Flowmeter provided with protective cover

A protective cover and flow meter technology, applied in the field of flow meters, can solve the problems of easy formation of dirt, short service life, high hardness, and achieve the effects of reducing friction, short drainage time and fast drainage speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

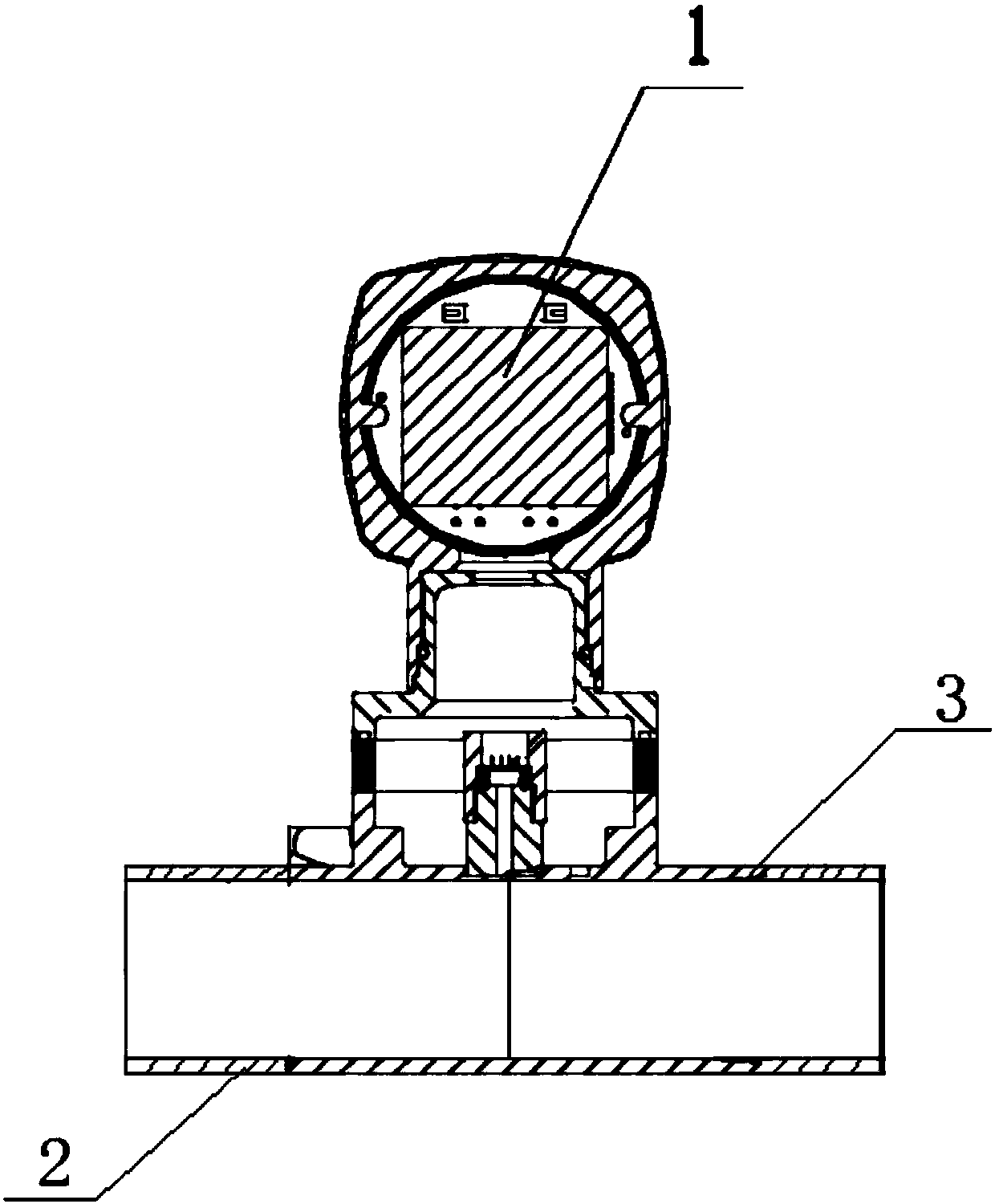

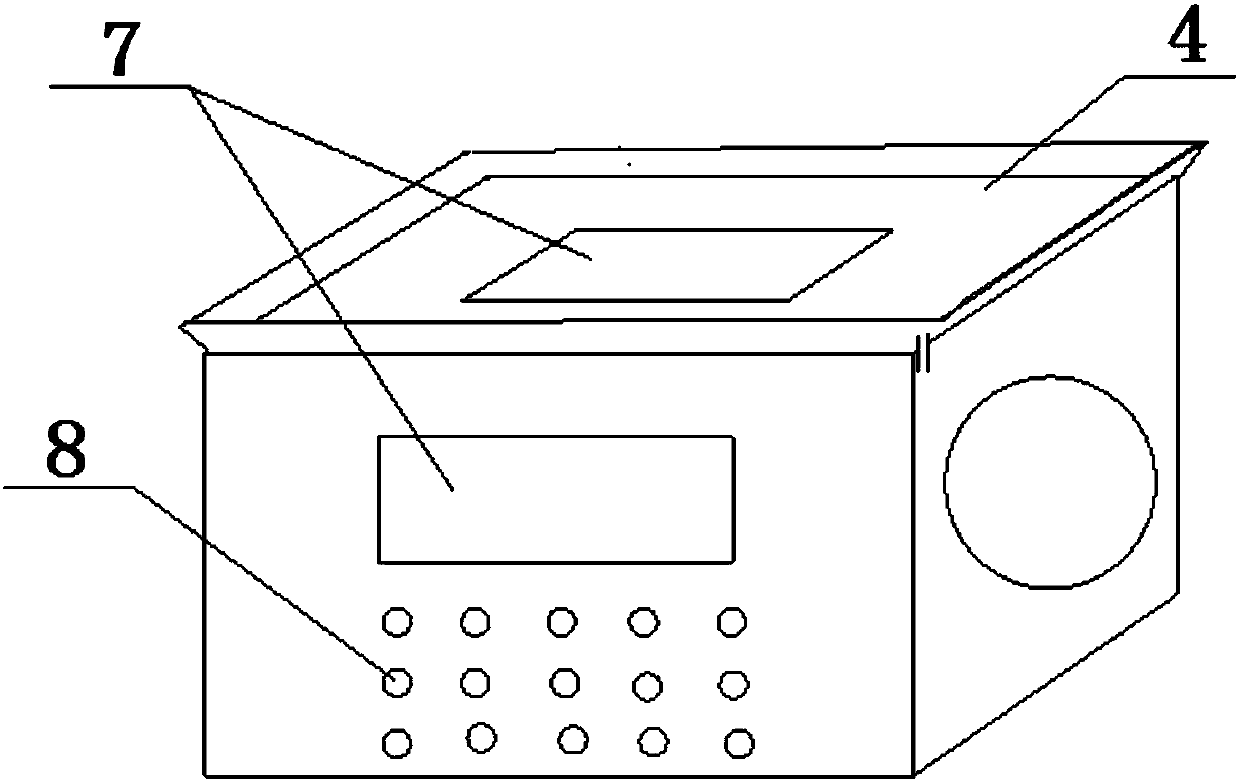

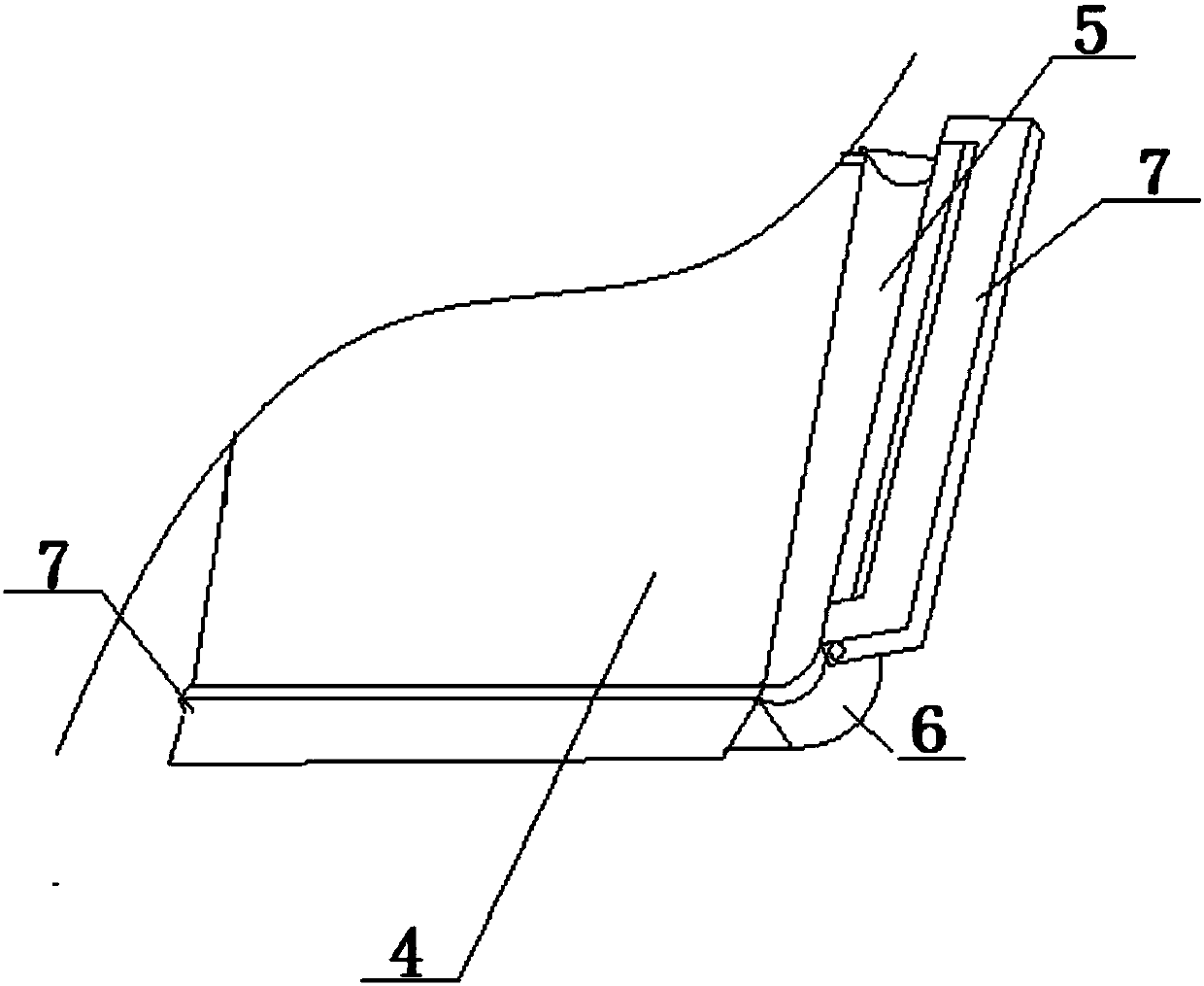

[0049] A flow meter with a protective cover provided in this embodiment has a structure such as Figure 1-4 As shown, it includes the flow meter head 1 and the flow tube. The flow tube is a hollow tubular structure. The flow tube is connected by the liquid inlet pipe 2 and the liquid outlet pipe 3. The flow meter head 1 is located in the middle of the flow tube length direction. The flow meter The head 1 is also covered with a protective cover, wherein:

[0050] The protective cover includes a protective cover body 4, a water guide groove arranged on the protective cover body 4 and an adapter 6. The protective cover body 4 is composed of five plates, and at least one side plate of the protective