Spatial guide vane body of vertical type multi-stage pump

A space guide vane and multi-stage pump technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of large hydraulic loss in the transition area of the impeller guide vane and the inability to eliminate the rotational component of the fluid velocity at the inlet of the secondary impeller, etc. , to achieve the effect of avoiding crowding and deterioration, simple structure and increasing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

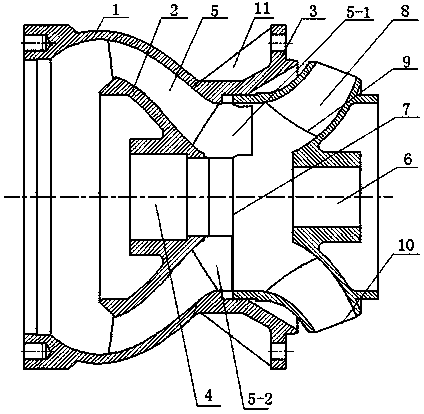

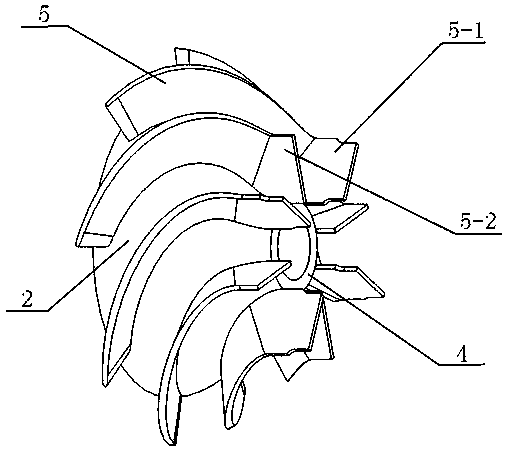

[0018] In the accompanying drawings: a space guide vane body of a vertical multi-stage pump, including an outer shell 1 and an inner shell 2; The guide vane hub 4 is set at the position, the guide vane blade 5 is arranged between the outer casing 1 and the inner casing 2, and the guide vane blade 5 is set as an arc-shaped curved surface; the end of the guide vane blade 5 is provided with an extension section along the axial direction The right side of the guide vane hub 4 is provided with a secondary impeller 6, the secondary impeller 6 is connected with the outer shell 1, and the left end of the secondary impeller 6 is set as the impeller inlet 7; the secondary impeller 6 is provided with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com