A mechanical petal-seeking device for citrus petals

A split and mechanical technology, applied in application, food science, food processing, etc., can solve the problems of low crushing rate and high equipment cost, achieve the effect of simple equipment, reduce damage rate and improve work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

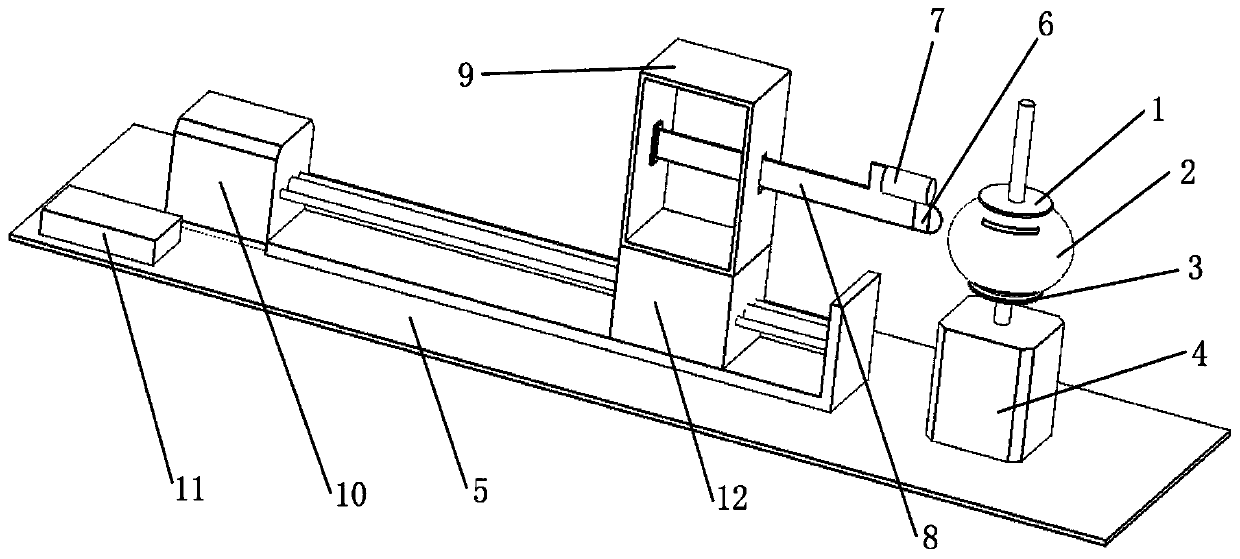

[0014] like figure 1 A kind of citrus citrus petal-seeking machine shown in the figure includes an orange ball rotating device fixed on the base 5, a single-chip microcomputer 11 and a line-finding device, and the orange ball rotating device includes a stepping motor 4, an upper clamp 1 and a lower Clamp 3, described stepper motor 4 is fixed on one end of base 5 and the shaft of stepper motor 4 is a long threaded shaft, and described shaft is provided with the lower clamp 3 that is used to support orange ball 2 and is used for clamping orange ball 2 The upper fixture 1, the line-hunting device is fixed on one side of the orange ball rotating device, the line-hunting device includes a probe base 8, a bracket 9, a linear motor 10 and a slider 12, and the linear motor 10 is fixed on the base 5 The other end of the slider 12 is arranged between the linear motor 10 and the stepper motor 4 and driven by the linear motor 10, the bracket 9 is fixed on the upper end of the slider 12, a...

Embodiment 2

[0018] Device structure is identical with embodiment 1, and described stepping motor 4 rotational speeds are 10 revolutions per minute; Described single-chip microcomputer 11 is stm32 single-chip microcomputer, and described piezoelectric sensor 6 is 1000g piezoelectric sensor, and described photoelectric sensor 7 is sensing distance 20mm, the speed of the linear motor is 20 meters forward or backward per minute. The device can detect the splitting line of 8 orange balls per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com