A kind of preparation method of bistable dye-doped liquid crystal film

A liquid crystal thin film and doping technology, which is applied in the fields of fine chemical industry and material science, can solve problems such as liquid crystal bistable state, achieve good solvent resistance and water resistance, bright and changeable colors, and bright color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

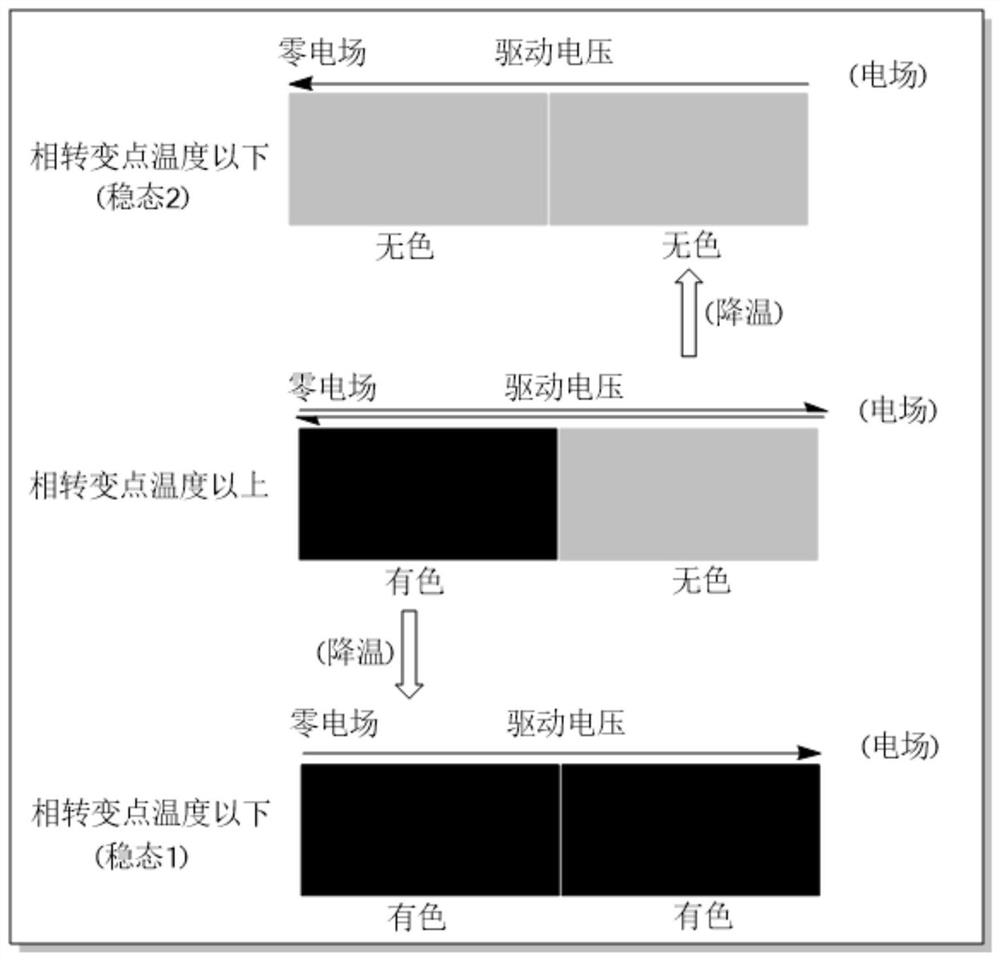

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

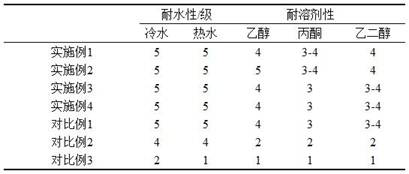

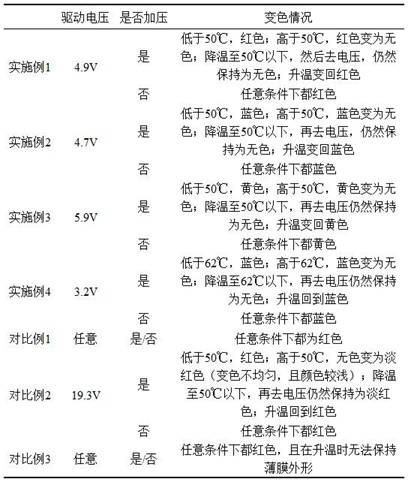

[0037] In a light-shielding environment, 4.0 g epoxy resin, 0.5 g photoinitiator IRG184, 1.5 g hydroxypropyl methacrylate, 1.5 g lauryl methacrylate, and 3.0 g paraffin phase change material were mixed in proportion; Stir uniformly at about ℃ for about 30 minutes; the obtained mixture A; mix the mixture A with dye-doped liquid crystal (0.20g C.I. Disperse Red 135; 20.0 g liquid crystal E7), and stir uniformly at about 40℃ for about 30 minutes; the obtained mixture B; add 5‰ spacers with a diameter of 20 microns and mix with B, and stir evenly at about 40°C for about 30 minutes; obtain the final bistable dye-doped liquid crystal film raw material; coating and pressing; curing under ultraviolet light, the Air bubbles remaining trapped in the film are completely pumped out. The photoelectric performance test (see Table 1) and the water resistance and solvent resistance performance test (see Table 2) were carried out on the bistable dye-doped liquid crystal film prepared above.

Embodiment 2

[0039] In a light-shielding environment, mix 3.0 g epoxy resin, 0.3 g photoinitiator IRG651, 2.0 g styrene, 2.0 g lauryl methacrylate, and 3.0 g paraffin phase change material in proportion; after mixing, stir evenly at about 40 °C About 30 minutes; the obtained mixture A; mix the mixture A with dye-doped liquid crystal (0.23g C.I. Disperse Blue 359; 23.0 g liquid crystal E7), and stir evenly at about 40°C for about 30 minutes; the obtained mixture B; add 5 ‰ spacers with a diameter of 20 microns are mixed with B, and stirred evenly at about 40°C for about 30 minutes; the final bistable dye-doped liquid crystal film raw material is obtained; coating and pressing; curing under ultraviolet light, leaving the residue in the film Air bubbles are completely drawn out. The photoelectric performance test (see Table 1) and the water resistance and solvent resistance performance test (see Table 2) were carried out on the bistable dye-doped liquid crystal film prepared above.

Embodiment 3

[0041] In a light-shielding environment, mix 5.0 g epoxy resin, 0.7 g photoinitiator IRG184, 3.0 g ethyl methacrylate, 3.0 g lauryl methacrylate, and 5.0 g paraffin phase change material in proportion; Stir uniformly from side to side for about 30 minutes; the obtained mixture A; mix the mixture A with dye-doped liquid crystal (1.15g C.I. Disperse Yellow 90; 15.0 g liquid crystal 5CB), and stir uniformly at about 40°C for about 30 minutes; the obtained mixture B Add 5‰ spacers with a diameter of 20 microns and mix with B, and stir evenly at about 40°C for about 30 minutes; obtain the final bistable dye-doped liquid crystal film raw material; coat and press; cure under ultraviolet light, and remove the remaining Air bubbles trapped in the film are completely pumped out. The photoelectric performance test (see Table 1) and the water resistance and solvent resistance performance test (see Table 2) were carried out on the bistable dye-doped liquid crystal film prepared above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com