Classified storing device and method for lithium battery processing and manufacturing

A technology for processing and manufacturing lithium batteries, applied in the field of classified placement equipment for lithium battery processing and manufacturing, can solve the problems of inconvenient equipment movement, inability to store different types of lithium batteries, inconvenience in picking and placing lithium batteries, etc., to prevent inversion and increase stability. Sex, avoid the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

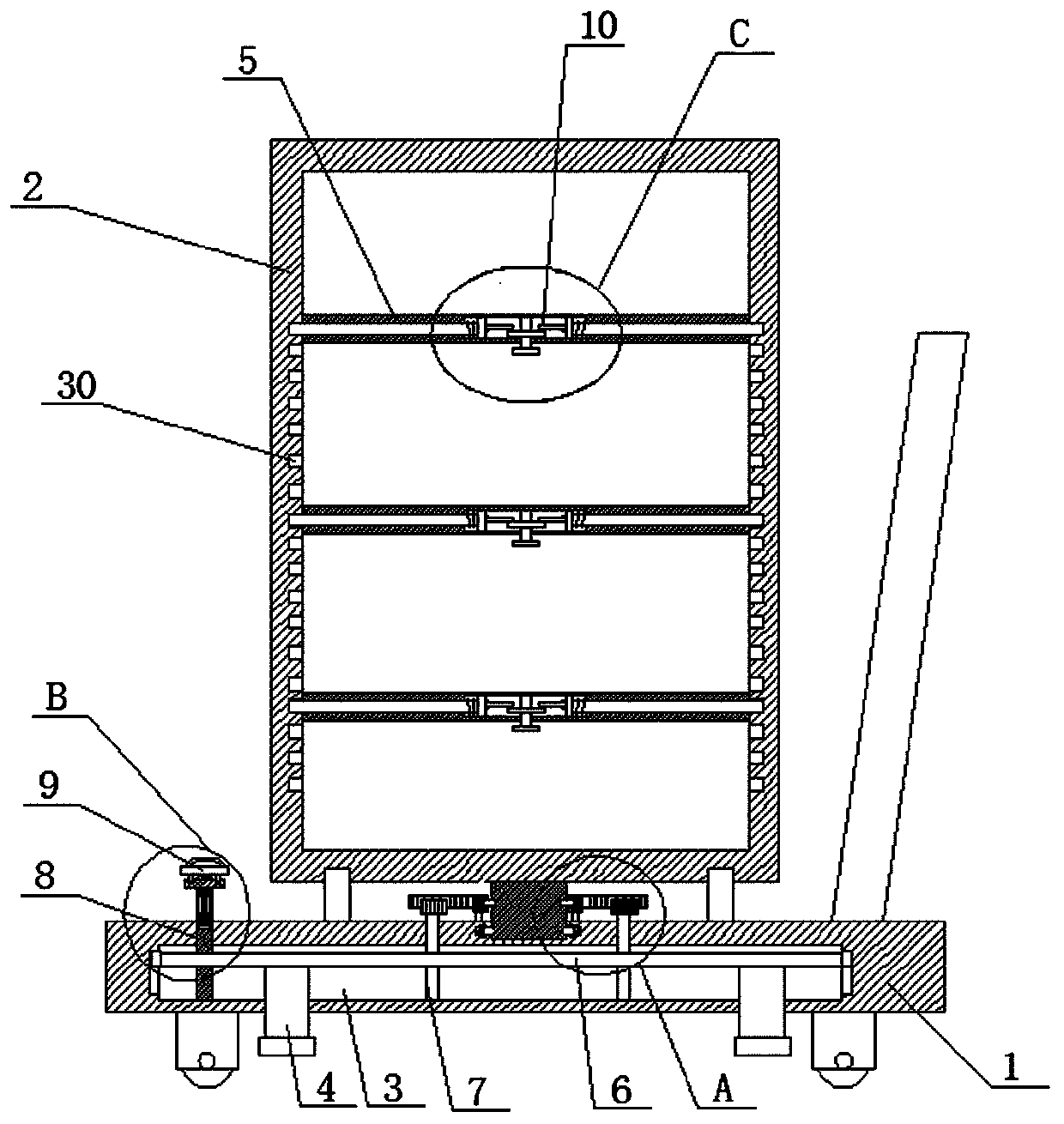

