Thin film packaging structure and display panel

A thin-film packaging and display panel technology, which is applied to identification devices, semiconductor/solid-state device components, instruments, etc., can solve problems such as film layer separation, inorganic layer fracture, and large stress, so as to improve bending performance and service life. Ensure the stability of the package and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

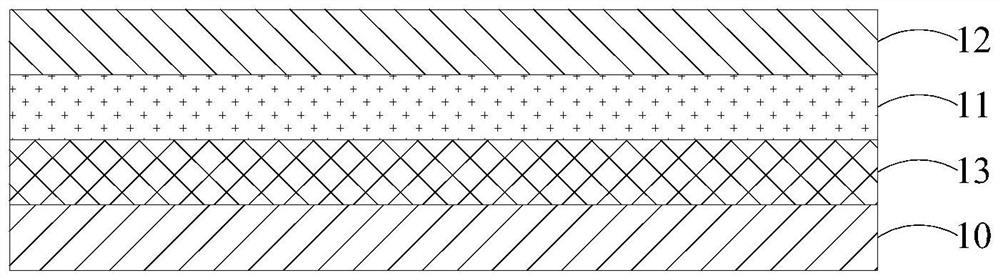

[0044] If the first inorganic encapsulation layer 10 of the thin film encapsulation structure is more likely to break or be separated from other film layers during the actual bending process of the display panel, then if figure 1As shown, the first inorganic adjustment layer 13 can be formed between the first inorganic encapsulation layer 10 and the organic encapsulation layer 11, so that the stress neutral layer at the bend can be shifted toward the first inorganic encapsulation layer 10, namely : The distance between the first inorganic encapsulation layer 10 and the stress-neutral layer is reduced, so that compared with the traditional scheme in which the first inorganic encapsulation layer 10 is directly combined with the organic encapsulation layer 11, under the same bending radius, The deformation of the first inorganic encapsulation layer 10 can be reduced, thereby alleviating the situation that the first inorganic encapsulation layer 10 is broken or separated from othe...

Embodiment 2

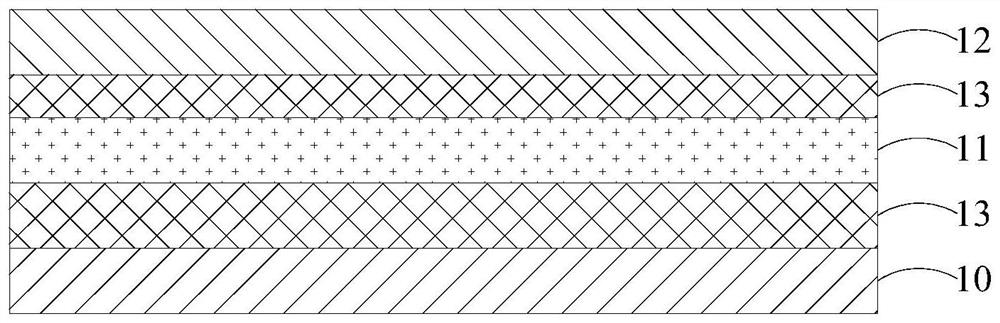

[0048] When the first inorganic adjustment layer 13 is silicon oxide and the second inorganic encapsulation layer 12 is silicon nitride, since the oxygen content of the first inorganic adjustment layer 13 is greater than the oxygen content of the second inorganic encapsulation layer 12, therefore, the first The contact angle between the inorganic adjustment layer 13 and the organic encapsulation layer 11 is smaller than the contact angle between the second inorganic encapsulation layer 12 and the organic encapsulation layer 11, and the bonding strength between the first inorganic adjustment layer 13 and the organic encapsulation layer 11 after curing can be Greater than the bonding strength between the second inorganic encapsulation layer 12 and the organic encapsulation layer 11 .

[0049] Based on this, if figure 2 As shown, compared with the first embodiment, in this embodiment, in addition to forming the first inorganic adjustment layer 13 between the first inorganic enca...

Embodiment 3

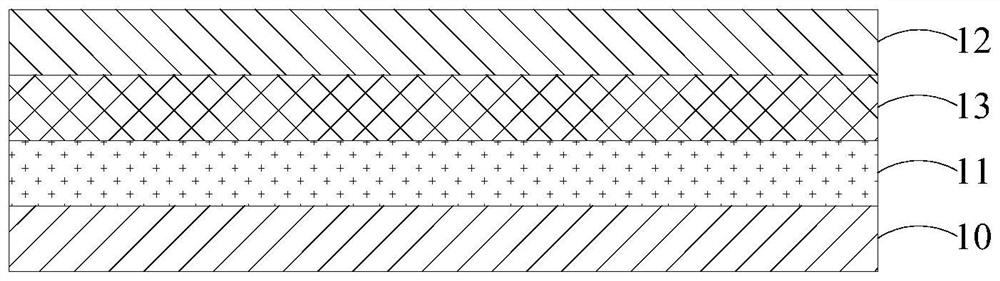

[0053] If the second inorganic encapsulation layer 12 of the thin film encapsulation structure is more likely to break or be separated from other film layers during the actual bending process of the display panel, the first inorganic adjustment layer 13 can be formed between the second inorganic encapsulation layer 12 and the other film layers. between organic encapsulation layers 11, such as image 3 shown; or the first inorganic adjustment layer 13 is formed on the side of the second inorganic encapsulation layer 12 away from the organic encapsulation layer 11, as Figure 4 or a first inorganic adjustment layer 13 is formed between the second inorganic encapsulation layer 12 and the organic encapsulation layer 11, and another first inorganic adjustment layer 13 is formed on the second inorganic encapsulation layer 12 away from the organic encapsulation layer 11 side, such as Figure 5 shown. Adopting these schemes can make the stress-neutral layer at the bend shift toward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com