Heat dissipation type vehicle headlamp lampshade

A heat-dissipating headlight technology, which is applied in the field of heat-dissipating vehicle headlight lampshades, can solve problems such as fog generated by car lights, heat deformation of parts, and melting, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

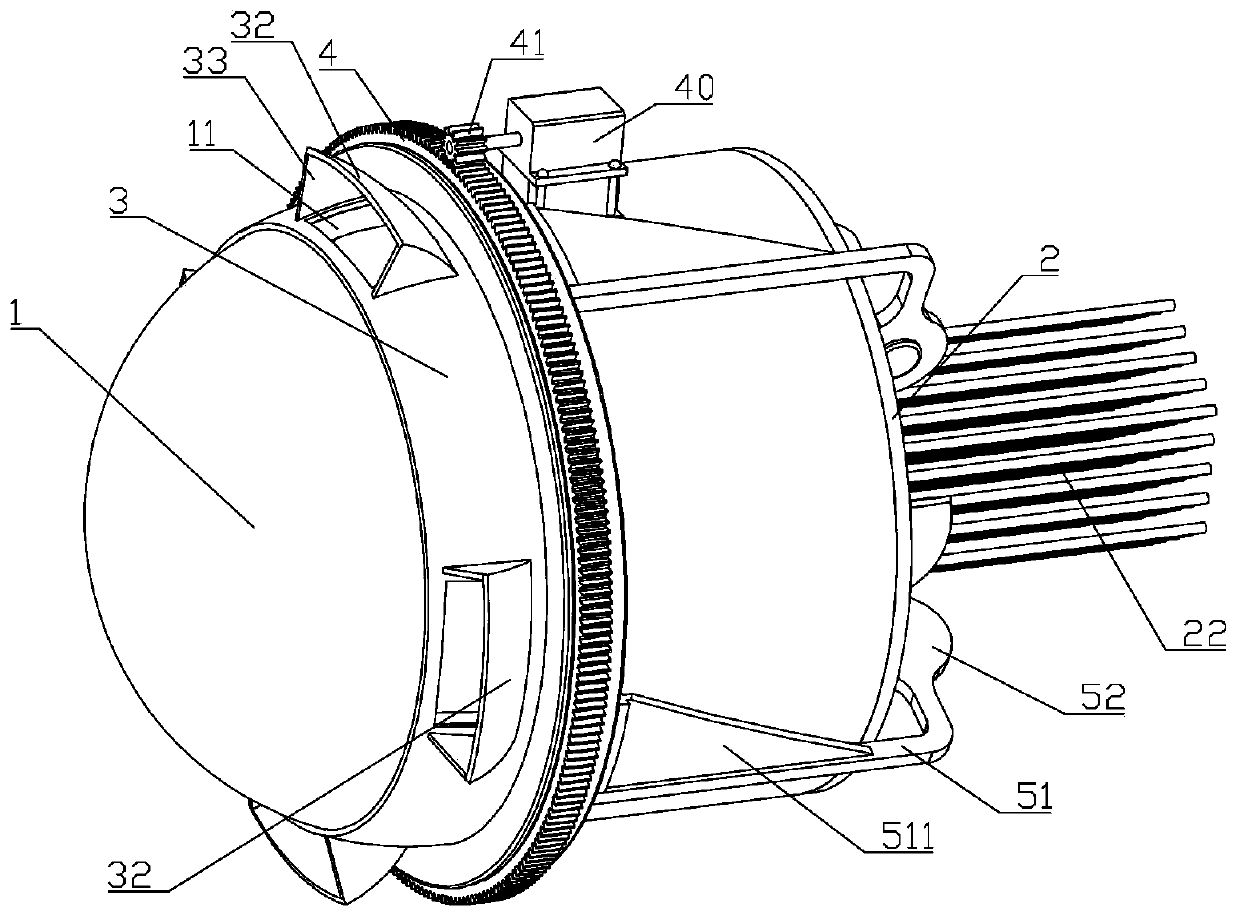

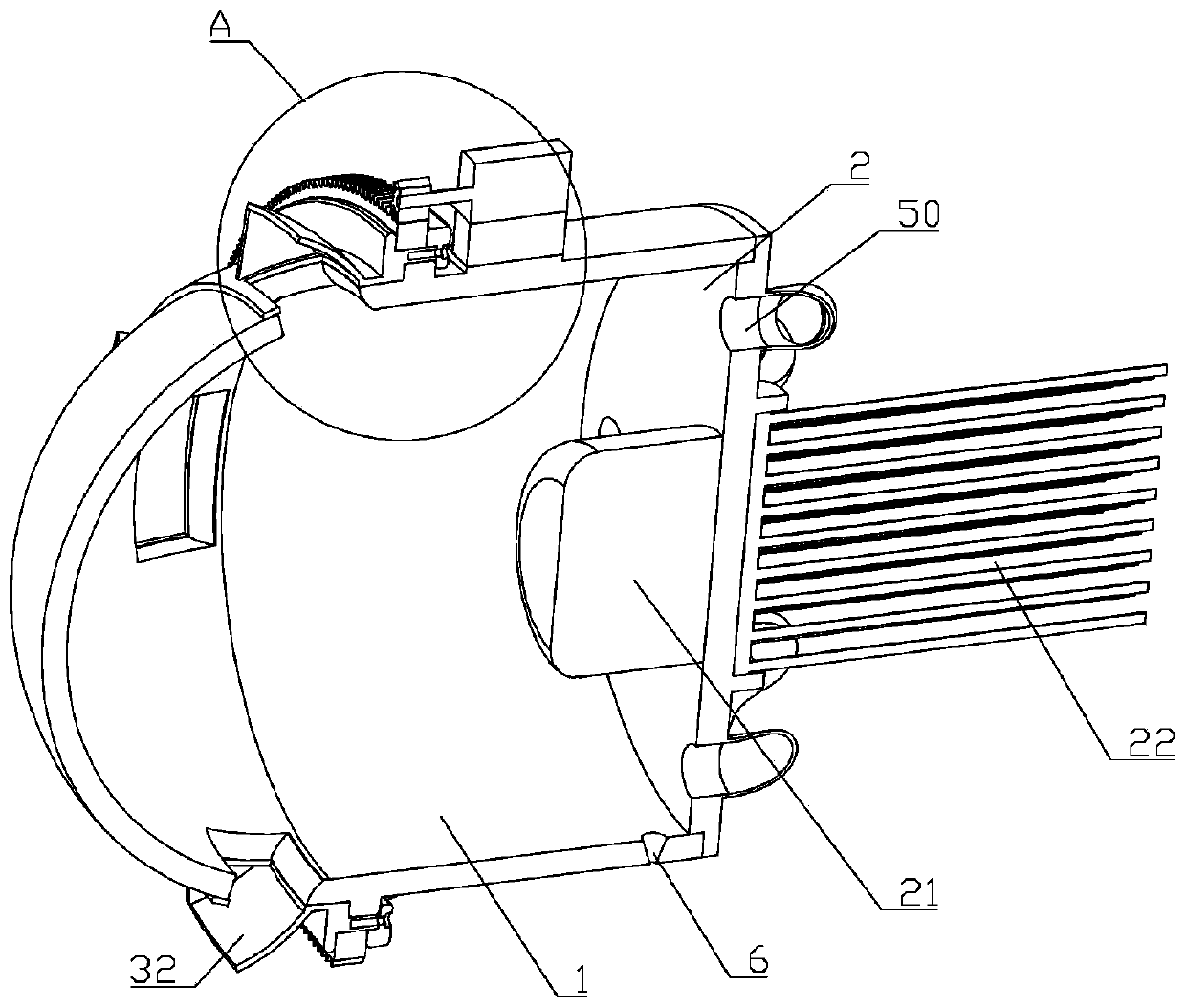

