Sliding-plug door

A technology for door panels and door locks, applied in door/window accessories, electric locks, power transmission/actuator features, etc., can solve problems such as poor door sealing, increased costs, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

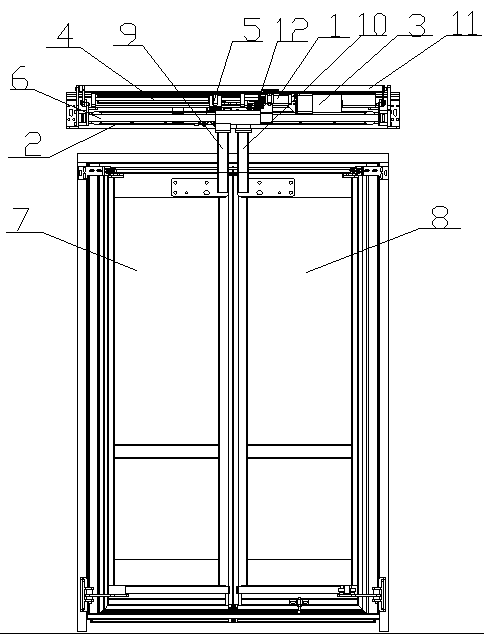

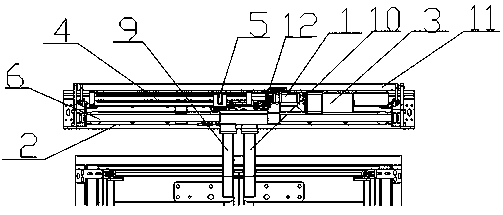

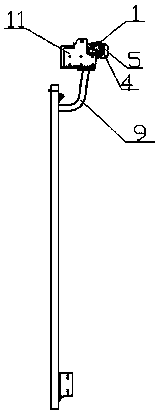

[0065] This embodiment provides a double sliding door, such as Figures 1 to 9 As shown, it mainly consists of door lock clutch device 1, door panel synchronization device 2, drive motor 3, lead screw 4, guide rail 48, lead screw nut 5, first door panel 7, second door panel 8, first door frame 9, the first Two door frames 10, the first slide bar 6 and the second slide bar 49 are formed, the drive motor 3 is fixed on the tray 11 of the sliding door, the first slide bar 6 and the second slide bar 49 are arranged parallel to each other and both ends are Fixed on both sides of the tray 11, the first slide bar 6 and the second slide bar 49 are arranged in parallel with the lead screw 4 and are located below the lead screw 4. One end of the lead screw 4 is rotationally connected with one side of the tray 11, and the other end is connected with the lead screw 4. The locking stopper 12 is coaxially fixed, and the lead screw 4 is horizontally located directly above the first door panel...

Embodiment approach 2

[0088] This embodiment provides a single sliding door, such as Figure 30 and 31 As shown, the single-sliding door is roughly the same as the double-sliding door in Embodiment 1, the only difference is that the single-sliding door has only one door panel, one door frame, one sleeve, one sliding rod and no door panel synchronization Device, its door panel is closed and locked and the process of unlocking and opening is basically the same as that of the double plug door, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com