Pneumatic tire

A technology for pneumatic tires and bead cores, applied to tire parts, bead edges, yarns, etc., can solve the problems of no enlightenment, no teaching of bead cores, etc., and achieve the goal of improving fatigue resistance, ensuring strength and fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

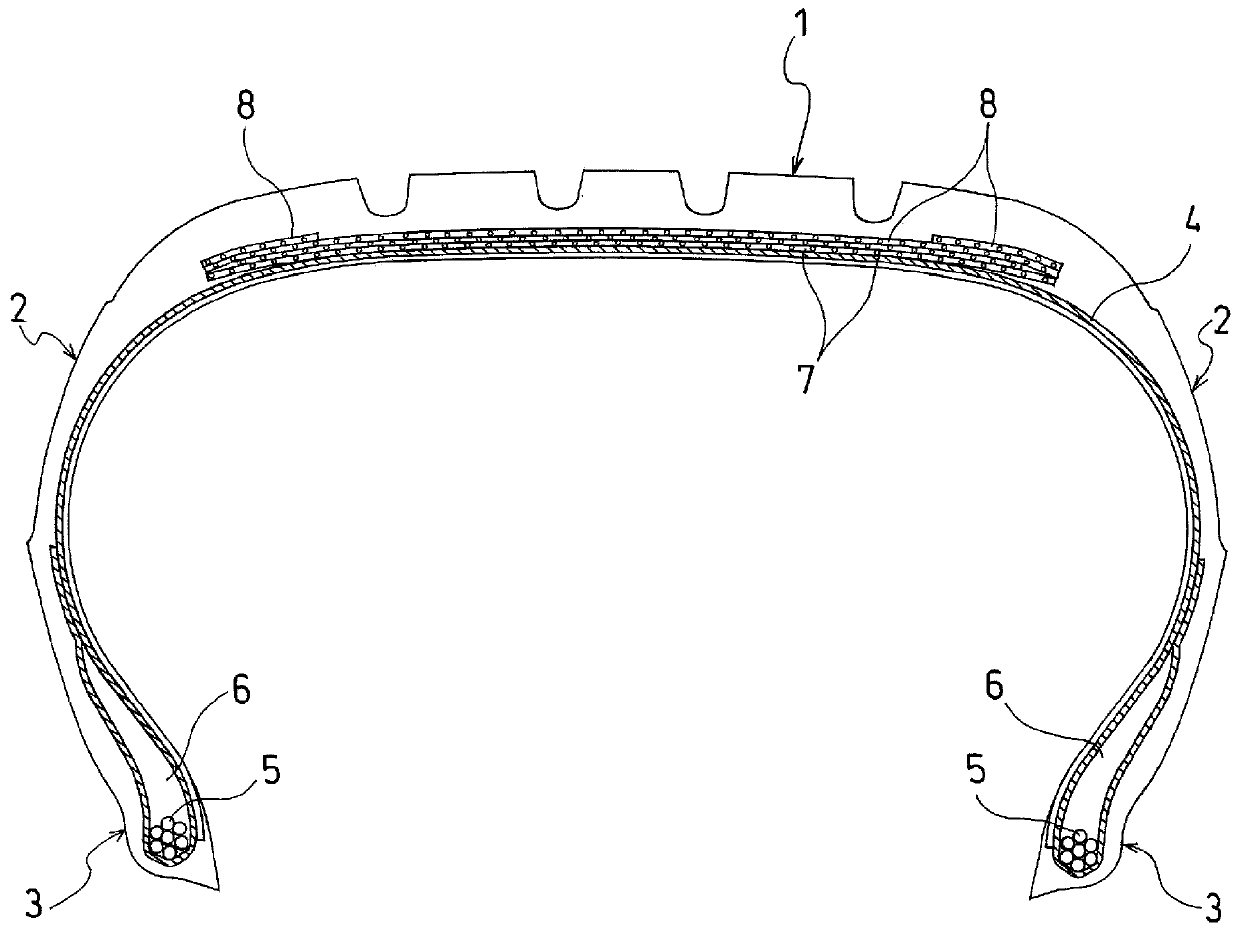