cover body 4 is movably connected to the protective cover. On the body 4, the two sides of the protective cover body 4 are respectively provided with nozzles for the liquid inlet pipe 2 and the liquid outlet pipe 3 to extend into, and the upper end of the protective cover body (4) and ...

Embodiment 2

[0053] This embodiment provides the flow meter with protective cover in Example 1. A layer of protective layer is provided on the protective cover, and the protective layer includes the following components in parts by mass:

[0054] Film-forming resin: 30 parts, black silicon carbide: 20 parts, fine-grained alumina: 25 parts, styrene-butadiene rubber: 10 parts, pigments and fillers: 7 parts, defoamer: 3 parts, dispersant: 5 parts, leveling Agent: 1 part, suspending agent: 3 parts, surfactant: 1 part, thixotropic agent: 0.5 part, silane coupling agent: 1 part, curing agent: 8 parts, compound rare earth: 1 part;

[0055] The film-forming resin is a mixture of water-based hydroxyl acrylic resin and bromocarbon polyurethane resin composite material, in which the water-based hydroxyl acrylic resin: bromocarbon polyurethane resin is 1:4 by mass ratio; the pigment and filler is composite iron-titanium powder; the defoamer is polysilicon Oxy-alkane defoamer; dispersant hydrophobicall...

Embodiment 3

[0075] This embodiment provides the flow meter with protective cover in Example 1. A layer of protective layer is provided on the protective cover, and the protective layer includes the following components in parts by mass:

[0076] Film-forming resin: 35 parts, black silicon carbide: 23 parts, fine-grained alumina: 30 parts, styrene-butadiene rubber: 15 parts, pigments and fillers: 9 parts, defoamer: 5 parts, dispersant: 8 parts, leveling Agent: 3 parts, suspending agent: 5 parts, surfactant: 3 parts, thixotropic agent: 1.0 parts, silane coupling agent: 4 parts, curing agent: 10 parts, compound rare earth: 3 parts;

[0077] The film-forming resin is a mixture of water-based hydroxyl acrylic resin and bromocarbon polyurethane resin composite material, wherein the water-based hydroxyl acrylic resin: bromocarbon polyurethane resin is 1:4 by mass ratio; the pigment and filler is sepiolite; the defoamer is polysiloxane Alkane defoamer; dispersant polyacrylic acid sodium salt; lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com