Apparatus and method for forming packs

A technology of equipment and conveying direction, which is applied in the direction of transportation and packaging, packaging machines, conveyors, etc., can solve the problems of long-term downtime, time-consuming, and cumbersome equipment, and achieve simplified reloading, simplified placement, and shortened reloading time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

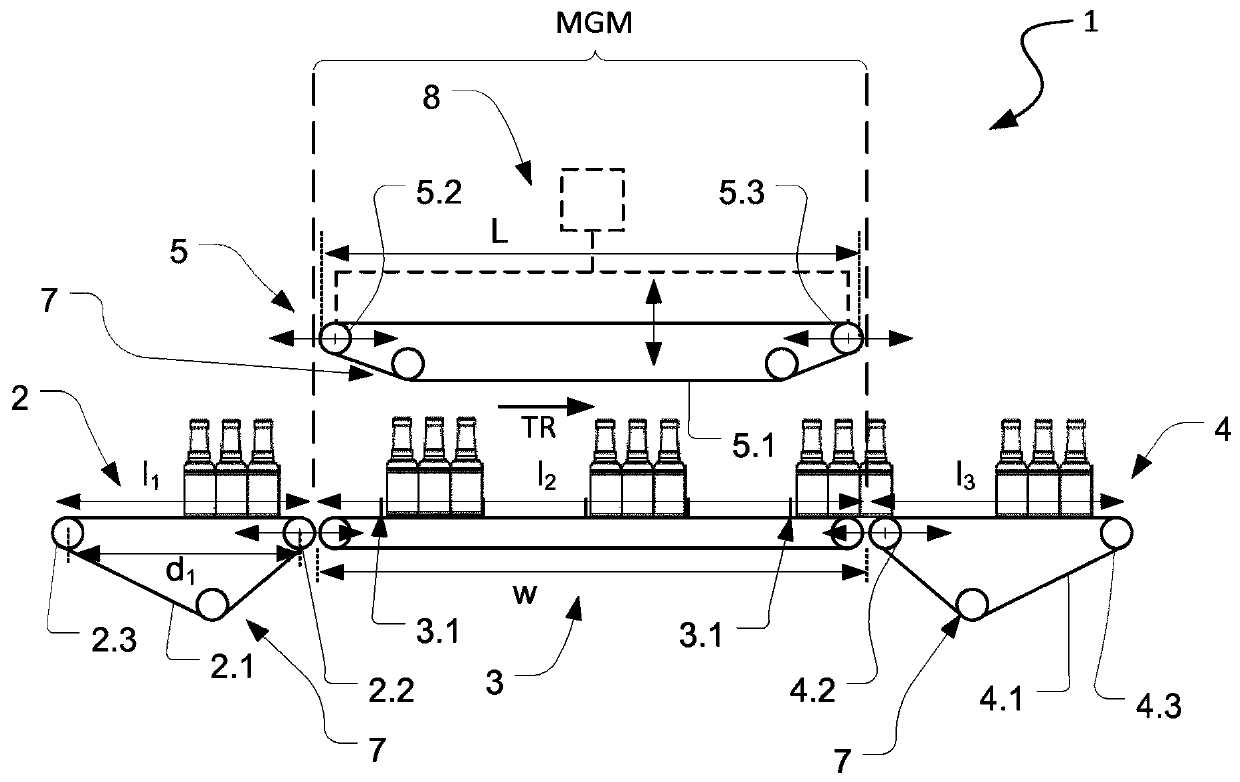

[0039] exist figure 1 In , a device 1 for forming a bundle from a plurality of packaging units is shown exemplarily and schematically with the reference number 1 . The plant 1 comprises a first conveying device 2 , a second conveying device 3 and a third conveying device 4 successively in the conveying direction TR. The first conveying device 2 can in particular be designed as a conveying device by means of which the second conveying device 3 is supplied with groups of packaging units. The third conveyor device 4 can be used to guide the packaging unit groups away from the second conveyor device 3 , for example to a shrink tunnel. The second conveying device 3 is used to convey the packaging unit group in the machine base module MGM in which the processing steps on the packaging unit group described in more detail below are carried out.

