Airflow ejector adopting annular swirl injection

A technology of ejector and annular nozzle, which is applied in the field of recovery devices for diffused gas, can solve problems such as no public reports, and achieve significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

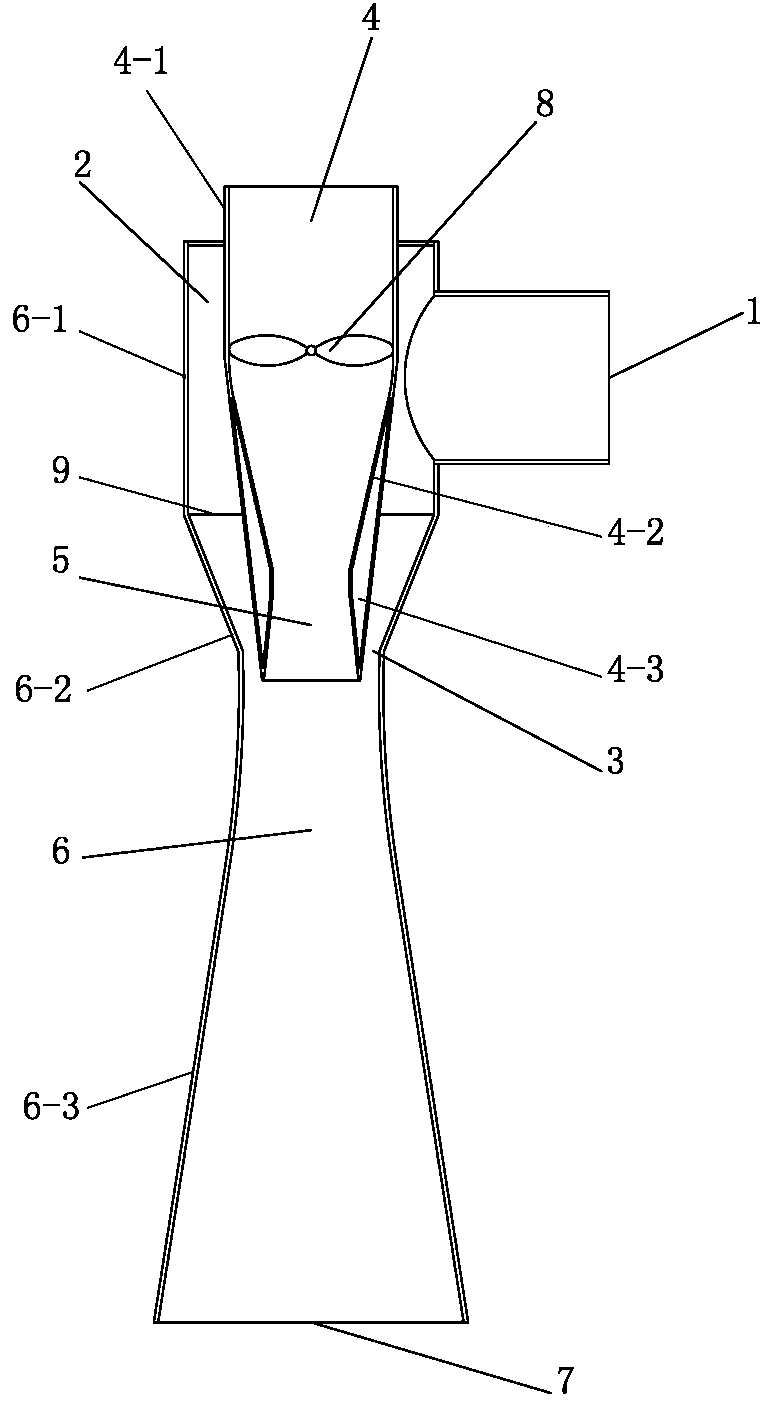

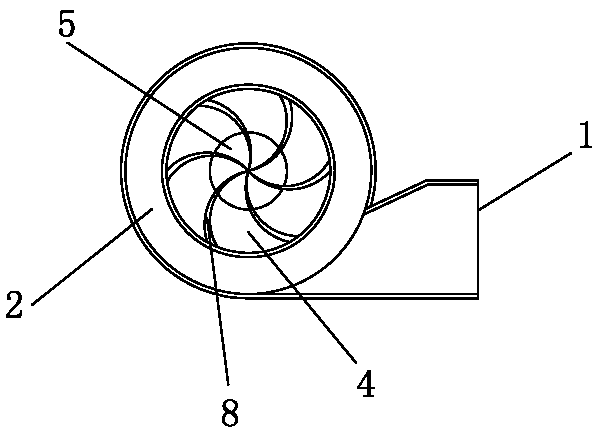

[0009] Such as figure 1 , figure 2 As shown, the present invention adopts the airflow ejector of annular swirl jet, comprises the ejection airflow inlet pipe 1, the ejected airflow inlet pipe 4 and the mixed airflow diffuser pipe 6, and the airflow ejector is formed by the ejected airflow inlet pipe 4 and the mixed airflow diffuser pipe 6. The airflow inlet pipe 4 is set in a sleeve tubular zoom structure formed in the upper center of the mixed airflow diffuser pipe 6. The ejected airflow inlet pipe 4 is composed of a first straight pipe section 4-1 and a first tapered section 4-2. 1. An integrated structure formed by connecting the first scaling section 4-3, and the mixed air flow diffuser pipe 6 is formed by connecting the second straight pipe section 6-1, the second tapering section 6-2, and the second zooming section 6-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com