Computer-aided design method for outer closed stirrup of concrete bridge strip-shaped component

A computer-aided design method technology, applied in computing, special data processing applications, instruments, etc., can solve the problems that designers cannot meet the requirements of rapid modeling, there is no rapid modeling method, and error-prone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

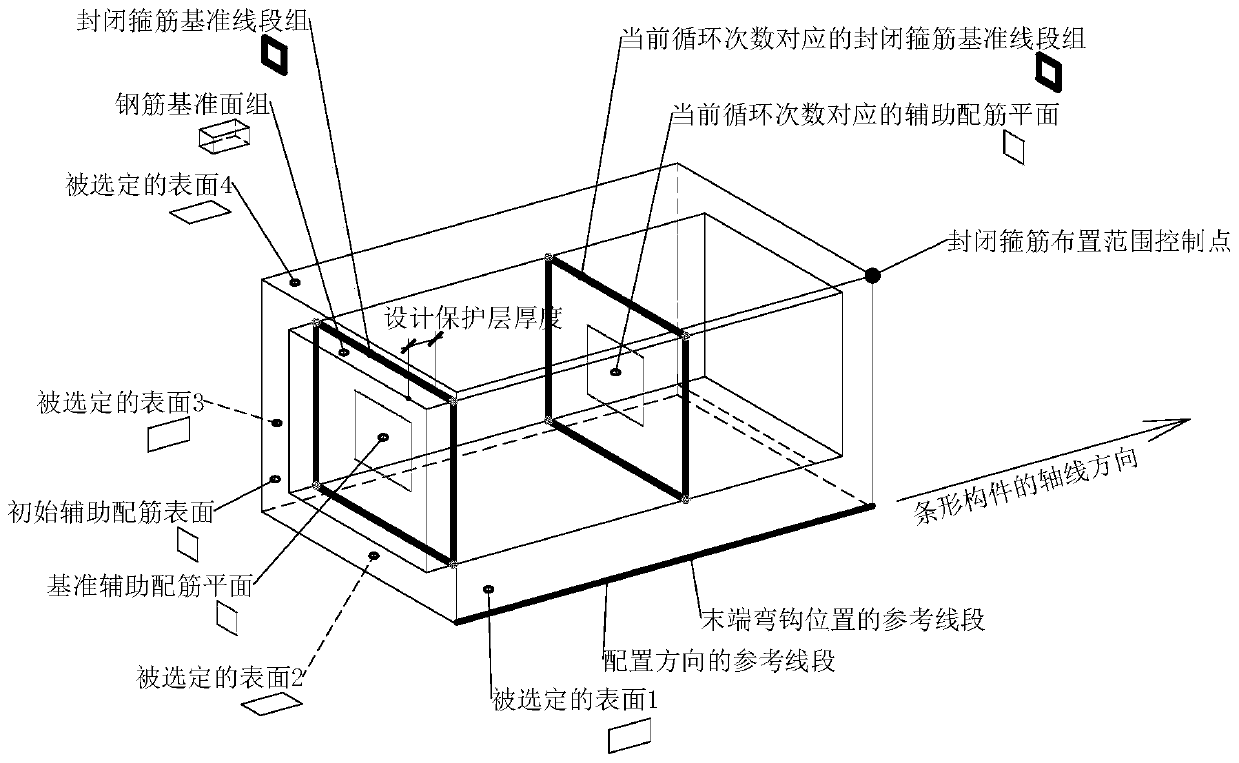

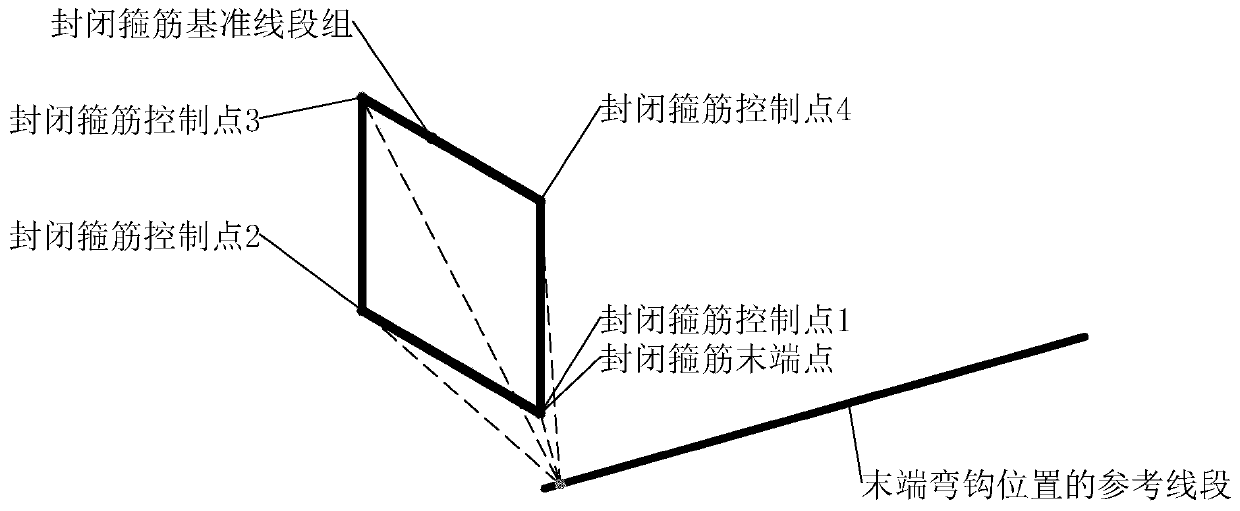

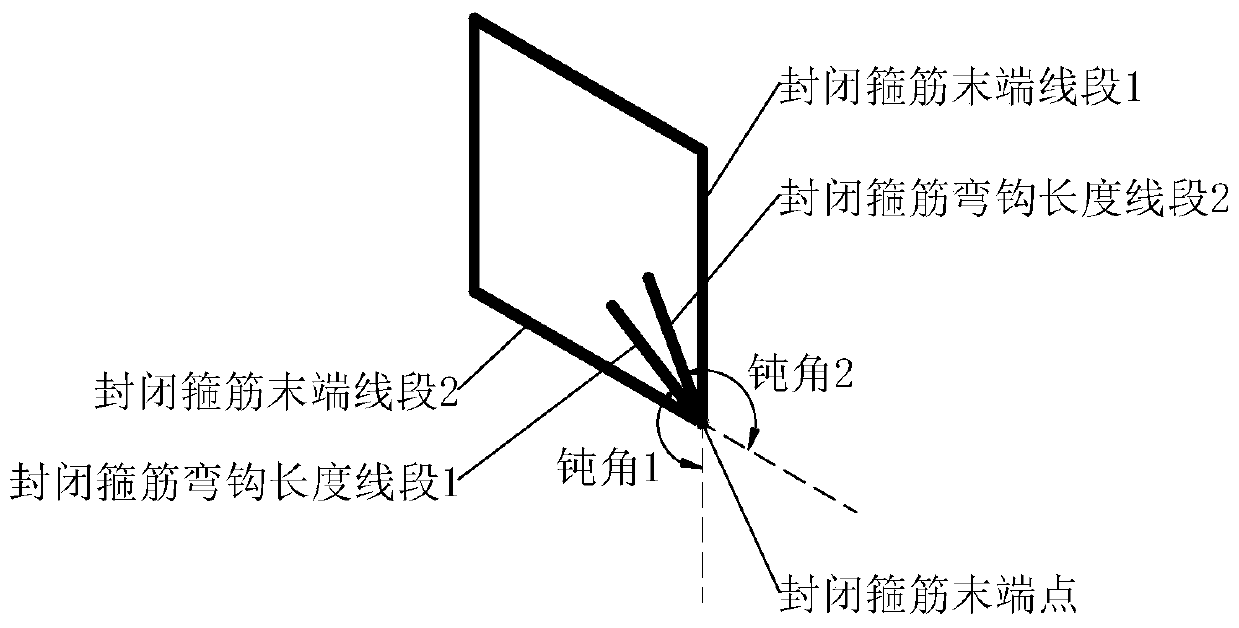

[0058] like Figure 1 to Figure 7 As shown, the computer-aided design method of the external closed stirrups of concrete bridge strip components; based on the CATIA software environment, and the concrete bridge components are modeled using the BIM model; in the BIM model of the concrete bridge components, multiple continuous intersections and The component surfaces that can form closed space graphics are used as the selected surface group, and the specific steps to generate closed stirrups are as follows:

[0059] Step 1. Offset the selected surface group according to the design cover thickness of the reinforcement, and the offset direction is to the inner side of the concrete bridge member;

[0060] Create multiple surfaces corresponding to multiple continuous surfaces in the selected surface group to form a steel bar datum face group, where multiple continuous surfaces in the steel bar datum face group are continuously intersected and form a closed space graphic structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com