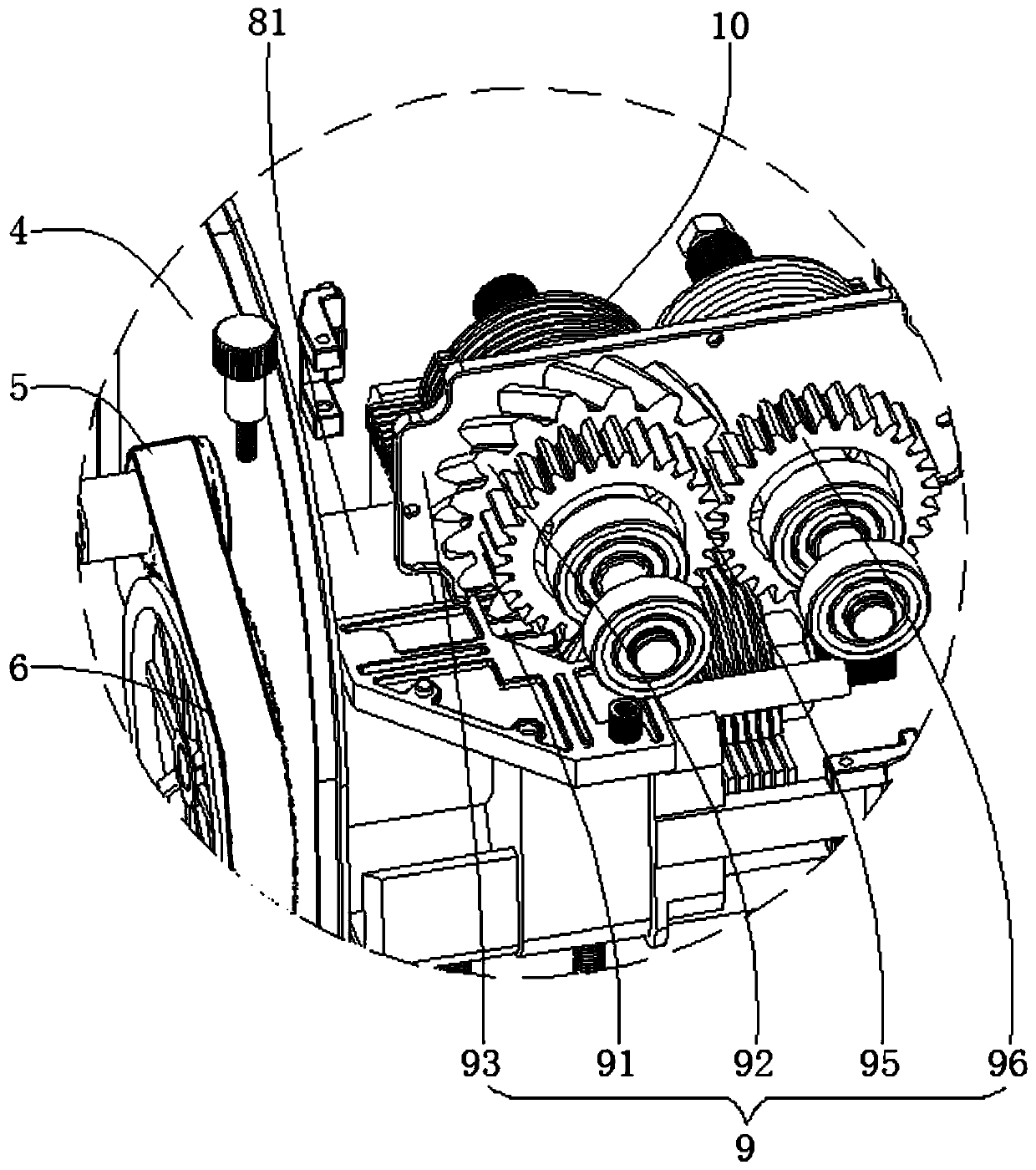

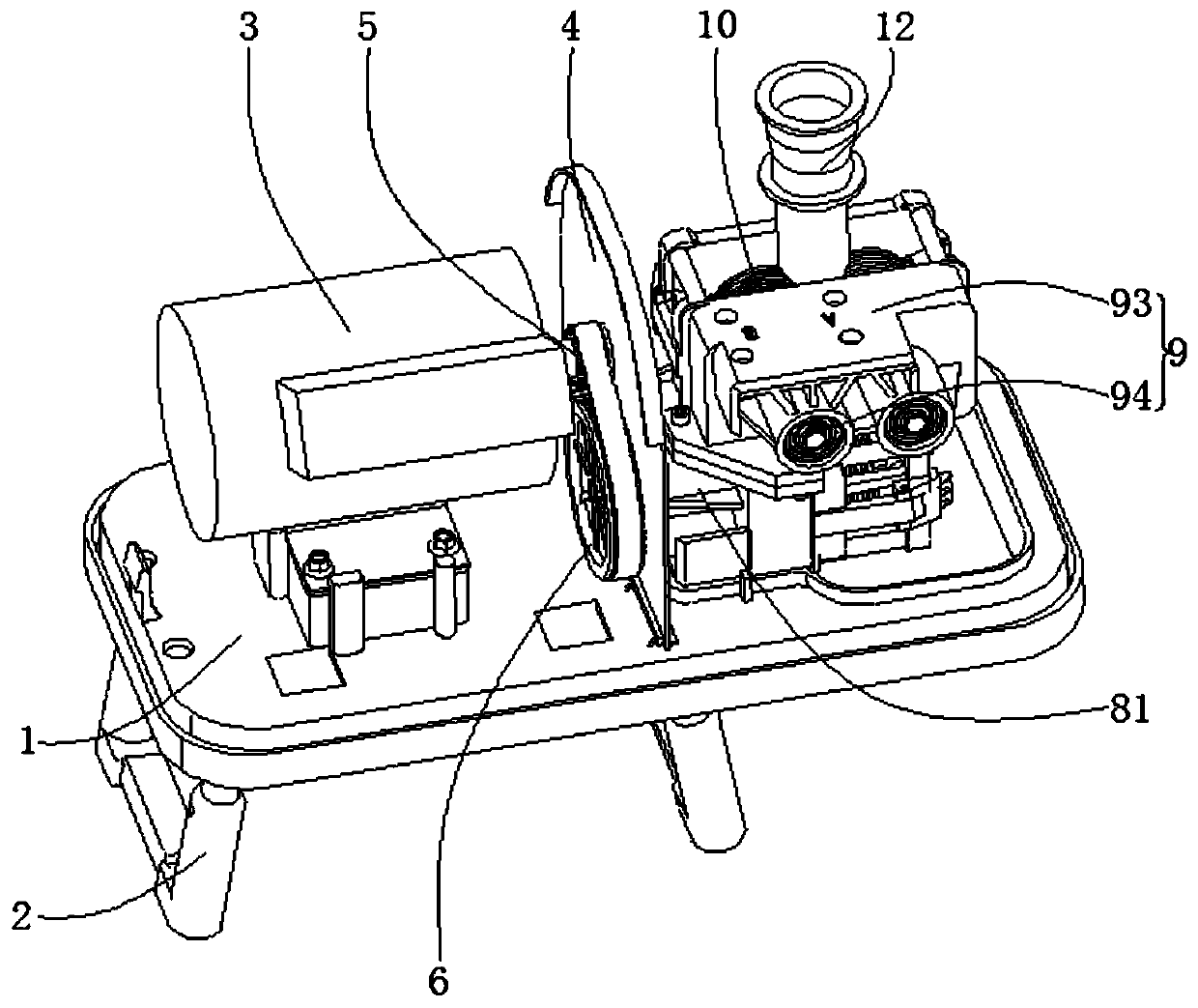

[0021] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the one-time molding shredded green onion machine provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 The schematic diagram of the installation structure of the part of the motor shown; Figure 4 for figure 1 The schematic diagram of the overall installed structure shown; Figure 5 for figure 2 The schematic diagram of the structure between the first power plant and the second power plant shown. A kind of one-time shaping green onion cutting machine comprises: base 1; support frame 2, described support frame is arranged on the bottom of described base 1; Motor 3, described motor 3 is arranged on the top of describ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap