A furnace door safety locking device

A locking device and safety technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of unstable locking and laborious connection, etc., and achieve the effect of increasing the locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

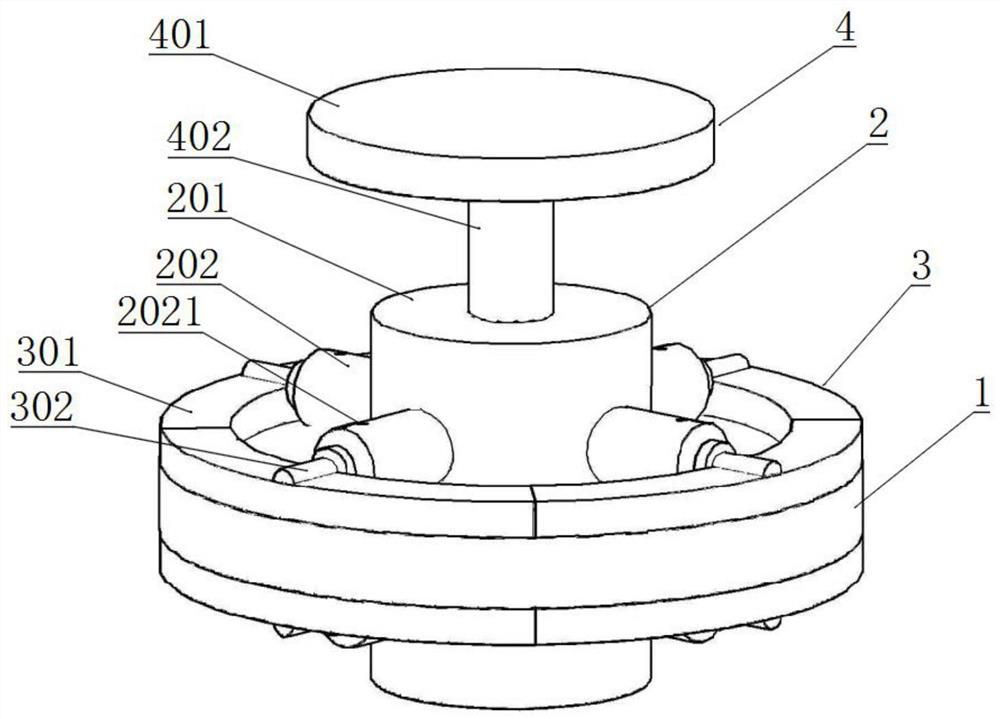

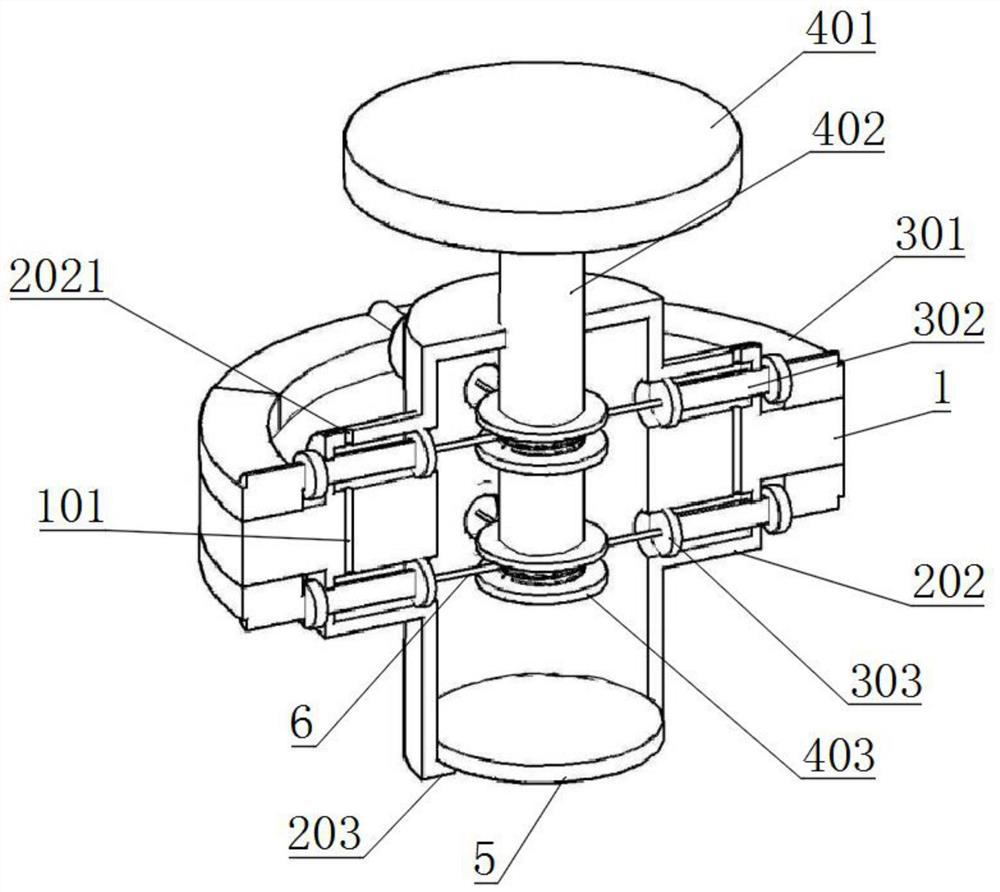

[0020] Such as Figure 1-3 A safety locking device for a furnace door is shown, comprising a sealed door, the sealed door includes a sealing plate 1, a pressure device 2 is provided in the middle of the sealing plate 1, and the pressure device 2 includes a pressure tube 201 penetrating through the sealing plate 1, and the pressure tube 201 is provided with a The piston 5 slidingly connected with it, the top of the pressure tube 201 is connected with the control mechanism 4, the control mechanism 4 is in transmission connection with the locking mechanism 3, the locking mechanism 3 is pneumatically connected with the pressure device 2, the locking mechanism 3 is slidingly connected with the sealing plate 1, and the pressure tube 201 The side is connected with the sliding cylinder 202, the sliding cylinder 202 is slidingly connected with the locking mechanism 3, the bottom end of the pressure tube 201 is open, and the bottom end of the inner wall of the pressure tube 201 is fixedl...

