Multi-purpose double-velocity winch

A multi-purpose, winch technology, applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problems of no speed adjustment, dangerous events, and large risk coefficient of the winch, and achieve a reduction in risk coefficient, simple operation, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

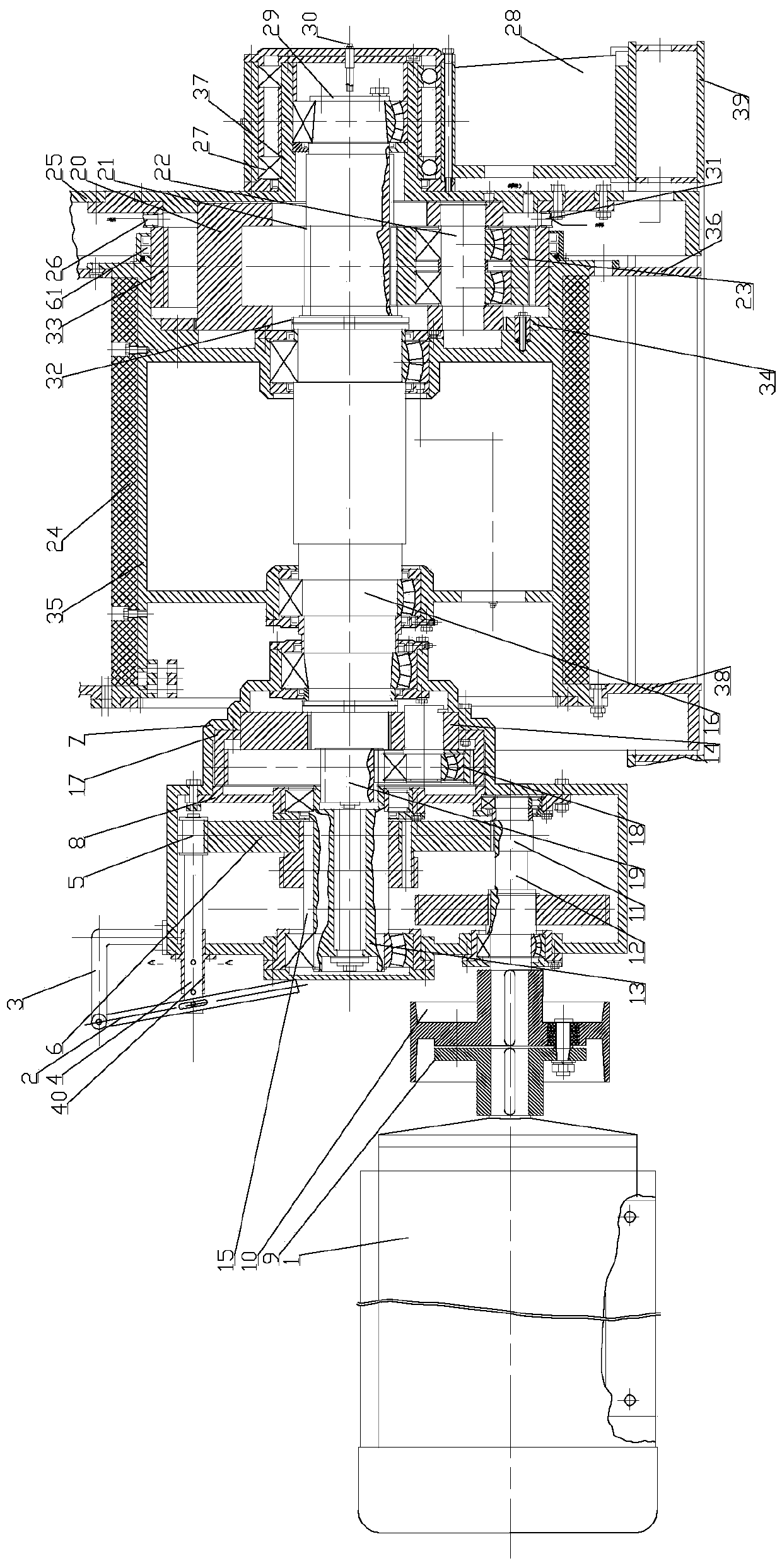

[0031] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a multi-purpose two-speed winch described in this embodiment includes a motor 1, a brake wheel device 10, a gearbox 7, a main shaft 16, a shaft coupling 9, an input shaft 12, a bearing bracket 28, a shaft Head pressing plate 29, brass oil nozzle 30, winch frame 39 and drum 35;

[0032] The output end of the motor 1 is connected to the brake wheel device 10 through the coupling 9, the shaft hole of the brake wheel device 10 is connected to one end of the input shaft 12 through a keyway, and the other end of the input shaft 12 is connected to the side plate of the gearbox 8 bore connection, the output end of the gearbox is connected with one end of the main shaft 16, two bearing cups are arranged on the spoke plate of the drum 35, the main shaft 16 is connected with the bore hole of the spoke plate of the drum 35 through bearings, and a bearing is provided on each bearing cup , and ...

