Tuber mustard peeling equipment and tuber mustard peeling method

An equipment and technology of mustard, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of limited production of mustard, rising labor costs, large labor force, etc., to reduce labor input, reduce labor costs, High-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

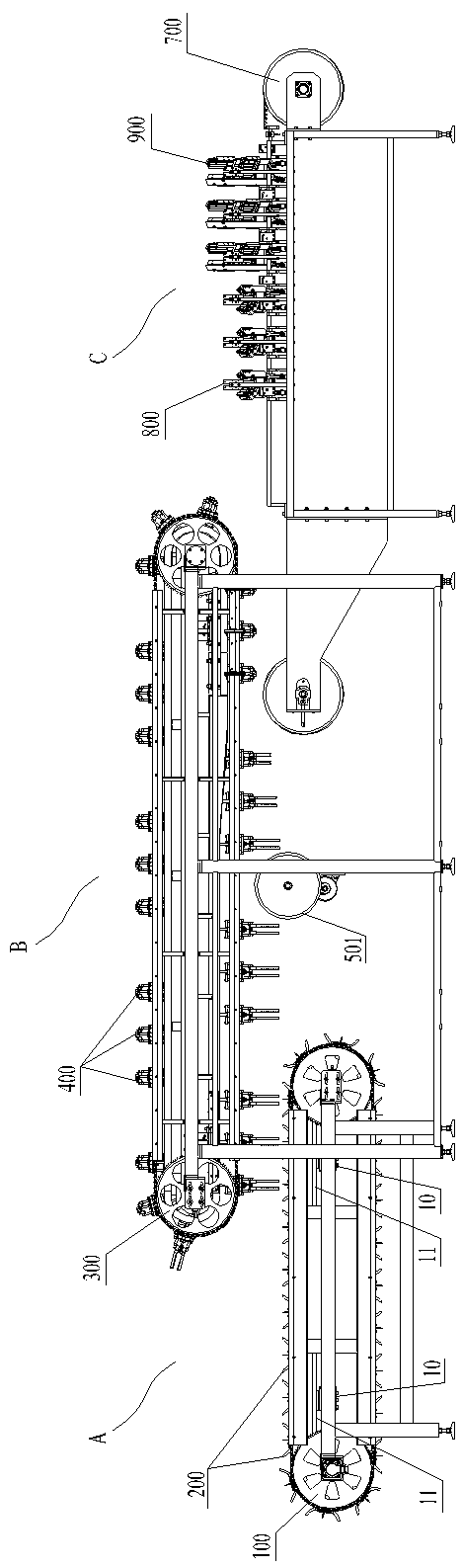

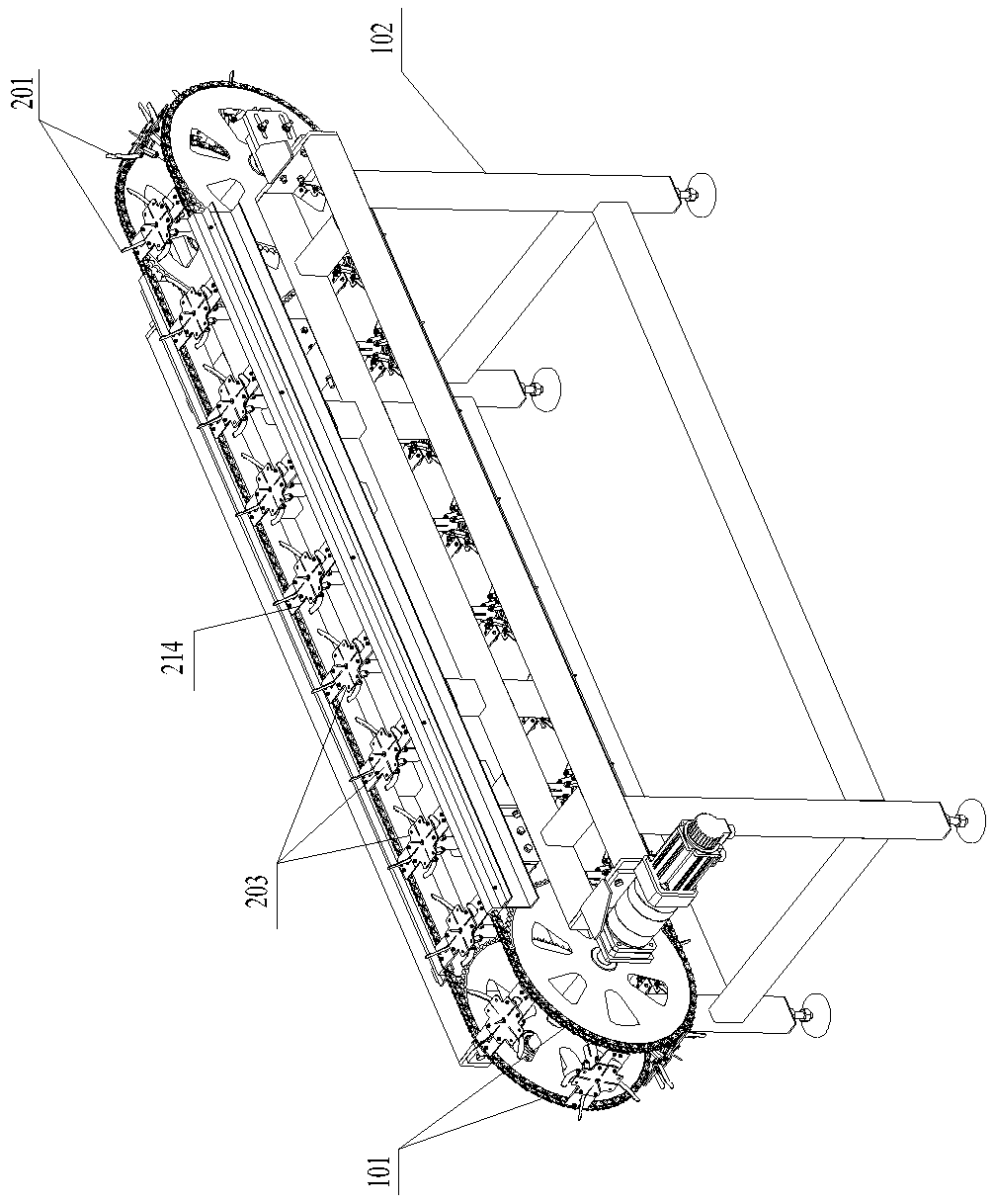

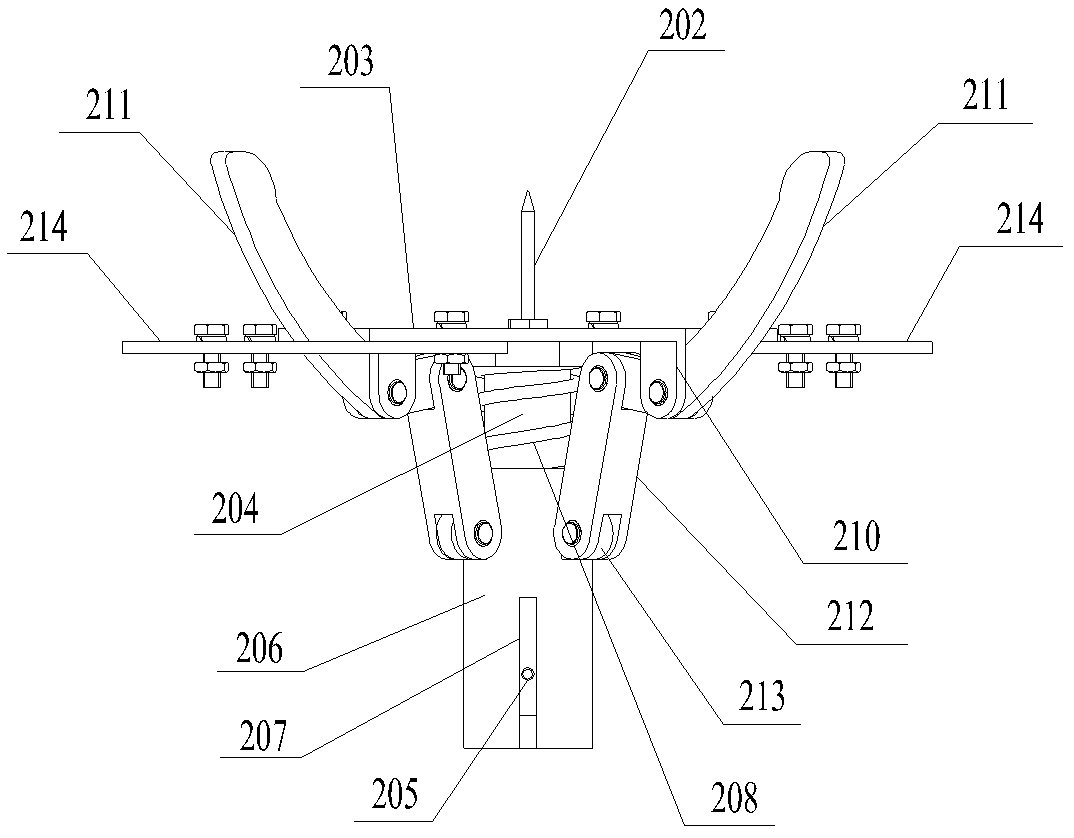

[0050] See Figure 1 to Figure 15 , a mustard peeling device of the present invention, which includes a positioning mechanism A, a grabbing mechanism B, and a peeling mechanism C arranged in sequence from left to right; the positioning mechanism A includes a first chain conveyor line 100, the chain of the first chain conveyor line Positioning and clamping components 200 are installed on the 101 at intervals along its circumference. The positioning and clamping components 200 include clamping jaws 201 and positioning pins 202 located in the middle of clamping jaws 201 and arranged vertically. The clamping jaws 201 are normally closed. The first end and the end of a chain conveyor line 100 are respectively equipped with a drive mechanism one for driving the corresponding jaws-201 to open; the gripping mechanism B includes a second chain conveyor line 300, and the head end of the second chain conveyor line 300 is located at Above the end of the first chain conveying line 100; on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com