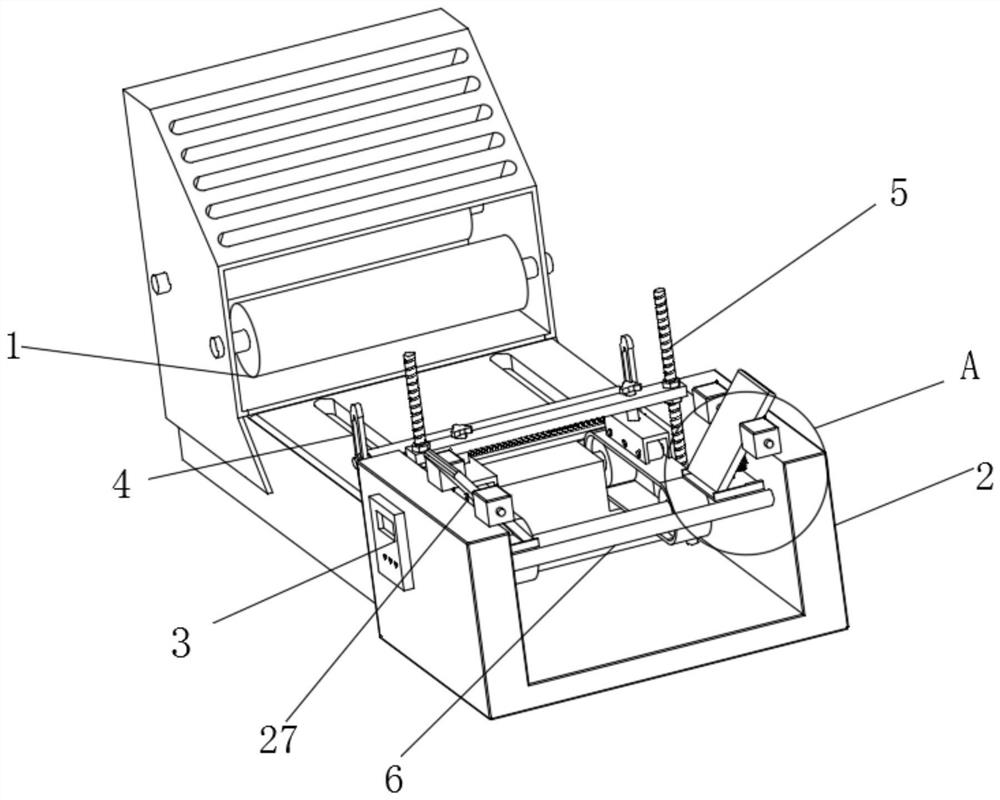

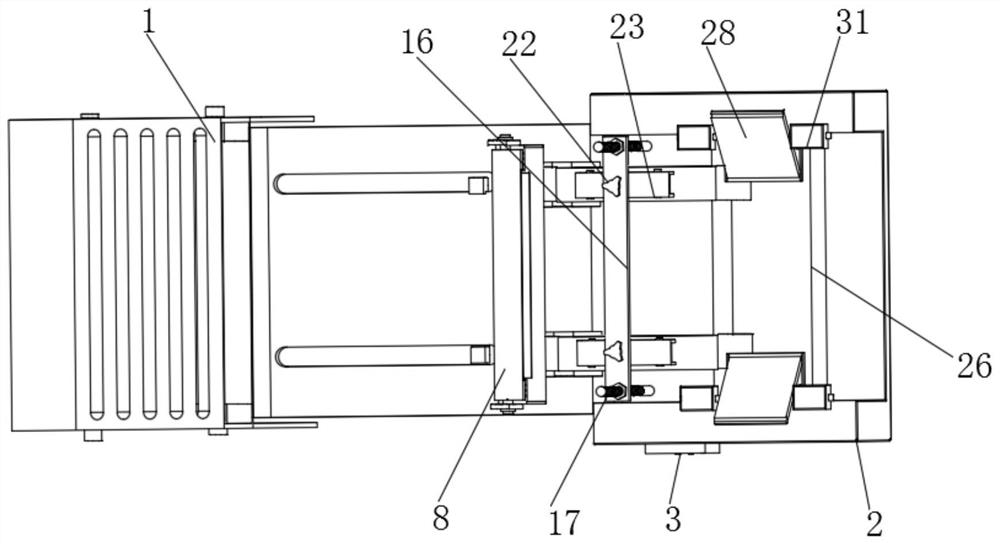

A paper clamping device for a printing machine

A printing press and paper clamping technology, applied in the field of printing presses, can solve the problems of poor printing quality, offset printing position, uneven edges of cartons, etc., and achieve the effect of maintaining printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

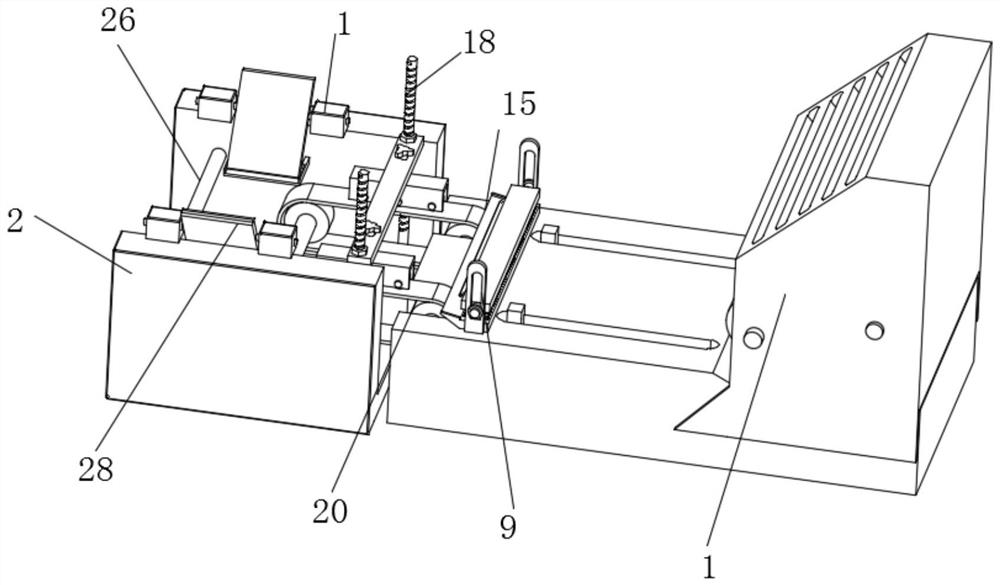

[0027] Specific implementation method: when the carton sheet is transmitted from the transmission belt 20, according to the thickness of the carton sheet, loosen the fixing nuts 11 at both ends of the second pressing plate 8, and push the second pressing plate 8 to slide along the waist-shaped hole 10, when the position is adjusted Finally, the fixing nut 11 is tightened, and the carton piece conveyed from the transmission belt 20 first touches the chute slope 15. When the carton piece slides along the chute slope 15, the light elastic piece 14 connected in the second pressing plate 8 is squeezed. Press on the surface of the carton sheet, so that the carton sheet is in full contact with the adsorption flannelette 33 in the first pressing plate 7 and the second pressing plate 8, the dust on the surface of the carton is absorbed by the adsorption flannelette 33, and at the same time, under the extrusion of the light elastic sheet 14, the carton sheet Bounce back the lightweight s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com