Wellhead safe operation method based on axial oblique jet suction and drainage

A technology for safe operation and oblique jetting, applied in the fields of oil and gas drilling, reverse circulation drilling, and drilling engineering, it can solve hidden safety hazards, cannot ensure the safety of on-site operations, and other problems, achieves elimination of safety risks, and is conducive to speed improvement. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the wellhead safety operation method based on axial oblique spraying and suction-assisted drainage of the present invention will be described in detail in combination with exemplary embodiments.

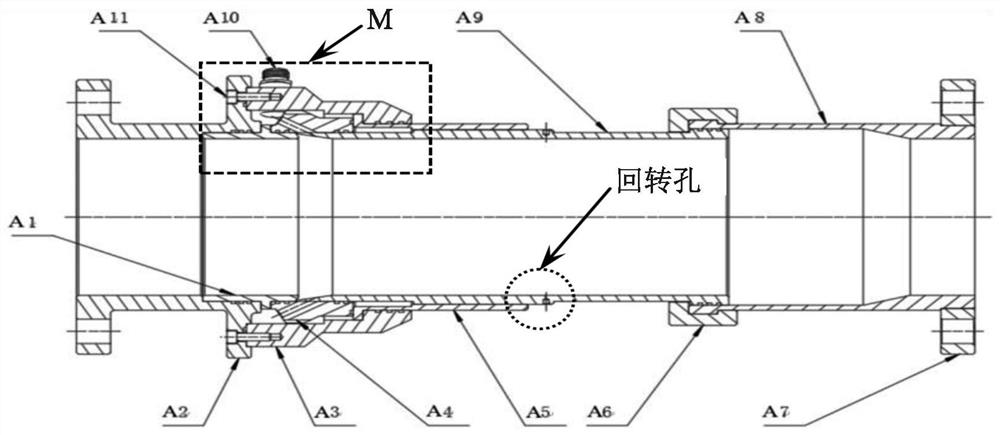

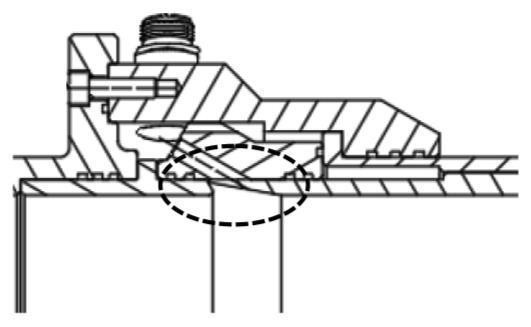

[0029]In an exemplary embodiment of the present invention, the wellhead safety operation method based on axial oblique injection suction drainage uses the wellhead safety operation system based on axial oblique injection suction drainage to realize the wellhead and / or drainage Suction of combustible gas, sand, mixture, etc. at the turn of the sand pipeline.

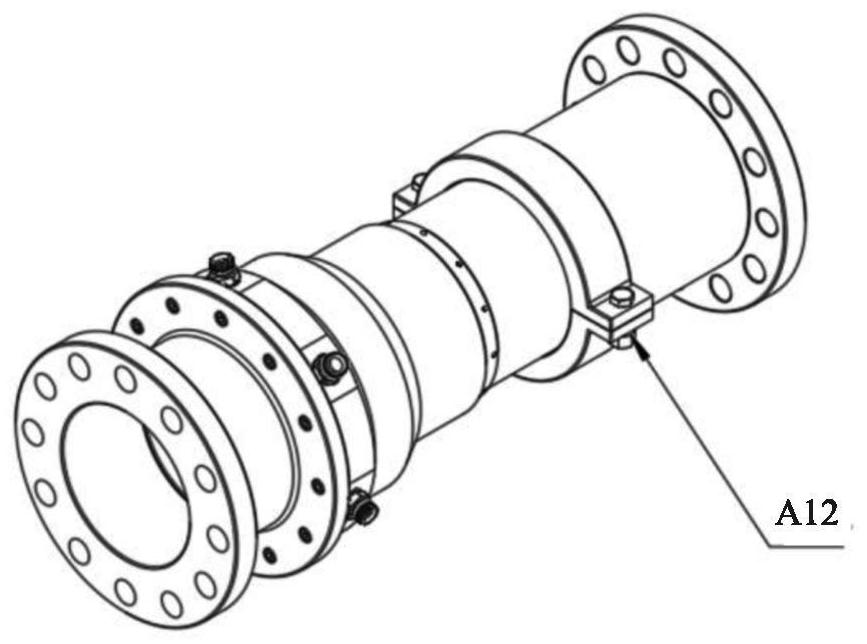

[0030] The wellhead safety operation system based on axial oblique injection suction drainage may include a sand discharge (or sand discharge) pipeline, a first axial oblique injection suction drainage assistance mechanism, an ignition device, a gas injection unit and a first gas injection manifold.

[0031] The first axial oblique jet suction and drainage aiding mechanism can directly or indirectly connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com