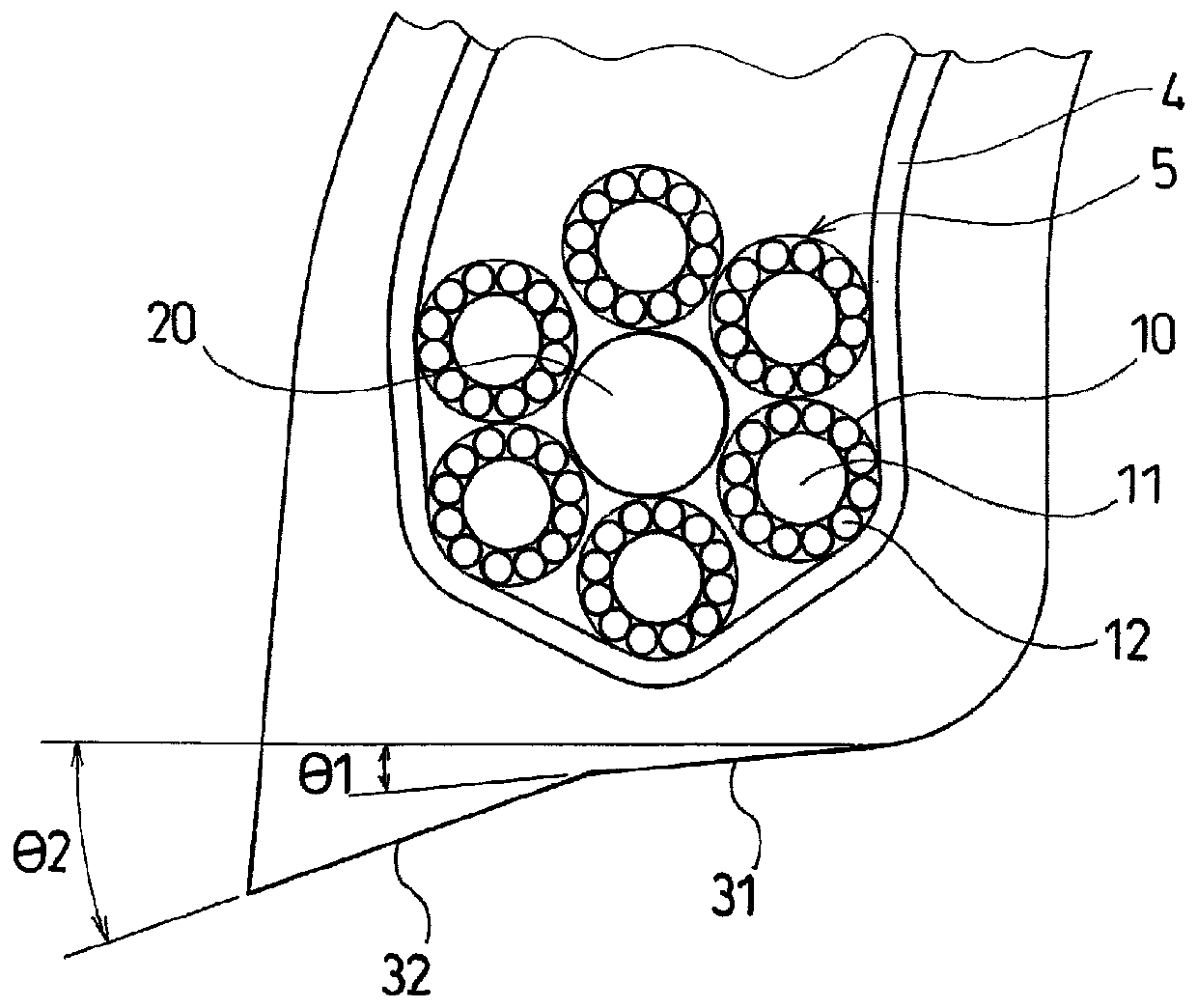

[0059] In a pneumatic tire having a tire size of 205 / 55R16, including an annular bead core embedded in the bead portion and a carcass layer locked to the bead core, a tire with only the structure of the bead core being different was produced. Tires of Conventional Example 1, Comparative Examples 1-2, and Examples 1-3.