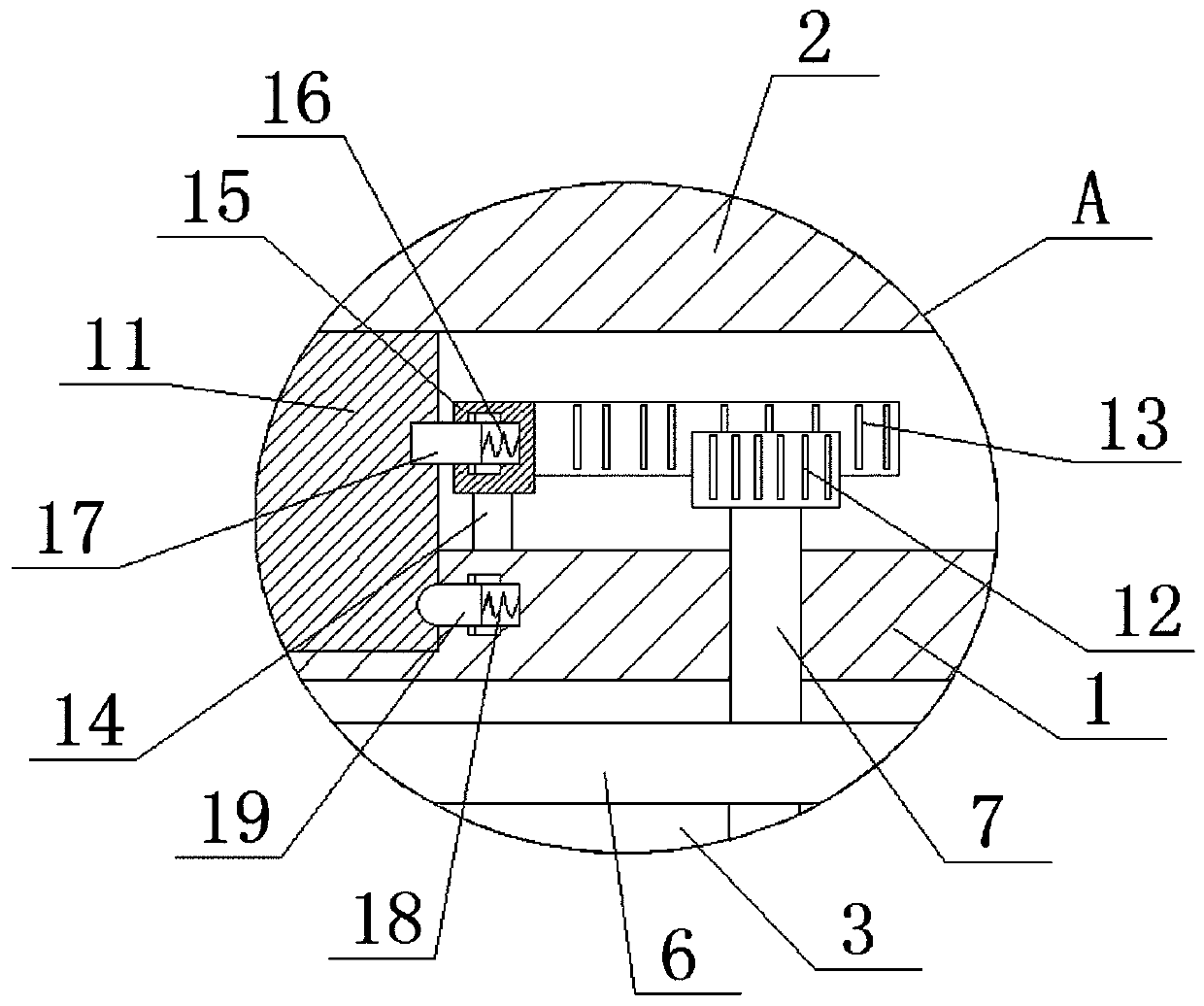

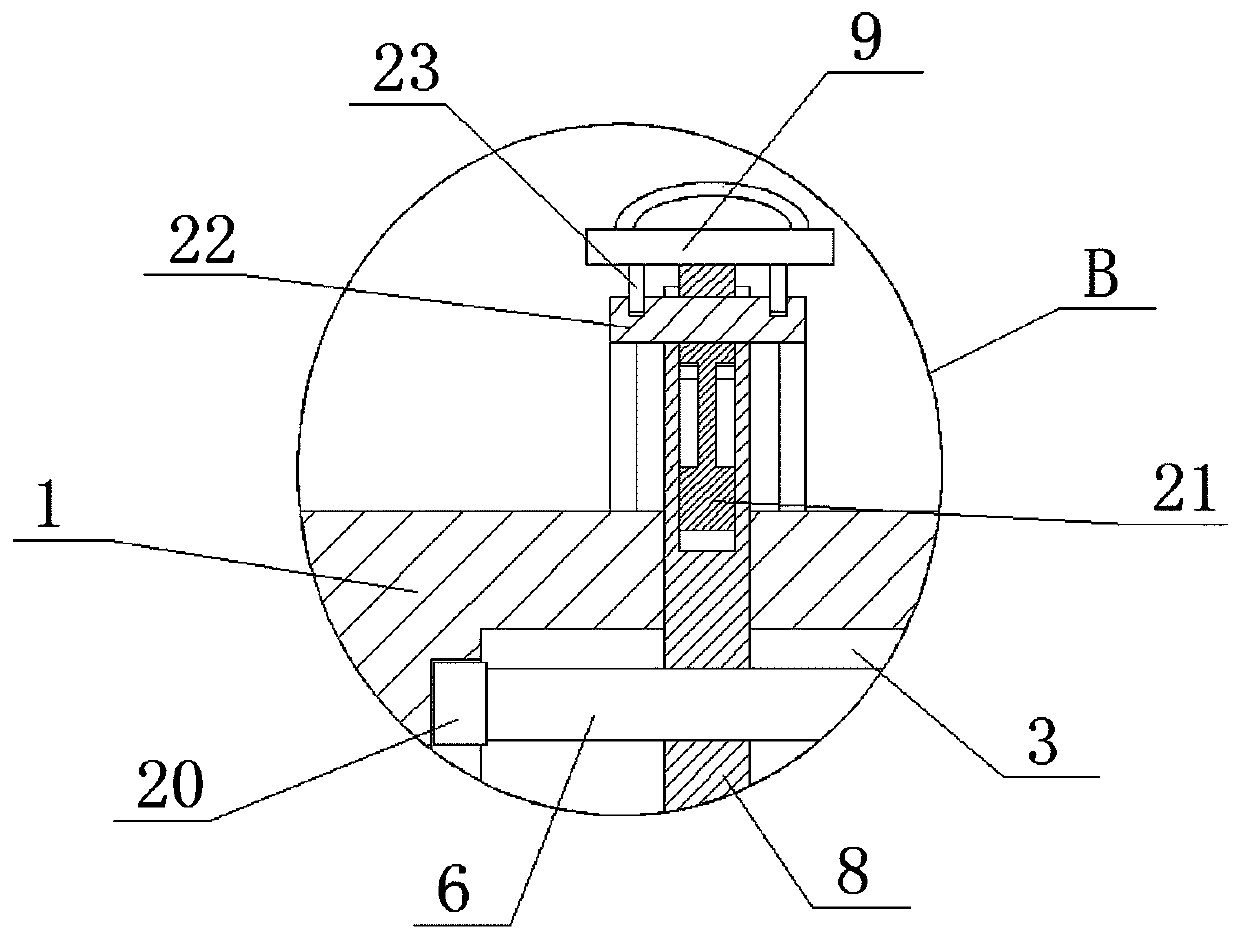

[0045] refer to Figure 1-5 , a sorting and placing device for lithium battery processing and manufacturing, including a mobile seat 1, a storage box 2 is installed on the top of the mobile seat 1, a plurality of placement plates 5 are movably installed in the storage box 2, and a cavity is opened on the mobile seat 1 3. A connecting plate 6 is slidably installed in the cavity 3, and the bottom of the connecting plate 6 is fixedly installed with four feet 4 by welding. The four feet 4 are all slidably connected with the moving seat 1, and the inner wall of the bottom of the cavity 3 rotates Lead screw 8 is installed, and lead screw 8 is threadedly connected with connecting plate 6, and two screw rods 7 are installed on the bottom inner wall of cavity 3, and two screw rods 7 are all threaded with connecting plate 6, and two screw rods 7 The threads are of opposite direction.

[0046] In this embodiment, the bottom of the moving base 1 is provided with four universal wheels, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com