Embodiment 2

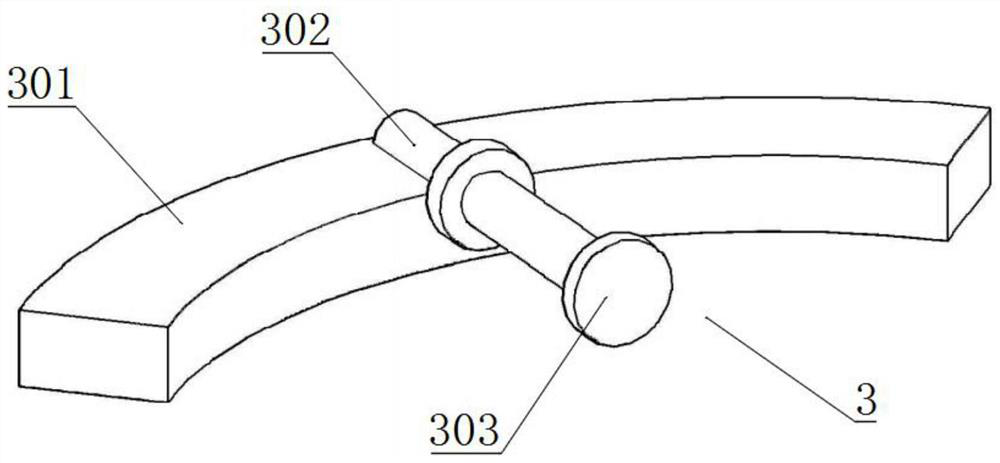

[0023] Such as Figure 1-3 As shown, a safety locking device for a furnace door includes a sealed door, and the sealed door includes a sealing plate 1. A pressure device 2 is provided in the middle of the sealing plate 1. The pressure device 2 includes a pressure tube 201 penetrating through the sealing plate 1. There is a piston 5 slidingly connected with it, and the top of the pressure tube 201 is connected with the control mechanism 4, the control mechanism 4 is in transmission connection with the locking mechanism 3, the locking mechanism 3 is pneumatically connected with the pressure device 2, the locking mechanism 3 is slidingly connected with the sealing plate 1, and the pressure tube The side of 201 communicates with the sliding cylinder 202, and the sliding cylinder 202 is slidingly connected with the locking mechanism 3. The shape of the chuck 301 is a hollow disc with an arc angle of 90 degrees. The vertical section of the chuck 301 is rectangular. The sliding cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com