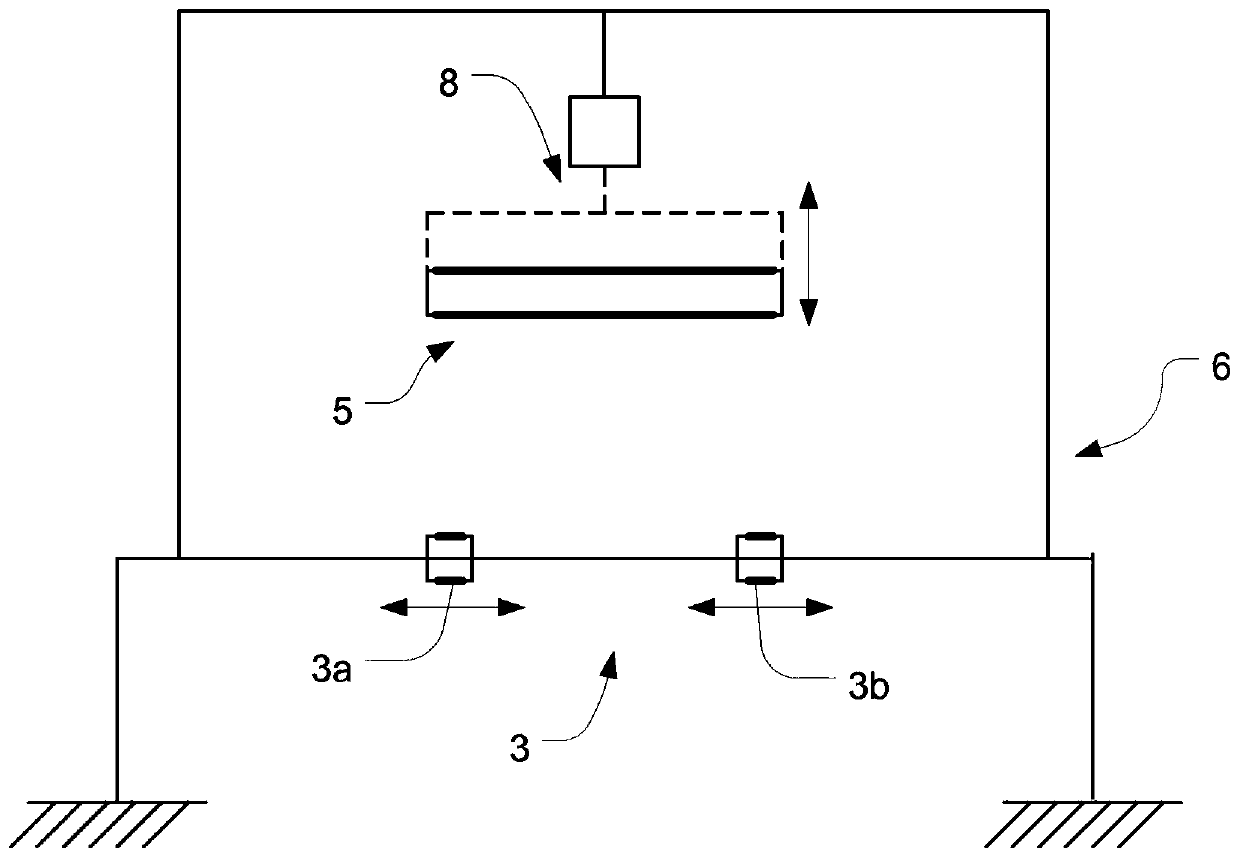

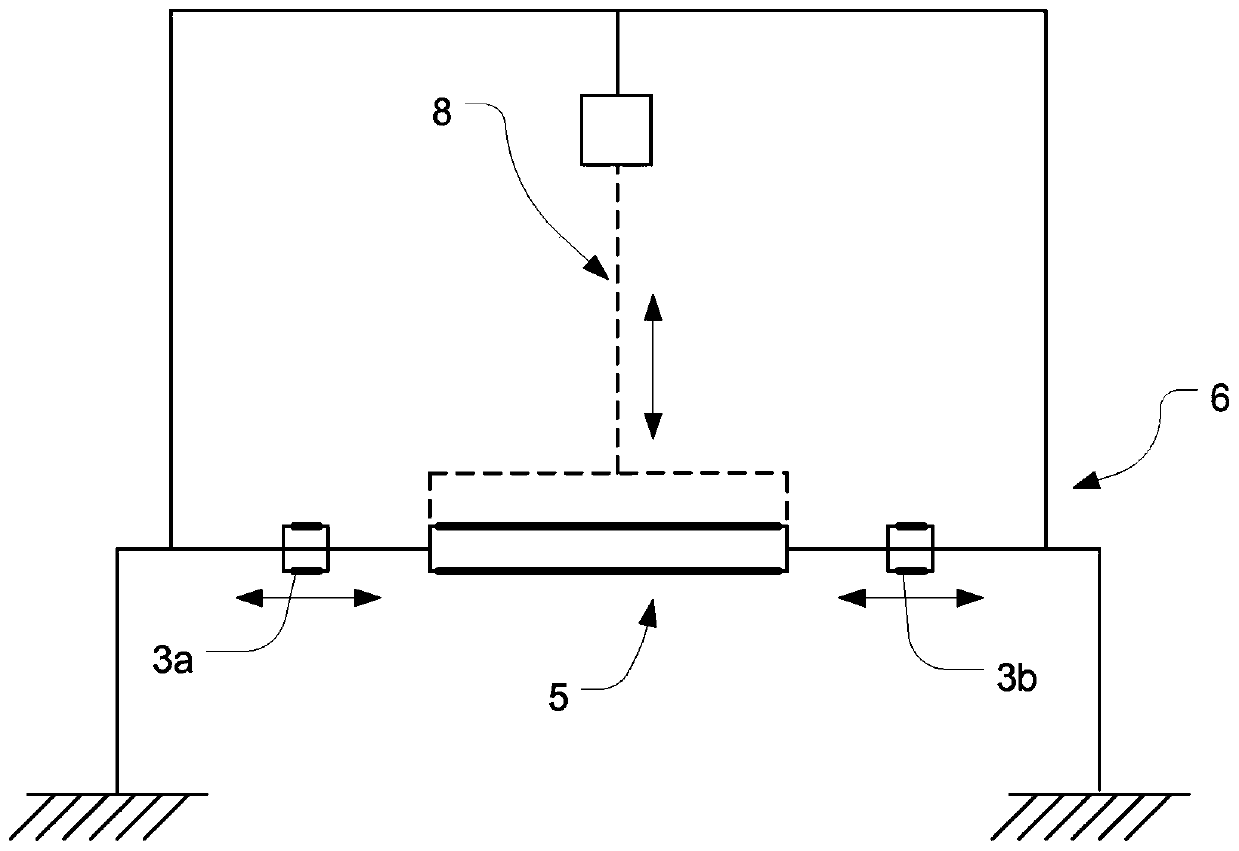

[0040] The device 1 also has a replacement conveyor device 5 which can be positioned instead of the second conveyor device 3 between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com