A device for garlic divisions and peeling

A technique for splitting and peeling garlic, which is applied to the field of devices for splitting and peeling garlic, can solve the problems of unsatisfactory peeling effect, mechanical damage of garlic, failure to reach food crops, etc., and achieves improved peeling quality, less damage by splitting, and splitting. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

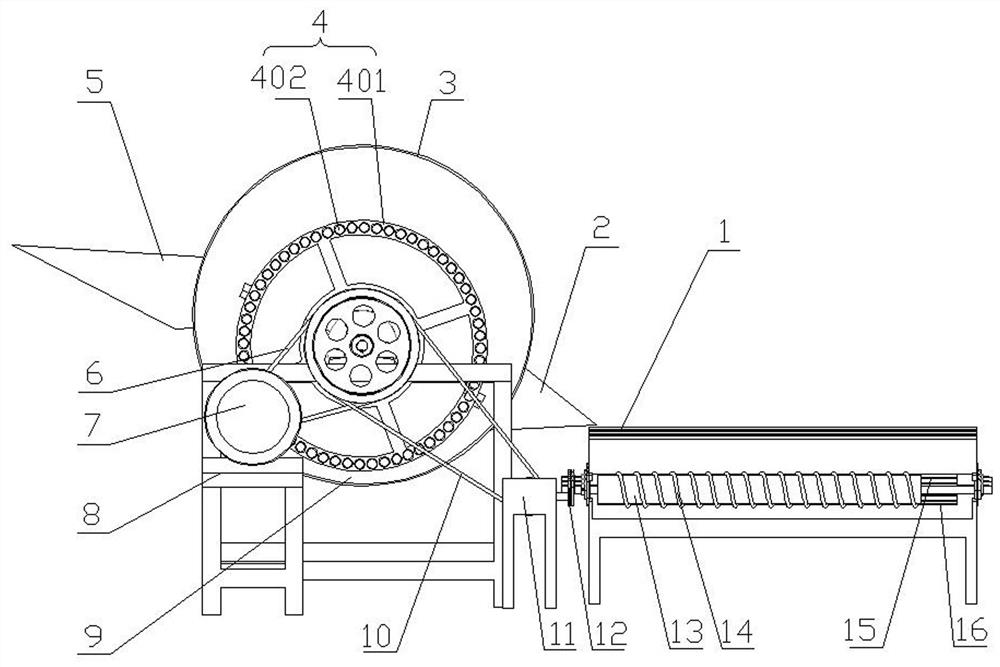

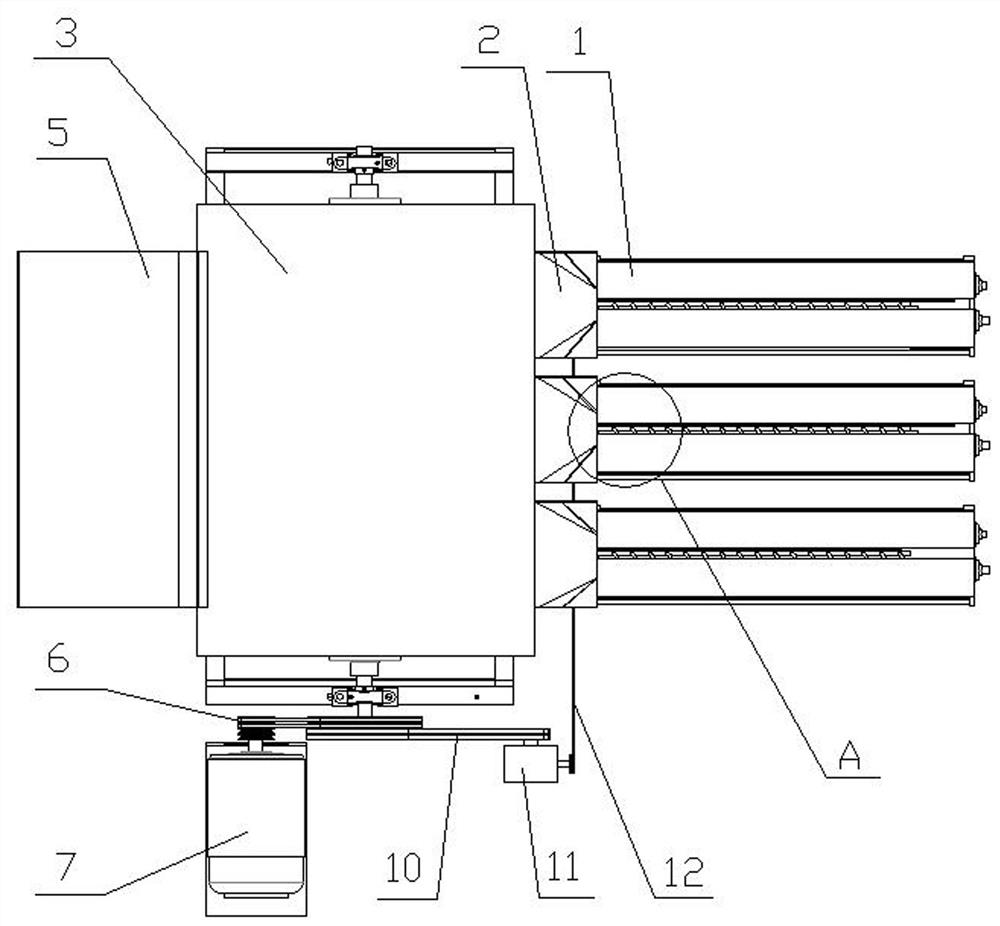

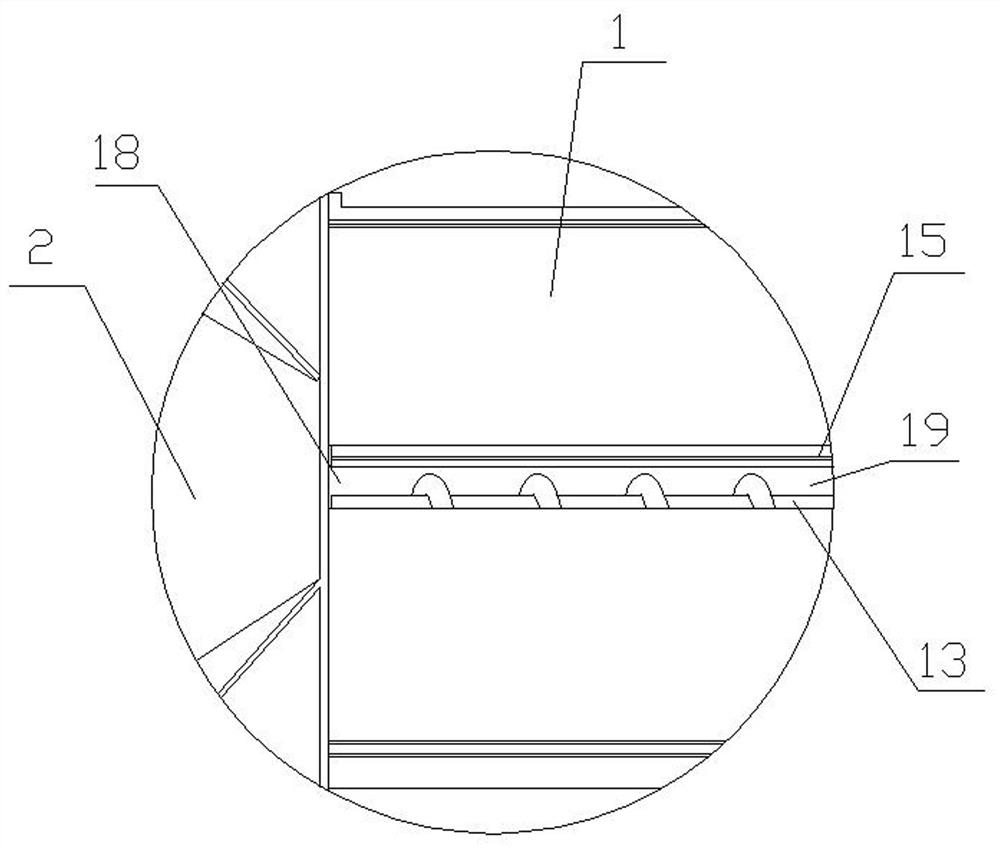

[0024] like figure 1 As shown, a device for dividing and peeling garlic cloves according to the present invention includes a frame 8 and a garlic head dividing unit and a garlic clove peeling unit sequentially arranged on the frame 8 from left to right. The garlic clove dividing unit is used to form discrete and peeled garlic cloves through extrusion; the garlic clove peeling unit is used to remove the garlic skin from the garlic cloves, so as to output the clean garlic cloves.

[0025] The garlic head splitting unit includes a cylindrical casing 3 fixed on a frame 8 and a drum 4 rotatably arranged in the casing 3 .

[0026] The two ends of the casing 3 are closed and welded and fixed on the frame 8 horizontally, and the center line thereof is distributed along the horizontal direction. The left and right sides of the casing 3 are respectively provided with a first feeding port 5 for feeding the whole garlic into the inner cavity of the casing 3 and a first discharging port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com