Lifting chair capable of improving safety

A safety and seat technology, applied in the field of furniture, can solve the problems of insufficient strength of the air pressure lifting device, insufficient nitrogen purity, rapid gas expansion, etc., and achieve the effect of convenient and quick adjustment, high safety in use, and not easy to shake and loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

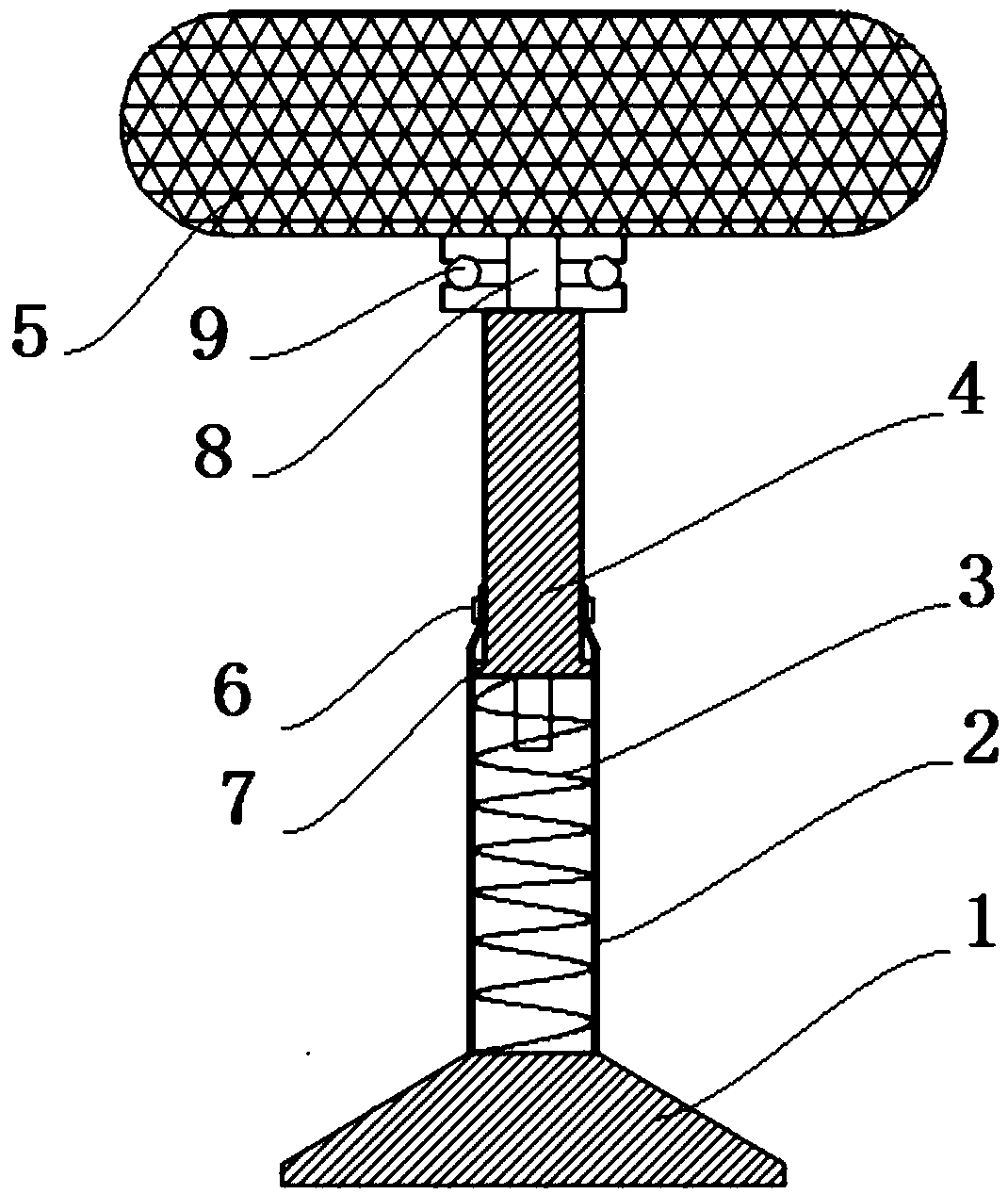

[0017] Such as figure 1 As shown, the present invention can improve the safety of a lifting seat, including a seat base 1, the top of the seat base 1 is fixedly connected to the outer sleeve 2, and the outer sleeve 2 is provided with a spring lifting mechanism 3 , the top port of the outer sleeve 2 is provided with a notch, the notch is opened along the length direction of the outer sleeve 2, and the function of the notch is to change the size of the top port of the outer sleeve 2, so as to facilitate the adjustment of the hoop 6, and the outer sleeve The diameter of the top opening of the cylinder 2 is smaller than the diameter of the outer sleeve 2, and the lifting shaft 4 is movably inserted in the outer sleeve 2, and the top of the lifting shaft 4 is fixedly connected to the seat 5, and the lifting shaft 4 and the seat 5 A rotating shaft 8 is provided between them, and a thrust ball bearing 9 is sleeved on the rotating shaft 8. The thrust ball bearing 9 is used for rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com