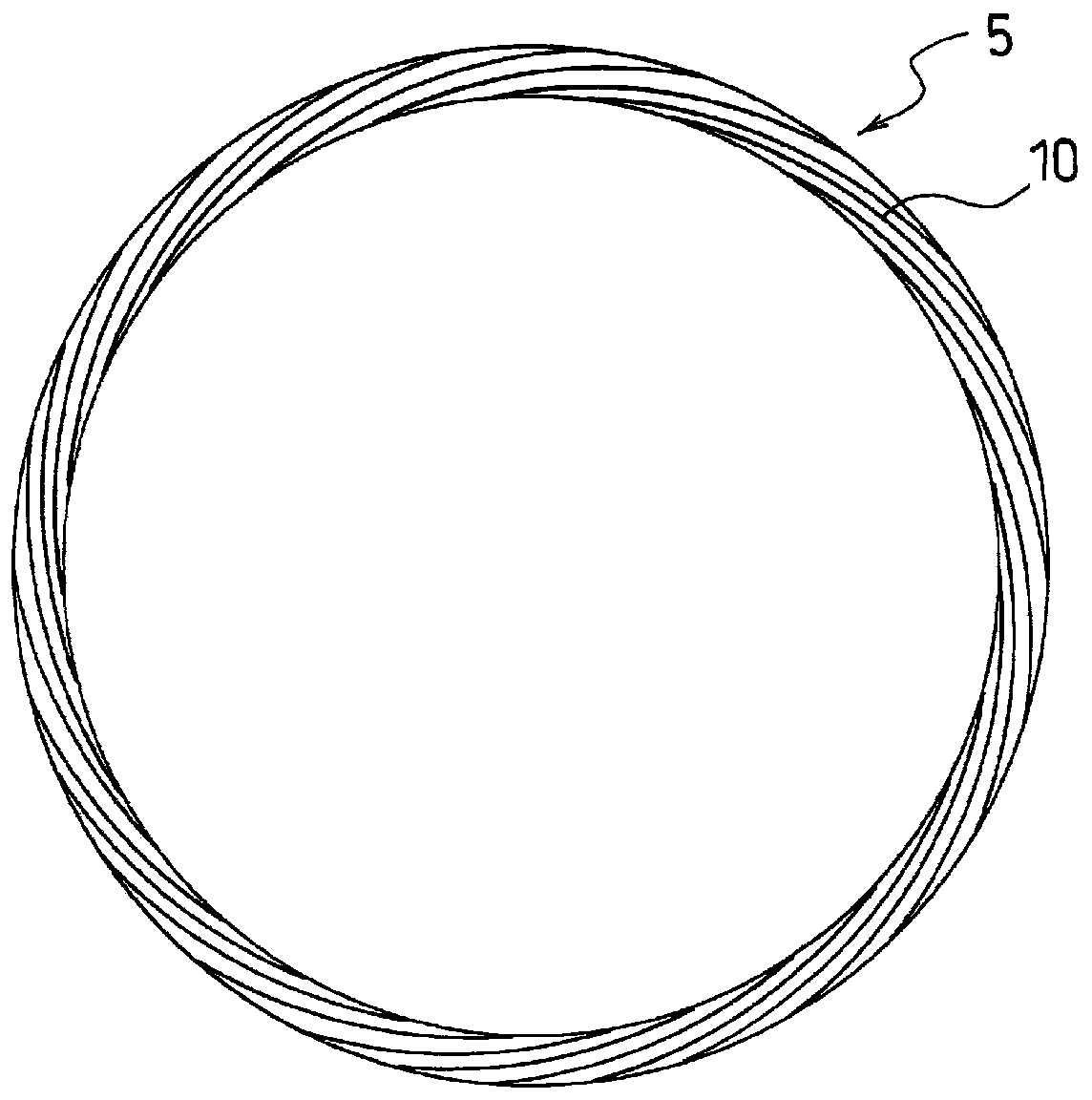

[0060] In Conventional Example 1, a bead core having a stacked bead structure having a hexagonal cross-section was used, and a steel wire was used as the wire material. In Comparative Example 1, a bead core having a stacked bead structure having a hexagonal cross-section was used, and a composite cord including a core wire made of carbon fibers and a plurality of side wires made of glass fibers arranged around the core wire was used. wire as its wire. In Comparative Example 2, a bead core having a cable bead structure was used, and carbon fiber cords were used as the core and side wires.

[0061]In Example 1, a bead core having a cable bead structure was used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com