specific Embodiment approach 2

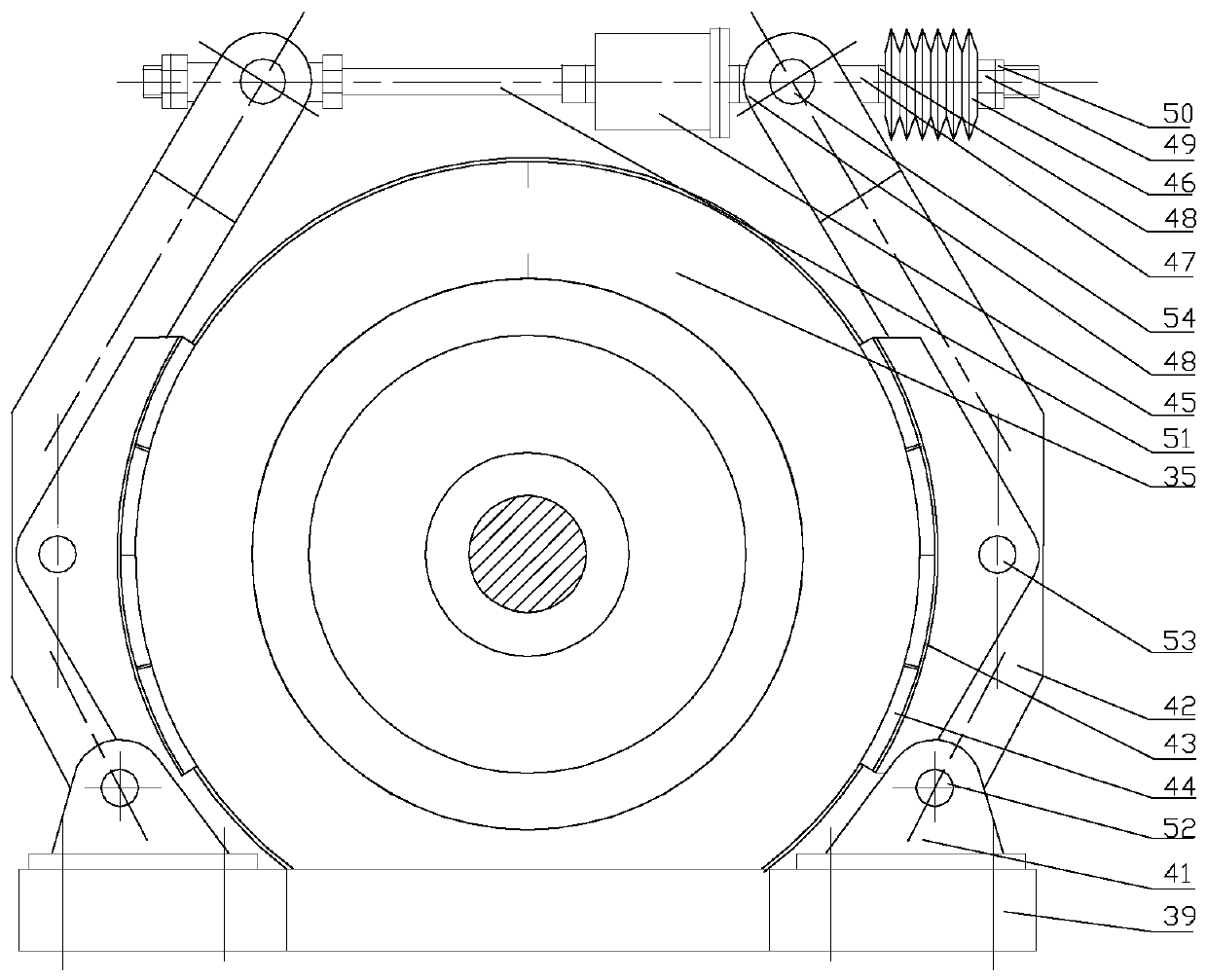

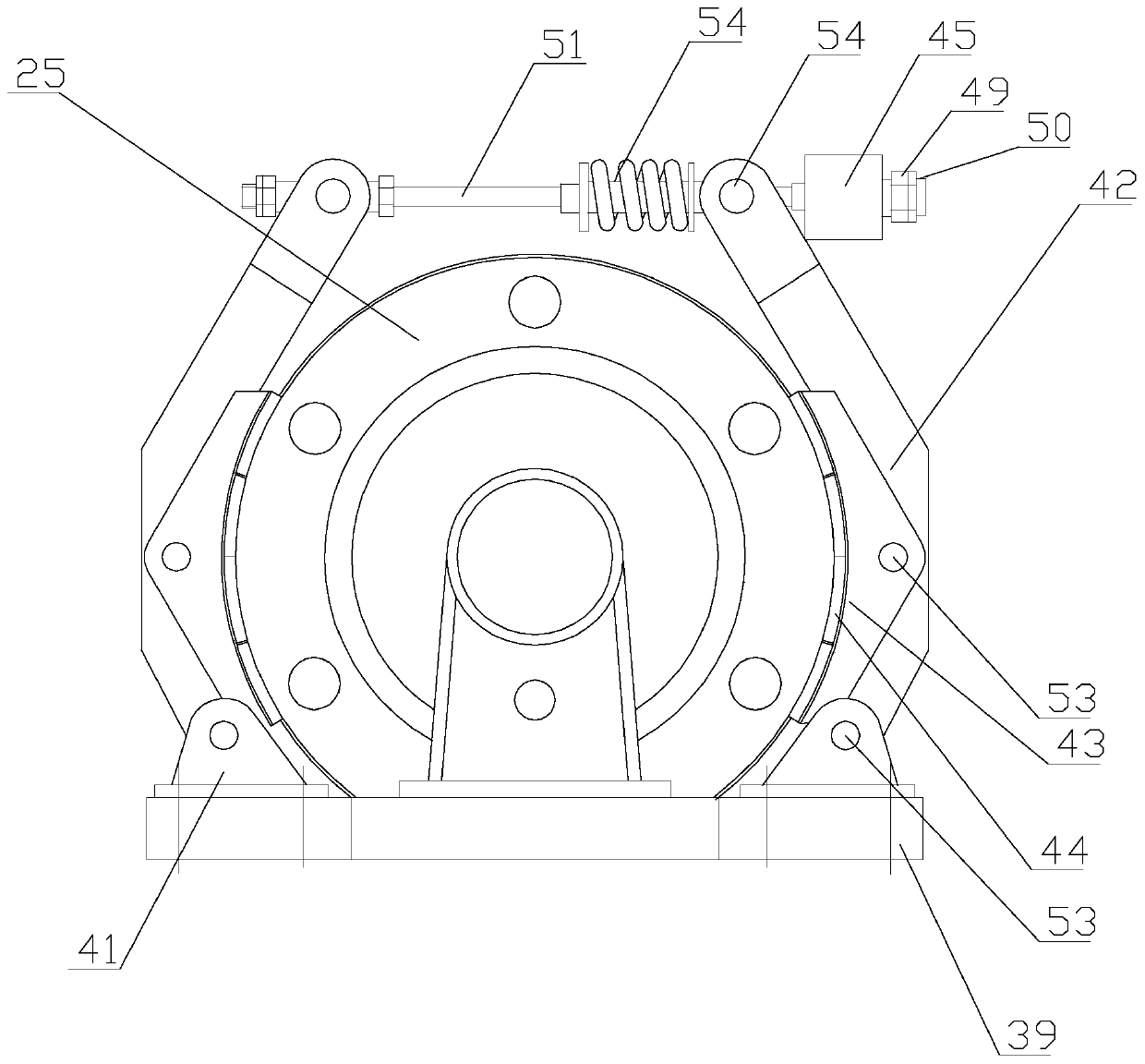

[0039] Specific implementation mode two: combination figure 2 Describe this embodiment, this embodiment is a further limitation on the winch described in the first specific embodiment, a multi-purpose two-speed winch described in this embodiment, the brake brake wheel device 38 includes a brake brake Wheel 38, brake tie rod 51, brake cylinder 45, disc spring 46, brake column 42, brake shoe 43, brake block 44, brake seat 41 and winch frame 39;

[0040] The four corners of the upper surface of the winch frame 39 are respectively provided with a brake seat 41, and each brake seat 41 is hingedly connected with the lower end of the brake column 42, and the brake column 42 is hingedly connected with the brake shoe 43, and the side surface of the brake shoe 43 is connected with the brake wheel 38. A plurality of brake blocks 44 are arranged between them, and the brake tie rod 51 passes through the upper pin shafts of the two left and right brake columns 42, the brake cylinder 45, th...

specific Embodiment approach 3

[0041] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, this embodiment is a further limitation on the winch described in the first embodiment, a multi-purpose two-speed winch described in this embodiment, the gearbox 7 includes a handle 2, a support arm 3 , shift shaft 4, shift wheel 5, slip gear 6, gearbox casing, bore side plate 8, driving gear 11, driven shaft 13, lead key 15, first-stage planetary gear carrier 14, first-stage planetary gear 18. Primary sun gear 19 and primary ring gear 17.

[0042] The gearbox casing is a cuboid with a cavity, and one side of the gearbox casing is provided with a stepped cylinder-shaped spindle chamber, which communicates with the interior of the gearbox casing. The box wall of the gearbox casing is fixedly connected with one end of the support arm 3, and the The other end of the arm 3 is hinged to one end of the handle 2, the middle notch of the handle 2 is hinged to one end of the shift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com