A large-scale vertical axis multi-section wind turbine assembly method and special equipment

A technology for wind turbines and special equipment, used in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult assembly, simple, low efficiency, no automation and mass production, etc., to improve installation accuracy and installation. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

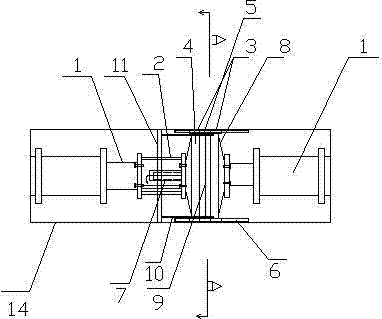

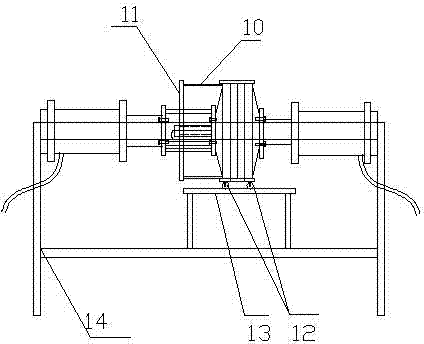

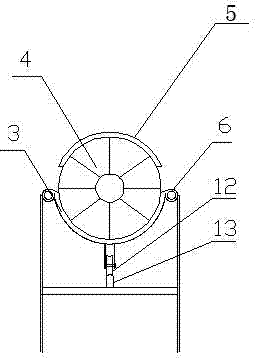

[0030] A special equipment for large-scale vertical shaft multi-section wind motor assembly, including a frame 14, a press 1, a slider 3, a slide rail 6, a cylindrical hollow support plate 2, a semicircular sleeve 5, a pulley, and a slideway. The two presses are respectively It is arranged at both ends of the frame, and the output end of one of the presses is connected with the cylindrical hollow support plate; there are matching sliders and slide rails on the frame, and a semicircular sleeve is provided above the frame; with a long The stator coil of the stator shaft 7 passes through the center of the lower casing 4 of the wind motor, and penetrates into the center of the cylindrical hollow support plate, and the wires of the long axis coil of the stator are kept out of the way so as not to damage the wires; the slider supports the wind motor T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com