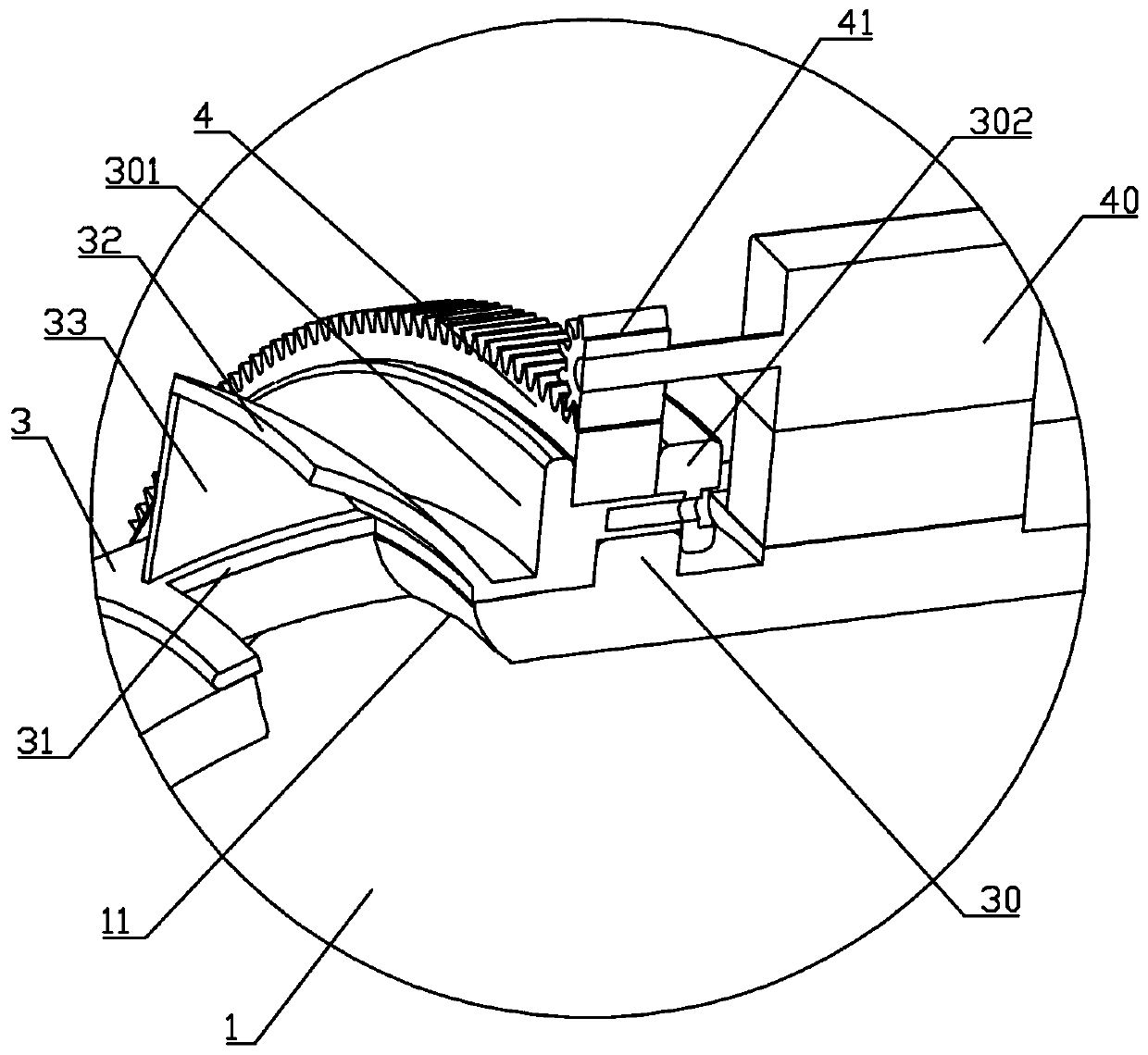

[0033] Such as Figure 1 to Figure 8 As shown, a heat dissipation type vehicle headlamp lampshade of the present invention includes a cover body 1 and a back plate 2 fixed on the rear side of the cover body 1. The back plate 2 is fixedly installed with a light source 21 inside the cover body 1. A radiator 22 is fixedly installed on the rear side of the plate 2, and a number of air inlets 11 are evenly opened at the front end of the cover body 1, and a filter screen is installed in the air inlet 11, and a closed ring 3 is connected to the cover body 1 in rotation at the corresponding position of the air inlet 11, and the closed ring 3 is provided with a slotted hole 31 matching the air inlet 11, an outer ring gear 4 is installed on the closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com